Tegheim - Home made 4 Rotor Wolvo project

#851

Simply amazing. I operate CnC equipment in our shop, we have a 7'x14' 150a HDplasma, 5'x10' 50k waterjet w/ taper control, and we just got our first 3-in-1 (hobby level) Patriot CnC as a starter machine to get into precision machining outside of flat cutting.

How did you determine the correct layout and dimensions of the 4-rotor you are building? Did you design it from the ground up or start with something and take measurements?

How did you determine the correct layout and dimensions of the 4-rotor you are building? Did you design it from the ground up or start with something and take measurements?

#852

Senior Member

Thread Starter

I have looked at 20B-shaft and 13B-shaft. Then measured, searched for info and designed.

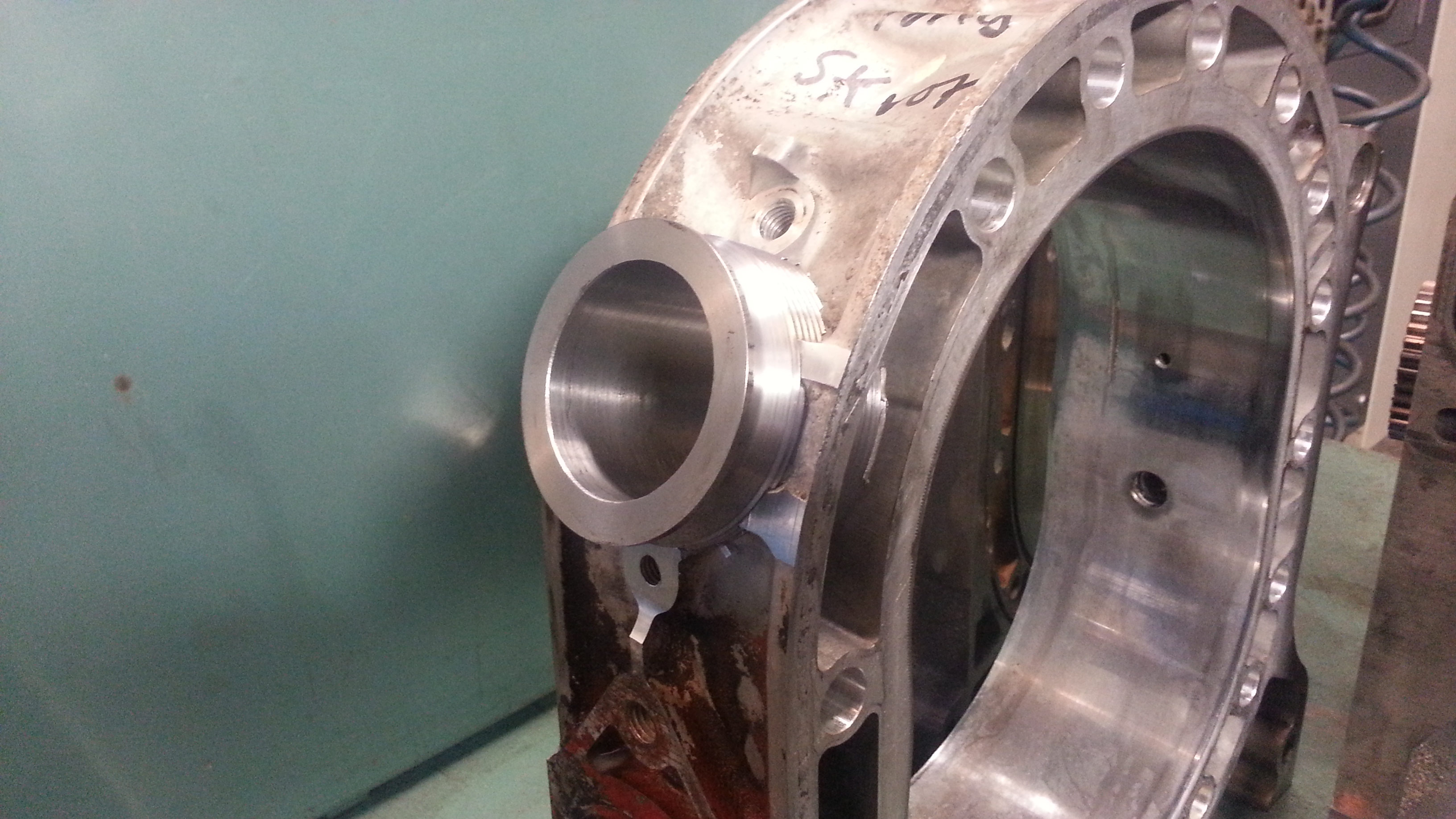

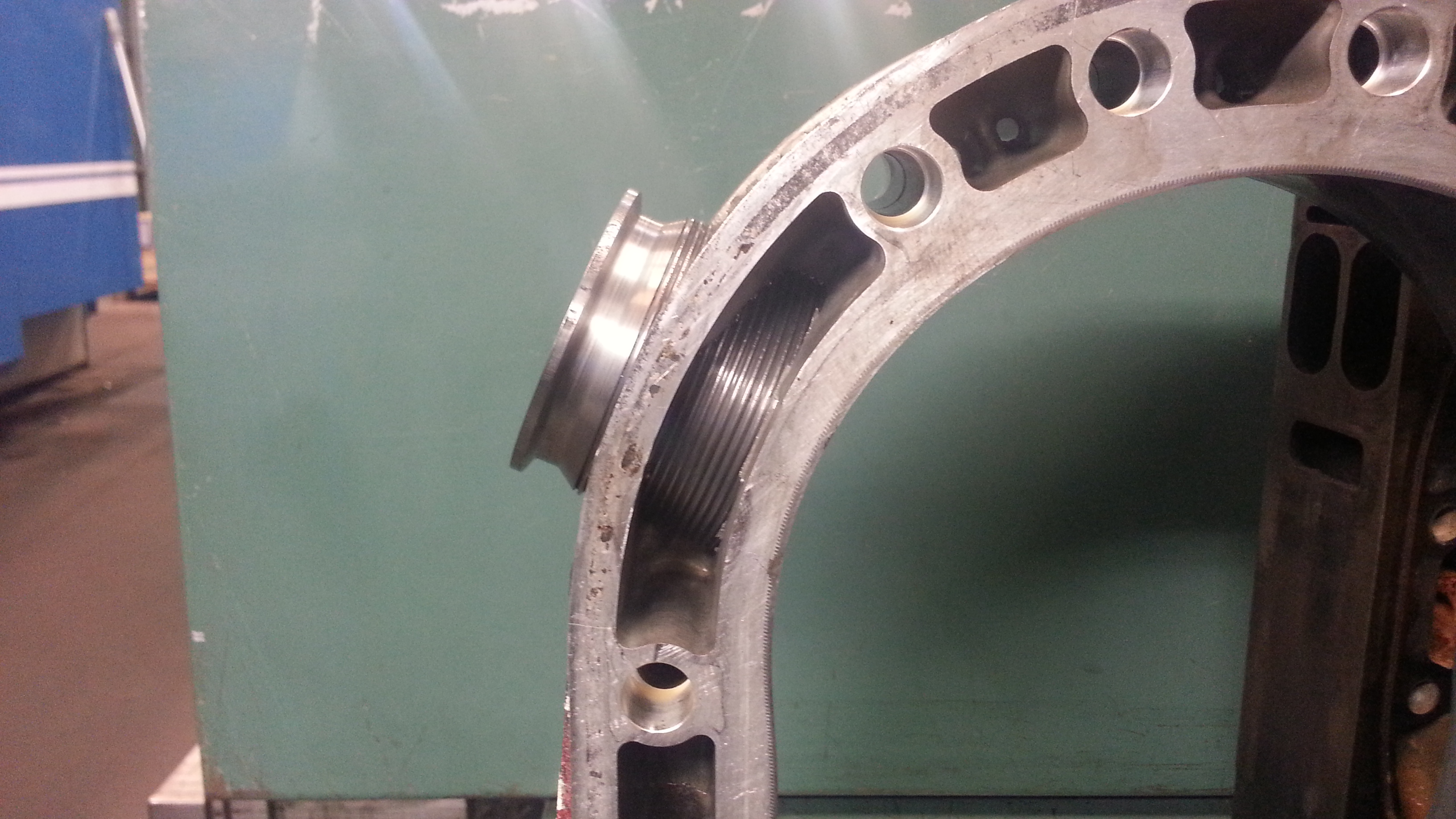

Havn't done much lately, but have done some with the steering, the wattlink and finally some on the intermediate-plates.

This was a LEGO i designed

And this is how that goes in the car.

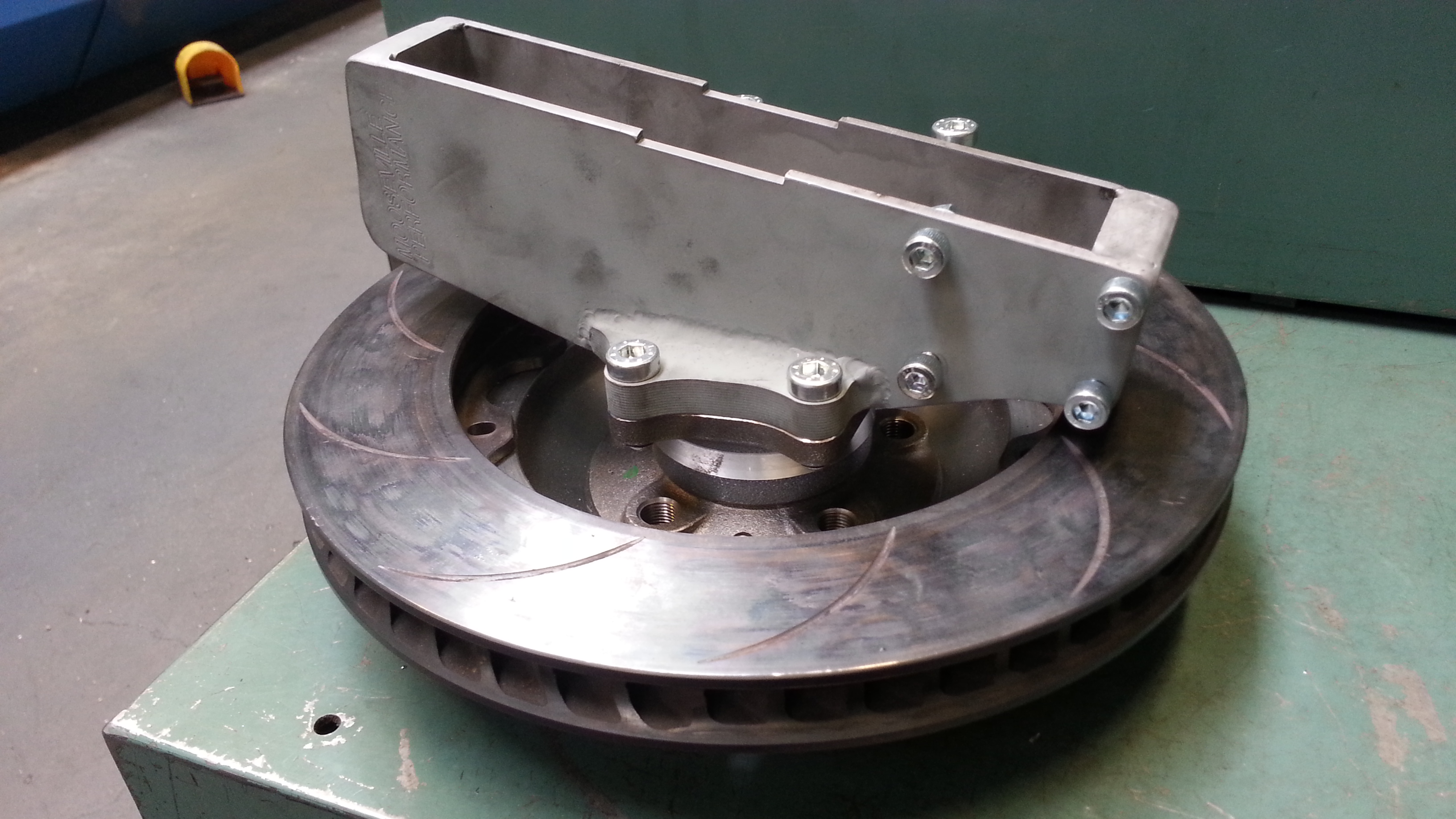

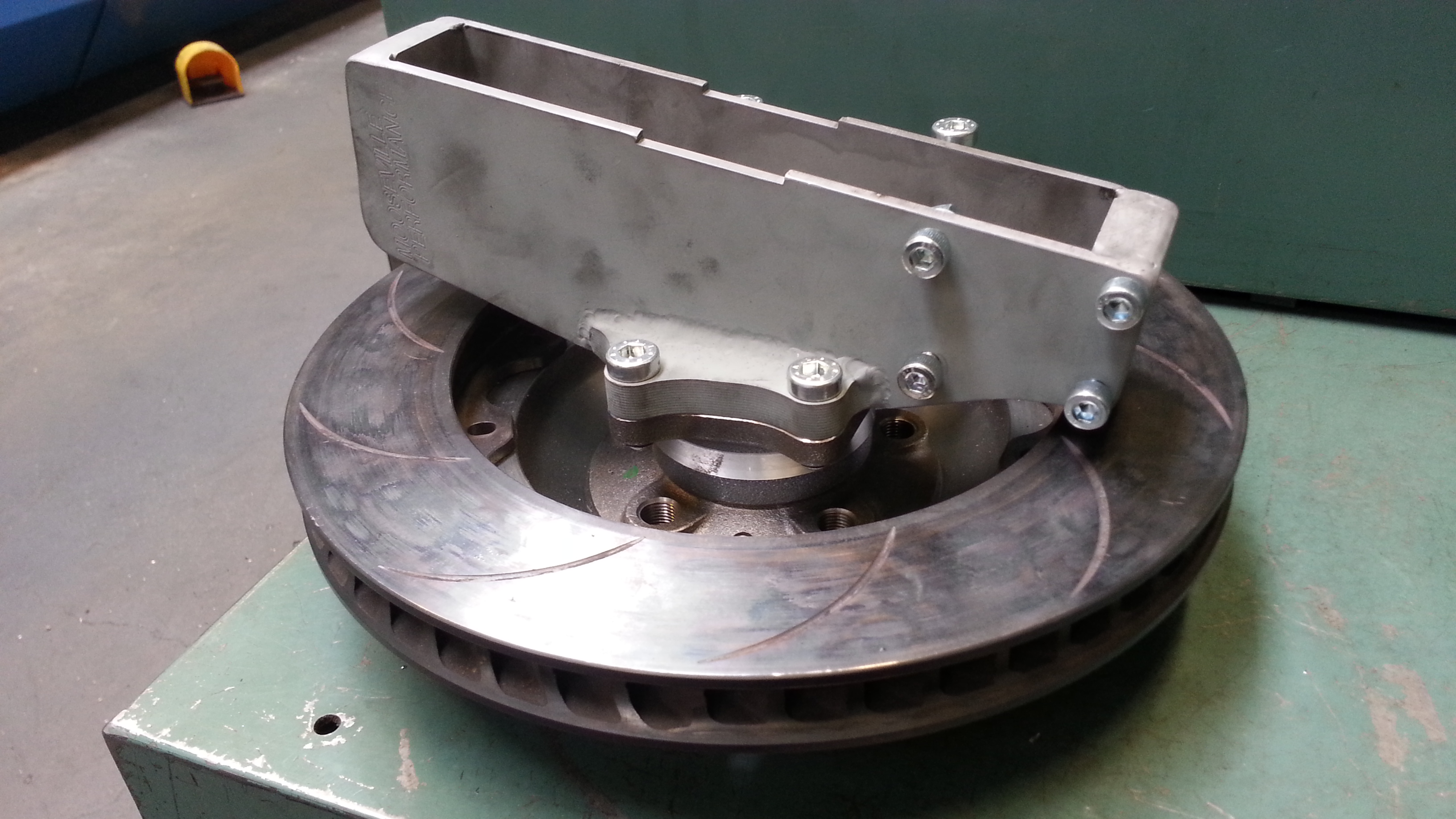

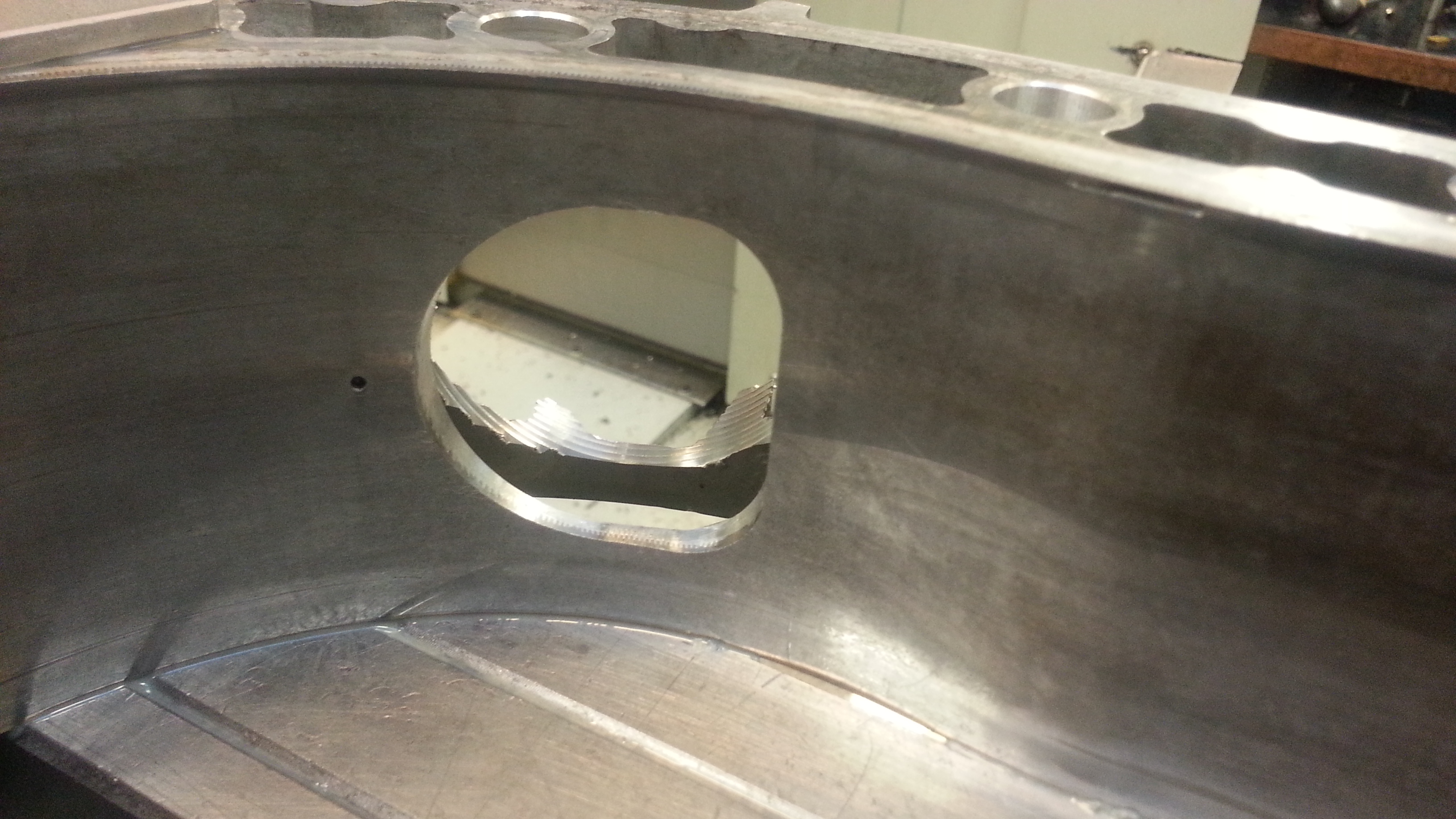

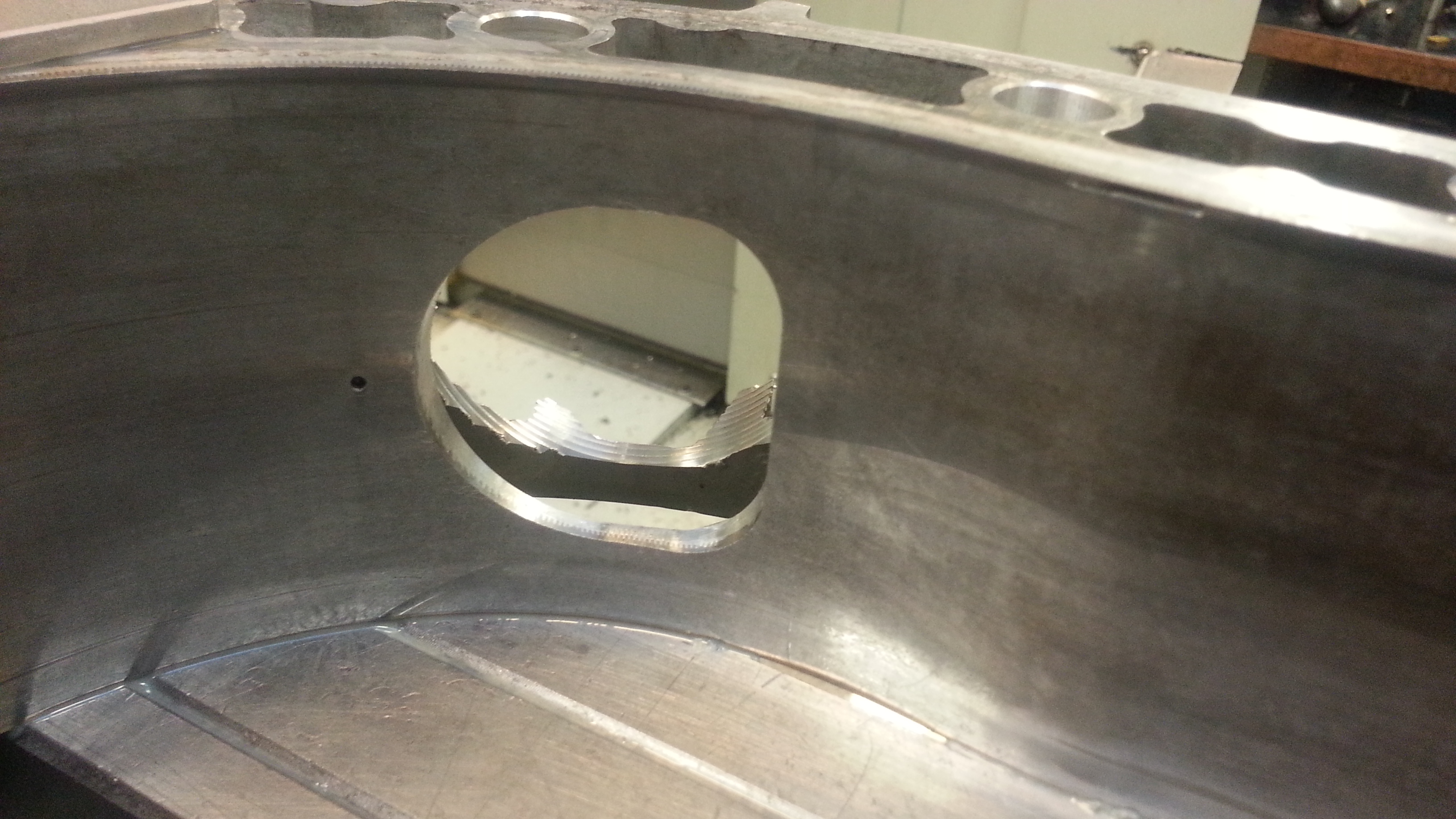

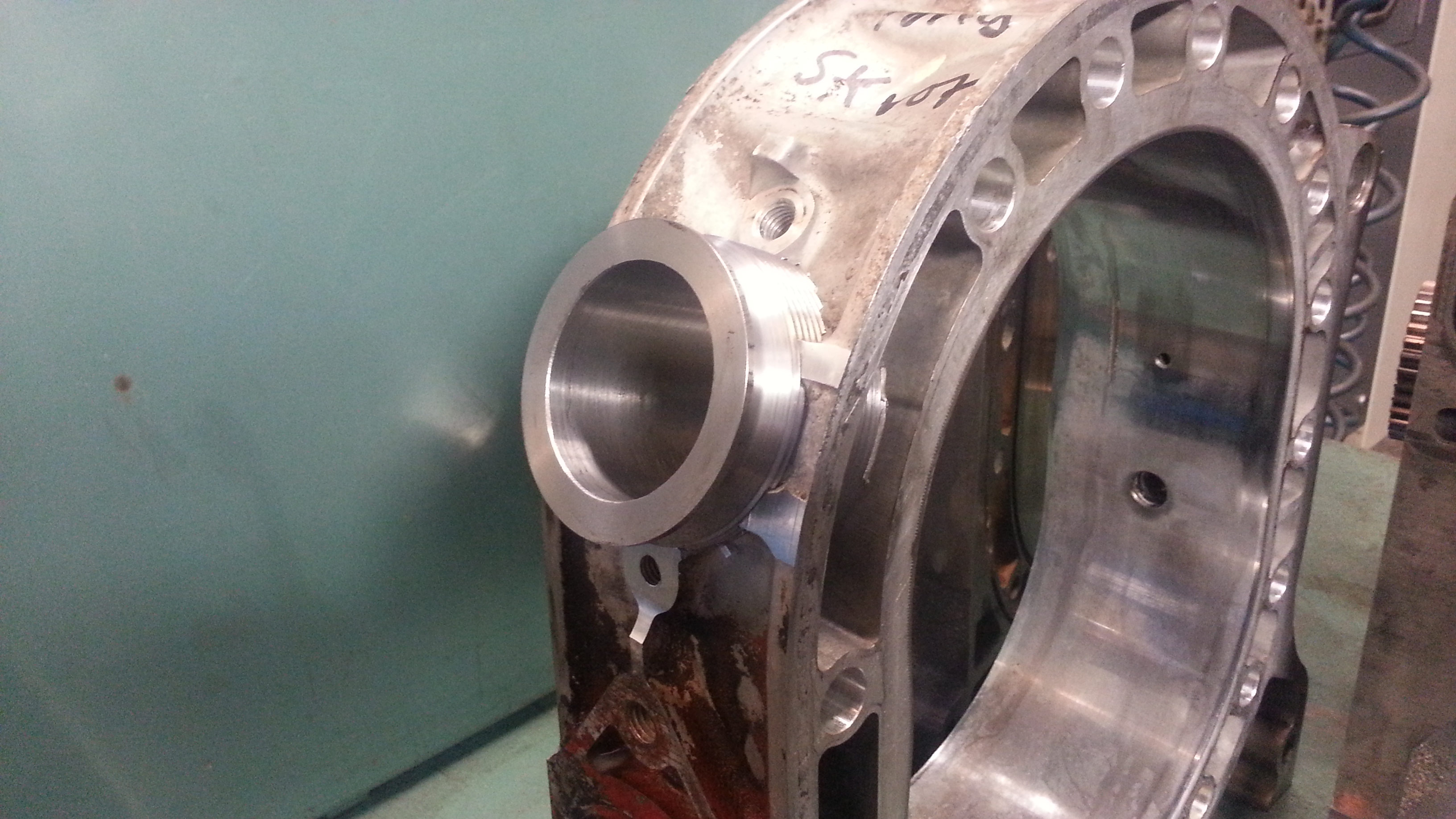

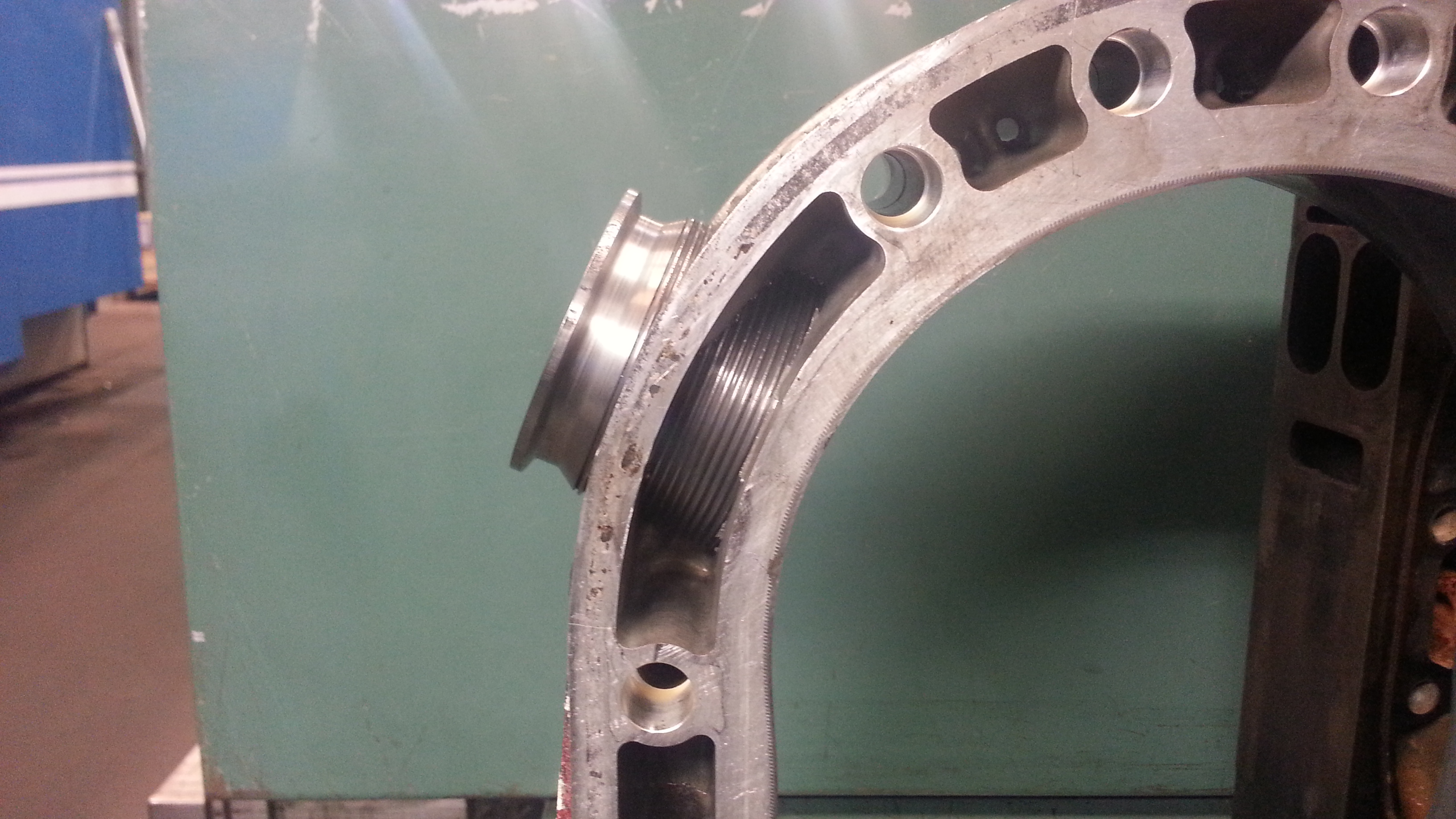

Here the intermediate-plate is prepared for the bearing

Havn't done much lately, but have done some with the steering, the wattlink and finally some on the intermediate-plates.

This was a LEGO i designed

And this is how that goes in the car.

Here the intermediate-plate is prepared for the bearing

#859

awesome work! this project goes beyond most peoples comprehension of "custom" two of my favorite automotive mfg's, mazda and Volvo.. I would love to rotary swap a p1800, with your help of course

#860

Senior Member

Thread Starter

Have lately spent some time with the porting of the engine. Most in SolidWorks, but also in reality.

Thought I run with V-band instead of what is in the renderings. However, I must turning one half of the V-band myself, and it seems difficult to find the measure of it.

If anyone has seen it, or know how they should look like, I am receptive :-) Happy to metric! The tubes I intend to use is 50x2, ie 46mm internally.

Thought I run with V-band instead of what is in the renderings. However, I must turning one half of the V-band myself, and it seems difficult to find the measure of it.

If anyone has seen it, or know how they should look like, I am receptive :-) Happy to metric! The tubes I intend to use is 50x2, ie 46mm internally.

#865

Senior Member

Thread Starter

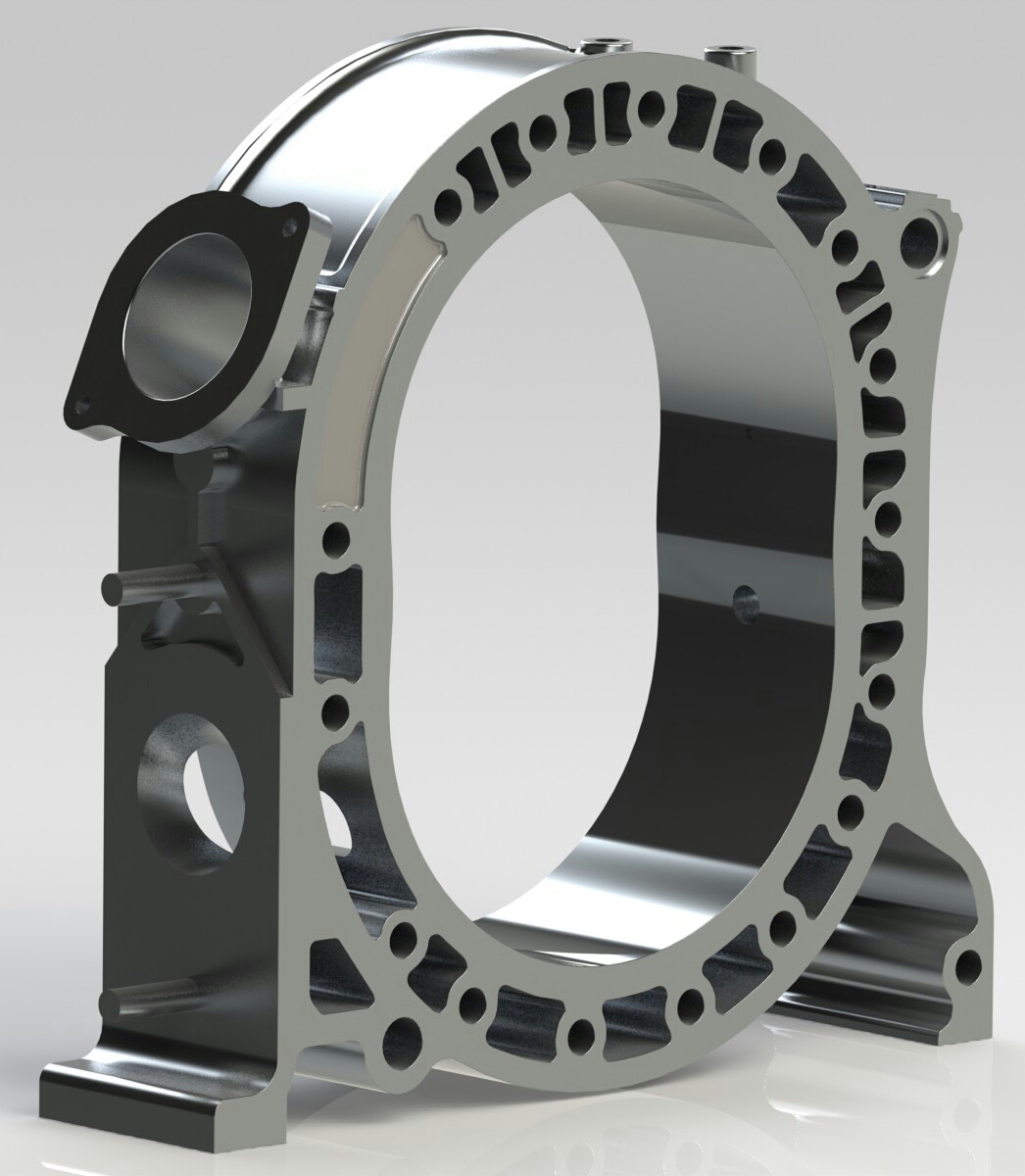

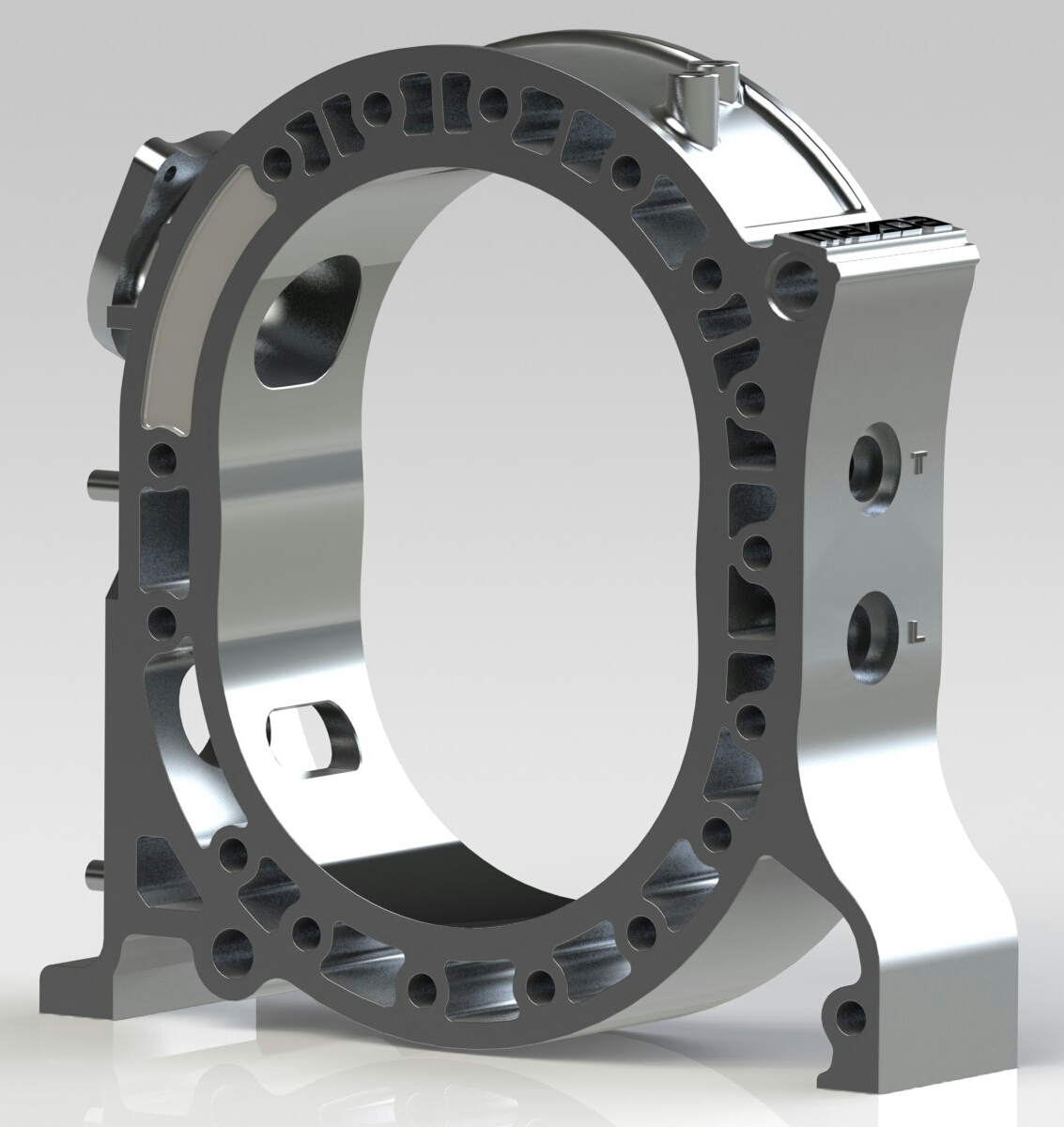

Thanks, I think Solid does a good job :-)

The answer is measure, measure and some measure... Its time consuming, but in my opinion worth it in the end.

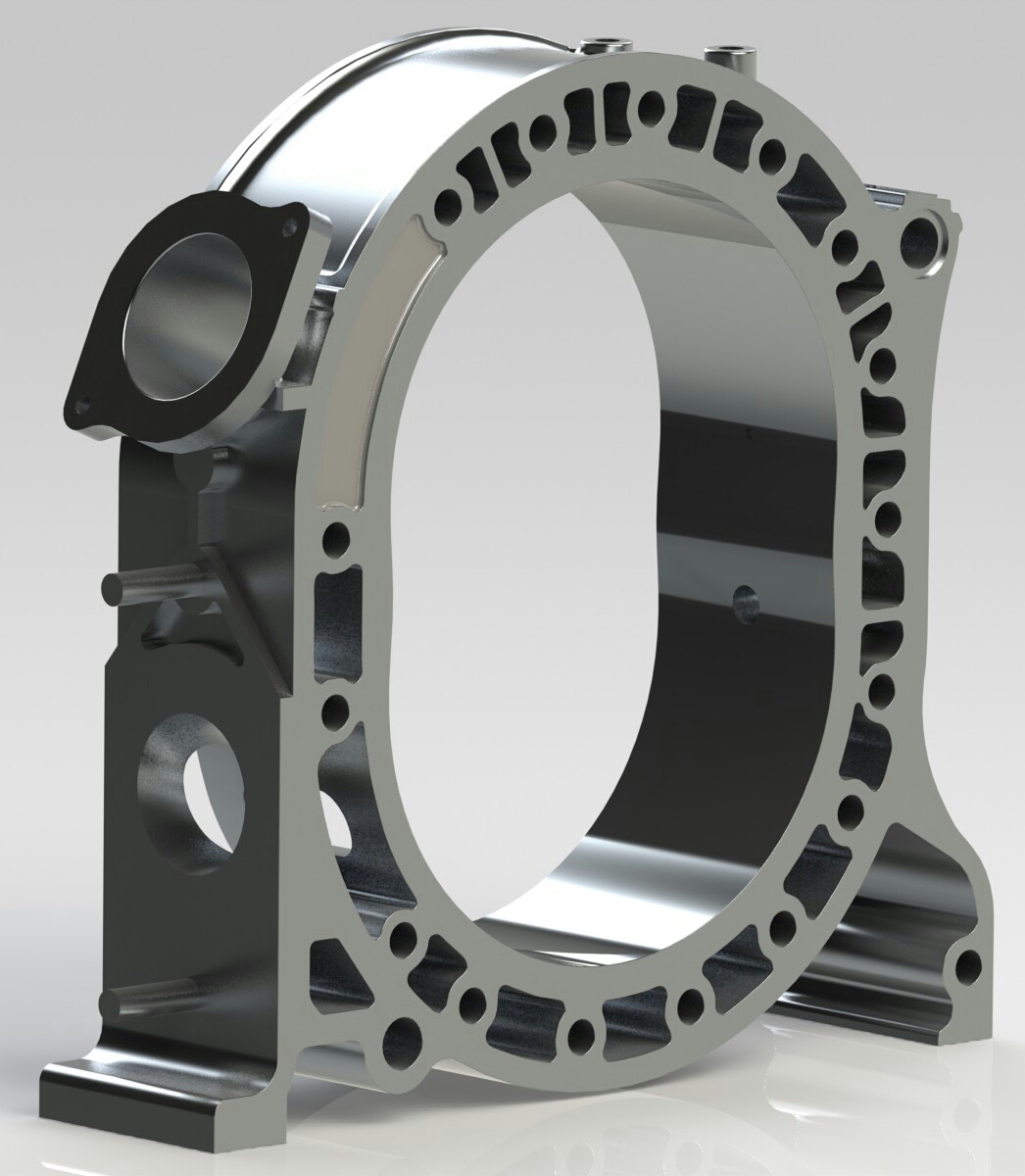

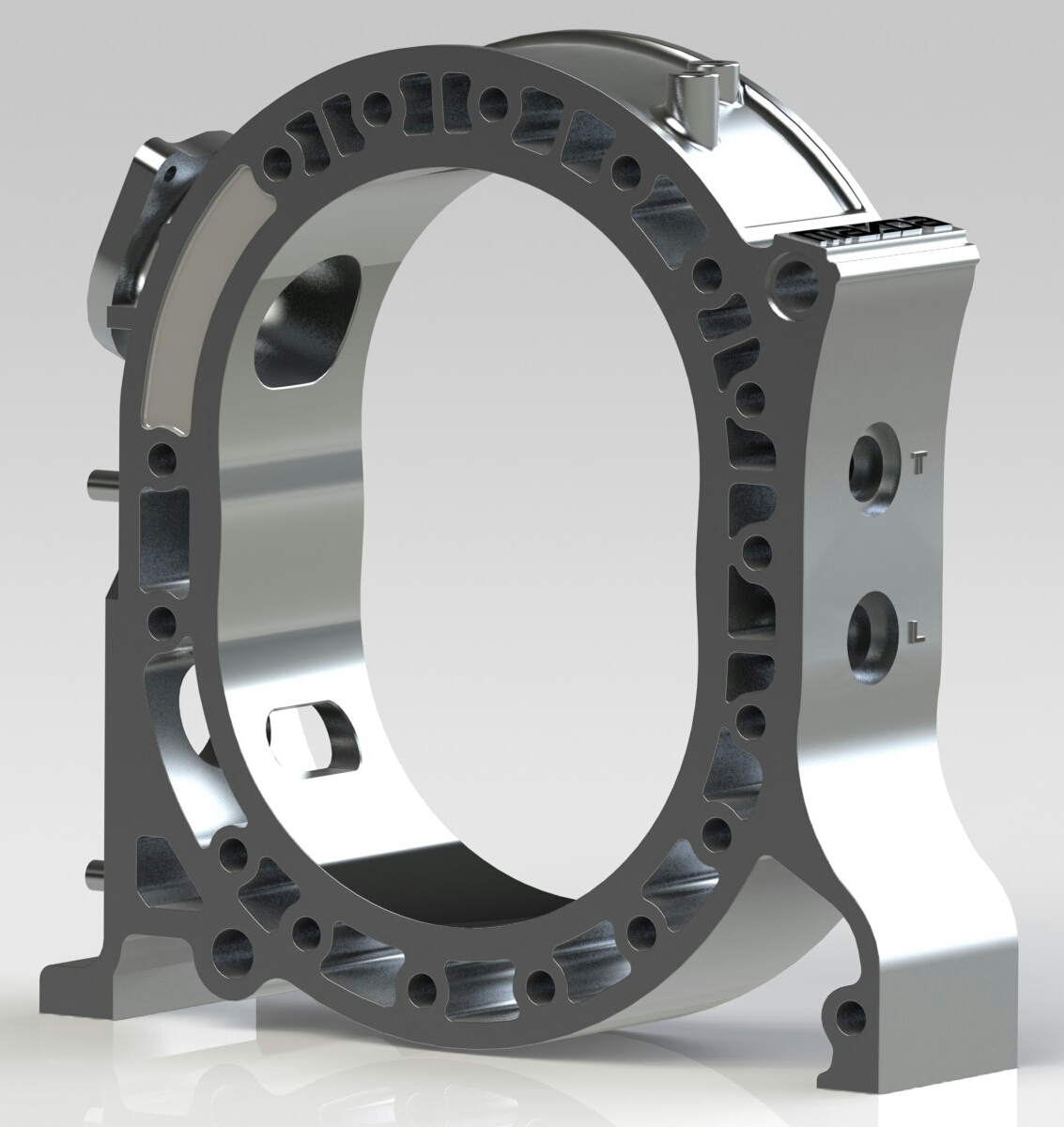

I like this one to. Would say 99% acurate to the real thing. Took me a few hours to measure.

I got all my published renderings at:

http://s815.photobucket.com/albums/z...142/SolidWorks

The answer is measure, measure and some measure... Its time consuming, but in my opinion worth it in the end.

I like this one to. Would say 99% acurate to the real thing. Took me a few hours to measure.

I got all my published renderings at:

http://s815.photobucket.com/albums/z...142/SolidWorks

#867

Senior Member

Thread Starter

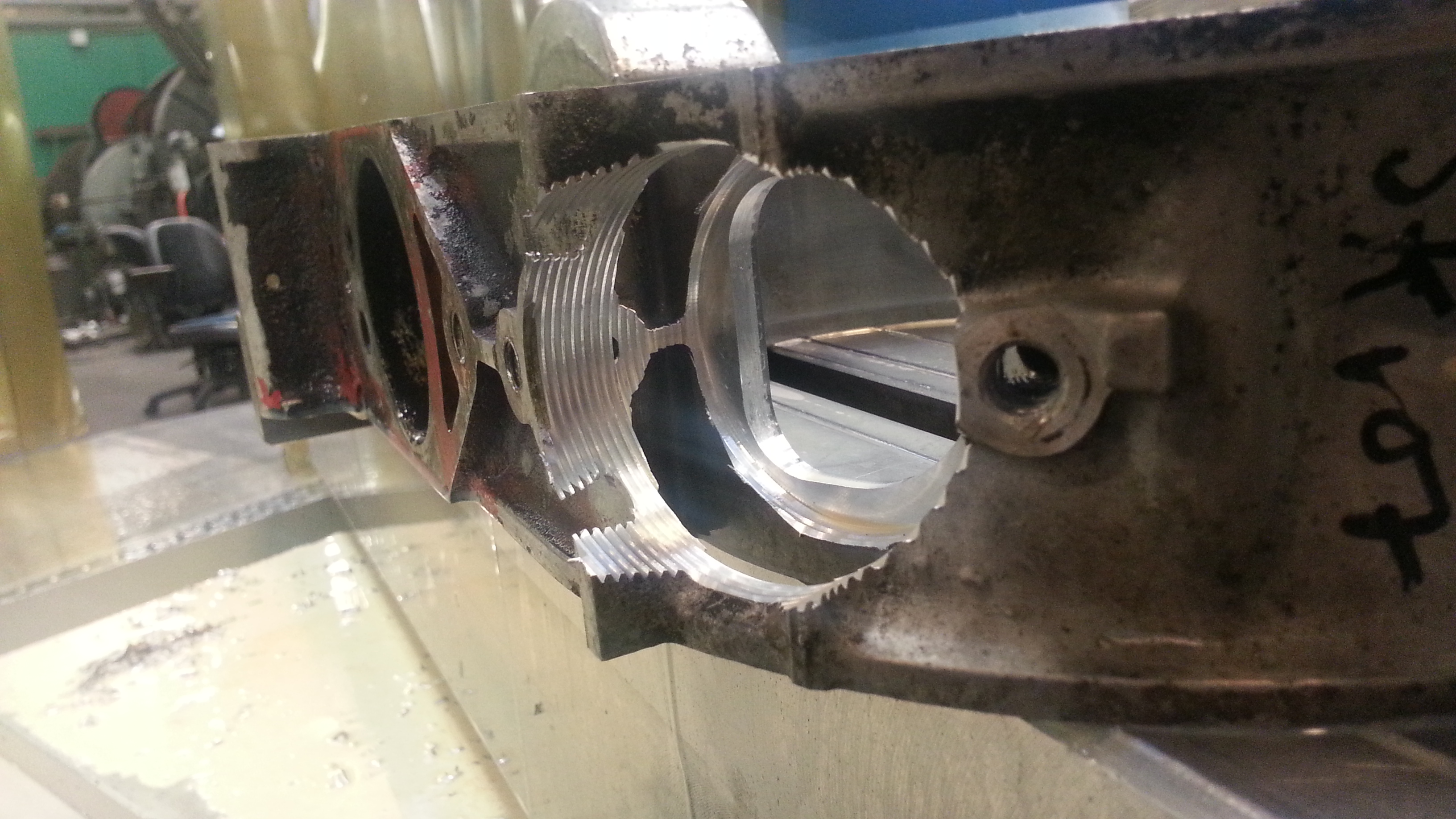

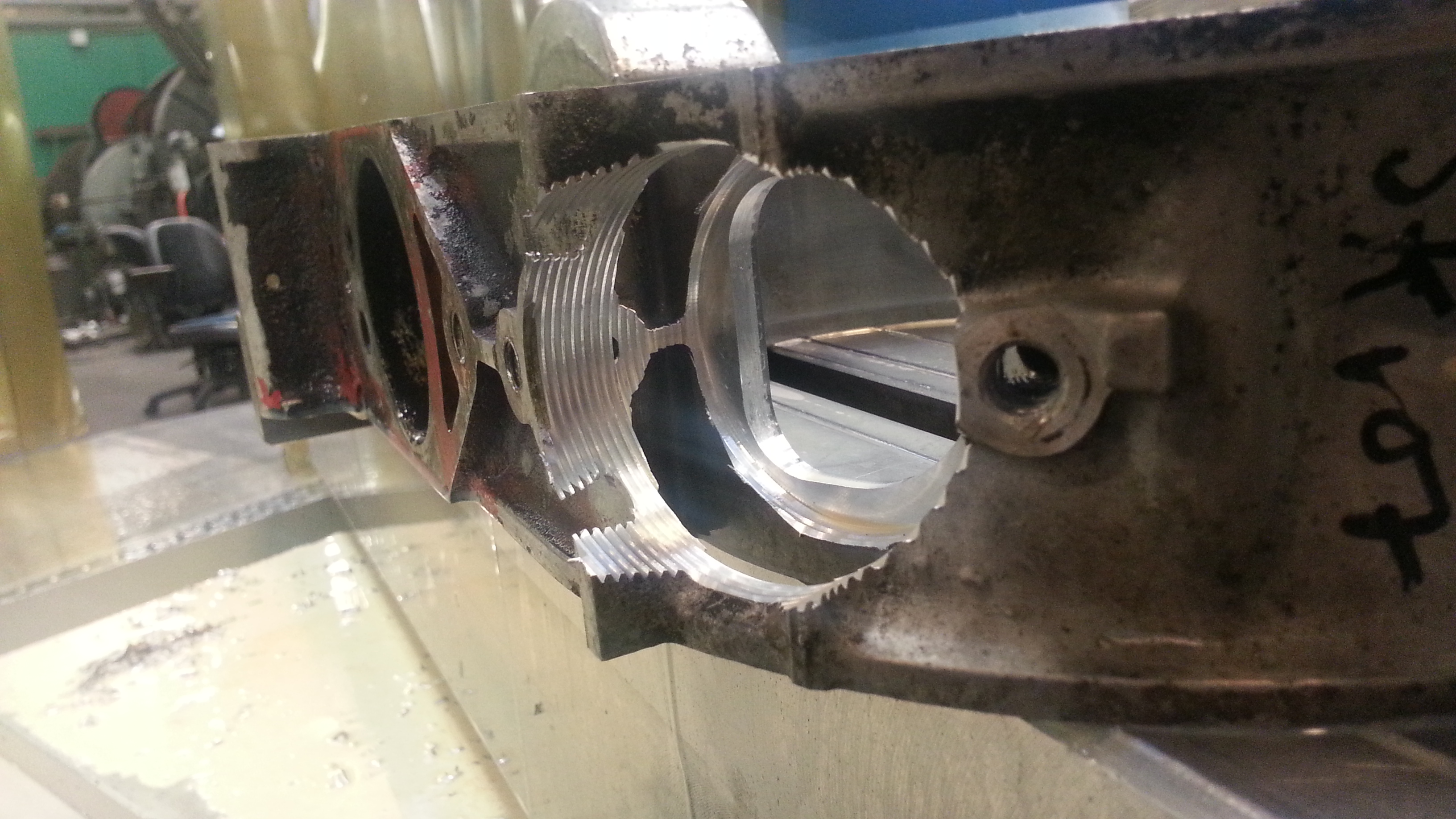

Continued today with the trash-housing.

Did a test sleeve in the cnc-lathe. I am very satisfied with this. Have minor improvements to do with the real ones later.

Did a test sleeve in the cnc-lathe. I am very satisfied with this. Have minor improvements to do with the real ones later.

#872

Senior Member

Thread Starter

I'm looking an flexplate from a Automatic FD (or FC if they ever was made?)

Anyone?

My flywheel is going to so small so I need the flexplate to start the engine :-)

Anyone?

My flywheel is going to so small so I need the flexplate to start the engine :-)

#874

or you might be able to make one....

mazdatrix also has some nice ones that accept small clutches:

http://www.mazdatrix.com/r-clutch-flywheel.htm

#875

Senior Member

Thread Starter

In this case you're right. I need the bigger flywheel because of my gearbox.

But, why should the smaller flywheel from N/A be less better in other considerations?

But, why should the smaller flywheel from N/A be less better in other considerations?