4-Rotor FC Build

#653

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,825

Received 2,591 Likes

on

1,840 Posts

lmao, that does look kind of stock! awesome

#659

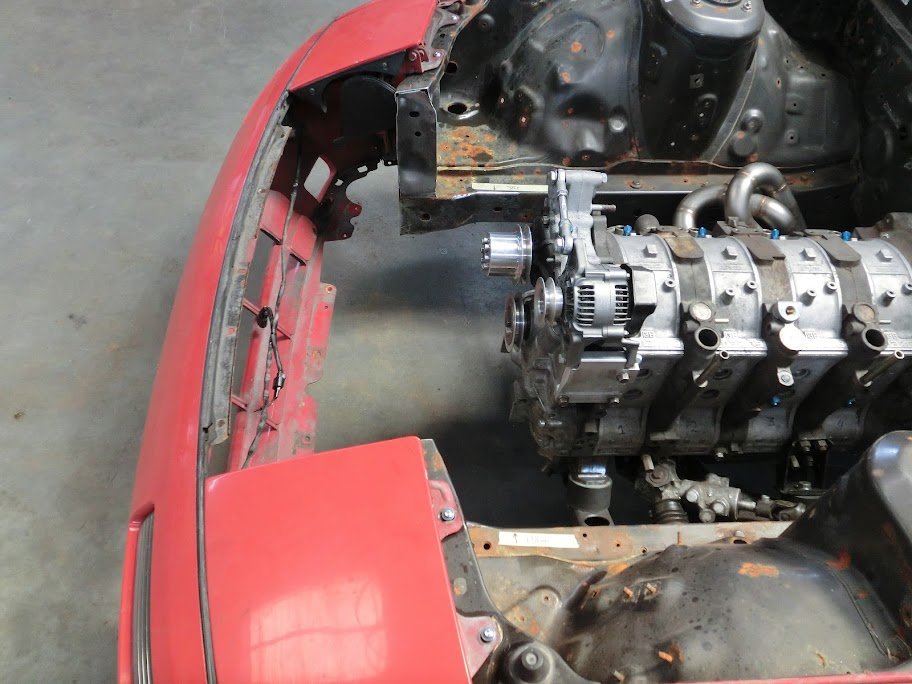

Tried figuring out how to fit the radiator and oil coolers. Couldn't find a way to fit everything nicely so I did this:

Holy crap, what have I done

Fitting the front panels and bumper to check if everything still fits ok, also took a lot of measurements so I could check if the front end of the car warped, it's still straight and everything still fits nicely, lot's of room now to do whatever I want

Cleaned some stuff up and made bumper mounts.

Next up is the radiator, already made all the needed parts, hopefully I can try to weld it together tomorrow. I hope it works out allright, since I don't have a lot of experience with welding aluminium.

Holy crap, what have I done

Fitting the front panels and bumper to check if everything still fits ok, also took a lot of measurements so I could check if the front end of the car warped, it's still straight and everything still fits nicely, lot's of room now to do whatever I want

Cleaned some stuff up and made bumper mounts.

Next up is the radiator, already made all the needed parts, hopefully I can try to weld it together tomorrow. I hope it works out allright, since I don't have a lot of experience with welding aluminium.

#666

been checking this build just about every day for the past three months, i cant wait till this car is done. truely an amazing build. definately my ultimate rotary dream build

#667

Thanks

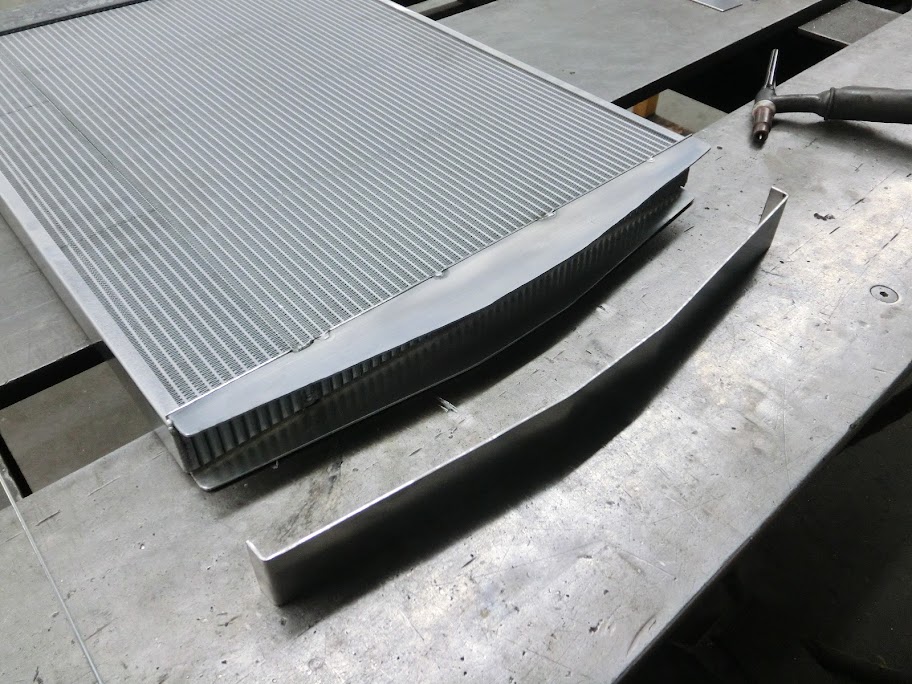

Started assembling the radiator today.

I've only welded aluminium a handfull of times, and usually didn't do a great job at it, so I started with cutting out some testpieces and tried figuring out how to weld aluminium for a few hours. Didn't want to start on the radiator straight away, since an aluminium radiator core isn't cheap. Once I sortoff thought I knew what I was doing work on the radiator started.

Tacking up an endtank here

And the other one

Almost done

So I didn't get it completely done yet, still need to do the last endtank, clean stuff up a bit and pressure test it. So far it's going pretty well I think, welds look pretty decent , I've seen tidier ones but this will do just fine.

, I've seen tidier ones but this will do just fine.

Started assembling the radiator today.

I've only welded aluminium a handfull of times, and usually didn't do a great job at it, so I started with cutting out some testpieces and tried figuring out how to weld aluminium for a few hours. Didn't want to start on the radiator straight away, since an aluminium radiator core isn't cheap. Once I sortoff thought I knew what I was doing work on the radiator started.

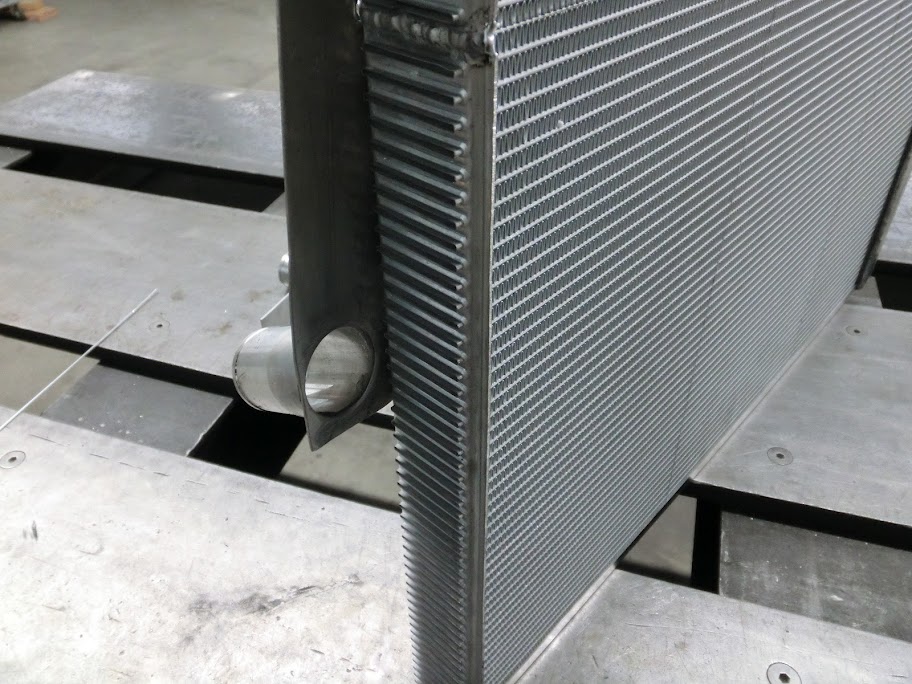

Tacking up an endtank here

And the other one

Almost done

So I didn't get it completely done yet, still need to do the last endtank, clean stuff up a bit and pressure test it. So far it's going pretty well I think, welds look pretty decent

, I've seen tidier ones but this will do just fine.

, I've seen tidier ones but this will do just fine.

#669

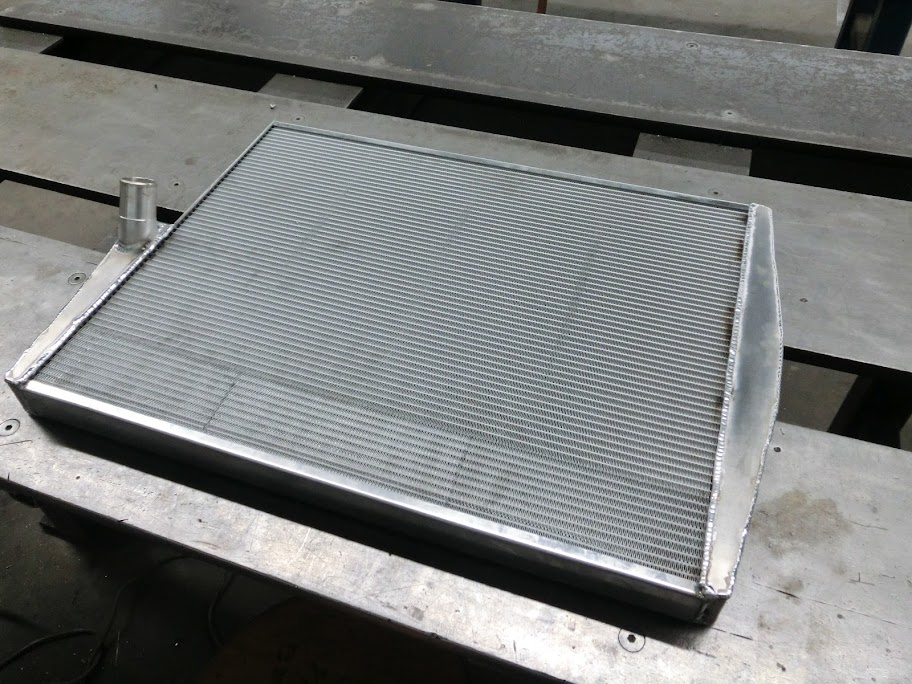

Finished the radiator today

Also added a drainage plug

Tested the radiator for leaks, pressurised it with compressed air and used soapy water to find them.

People at home be carefull pressurising radiators like this, they can blow up if you put a lot of pressure on them. I used about 16 psi.

It was a good thing I checked for leaks, I found a few. Got them all fixed pretty easily though.

Also added a drainage plug

Tested the radiator for leaks, pressurised it with compressed air and used soapy water to find them.

People at home be carefull pressurising radiators like this, they can blow up if you put a lot of pressure on them. I used about 16 psi.

It was a good thing I checked for leaks, I found a few. Got them all fixed pretty easily though.

#671

It's better to pressure-test with some fluid inside. Only air could be a good explosion because air compresses more. If you have some water in i, and the fail is there, there will only be a little poof.

16Psi isn't much? You will have 14-15psi all the time later on?

16Psi isn't much? You will have 14-15psi all the time later on?

#675

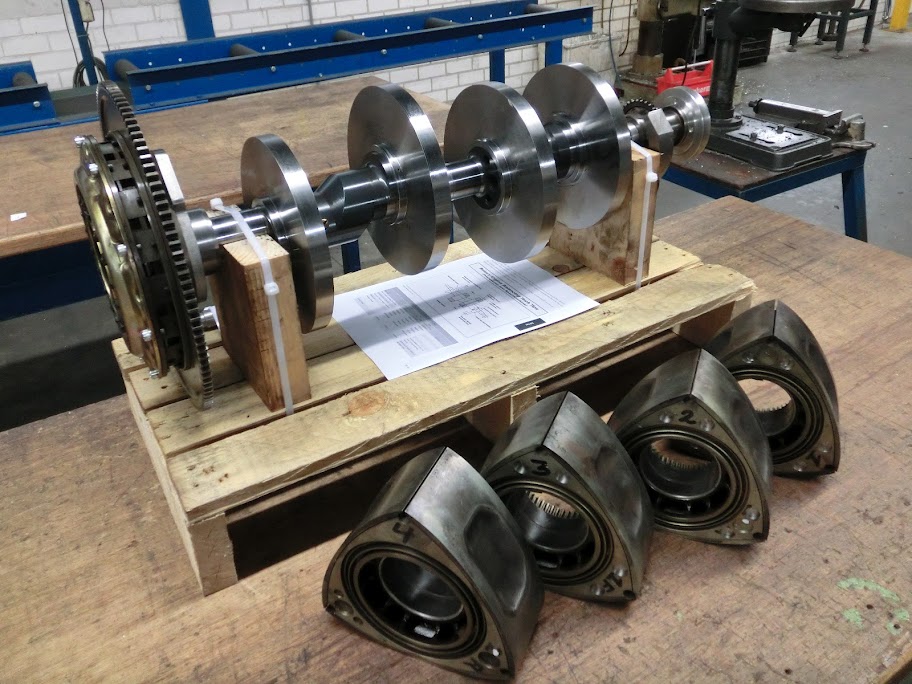

The rotors came back from balancing.  At first they balanced the jig I made up to mount the rotors in the balancing machine. After that every rotor was checked, they were all pretty good, the worst one was 2,5 grams off, 50 grams being the tolerance limit. We could balance every rotor to perfection, but then the weight between the rotors wouldn't be equal anymore, and since we were so far within the tolerance limit we didn't modify the rotors. It would be possible to get them balanced and get the weight equal by machining the rotors with good balance on all three sides, but that would take a lot of expensive manhours for no noticable gains.

At first they balanced the jig I made up to mount the rotors in the balancing machine. After that every rotor was checked, they were all pretty good, the worst one was 2,5 grams off, 50 grams being the tolerance limit. We could balance every rotor to perfection, but then the weight between the rotors wouldn't be equal anymore, and since we were so far within the tolerance limit we didn't modify the rotors. It would be possible to get them balanced and get the weight equal by machining the rotors with good balance on all three sides, but that would take a lot of expensive manhours for no noticable gains.

Next up is balancing the entire rotating assembly, I re-checked the weight of each rotor and every dummy weight and assembled the rotating assembly for balancing.

At first they balanced the jig I made up to mount the rotors in the balancing machine. After that every rotor was checked, they were all pretty good, the worst one was 2,5 grams off, 50 grams being the tolerance limit. We could balance every rotor to perfection, but then the weight between the rotors wouldn't be equal anymore, and since we were so far within the tolerance limit we didn't modify the rotors. It would be possible to get them balanced and get the weight equal by machining the rotors with good balance on all three sides, but that would take a lot of expensive manhours for no noticable gains.

At first they balanced the jig I made up to mount the rotors in the balancing machine. After that every rotor was checked, they were all pretty good, the worst one was 2,5 grams off, 50 grams being the tolerance limit. We could balance every rotor to perfection, but then the weight between the rotors wouldn't be equal anymore, and since we were so far within the tolerance limit we didn't modify the rotors. It would be possible to get them balanced and get the weight equal by machining the rotors with good balance on all three sides, but that would take a lot of expensive manhours for no noticable gains.Next up is balancing the entire rotating assembly, I re-checked the weight of each rotor and every dummy weight and assembled the rotating assembly for balancing.

Last edited by John Huijben; 05-24-12 at 05:24 PM.