BigAl's FD 20B racecar project

#229

#232

So the fuel system is basically pressurized in a separate tank before its run to the engine? (forgive my witlessness, still trying to learn about high HP applications)

#233

>>So the fuel system is basically pressurized in a separate tank before its run to the engine?

Nope, the pressure is from the pressure pumps to the fuel rail, and the pressure pumps get the fuel from the seperate tank (surge tank), the seperate tank is just kept full in order to prevent fuel starve when the main tank gets low and the fuel sloshes around causing the main tank pickup to get air instead of fuel. The surge tank stays full so that you can run the main tank very low and not fuel starve under high G force conditions.

The surge tank gets filled from low a pressure pump in the main tank, and has a return line back to the main tanks, so it does not really see real pressure, just flow.

I built a similar setup for my race car, although Rob's setup is much 'nicer' :-)

pic of my setup during the install:

#234

Ill get this one for ya BigAl;-)

>>So the fuel system is basically pressurized in a separate tank before its run to the engine?

Nope, the pressure is from the pressure pumps to the fuel rail, and the pressure pumps get the fuel from the seperate tank (surge tank), the seperate tank is just kept full in order to prevent fuel starve when the main tank gets low and the fuel sloshes around causing the main tank pickup to get air instead of fuel. The surge tank stays full so that you can run the main tank very low and not fuel starve under high G force conditions.

The surge tank gets filled from low a pressure pump in the main tank, and has a return line back to the main tanks, so it does not really see real pressure, just flow.

>>So the fuel system is basically pressurized in a separate tank before its run to the engine?

Nope, the pressure is from the pressure pumps to the fuel rail, and the pressure pumps get the fuel from the seperate tank (surge tank), the seperate tank is just kept full in order to prevent fuel starve when the main tank gets low and the fuel sloshes around causing the main tank pickup to get air instead of fuel. The surge tank stays full so that you can run the main tank very low and not fuel starve under high G force conditions.

The surge tank gets filled from low a pressure pump in the main tank, and has a return line back to the main tanks, so it does not really see real pressure, just flow.

thank you, nicely put!

BigAl...

#235

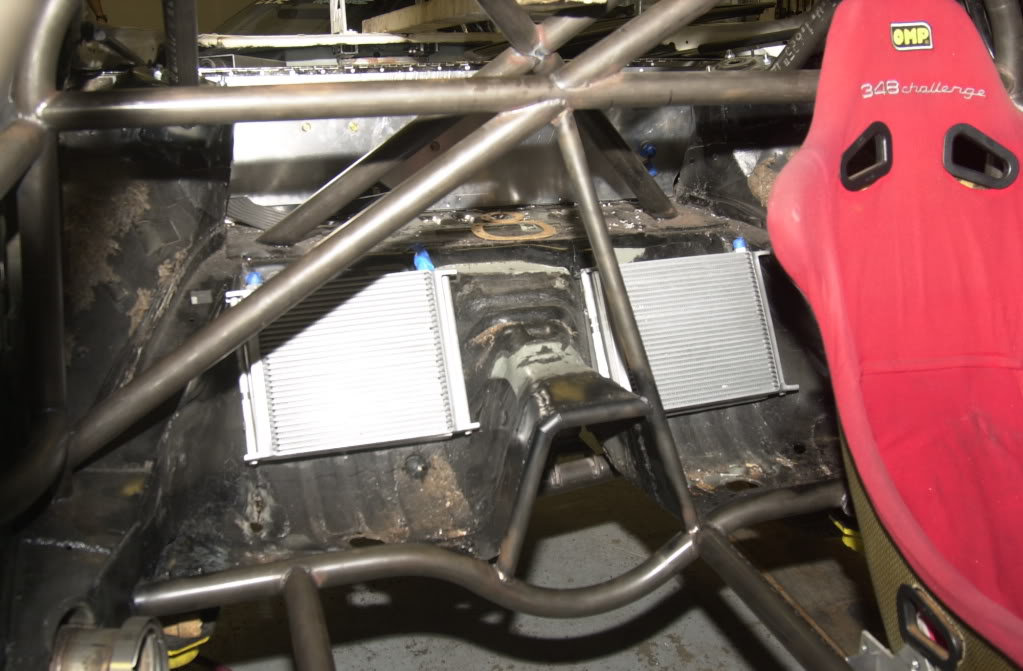

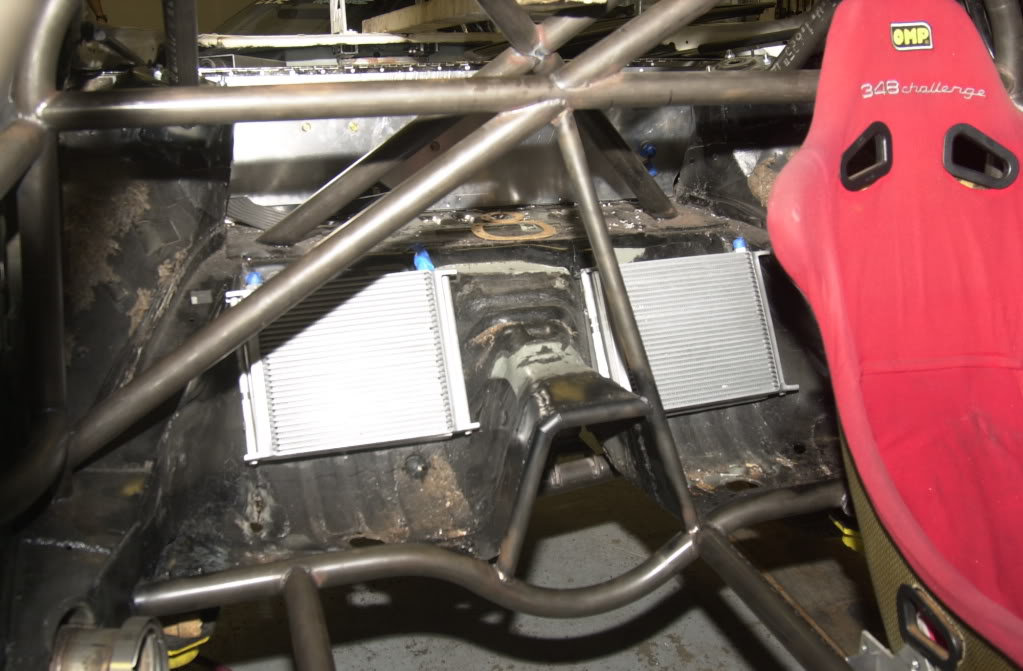

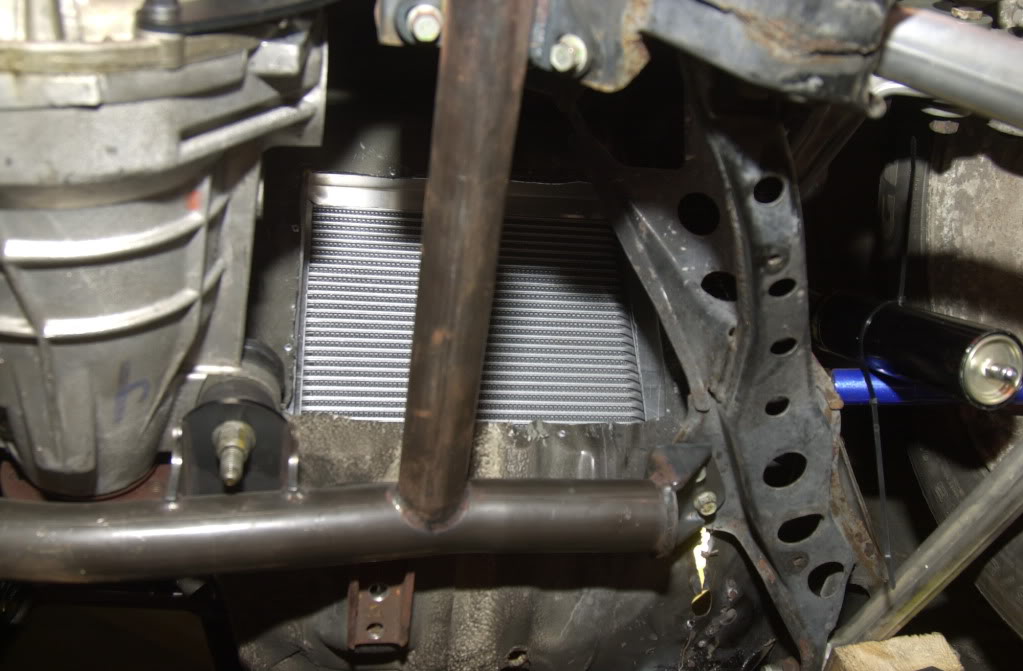

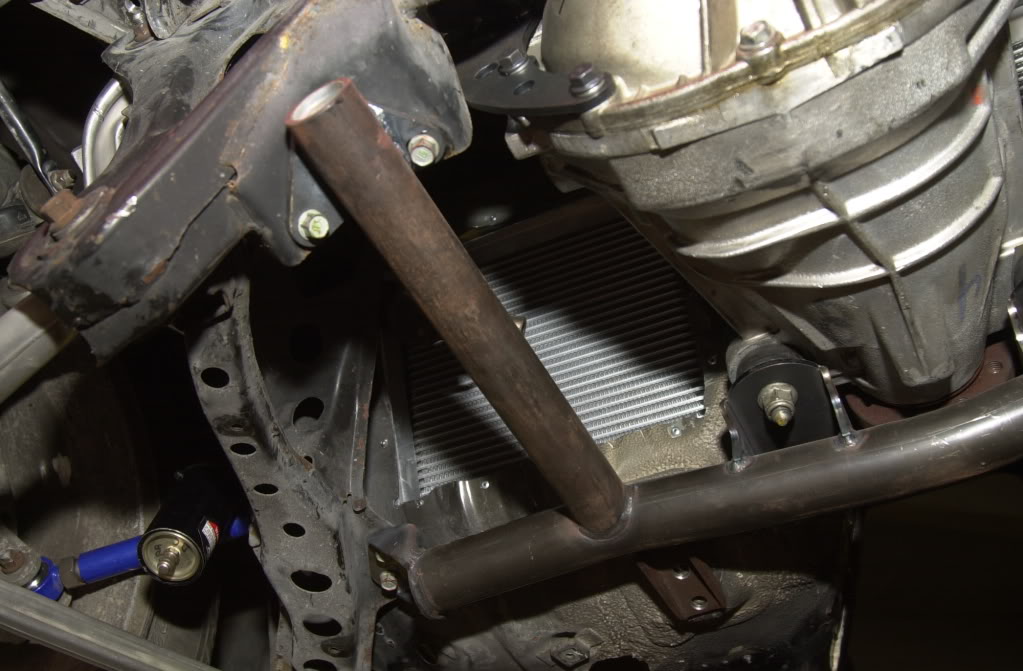

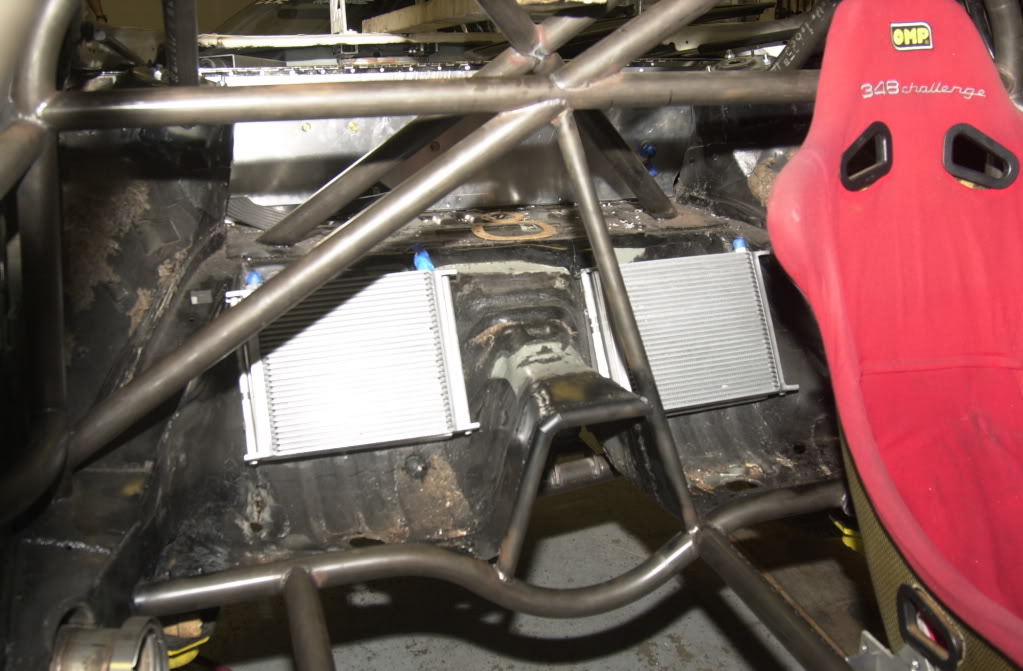

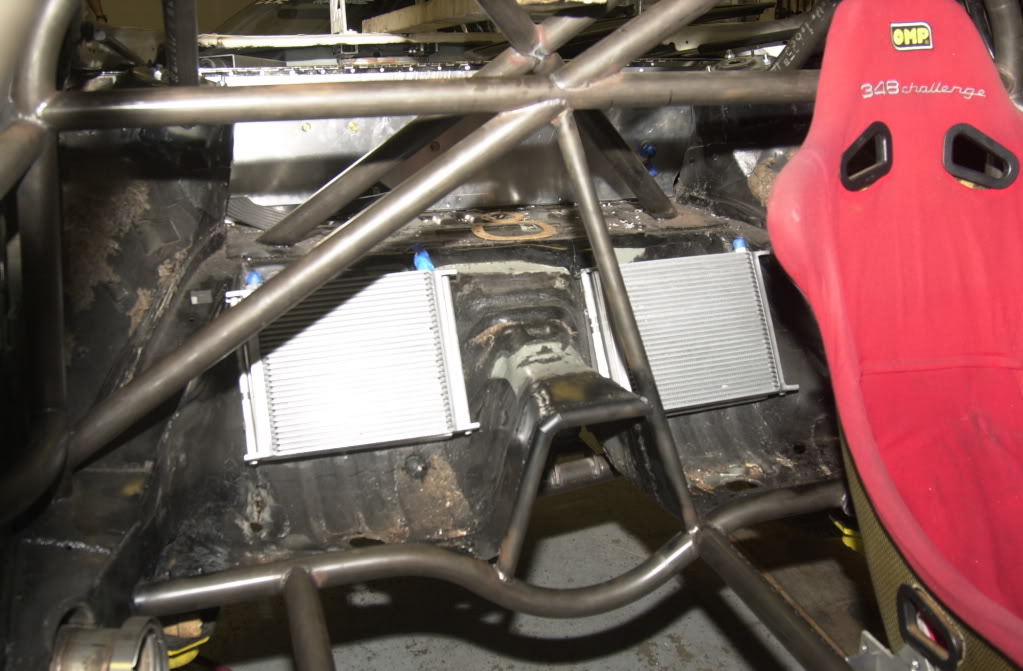

Well we're back at it, this time around we installed the oil coolers for the diff and tranny.

Here you see the coolers already installed, we made and aluminum frame that spaces the coolers about and inch and a quarter off the steel

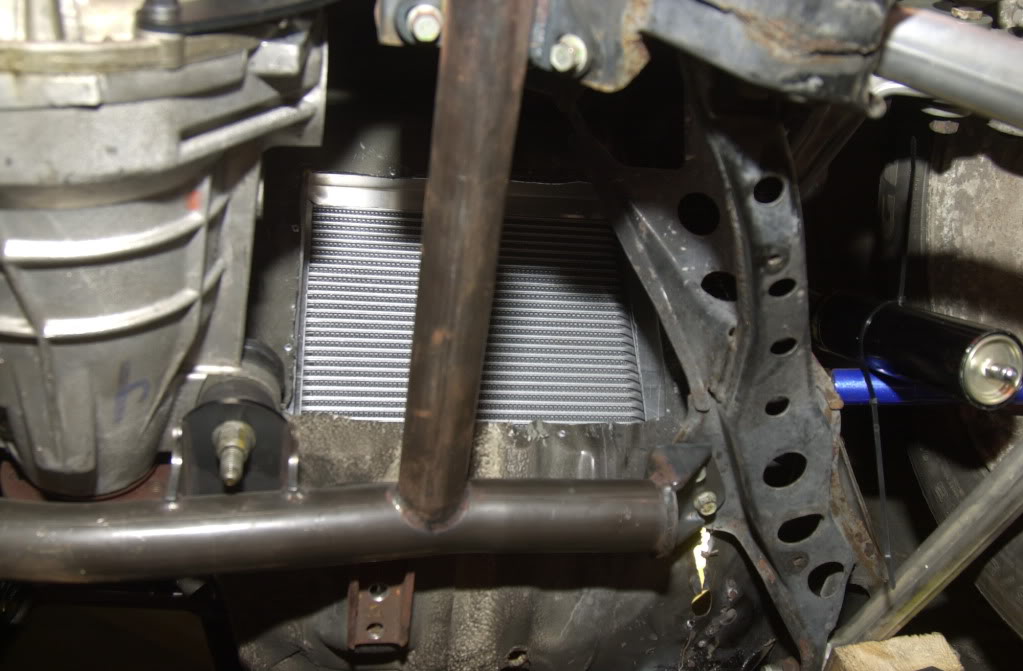

another angle

underside showing the exit for the coolers

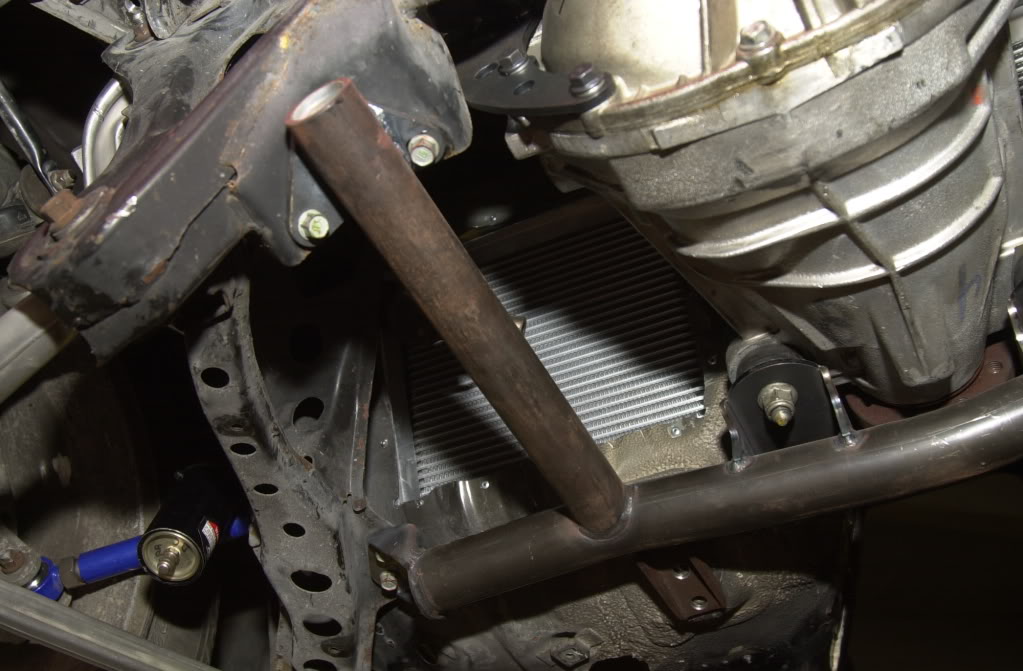

drivers side

ofcourse they are still missing the shrouds and fans that will be fed by NACA ducts installed in the bodywork.

next we're gonna be working on the front passenger side frame rail, this car was crashed and the previous owner had it pulled, but the place didn't do such a great job so we're gonna just replace it. We're also gonna cutout most of the sheetmetal around the shock tower (got the Idea from Vest Racing a fellow board member).

hope you enjoy

BigAl...

Here you see the coolers already installed, we made and aluminum frame that spaces the coolers about and inch and a quarter off the steel

another angle

underside showing the exit for the coolers

drivers side

ofcourse they are still missing the shrouds and fans that will be fed by NACA ducts installed in the bodywork.

next we're gonna be working on the front passenger side frame rail, this car was crashed and the previous owner had it pulled, but the place didn't do such a great job so we're gonna just replace it. We're also gonna cutout most of the sheetmetal around the shock tower (got the Idea from Vest Racing a fellow board member).

hope you enjoy

BigAl...

#238

they are very common on the professional level, some classes use big cans (like NASCAR) most others use fuel towers at the pit wall that hold more fuel than the cans. the sanctioning body that we race does a lot of 2 hour enduros so this really gives us an advantage. I can dump 10 gallons in about 15 seconds and the rules state that if you don't have a dry break the driver must be out of the car so thats gotta be worth at least a minute in driver removal. the alternative would be 5 gallon jugs you get at the local hardware store, how long do you think that takes to empty with that tiny little vent hole?

thanks for the compliments, our philosophy is simple, spend a little extra time doing it as best you can the first time and you'll be much happier later.

BigAl...

#239

[QUOTE=BigAl...;9491495]Well we're back at it, this time around we installed the oil coolers for the diff and tranny.

Here you see the coolers already installed, we made and aluminum frame that spaces the coolers about and inch and a quarter off the steel

My god... so beautiful!

so beautiful!

~Shar

Here you see the coolers already installed, we made and aluminum frame that spaces the coolers about and inch and a quarter off the steel

My god...

so beautiful!

so beautiful!~Shar

#241

I'm an amateur but something doesn't look right with that "flat" fuel filler/inlet...

B/c the pipe is flat, won't the fuel just run out whatever is in the filler inlet when you remove the fuel filling hose/rig?

Every fuel filler/inlet I've ever seen is downward facing so gravity can allow the fuel to drop into the tank. How are you going to ensure your fuel doesn't run out the inlet?

#242

>>How are you going to ensure your fuel doesn't run out the inlet?

This is not a comment on the horizintal pipe, but...on on your comment above:

It is a dry-break setup, it can't run out. It can only flow past when the opposite fitting is in, from the filler tank, and at that point the gas flow from the filler tank will push its way into the car tank.

This is not a comment on the horizintal pipe, but...on on your comment above:

It is a dry-break setup, it can't run out. It can only flow past when the opposite fitting is in, from the filler tank, and at that point the gas flow from the filler tank will push its way into the car tank.

#243

no need to steal, consider it a gift

make sure you make the frame to space them at least one inch off the steel. The diff is an 03-04 cobra and the cradle is from Justin Sanberg (fellow board member, nice job).

make sure you make the frame to space them at least one inch off the steel. The diff is an 03-04 cobra and the cradle is from Justin Sanberg (fellow board member, nice job).gracer7-rx7, what Damian said is spot on!

#245

>>make sure you make the frame to space them at least one inch off the steel.

sure, makes sense, also to alow the mounting on vibration isolators so the coolers dont get beat up.

Those are some big coolers too, I would probably go 1/2 that size :-) ... but i really like the idea especially for enduros. Most of my races are sprint races (35-45 minutes) but I plan to do more 2 to 3 hour enduros so I am looking at adding coolers for the trans, diff, and fuel.

>>off the steel. The diff is an 03-04 cobra and the cradle is from Justin Sanberg (fellow board member, nice job).

Yeah I have been looking at those setups, and Justin does nice work. I may move to that soon for a few reasons, mianly more rear end ratio options, but also since it is stronger than stock, although I have not had a failure with a stock rear end yet.

sure, makes sense, also to alow the mounting on vibration isolators so the coolers dont get beat up.

Those are some big coolers too, I would probably go 1/2 that size :-) ... but i really like the idea especially for enduros. Most of my races are sprint races (35-45 minutes) but I plan to do more 2 to 3 hour enduros so I am looking at adding coolers for the trans, diff, and fuel.

>>off the steel. The diff is an 03-04 cobra and the cradle is from Justin Sanberg (fellow board member, nice job).

Yeah I have been looking at those setups, and Justin does nice work. I may move to that soon for a few reasons, mianly more rear end ratio options, but also since it is stronger than stock, although I have not had a failure with a stock rear end yet.

#246

How much would the cobra rear end cost with everything to get it running? I need to go for a 5.0 ratio on my new setup to lower the top speed. At 9500 rpm 0.82 transmission and a 4.3 diff, im going to get about 320km/h top speed. Wich is way to high for my tracks. And i need to get the revs up in some turns.

So a price estimate would be great

So a price estimate would be great

#248

good question, not really sure of the answer, would be interesting to try, although the air under the car "if done correctly" should be moving faster so that would probably create a vacuum. not really sure how that would work.

BigAl...

#249

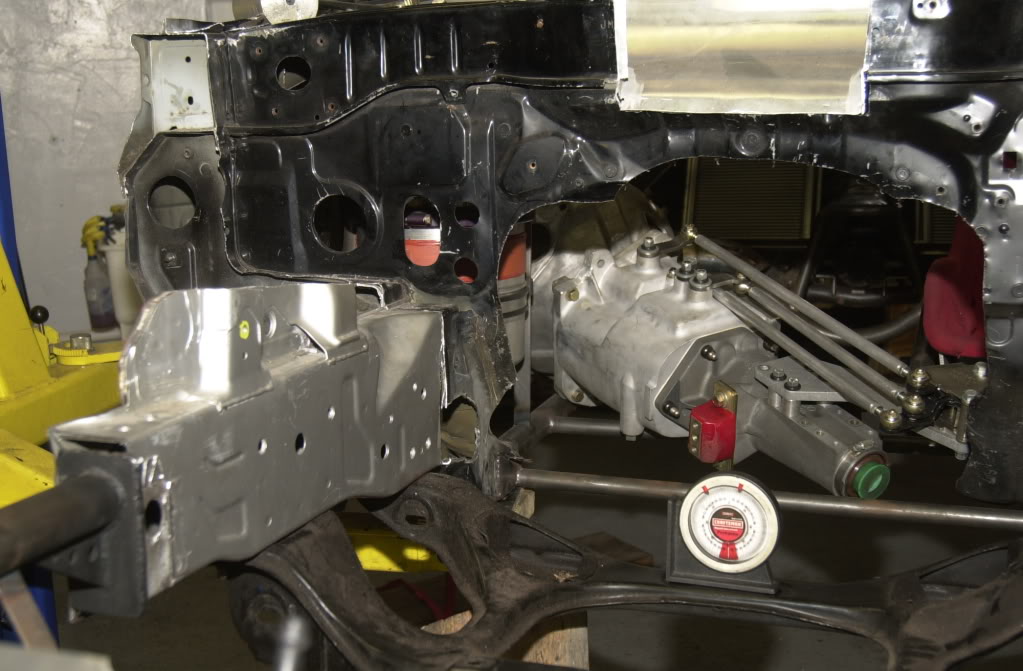

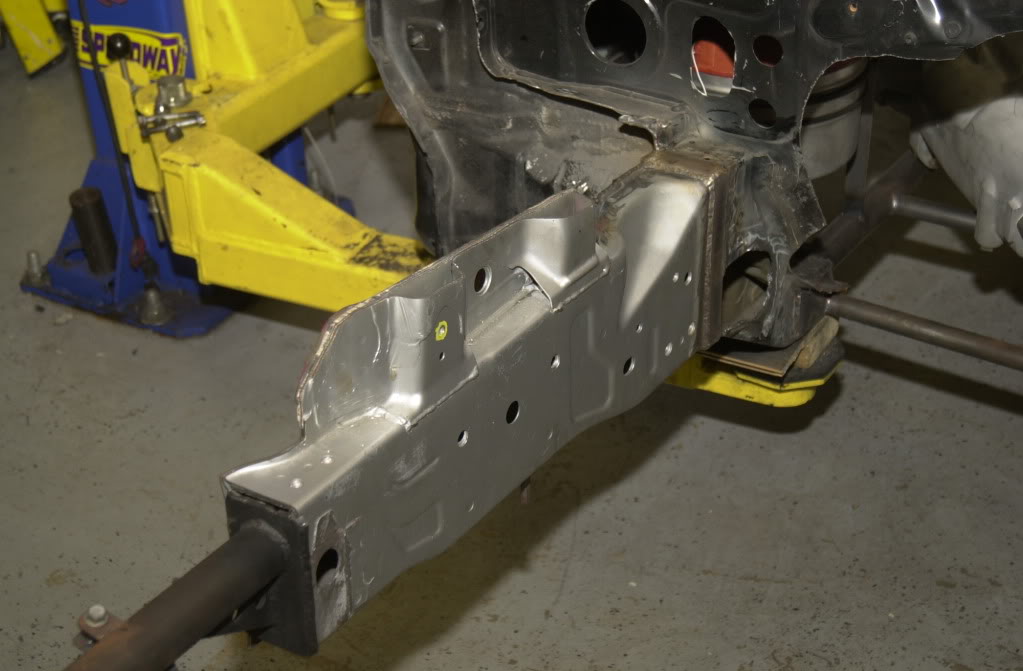

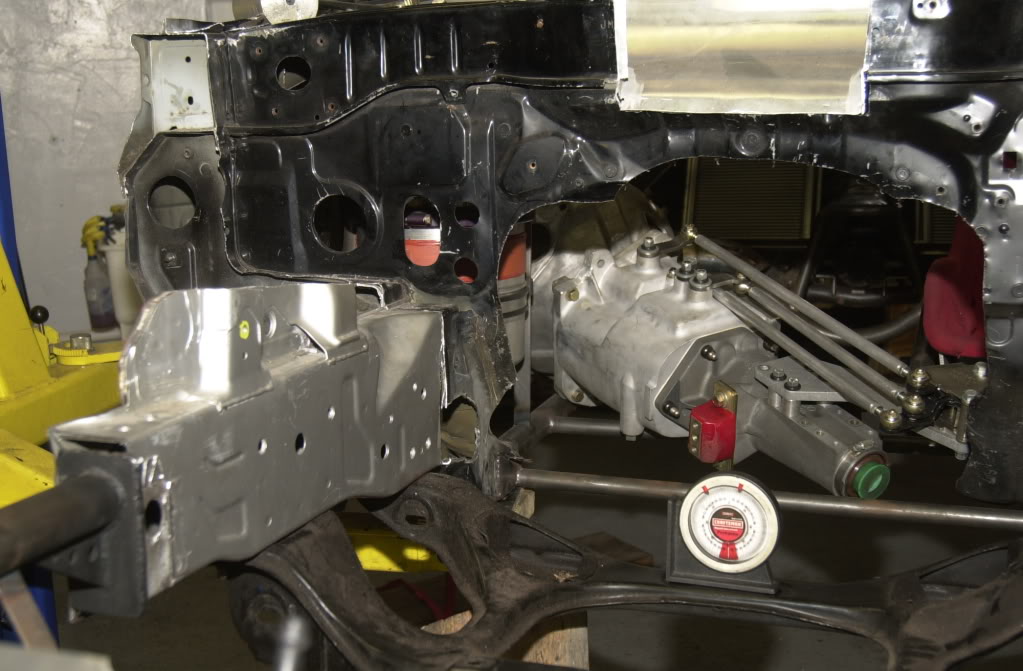

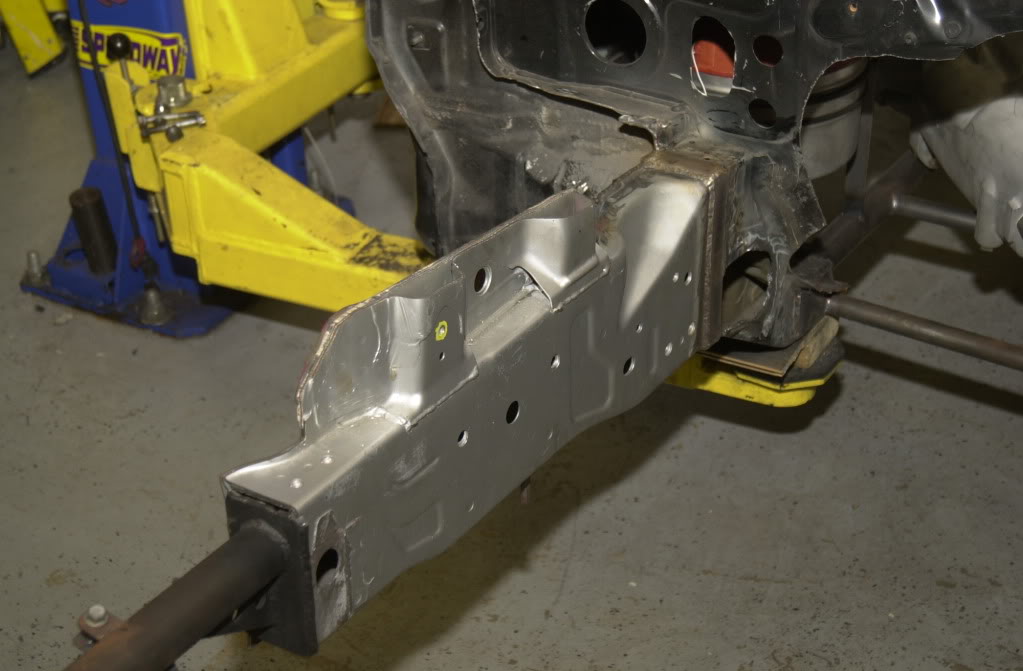

some of you might have seen the thread on this board where the member is redoing the shock towers on his fd (just incase you didn't https://www.rx7club.com/3rd-generation-specific-1993-2002-16/norwegian-fd-project-lots-pics-771978/page5/). As mentioned in my previous post my car needed to have the right frame rail replaced, so I decided to do that and also redo the shock towers.

this is what it used to look like before we started

chopity chop

here's the new piece mocked up

another shot

all welded up and straight

next will be the bending of the tubes, that won't be until after sevenstock

BigAl...

this is what it used to look like before we started

chopity chop

here's the new piece mocked up

another shot

all welded up and straight

next will be the bending of the tubes, that won't be until after sevenstock

BigAl...

#250

This might be of interest. An European NSX guy was using NACA ducts on his undertray to feed air into the engine bay. I can not come up with a real reason why this could not be used to feed the radiators (especially b.c you have fans).

http://www.nsxprime.com/forums/showthread.php?t=116208

Some pretty nice fabrication on the under tray.