Tegheim - Home made 4 Rotor Wolvo project

#558

2yrs huh. feels like 5 months. I started my build before you . Although your not building, your producing "1"

. Although your not building, your producing "1"  . Theres not many people that understand what it takes to actually build a automobile. You always hear "is your car going to be done this summer"...."no"......"wtf are you waiting on? Should be done by now. If it was mine it would be done". And they dont have a single clue. Congrats on the Project and keep struting it

. Theres not many people that understand what it takes to actually build a automobile. You always hear "is your car going to be done this summer"...."no"......"wtf are you waiting on? Should be done by now. If it was mine it would be done". And they dont have a single clue. Congrats on the Project and keep struting it . Looking forward to the finished product in the next 2yrs!

. Looking forward to the finished product in the next 2yrs!

. Although your not building, your producing "1"

. Although your not building, your producing "1"  . Theres not many people that understand what it takes to actually build a automobile. You always hear "is your car going to be done this summer"...."no"......"wtf are you waiting on? Should be done by now. If it was mine it would be done". And they dont have a single clue. Congrats on the Project and keep struting it

. Theres not many people that understand what it takes to actually build a automobile. You always hear "is your car going to be done this summer"...."no"......"wtf are you waiting on? Should be done by now. If it was mine it would be done". And they dont have a single clue. Congrats on the Project and keep struting it . Looking forward to the finished product in the next 2yrs!

. Looking forward to the finished product in the next 2yrs!

#564

Senior Member

Thread Starter

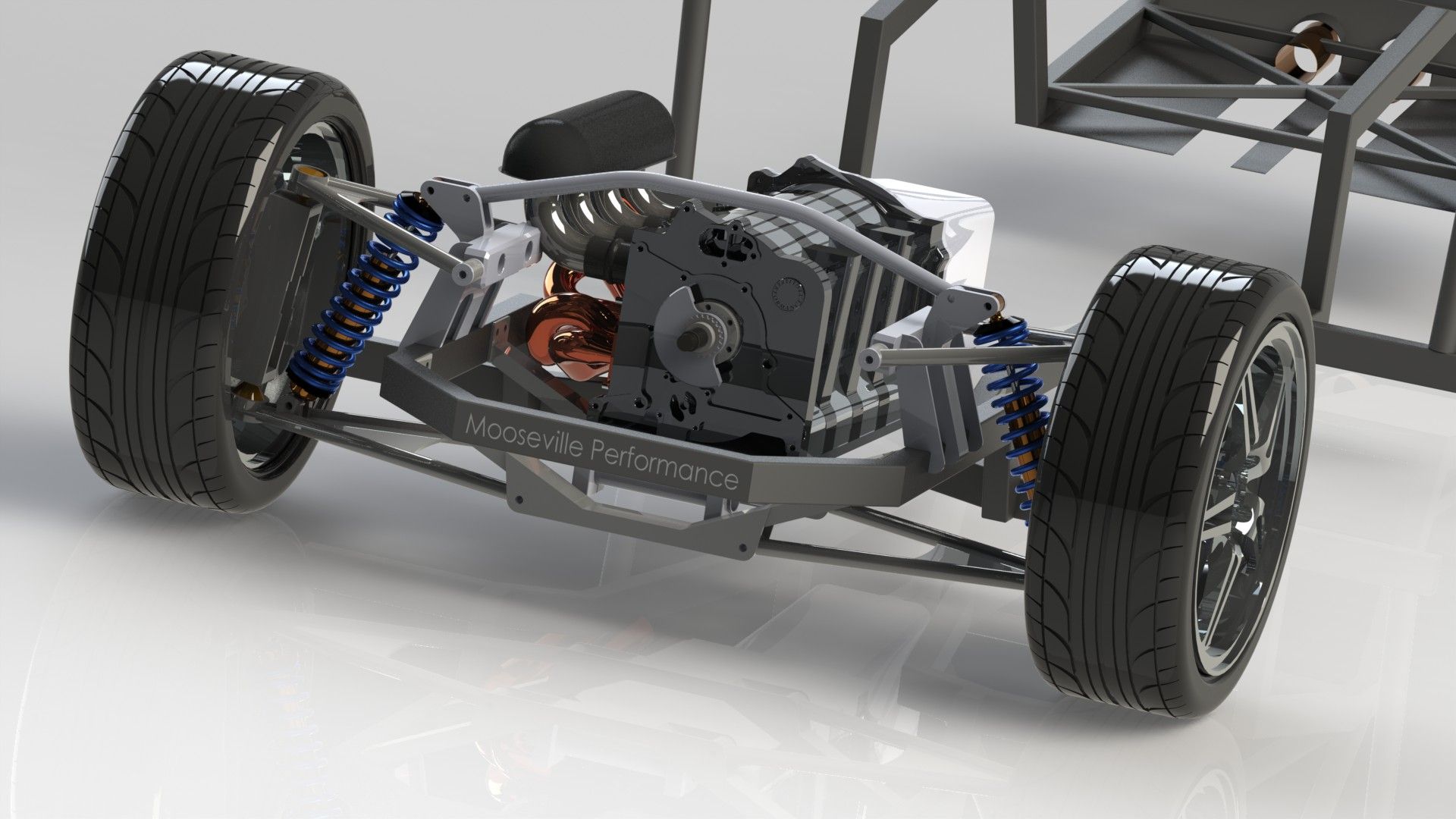

There will be much more pipes in the engine-bay later. The rollcage will continue in there, and there will be wheelhouse, crosses and yeah... Just not so easy to CAD in at the moment, easier to build in place

#566

Senior Member

Thread Starter

Improved some design to get it stronger...

Putted on the hood to see how much space it is under there.

Did also put the wheel in rideheight so you can se how high it would be.

Sadly it not high enough for the DTM-wheelhouse's

Putted on the hood to see how much space it is under there.

Did also put the wheel in rideheight so you can se how high it would be.

Sadly it not high enough for the DTM-wheelhouse's

#571

Senior Member

Thread Starter

#572

tard of teh century

What kind of steel and thicknesses are you using for those uprights? I've become a big fan of the boxed sheet metal uprights after seeing how hard it is to get people to cut and machine just a couple of uprights out of aluminum without waiting months and months.

And don't listen to the other guys only wanting engine pics, that chassis is dead sexy so keep posting plenty of pics

And don't listen to the other guys only wanting engine pics, that chassis is dead sexy so keep posting plenty of pics

#574

Senior Member

Thread Starter

What kind of steel and thicknesses are you using for those uprights? I've become a big fan of the boxed sheet metal uprights after seeing how hard it is to get people to cut and machine just a couple of uprights out of aluminum without waiting months and months.

And don't listen to the other guys only wanting engine pics, that chassis is dead sexy so keep posting plenty of pics

And don't listen to the other guys only wanting engine pics, that chassis is dead sexy so keep posting plenty of pics

The weight-save in aluminium isn't that much if you want the same strenght.

I'm probably stupid, but if I understand you correctly, I made everything in the front itself apart from the wheel bearing and brake disc. The disc-hub I machined though.

Most of it is welded. Just the mount to the wheel bearing is machined to fit prior to welding.

I'm not good at English, so sometimes I do not understand your questions

But I will gladly answer as best I can