My Budget Peripheral Port/80mm Turbo/60mm ITB/Intake Manifold/Fuel System Build

#151

#152

Hot Dicken's Cider

Thread Starter

iTrader: (2)

Join Date: May 2003

Location: Marion, Ohio

Posts: 1,428

Likes: 0

Received 0 Likes

on

0 Posts

^Yep, already have a new pivot turned down. I made it from O-1 tool steel, I haven't yet had a chance to harden it though; I will post a pic after it is done.

#153

Bus, sorry I couldn't make it this weekend, or any other weekends. I owe you something for keeping on breaking our plans. I also may not get to go to the lake this weekend. I won't know until later this week. I will call you.

Keep up the great work, btw, you missed an awesome 18 holes on saturday!

Jackson

Keep up the great work, btw, you missed an awesome 18 holes on saturday!

Jackson

#154

#156

Oooo- are you just going to hardface the ball tip or differentially heat treat the ball to leave the tapered area flexible enough to absorb the stresses?

It seems like the typical pivot failures are from the stock mazda piece being too hard (brittle), not from wearing out.

Or a new pivot design?

Can you tell I am too cheap for a twin disc :P When I tried a 2nd gear launch the clutch just slips till the rpms drop out of the powerband and I have the sprung 6 puck and 2nd heaviest ACT PP.

It seems like the typical pivot failures are from the stock mazda piece being too hard (brittle), not from wearing out.

Or a new pivot design?

Can you tell I am too cheap for a twin disc :P When I tried a 2nd gear launch the clutch just slips till the rpms drop out of the powerband and I have the sprung 6 puck and 2nd heaviest ACT PP.

#157

Hot Dicken's Cider

Thread Starter

iTrader: (2)

Join Date: May 2003

Location: Marion, Ohio

Posts: 1,428

Likes: 0

Received 0 Likes

on

0 Posts

Got a few things done, finals week is coming up and every prof thinks their class is all-important and the only thing you have going on.

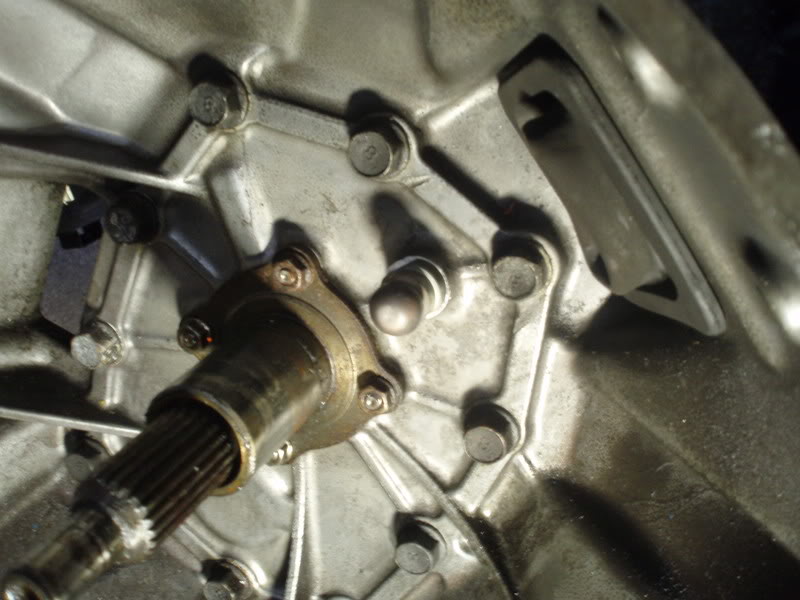

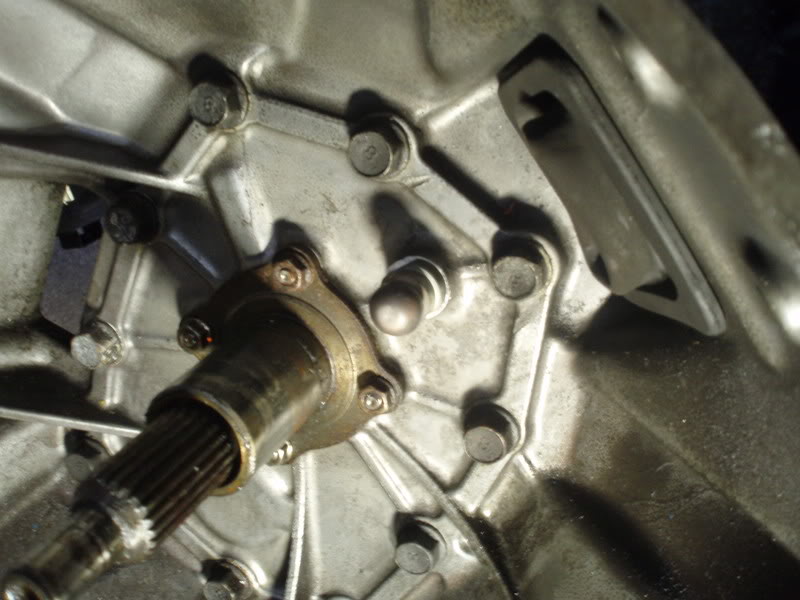

Here is the new pivot. It does not taper down nearly as much as the stock, I think it should hold up quite well.

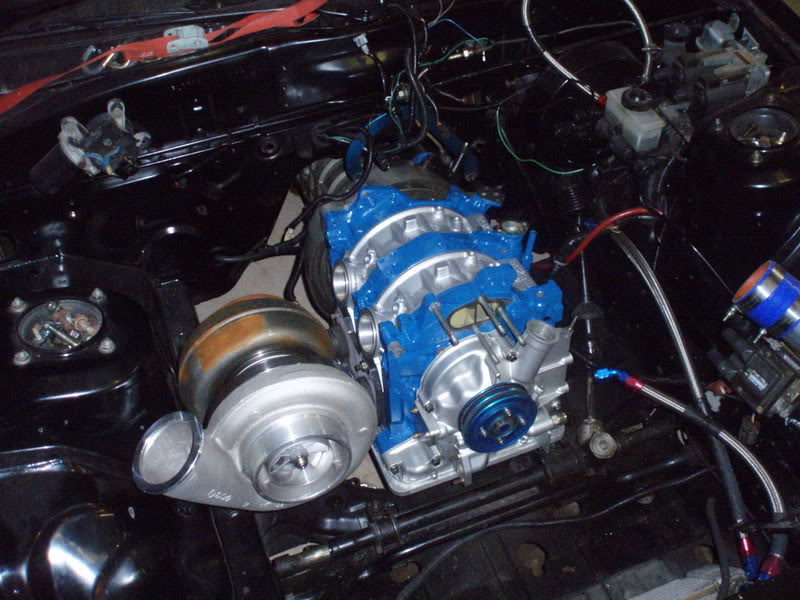

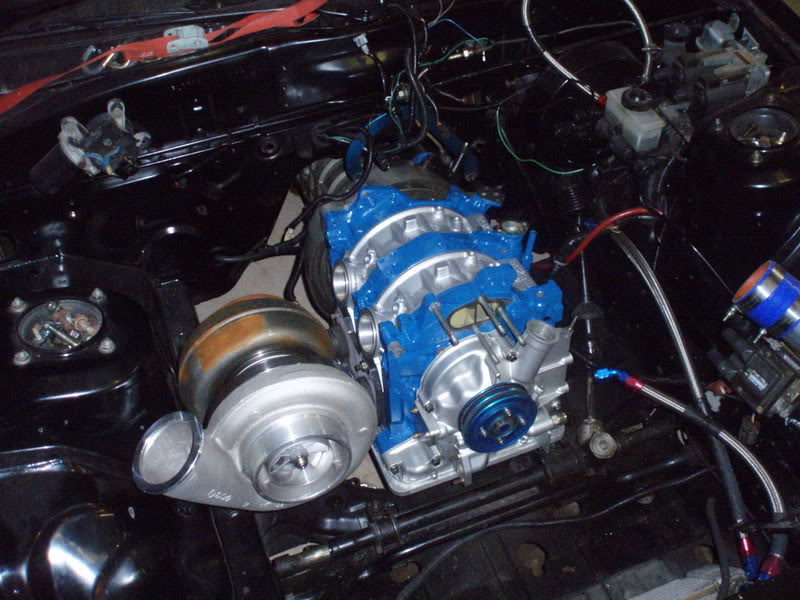

Motor is all together finally.

In the car. Had to notch the steering rack mount a little bit (Damn heat expansion! )

)

With the turbo.

Here is the new pivot. It does not taper down nearly as much as the stock, I think it should hold up quite well.

Motor is all together finally.

In the car. Had to notch the steering rack mount a little bit (Damn heat expansion!

)

)

With the turbo.

#160

FC Mobsta

#163

Sweet, sweet, sweet!

If you ever need to make a little quick money you could fab up some clutch fork and pivot kits for everybody w/ a burly left leg and a thin wallet

I bet you could put a big mark up on it since it will still end up way cheaper than a twin disk set up.

If you ever need to make a little quick money you could fab up some clutch fork and pivot kits for everybody w/ a burly left leg and a thin wallet

I bet you could put a big mark up on it since it will still end up way cheaper than a twin disk set up.

#165

adiabaticly inefficient

Join Date: Aug 2001

Location: nw houston,TX or w. hollywood,CA

Posts: 386

Likes: 0

Received 0 Likes

on

0 Posts

looks like the intake manifold is gonna have a pretty sharp angle right before the vbands on the rotor housings,due to the turbine housing placement. but then again im sure you have it all under control! this is the best fab i have ever seen on a fc!

#167

Rotary Apprentice

Join Date: Jan 2005

Location: USA

Posts: 2,181

Likes: 0

Received 0 Likes

on

0 Posts

#168

I guess he got his hands on one of those replicator things that they have on board the Starship Enterprise!

#169

Rotary Enthusiast

Ignorance is fearless.......

I am a mechanical engineer and all I do is come up with ways to make NC Programs/Processes for medical devices so that when the machinist pushes start the machine does what it should......all I can say is that they don't do anything themselves and that is certainly isn't just "pushing a button" on the machinist's side either....... It takes a very special brain to program, setup and operate CNC machinery, not to mention to such an extensive degree as this and Delslow has got it down incredibly well.

NOPR, I recommend you do a search online and find out why people in the manufacturing industry get paid so well and exactly why companies would be doing so if all there was is simply to "push start".

Delslow, keep up the good work, you have not ceased to impress me.....makes me want to do something like this myself.

Chris

#174

hmmmmmmm!

Ignorance is fearless.......

I am a mechanical engineer and all I do is come up with ways to make NC Programs/Processes for medical devices so that when the machinist pushes start the machine does what it should......all I can say is that they don't do anything themselves and that is certainly isn't just "pushing a button" on the machinist's side either....... It takes a very special brain to program, setup and operate CNC machinery, not to mention to such an extensive degree as this and Delslow has got it down incredibly well.

NOPR, I recommend you do a search online and find out why people in the manufacturing industry get paid so well and exactly why companies would be doing so if all there was is simply to "push start".

Delslow, keep up the good work, you have not ceased to impress me.....makes me want to do something like this myself.

Chris

Ignorance is fearless.......

I am a mechanical engineer and all I do is come up with ways to make NC Programs/Processes for medical devices so that when the machinist pushes start the machine does what it should......all I can say is that they don't do anything themselves and that is certainly isn't just "pushing a button" on the machinist's side either....... It takes a very special brain to program, setup and operate CNC machinery, not to mention to such an extensive degree as this and Delslow has got it down incredibly well.

NOPR, I recommend you do a search online and find out why people in the manufacturing industry get paid so well and exactly why companies would be doing so if all there was is simply to "push start".

Delslow, keep up the good work, you have not ceased to impress me.....makes me want to do something like this myself.

Chris

Bus, call me. Plan is to go to Norwalk on friday(which i doubt you can make do to work) and Saturday I plan on playing 18 holes pending weather. After Golf, I can help you finish up the car.

Jackson

#175

Rotary Enthusiast

Reading sarcasm owns many people on forums, and you sir are indeed one of these said people. LOL. NOPR is a sarcastic SOB. He is well informed of the processes to transform a block of meteal into what DelSlow has made, as both DelSlow and NOPR are M.E. They are also extremely good friends, which is part of the reason NOPR was ribbing DelSlow.

Bus, call me. Plan is to go to Norwalk on friday(which i doubt you can make do to work) and Saturday I plan on playing 18 holes pending weather. After Golf, I can help you finish up the car.

Jackson

Bus, call me. Plan is to go to Norwalk on friday(which i doubt you can make do to work) and Saturday I plan on playing 18 holes pending weather. After Golf, I can help you finish up the car.

Jackson

I've run into so many people on forums that assume stuff and de-preciate other's work that I thought this was one of those instances.

My sincere apologies to NOPR.

DelSlow...Still impressed

Chris