4-Rotor FC Build

#727

Update

Made some progress on the hood vent. Finished reinforcing the hood, and made aluminium ducting between the radiator and the hood.

Me welding some sheets together

After a day of fiddling around it looked like this

All the ducting is bolted on, nothing is welded to the radiator. The hood vent and lower ducting can all be removed in a few minutes without having to remove other stuff.

Looks a bit strange, total stock body with a hood vent. I think the suspension and wheels will make it look more at home

Made some progress on the hood vent. Finished reinforcing the hood, and made aluminium ducting between the radiator and the hood.

Me welding some sheets together

After a day of fiddling around it looked like this

All the ducting is bolted on, nothing is welded to the radiator. The hood vent and lower ducting can all be removed in a few minutes without having to remove other stuff.

Looks a bit strange, total stock body with a hood vent. I think the suspension and wheels will make it look more at home

#729

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,841

Received 2,605 Likes

on

1,848 Posts

i think it looks badass!

#730

I'm doing something similar right now on my hood as well. I had a shitty Evo 8 hood vent on mine... awful.

I think, however, you might need to add a lip of some sort to the front of the hole in your hood. Something to create an area of low pressure behind it, sucking air out of the hood. Otherwise, you may be presented with the same problem I was having. It created a high pressure area on both top and underneath, making for no airflow at all.

By the way, what did you use to cut the hole in your hood? I tried using a cutoff wheel on an angle grinder, then tried an air-powered cutoff wheel, then moved on to a reciprocating saw. The latter, I don't recommend

I think, however, you might need to add a lip of some sort to the front of the hole in your hood. Something to create an area of low pressure behind it, sucking air out of the hood. Otherwise, you may be presented with the same problem I was having. It created a high pressure area on both top and underneath, making for no airflow at all.

By the way, what did you use to cut the hole in your hood? I tried using a cutoff wheel on an angle grinder, then tried an air-powered cutoff wheel, then moved on to a reciprocating saw. The latter, I don't recommend

#735

I'm doing something similar right now on my hood as well. I had a shitty Evo 8 hood vent on mine... awful.

I think, however, you might need to add a lip of some sort to the front of the hole in your hood. Something to create an area of low pressure behind it, sucking air out of the hood. Otherwise, you may be presented with the same problem I was having. It created a high pressure area on both top and underneath, making for no airflow at all.

By the way, what did you use to cut the hole in your hood? I tried using a cutoff wheel on an angle grinder, then tried an air-powered cutoff wheel, then moved on to a reciprocating saw. The latter, I don't recommend

I think, however, you might need to add a lip of some sort to the front of the hole in your hood. Something to create an area of low pressure behind it, sucking air out of the hood. Otherwise, you may be presented with the same problem I was having. It created a high pressure area on both top and underneath, making for no airflow at all.

By the way, what did you use to cut the hole in your hood? I tried using a cutoff wheel on an angle grinder, then tried an air-powered cutoff wheel, then moved on to a reciprocating saw. The latter, I don't recommend

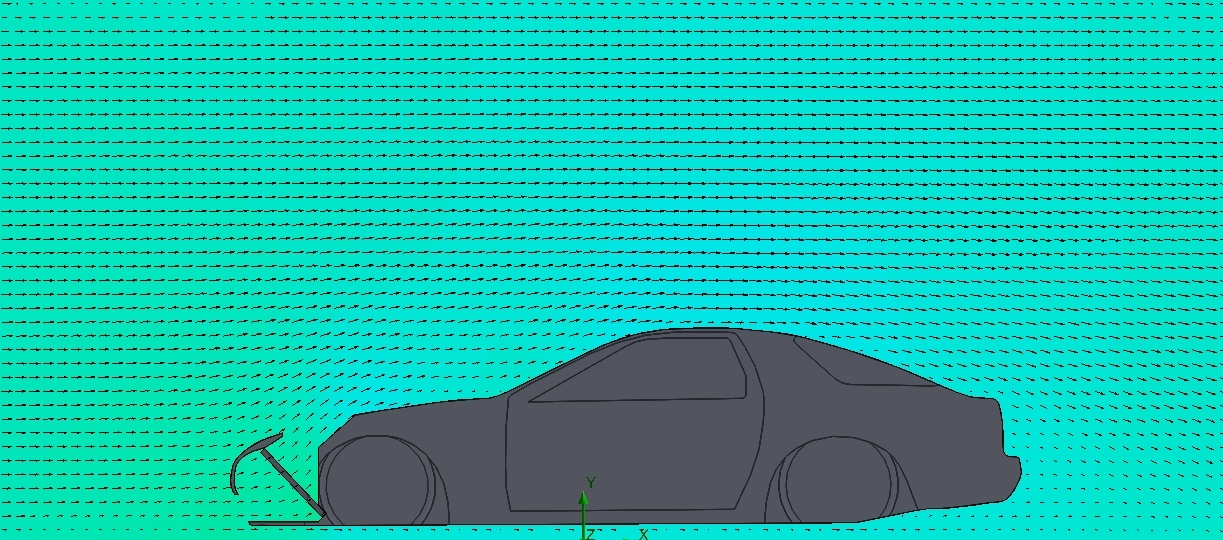

Stock FC

Current situation

With lip

Flow simulation doesn't show a large difference between adding a lip or not, so I'm doubting if I should make one. I'll think about it.

I don't see any problems with transmission temperature. If anything the transmission should see lower temperatures because the temperature underneath the hood is lower. I made 2 openings for cool air to enter the engine bay to supply cool air. If I was the transmission I'd be much more worried about the huge 4-rotor trying to eat me instead of the wimpy piece of aluminium sheet behind it.

Last edited by John Huijben; 06-11-12 at 05:55 PM.

#736

Hmm... that's interesting. I figured you had done some research. From what I saw, most cars that have functional hood vents actually use one. What happens when you take the speed down to something most people would do on the road. For instance, 100 kph?

Also, keep in mind that the air flow won't just stop right there at the engine.

I think you're right about my cutoff wheel. Works great on steel, chews aluminum up like I was cutting it with my teeth.

Also, keep in mind that the air flow won't just stop right there at the engine.

I think you're right about my cutoff wheel. Works great on steel, chews aluminum up like I was cutting it with my teeth.

#741

Wasted spark plug

Man, this looks better every day!

Q: isn't this position of the radiator makes the car light on the nose when putting some kphs on the car?

When you turn the radiator 90 deg. (and the blowers hidden underneath it) it's more in the flow line.

Cuz the blowers don't run that often, they are just an obstruction for the flow now.

But that's just me.

I know it's easy to comment but i don't doubt your skills, that should be clear!

Anyway, I'm just enjoying what you are building mate!

Keep up the good work!

Grtz Dee.

PS note the blue areas become bigger than stock...

Q: isn't this position of the radiator makes the car light on the nose when putting some kphs on the car?

When you turn the radiator 90 deg. (and the blowers hidden underneath it) it's more in the flow line.

Cuz the blowers don't run that often, they are just an obstruction for the flow now.

But that's just me.

I know it's easy to comment but i don't doubt your skills, that should be clear!

Anyway, I'm just enjoying what you are building mate!

Keep up the good work!

Grtz Dee.

PS note the blue areas become bigger than stock...

Last edited by Black and Blue RX; 06-12-12 at 11:57 AM.

#743

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,841

Received 2,605 Likes

on

1,848 Posts

I even did some flow analysis.

I don't see any problems with transmission temperature. If anything the transmission should see lower temperatures because the temperature underneath the hood is lower. I made 2 openings for cool air to enter the engine bay to supply cool air. If I was the transmission I'd be much more worried about the huge 4-rotor trying to eat me instead of the wimpy piece of aluminium sheet behind it.

I don't see any problems with transmission temperature. If anything the transmission should see lower temperatures because the temperature underneath the hood is lower. I made 2 openings for cool air to enter the engine bay to supply cool air. If I was the transmission I'd be much more worried about the huge 4-rotor trying to eat me instead of the wimpy piece of aluminium sheet behind it.

+1 on the trans, my buddy with a 2 rotor PP has gone thru 3 turbo transmissions and a diff... if anything the 4 rotor will be better, less Tq fluctuation and the power band is going to fit the horrid gearing better.

#744

Hmm... that's interesting. I figured you had done some research. From what I saw, most cars that have functional hood vents actually use one. What happens when you take the speed down to something most people would do on the road. For instance, 100 kph?

Also, keep in mind that the air flow won't just stop right there at the engine.

I think you're right about my cutoff wheel. Works great on steel, chews aluminum up like I was cutting it with my teeth.

Also, keep in mind that the air flow won't just stop right there at the engine.

I think you're right about my cutoff wheel. Works great on steel, chews aluminum up like I was cutting it with my teeth.

Pressures acting on the car are much more equal at lower speeds. Flow direction's don't change a whole lot though. Flow velocity obviously does.

100Km/h:

50Km/h:

I know that the airflow doesn't stop, that wouldn't be good at all, but it can't get into the engine bay, the entire path from where the air enters the holes in the front bumper to the exit point in the front hood is almost completely covered with ducting.

Man, this looks better every day!

Q: isn't this position of the radiator makes the car light on the nose when putting some kphs on the car?

When you turn the radiator 90 deg. (and the blowers hidden underneath it) it's more in the flow line.

Cuz the blowers don't run that often, they are just an obstruction for the flow now.

But that's just me.

I know it's easy to comment but i don't doubt your skills, that should be clear!

Anyway, I'm just enjoying what you are building mate!

Keep up the good work!

Grtz Dee.

PS note the blue areas become bigger than stock...

Q: isn't this position of the radiator makes the car light on the nose when putting some kphs on the car?

When you turn the radiator 90 deg. (and the blowers hidden underneath it) it's more in the flow line.

Cuz the blowers don't run that often, they are just an obstruction for the flow now.

But that's just me.

I know it's easy to comment but i don't doubt your skills, that should be clear!

Anyway, I'm just enjoying what you are building mate!

Keep up the good work!

Grtz Dee.

PS note the blue areas become bigger than stock...

you could do the old school way too, racing beat taped yarn to the car and then turned the camera on and went for a run, it would be fun to do that.

+1 on the trans, my buddy with a 2 rotor PP has gone thru 3 turbo transmissions and a diff... if anything the 4 rotor will be better, less Tq fluctuation and the power band is going to fit the horrid gearing better.

+1 on the trans, my buddy with a 2 rotor PP has gone thru 3 turbo transmissions and a diff... if anything the 4 rotor will be better, less Tq fluctuation and the power band is going to fit the horrid gearing better.

If I get this engine running the way it should run it will probably eat a transmission or two. I think I'll probably try to figure out a decent transmission for the car when it's up and running. Pneumatically operated close ratio straight cut sequential gearbox would go nice with this engine

But that's an entirely different project on it's own.

But that's an entirely different project on it's own. By the way, quick question for everyone that's reading, I'm figuring out how to do the fuel system on the car, at the moment I'm doubting between a stock fuel tank with a swirl pot in the engine bay (got lot's of room left for one), or a fuel cell in the trunk, any thoughts?

#745

Rotary Enthusiast

iTrader: (2)

Join Date: May 2005

Location: E-L Netherlands

Posts: 1,165

Likes: 0

Received 0 Likes

on

0 Posts

Stock tank, you need as much fuel capacity as possible

Especially since its a streetcar.

Colleage of mine built a fiat 600 with gsx-r engine and could not fit anything bigger then a 15liter tank. Driving fun is over real quick..

Especially since its a streetcar.

Colleage of mine built a fiat 600 with gsx-r engine and could not fit anything bigger then a 15liter tank. Driving fun is over real quick..

#746

Gold Wheels FTW

That would be fun!

If I get this engine running the way it should run it will probably eat a transmission or two. I think I'll probably try to figure out a decent transmission for the car when it's up and running. Pneumatically operated close ratio straight cut sequential gearbox would go nice with this engine But that's an entirely different project on it's own.

But that's an entirely different project on it's own.

If I get this engine running the way it should run it will probably eat a transmission or two. I think I'll probably try to figure out a decent transmission for the car when it's up and running. Pneumatically operated close ratio straight cut sequential gearbox would go nice with this engine

But that's an entirely different project on it's own.

But that's an entirely different project on it's own.

#747

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,841

Received 2,605 Likes

on

1,848 Posts

By the way, quick question for everyone that's reading, I'm figuring out how to do the fuel system on the car, at the moment I'm doubting between a stock fuel tank with a swirl pot in the engine bay (got lot's of room left for one), or a fuel cell in the trunk, any thoughts?