BigAl's FD 20B racecar project

#476

Love your Fabricator!

Thread Starter

Join Date: Sep 2004

Location: Miami, FL

Posts: 353

Likes: 0

Received 0 Likes

on

0 Posts

Here you can see the brackets I made for the calipers, they were rough cut by the water jet and then I milled them to perfection on the bridgeport. As you can see I also added timeserts to add life to the threads.

#477

Senior Member

Join Date: Nov 2001

Location: Crescent City, CA

Posts: 295

Likes: 0

Received 0 Likes

on

0 Posts

I would add inline duct fans for your coolers. You can find old nascar units on ebay for cheap. That way you can be cooling your system whilst in the paddock

#478

Love your Fabricator!

Thread Starter

Join Date: Sep 2004

Location: Miami, FL

Posts: 353

Likes: 0

Received 0 Likes

on

0 Posts

thanks

BigAl...

#479

Love your Fabricator!

Thread Starter

Join Date: Sep 2004

Location: Miami, FL

Posts: 353

Likes: 0

Received 0 Likes

on

0 Posts

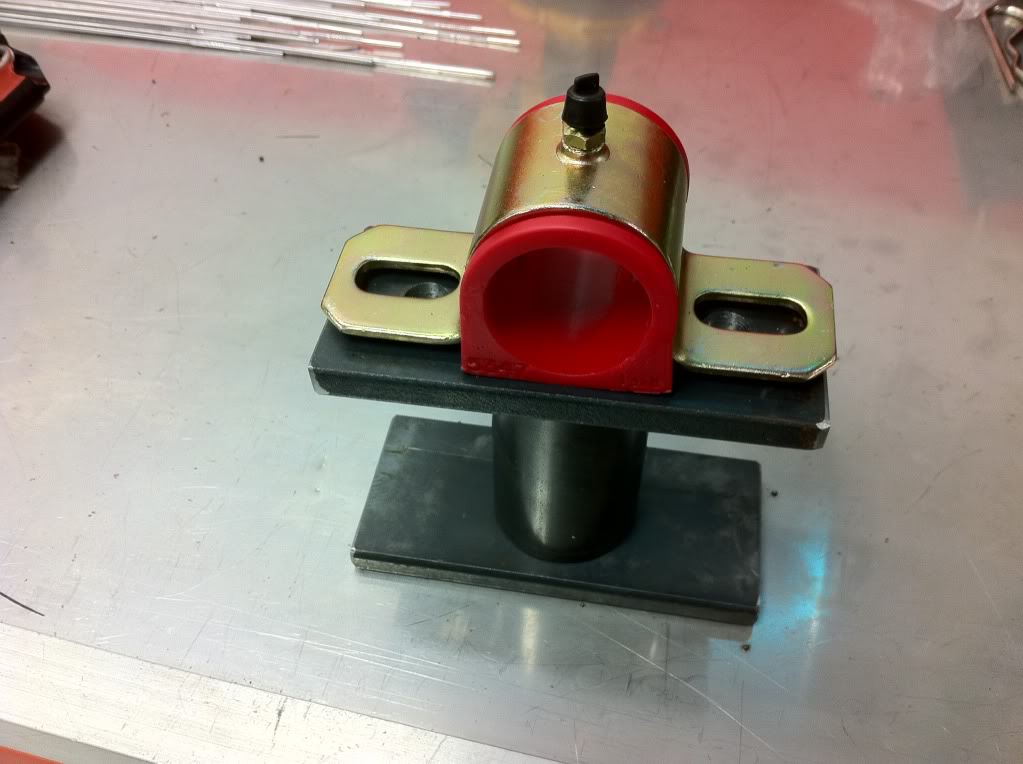

swayin to the music

So a while back my buddy Louie gave me some sway bar blades, so all I had to do was fab the sway bar. so below is what I think a sway bar should look like.

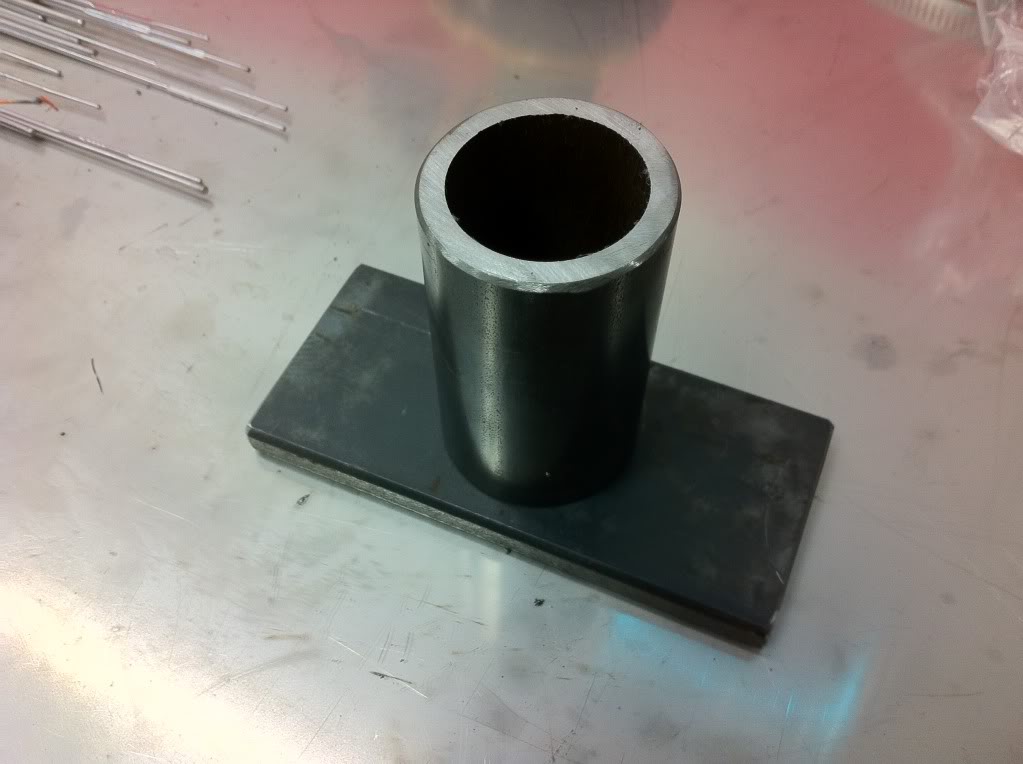

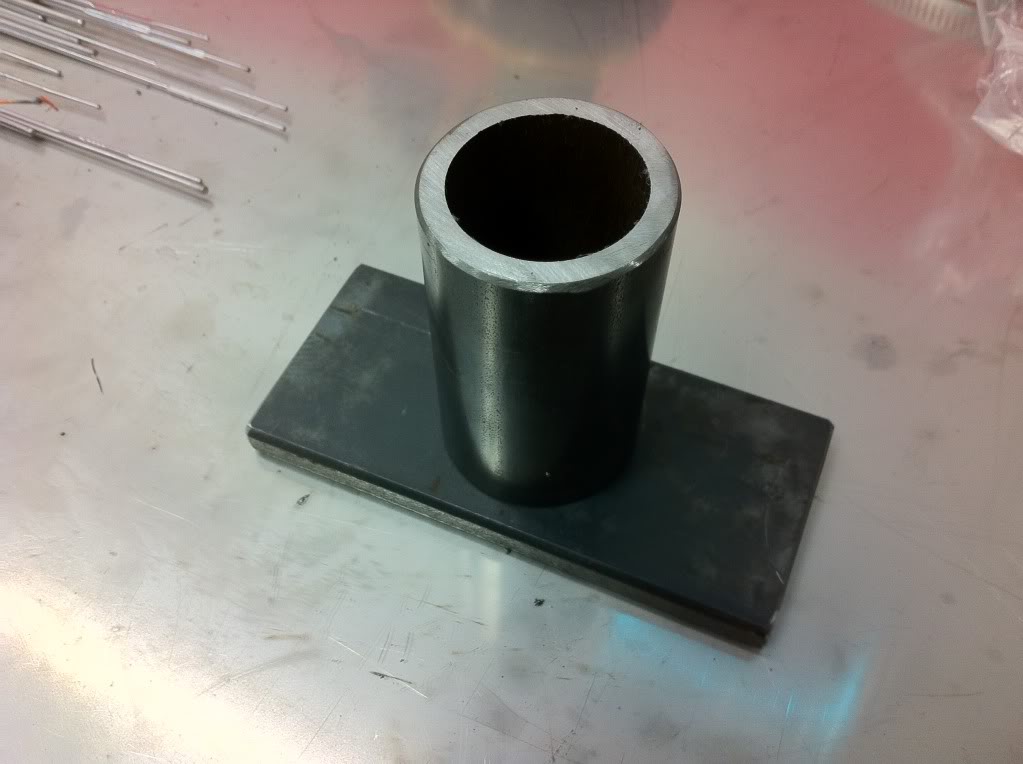

the next few pics is of the standoff being fabricated

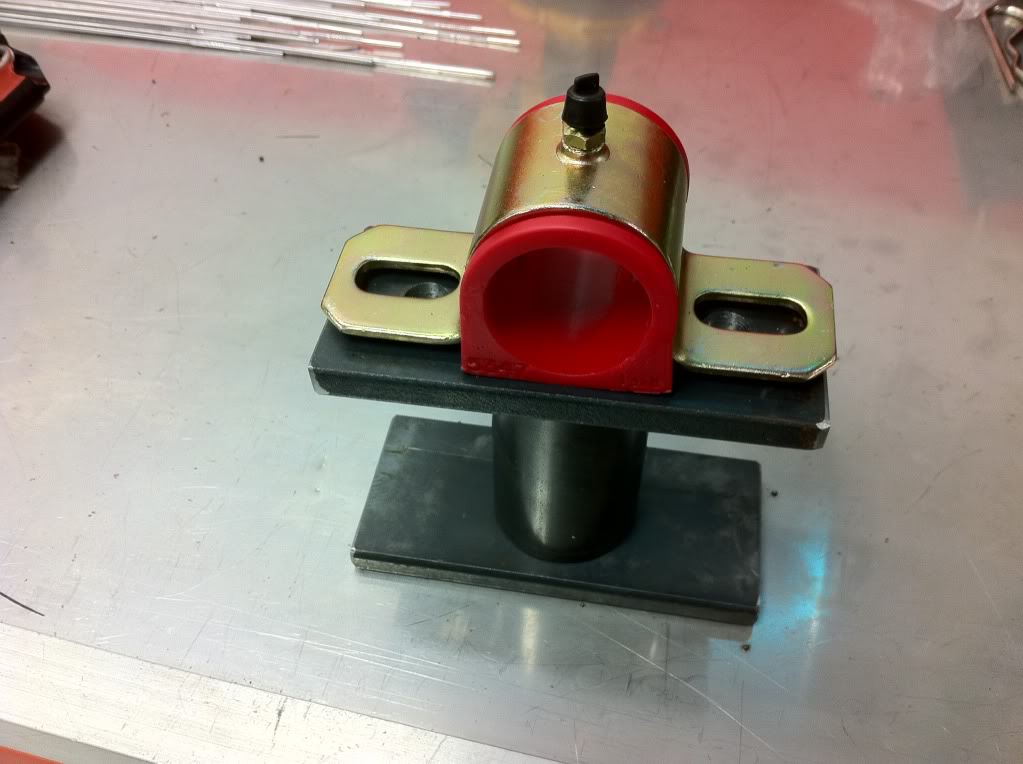

suspension techniques sway bar bushings

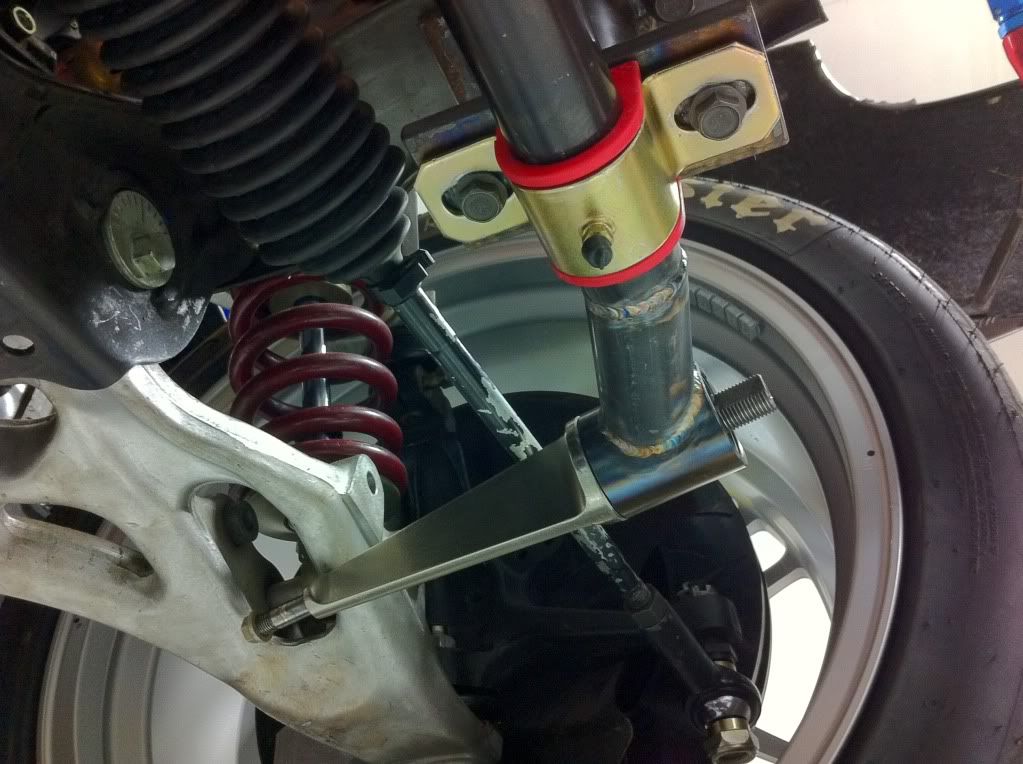

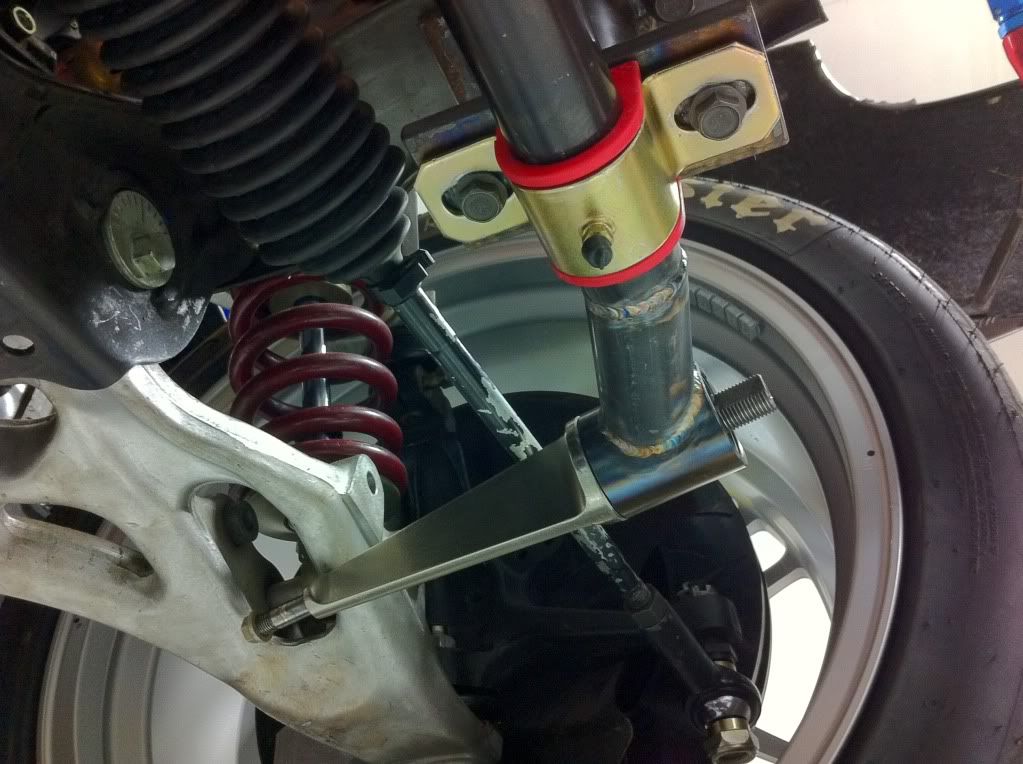

with the standoffs done I had to mount the blades

now came the other side, luckily they sell a barrel with the bearings, all I had to do was spend three hours aligning and measuring and measuring and measuring... oh and welding and welding...

and the finished product... well almost finished, still have to mount the cable so I can adjust this bad boy from the drivers seat!!!

more later

BigAl...

the next few pics is of the standoff being fabricated

suspension techniques sway bar bushings

with the standoffs done I had to mount the blades

now came the other side, luckily they sell a barrel with the bearings, all I had to do was spend three hours aligning and measuring and measuring and measuring... oh and welding and welding...

and the finished product... well almost finished, still have to mount the cable so I can adjust this bad boy from the drivers seat!!!

more later

BigAl...

#480

2 questions.

what grade tubing did you use on the bar?

also did they not sell any 2 piece solid bushings for the bar?

ok i lies, more questions... what rate do you expect that bar to be?

is that why you used 2 blades?

what grade tubing did you use on the bar?

also did they not sell any 2 piece solid bushings for the bar?

ok i lies, more questions... what rate do you expect that bar to be?

is that why you used 2 blades?

#481

Love your Fabricator!

Thread Starter

Join Date: Sep 2004

Location: Miami, FL

Posts: 353

Likes: 0

Received 0 Likes

on

0 Posts

I used .188 wall chromolly tubing

I didn't find any solid bushings

I don't know what "rate" the bar will be. Does anybody ever really know what rate a bar is? if you don't use the exact bushings that were used during the test, do you really know what rate your bar is??? My intensions were to make the bar as stiff as possible and then adjust the blades to fit my needs. Hope that answers your question.

BigAl...

#482

absolutely love it all. What front bumper is that again?! Are you going to be staying with the Flat black Wrap? have you considered 3m DINOC Carbon Fiber Wrap? I have been considering doing my whole roof on my fd as it's really quality stuff and pretty cheap as well!

- ap

- ap

#483

Love your Fabricator!

Thread Starter

Join Date: Sep 2004

Location: Miami, FL

Posts: 353

Likes: 0

Received 0 Likes

on

0 Posts

absolutely love it all. What front bumper is that again?! Are you going to be staying with the Flat black Wrap? have you considered 3m DINOC Carbon Fiber Wrap? I have been considering doing my whole roof on my fd as it's really quality stuff and pretty cheap as well!

- ap

- ap

You know, I have no clue what bumper that is, it was on ebay a long time ago. yup the whole car is done in the matt black. it looks really cool.

thanks

BigAl...

#485

I used .188 wall chromolly tubing

I didn't find any solid bushings

I don't know what "rate" the bar will be. Does anybody ever really know what rate a bar is? if you don't use the exact bushings that were used during the test, do you really know what rate your bar is??? My intensions were to make the bar as stiff as possible and then adjust the blades to fit my needs. Hope that answers your question.

BigAl...

I didn't find any solid bushings

I don't know what "rate" the bar will be. Does anybody ever really know what rate a bar is? if you don't use the exact bushings that were used during the test, do you really know what rate your bar is??? My intensions were to make the bar as stiff as possible and then adjust the blades to fit my needs. Hope that answers your question.

BigAl...

I guess you dont have any data to fill the suspension worksheet in yet...

but job done on making it as stiff as possible!

#487

And one final pic that wouldn't fit in the other post. This is a great book by the way, It covers just about any suspension related question you can think of, even a little bit about active suspension. In my opinion it is well worth the $30 on amazon to buy this if anybody is planning on doing anything suspension related.

#488

I think what BigAl was getting at is that it's impossible to predict bar stiffness because there are too many variables not considered in those calculations and others like them. The bar's material for example, makes a big difference and I havent seen a calculator yet that has the bending strengths of different popular metals as an option. Also, welds can change the strength of the bar and change how the bar gets loaded. It's cool to say how stiff a bar is, but do you really know how stiff is "just right". The adjustable setup is optimal. Make a bar that's somewhere in the ballpark and be able to tune it to your car/driving style.

#490

Love your Fabricator!

Thread Starter

Join Date: Sep 2004

Location: Miami, FL

Posts: 353

Likes: 0

Received 0 Likes

on

0 Posts

I think what BigAl was getting at is that it's impossible to predict bar stiffness because there are too many variables not considered in those calculations and others like them. The bar's material for example, makes a big difference and I havent seen a calculator yet that has the bending strengths of different popular metals as an option. Also, welds can change the strength of the bar and change how the bar gets loaded. It's cool to say how stiff a bar is, but do you really know how stiff is "just right". The adjustable setup is optimal. Make a bar that's somewhere in the ballpark and be able to tune it to your car/driving style.

GET OUT OF MY HEAD!!! that's exactly my thoughts, ajhehr I hope you weren't insulted by my response, but shainiac's response is spot on.

BigAl...

#491

Lol, no I am not insulted, but thanks for the concern... My gut reaction to the bar was holy cow that is unbelievably stiff! even with both blades flat (assuming a 1.25 od tube, but your tube looks larger then that) the rate of the bar is in the 400lbs range... so the lightest rate of your bar would be 300lbs? on second thought though a 20k spring would be about right considering where the pickup is for the end link...

so NM i guess, I have no experience with the fd chassis. but i think I would have error on the other side of the the line so not to take any suspension away from the car that i didnt have to... and definitely used pillow blocks to ensure your rate...

so NM i guess, I have no experience with the fd chassis. but i think I would have error on the other side of the the line so not to take any suspension away from the car that i didnt have to... and definitely used pillow blocks to ensure your rate...

#492

Love your Fabricator!

Thread Starter

Join Date: Sep 2004

Location: Miami, FL

Posts: 353

Likes: 0

Received 0 Likes

on

0 Posts

haha, it's funny you should say that. that was my original idea, I ordered the blocks from www.thebigbearingstore.com and when they arrived they were the size of my house. The pair must weigh 20+ lbs. Thats when I ordered the ones in the pics. they weren't very expensive so I just kept them, if you're interested I'll sell 'em to ya for a song.

BigAl...

BigAl...

#497

Love your Fabricator!

Thread Starter

Join Date: Sep 2004

Location: Miami, FL

Posts: 353

Likes: 0

Received 0 Likes

on

0 Posts

thanks for all the kind words guys.

this weeks installment shows the installation of the Racepak dash

here is the final product, new OMP with all the decals in place and of course dash in background.

here's a bird's eye of the brackets I made to mount the dash

one last angle

more to come

BigAl...

this weeks installment shows the installation of the Racepak dash

here is the final product, new OMP with all the decals in place and of course dash in background.

here's a bird's eye of the brackets I made to mount the dash

one last angle

more to come

BigAl...

#499

Love your Fabricator!

Thread Starter

Join Date: Sep 2004

Location: Miami, FL

Posts: 353

Likes: 0

Received 0 Likes

on

0 Posts