Tegheim - Home made 4 Rotor Wolvo project

#486

You have ***** of steel, or whatever material you're machining those rotors out of.

Speaking of *****, now I have a question about your shaft (get your mind out of the gutter). Which oil squirters will you install in the shaft? Or will you install a set of weber jets like the racers do? I ask because 12A use a small ball and 13B use a big ball that's large enough to take up lots of room inside the machined holes in the shaft. Just curious, and it's nothing sexual. Thanks.

By the way, this link takes you to the the "Eccentric Shaft Oil Jet" I was talking about. http://www.mazdatrix.com/boil3.htm

Speaking of *****, now I have a question about your shaft (get your mind out of the gutter). Which oil squirters will you install in the shaft? Or will you install a set of weber jets like the racers do? I ask because 12A use a small ball and 13B use a big ball that's large enough to take up lots of room inside the machined holes in the shaft. Just curious, and it's nothing sexual. Thanks.

By the way, this link takes you to the the "Eccentric Shaft Oil Jet" I was talking about. http://www.mazdatrix.com/boil3.htm

#487

Doing the Ricky Bobby

iTrader: (1)

Join Date: Jan 2008

Location: Dallas, Texas

Posts: 137

Likes: 0

Received 0 Likes

on

0 Posts

You should sell some of the parts that you make like the aluminum irons.(that just doesn't sound right) I'd be interested in them on my next build and I'm sure there would be alot of people that would pony up for the materpeices you are building...

#489

Senior Member

Thread Starter

*****, Shaft, and Squiters?! WTF?!

I will use a plain hole in a threaded screw so I can change insert.

If you look at some of my pics on the E-shaft, you see the thread behind the excentric part. Same as stock, but in my own way

The "irons" are iron. They had a start-weight at 22kg a piece

I will use a plain hole in a threaded screw so I can change insert.

If you look at some of my pics on the E-shaft, you see the thread behind the excentric part. Same as stock, but in my own way

The "irons" are iron. They had a start-weight at 22kg a piece

#491

Senior Member

Thread Starter

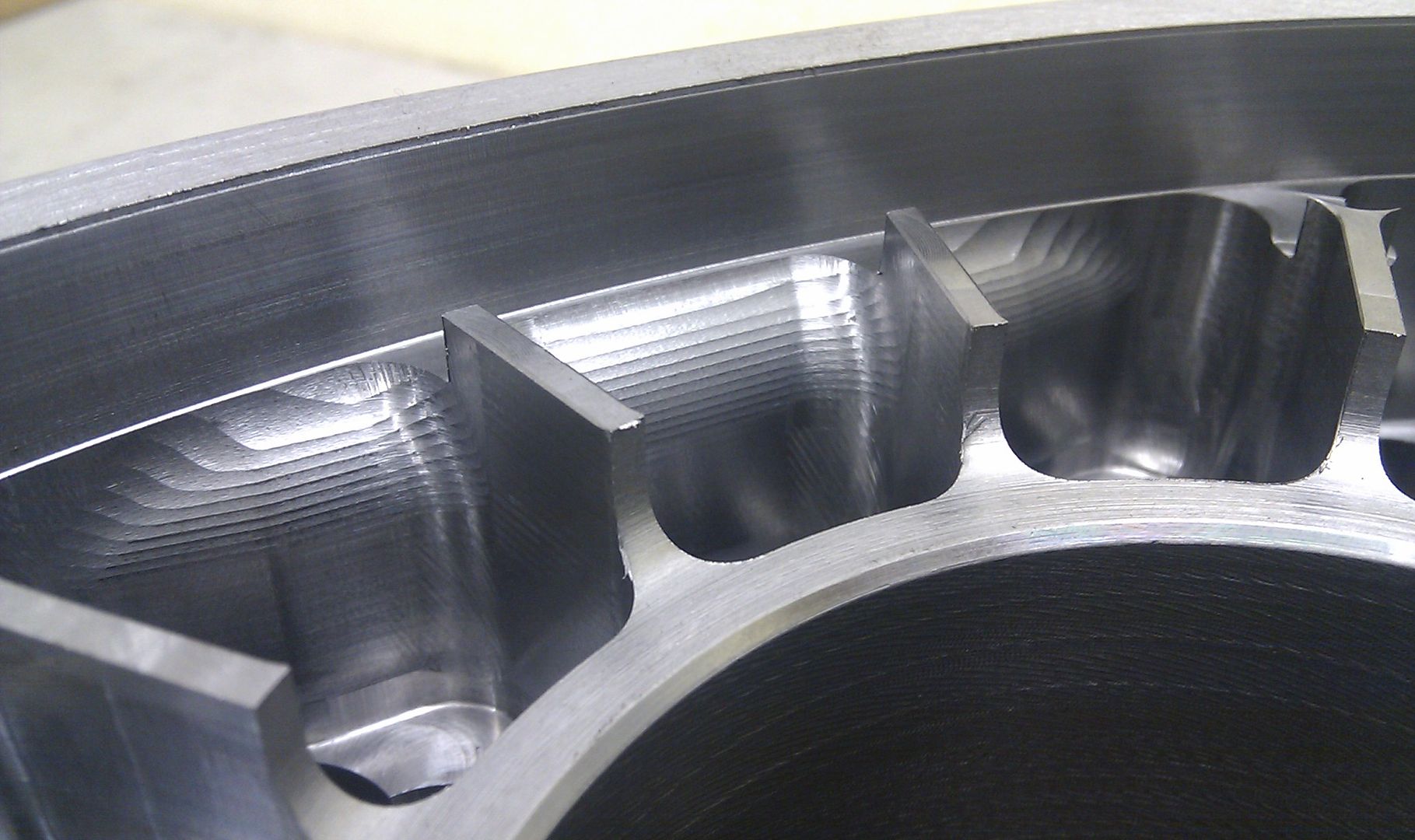

Now I've cleaned up after me and takes weekend.

This took a lot longer than I guessed. Then it's always so well with the first, but had probably hoped for smoother processing

Has anyway tried to run a finishing the outline today. Is not quite satisfied, however, it does not matter for the function. Has left 0.5mm for further testing

To be continued in the Christmas Holidays!

This took a lot longer than I guessed. Then it's always so well with the first, but had probably hoped for smoother processing

Has anyway tried to run a finishing the outline today. Is not quite satisfied, however, it does not matter for the function. Has left 0.5mm for further testing

To be continued in the Christmas Holidays!

#494

What sort of cutter did you use for the outer contour and the compression bowls?

I wouldn't mind the rough surface too much if there aren't any sharp points. sharp points start to glow and are a detonation source.

By the way, did you melt a cutter milling out the rotor, looks like you did in the lower left corner. Not that it matters, I'm just curious if I saw it right.

I wouldn't mind the rough surface too much if there aren't any sharp points. sharp points start to glow and are a detonation source.

By the way, did you melt a cutter milling out the rotor, looks like you did in the lower left corner. Not that it matters, I'm just curious if I saw it right.

#497

#498

i don't really see any location for a seal for the side plates though so you got me.

#499

Gold Wheels FTW

would be more like oil right out the tailpipe. should have some sort of seal, there will be some pressure trying to push the oil out of the side plates and into the chambers otherwise. something like a viton seal should do the job just fine unless the oil temps start to go beyond 400F somehow.

i don't really see any location for a seal for the side plates though so you got me.

i don't really see any location for a seal for the side plates though so you got me.

#500

Senior Member

Thread Starter

The seal will be there. But thats the only part I will not show. A man gonna have some secrets

But, its pretty simple actually. And if I show the world the solution, maybe we will see someone else selling mine and Gus3fd's rotor-design. That would be sad

But, its pretty simple actually. And if I show the world the solution, maybe we will see someone else selling mine and Gus3fd's rotor-design. That would be sad