I Bit Off More Than I Can Chew: A Drift Car

#151

Senior Member

Thread Starter

Kinda small update, been busy doing the garage instead of the car so I can have more time to work on the car (ironic no?) but now like 6 weeks later finally getting somewhere.

Was getting pretty frustrated with my old situation. Seemed like every time I went I spent more time setting up and cleaning up than making progress, more and more water on the car as the roof started leaking a little and the tarp just didnít get every drop. Then distractions (love the fam and all but need time for both that is not at the same time), also my stupid truck breaking on the reg (a different story for later), etc etc. First world problems fully and donít mistake my frustrations for ungratefulness to my parents for the use of their property. But it was time to grow up and get my own space on my own dime.

Didnít take before and after pics, cuz it was that bad. Like 4-5 dump runs and a few scrap metals runs, couple hundred dropped at home depot, and many hours of hard physical labour we had something to work with. Also learned I kinda suck at things when I donít plan it out beforehand. Weíll just not talk about the first tire rack though lol.

Very much grateful to my new garage mate Kris and his mom for their hospitality and this opportunity. Space feels very much like my own and feels very permanent. Youíll be seeing more of his skyline in future updates when its moreÖ straight.

Built a shelf and tire rack.

Put some stuff on it.

Since then I re did the tire rack as we came up with a better design mostly measurements wise. That one was a little big and with wood we had kicking around.

And then on what turned out to be a magical monday after work (and a late one), brought the car to its new home.

This is one of those times where Iím grateful for the people in my life, namely Kris. We swapped the t case in my truck, then loaded the car and the last of the parts and dragged the thing 35 minutes away. Finished all but 10 minutes before it started to rain, then took the trailer all the way back to my dads, got home somewhere near midnight. On a monday. We both start before 7:00 am.

Theres still some stuff that weíre planning on having leave such as the big block and brake lathe etc. But I have decent space to open the doors and work around the entire car. Itís around the size of a 1 car garage, which is all I could ask for. Especially since I can leave it in pieces if I want

Spent the next while getting more and more setup, bringing stuff over, organizing. Bought some LED strips to try using as the primary light source as the current fluorescent tubes were pretty weak. Weeeeellllll its kinda worse. More evenly lit on my side but not gonna cut it. The bench light was a neat touch even though its terrible as working light. But i had it laying around so why not.

Before I took it there though I did do some final playing around.

Was getting pretty frustrated with my old situation. Seemed like every time I went I spent more time setting up and cleaning up than making progress, more and more water on the car as the roof started leaking a little and the tarp just didnít get every drop. Then distractions (love the fam and all but need time for both that is not at the same time), also my stupid truck breaking on the reg (a different story for later), etc etc. First world problems fully and donít mistake my frustrations for ungratefulness to my parents for the use of their property. But it was time to grow up and get my own space on my own dime.

Didnít take before and after pics, cuz it was that bad. Like 4-5 dump runs and a few scrap metals runs, couple hundred dropped at home depot, and many hours of hard physical labour we had something to work with. Also learned I kinda suck at things when I donít plan it out beforehand. Weíll just not talk about the first tire rack though lol.

Very much grateful to my new garage mate Kris and his mom for their hospitality and this opportunity. Space feels very much like my own and feels very permanent. Youíll be seeing more of his skyline in future updates when its moreÖ straight.

Built a shelf and tire rack.

Put some stuff on it.

Since then I re did the tire rack as we came up with a better design mostly measurements wise. That one was a little big and with wood we had kicking around.

And then on what turned out to be a magical monday after work (and a late one), brought the car to its new home.

This is one of those times where Iím grateful for the people in my life, namely Kris. We swapped the t case in my truck, then loaded the car and the last of the parts and dragged the thing 35 minutes away. Finished all but 10 minutes before it started to rain, then took the trailer all the way back to my dads, got home somewhere near midnight. On a monday. We both start before 7:00 am.

Theres still some stuff that weíre planning on having leave such as the big block and brake lathe etc. But I have decent space to open the doors and work around the entire car. Itís around the size of a 1 car garage, which is all I could ask for. Especially since I can leave it in pieces if I want

Spent the next while getting more and more setup, bringing stuff over, organizing. Bought some LED strips to try using as the primary light source as the current fluorescent tubes were pretty weak. Weeeeellllll its kinda worse. More evenly lit on my side but not gonna cut it. The bench light was a neat touch even though its terrible as working light. But i had it laying around so why not.

Before I took it there though I did do some final playing around.

Last edited by teeson; 03-25-18 at 02:15 AM.

#152

Senior Member

Thread Starter

Put everything in place and plugged in just to see if my wiring was going as planned. One or two small surprises but nothing that worries me. Also trimmed the vents out to fit the gauges like I had planned so long ago.

One challenge I was expecting but am not prepared for is how to deal with this. has to go here

This is kinda the main point of having the full interior, for the window defog. But I put a roll bar in the way. Really want it to line up with the factory vent assembly so it looks clean and un altered.

Any ideas that doesn’t involve fibreglassing a new shape and is still removable hit me up.

Moving forward and downward tho

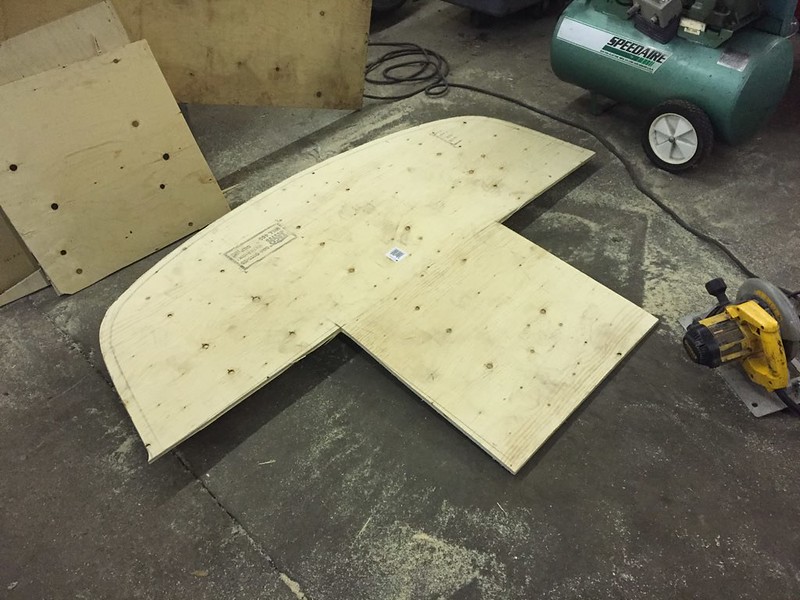

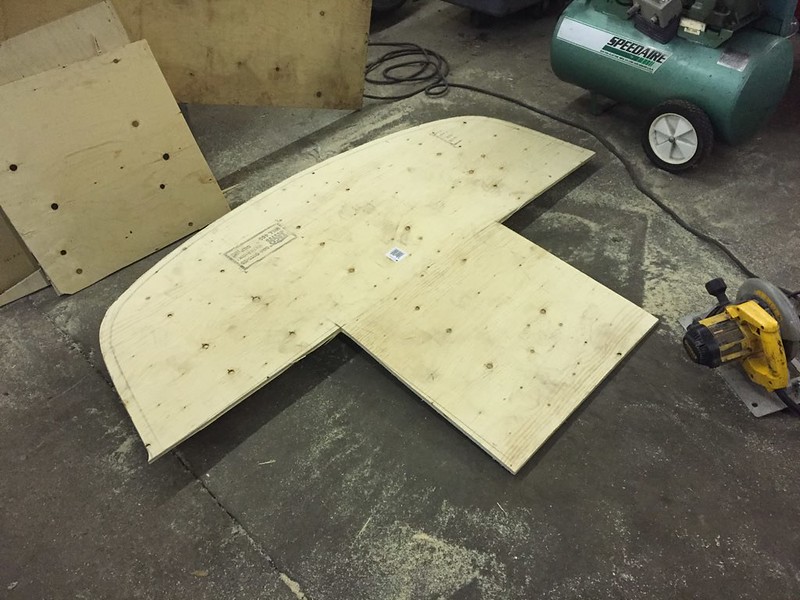

amongst all those Home Depot trips I bought a sheet of 1/2 ply for a wood splitter.

Traced the bumper out then added an inch all around the outside. Thought about tapering it in where it meets the tire but nawww, like this better.

Can see my links chilling on the floor

Going to make a set or two for my buddies and see how they go. Kinda need 6 mount points to really make this stable though, it gets tricky from chassis to chassis but we’ll see what we come up with.

Still dreaming up the best way to make this part quick release but for now 2 long M6 bolts to where the old under tray used to mount to works.

One challenge I was expecting but am not prepared for is how to deal with this. has to go here

This is kinda the main point of having the full interior, for the window defog. But I put a roll bar in the way. Really want it to line up with the factory vent assembly so it looks clean and un altered.

Any ideas that doesn’t involve fibreglassing a new shape and is still removable hit me up.

Moving forward and downward tho

amongst all those Home Depot trips I bought a sheet of 1/2 ply for a wood splitter.

Traced the bumper out then added an inch all around the outside. Thought about tapering it in where it meets the tire but nawww, like this better.

Can see my links chilling on the floor

Going to make a set or two for my buddies and see how they go. Kinda need 6 mount points to really make this stable though, it gets tricky from chassis to chassis but we’ll see what we come up with.

Still dreaming up the best way to make this part quick release but for now 2 long M6 bolts to where the old under tray used to mount to works.

#153

Senior Member

Thread Starter

It does have some give to flex around any obstacles it encounters so just to be safe I gave the tire more than enough room

While I can reach the pins with the bumper on, I really donít see myself removing one without the other.

Hereís hoping that it keeps my bumper from exploding, as Nate from villains tells me it does for them. Also have to acknowledge Kam Cadwells design on these. His are better though haha

Finally got around to this. Love the ability to just knock out a 20 minute job when I have only 20 minutes. Garage is 5 minutes from home and on the way from work.

Any hope I had of reselling this Steeda Tri-Ax is gone lol. Took the last little bit I didnít need off the top and took pics of the shifter.

Until I determine what **** height and throw length I like the ugly bits stay ugly. Though the centre bit really needs some horizontal pieces to stabilize itÖ

It feels really good though, much better than the dog leg shifter thing abomination I had before.

Then I spent/blew my tax return

18x9.5 +12 (i thinkÖ.. either 12 or 15) Enkei RPF1 in SBC

While I can reach the pins with the bumper on, I really donít see myself removing one without the other.

Hereís hoping that it keeps my bumper from exploding, as Nate from villains tells me it does for them. Also have to acknowledge Kam Cadwells design on these. His are better though haha

Finally got around to this. Love the ability to just knock out a 20 minute job when I have only 20 minutes. Garage is 5 minutes from home and on the way from work.

Any hope I had of reselling this Steeda Tri-Ax is gone lol. Took the last little bit I didnít need off the top and took pics of the shifter.

Until I determine what **** height and throw length I like the ugly bits stay ugly. Though the centre bit really needs some horizontal pieces to stabilize itÖ

It feels really good though, much better than the dog leg shifter thing abomination I had before.

Then I spent/blew my tax return

18x9.5 +12 (i thinkÖ.. either 12 or 15) Enkei RPF1 in SBC

#154

Senior Member

Thread Starter

Surprisingly aggressive in the front.

But with a small spacer pretty ideal in the rear.

Pretty stoked on having another set of 18” wheels, the SBC is cool and when a pair is scratched and chipped enough I’ll paint them white to match. I kinda want to buy one more pair of wheels but at the moment I have enough 18” alone (planning to run 18/18) for a healthy track day.

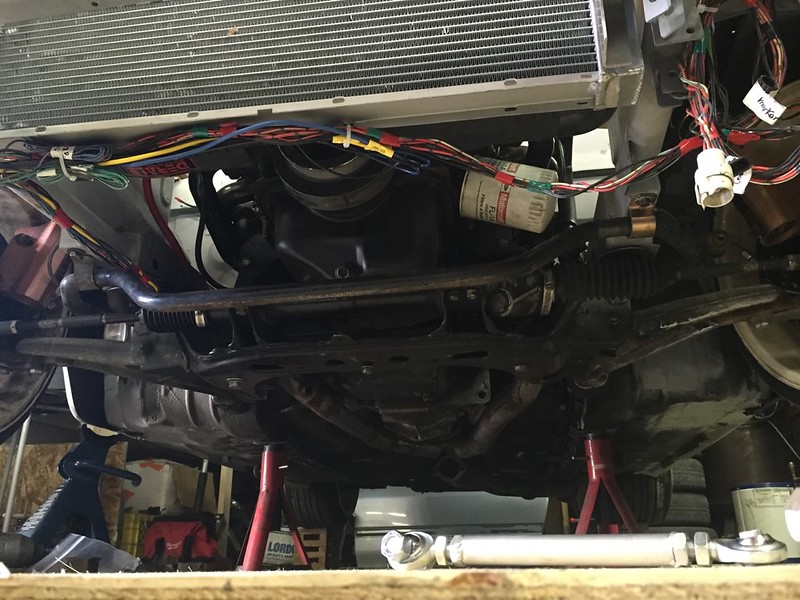

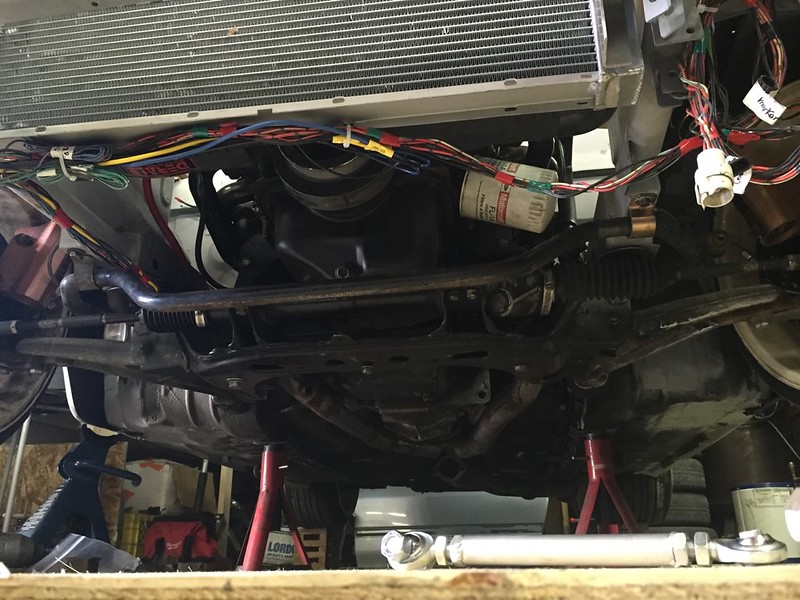

Also made a relevant discovery to any FC owners with a swapped car. Well at least to me, I feel like this is old news to may ppl on the inter web but I have spent hours searching for a solution for the sway bar hitting the oil pan. Closest thing I found was a rumour that a specific e36 bar fit (never found out which though) and that a Mercedes ML suv rear bar fit.

But an S13 bar fits

top to bottom we have an R32 rear bar, what we think is an s14 front bar, then an s13 front and the stock FC. They both weigh a ton so I think they are both solid and they happen to be the same diameter. Kris had a bunch laying around so I tried them all lol.

room for oil pan clearance, still clears the diffuser too. Has a decent amount of wheel clearance but I feel this could be improved. It will still hit at max lock.

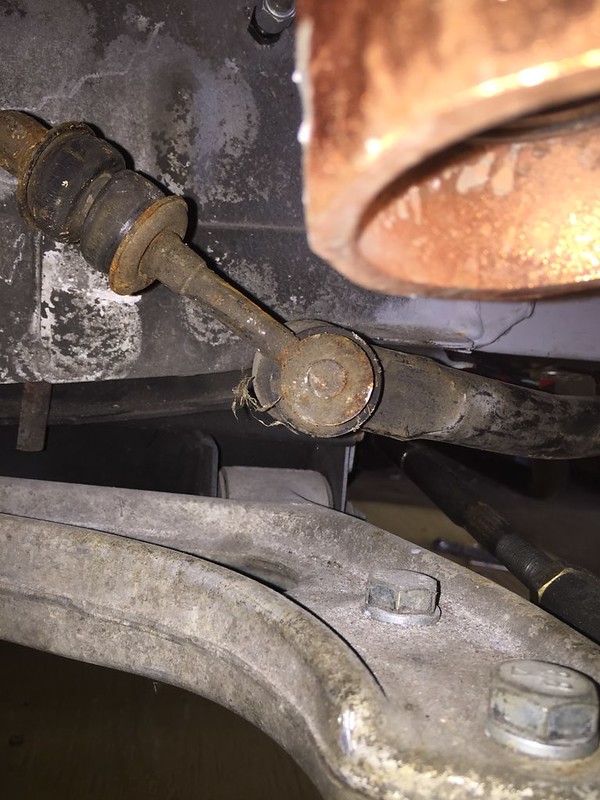

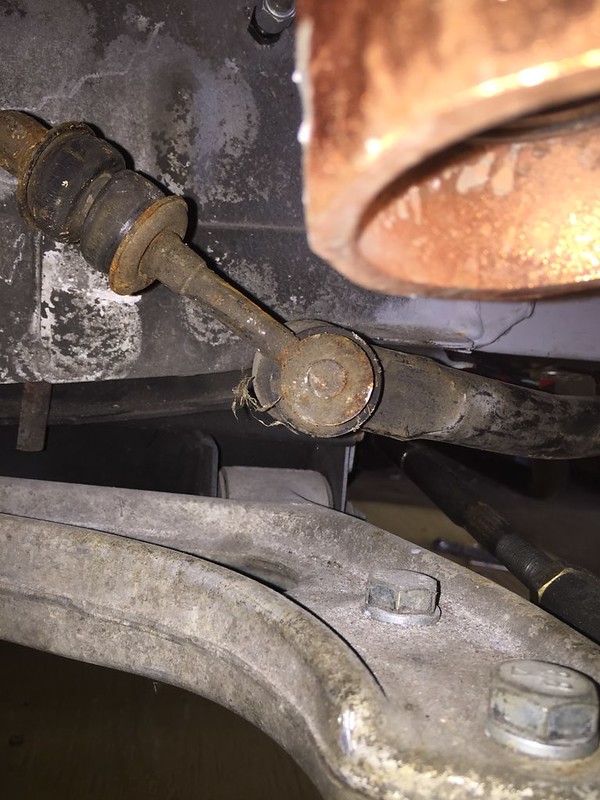

obviously gonna have to make custom end links of some kind, s chassis is a different style and it doesn’t sit exactly the same as the FC bar. I’m sure this will affect its effective stiffness depending on where I attach it but probably try for same place as stock.

and the S13 bushings and brackets even fit. The only catch there is they are at the limit of the straight part of the bar before the bend. So I will probably have to make a plate moving it in like 1/2 a side or something if I’m finding it binding. Ignore the tube front in this case, I put the sway bar mounts in the stock location.

But with a small spacer pretty ideal in the rear.

Pretty stoked on having another set of 18” wheels, the SBC is cool and when a pair is scratched and chipped enough I’ll paint them white to match. I kinda want to buy one more pair of wheels but at the moment I have enough 18” alone (planning to run 18/18) for a healthy track day.

Also made a relevant discovery to any FC owners with a swapped car. Well at least to me, I feel like this is old news to may ppl on the inter web but I have spent hours searching for a solution for the sway bar hitting the oil pan. Closest thing I found was a rumour that a specific e36 bar fit (never found out which though) and that a Mercedes ML suv rear bar fit.

But an S13 bar fits

top to bottom we have an R32 rear bar, what we think is an s14 front bar, then an s13 front and the stock FC. They both weigh a ton so I think they are both solid and they happen to be the same diameter. Kris had a bunch laying around so I tried them all lol.

room for oil pan clearance, still clears the diffuser too. Has a decent amount of wheel clearance but I feel this could be improved. It will still hit at max lock.

obviously gonna have to make custom end links of some kind, s chassis is a different style and it doesn’t sit exactly the same as the FC bar. I’m sure this will affect its effective stiffness depending on where I attach it but probably try for same place as stock.

and the S13 bushings and brackets even fit. The only catch there is they are at the limit of the straight part of the bar before the bend. So I will probably have to make a plate moving it in like 1/2 a side or something if I’m finding it binding. Ignore the tube front in this case, I put the sway bar mounts in the stock location.

Last edited by teeson; 03-25-18 at 02:35 AM.

#155

Senior Member

Thread Starter

Also promising is the GK tech sway bar kit may fit. Its a splined bar with high steering angle in mind.

I actually email GK a long while back before the bar was for sale and asked for rough dimensions. He emailed me back the drawing for it and it looks very close. the last pic is pretty telling, I also don’t think the bearing can ride on the splines so a bracket to move it in will be a must I if ever try that. The end plates are a slight gamble if they’ll clear as well….

I actually email GK a long while back before the bar was for sale and asked for rough dimensions. He emailed me back the drawing for it and it looks very close. the last pic is pretty telling, I also don’t think the bearing can ride on the splines so a bracket to move it in will be a must I if ever try that. The end plates are a slight gamble if they’ll clear as well….

Last edited by teeson; 03-25-18 at 02:22 AM.

#156

Senior Member

Thread Starter

Have a whole list of little things to do before I can begin tear down for paint

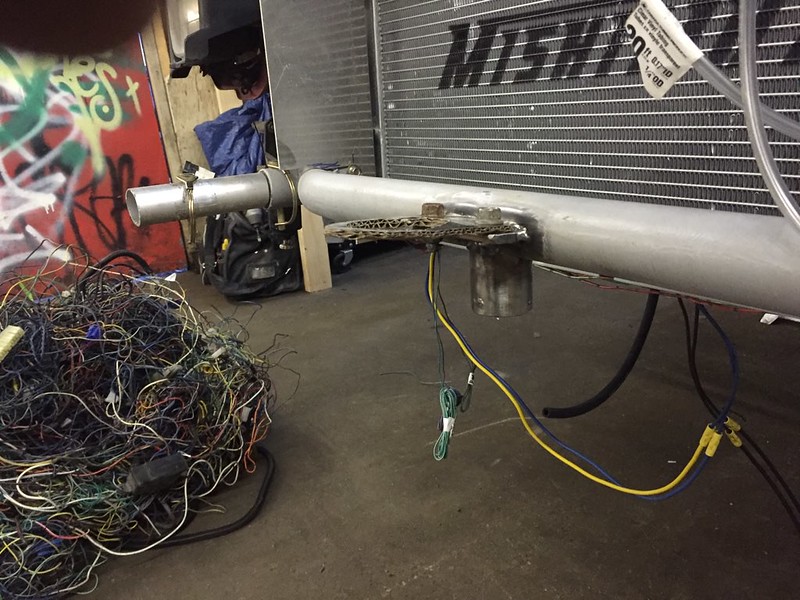

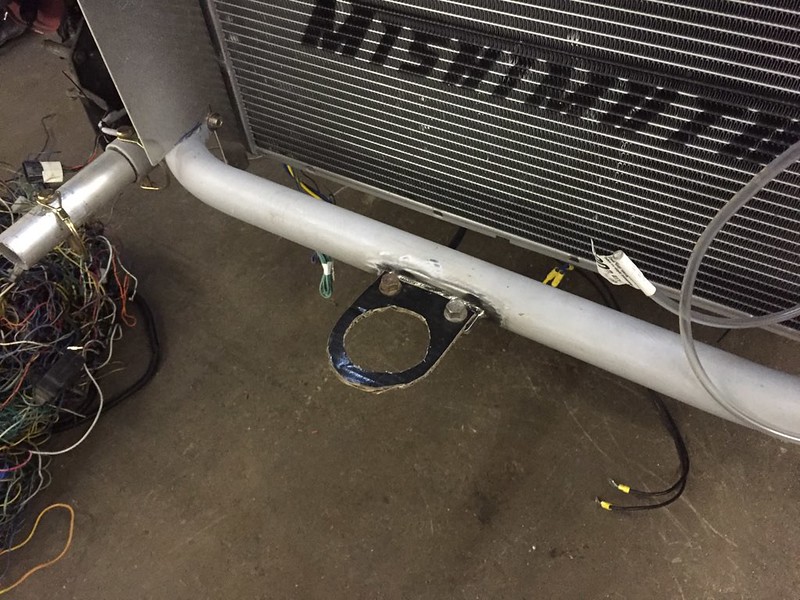

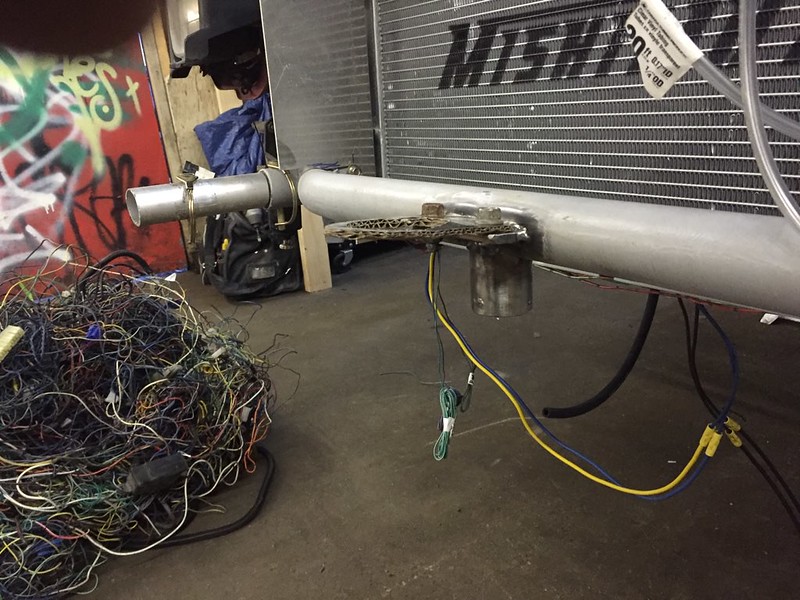

ran the hose for the rad sprayer and put some rivnuts in for the holders. For the tube sections though I wasn’t a fan of rivnuts so I welded nuts in

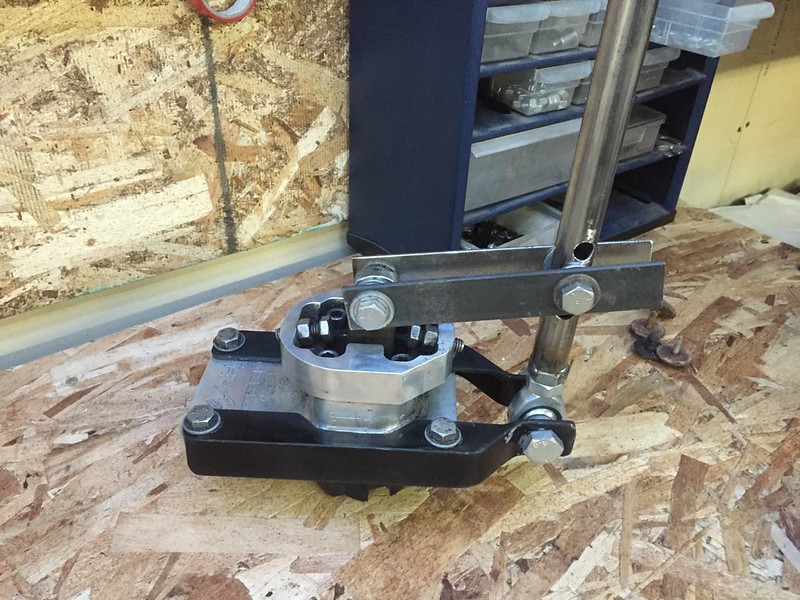

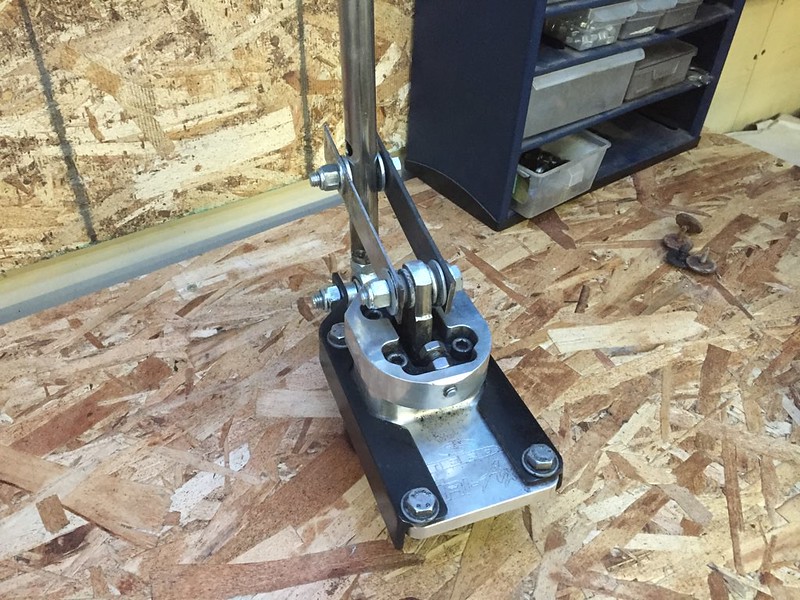

Next up was to test if the power steering works and doesn’t leak, but need to swap racks to the 2 hole rack I have. Didn’t want to remove the whole engine to drop the crossmember so I built a lift plate.

ran the hose for the rad sprayer and put some rivnuts in for the holders. For the tube sections though I wasn’t a fan of rivnuts so I welded nuts in

Next up was to test if the power steering works and doesn’t leak, but need to swap racks to the 2 hole rack I have. Didn’t want to remove the whole engine to drop the crossmember so I built a lift plate.

#157

Senior Member

Thread Starter

My dad had one of these engine supports for doing fwd clutches but works well for this too. Iím not 100% sold on it though. When I bolted it all back together the intake had lifted and formed a vacuum leak, I guess the weight pulled the manifold and the engine apart and the gasket lost its seal. Not sure if the bolts stretched or were a bit loose or what but Iím going to be careful going forward. I hope it was just loose cuz this thing is very convenient.

rack out

this crossmember has the poly bushings in it, but also an 3 hole rack in it. Have a 2 hole for simplified plumbing (though I could just block the otters hole on a 3 hole but this is tidier)

was painted black from before, gave it a quick wipe clean and put it together with the poly rack bushings

Getting the power steering lines in and connected was sure a hassle. Feel like the cradle could be better here..

routed the wire for the wiper motor

I didnít want to see the wires but I also didnít want them in the way of the assembly or in a spot they would let water into the cabin

worth mentioning that if I need to remove the wire it now involves de pinning the connector to fit through the hole. More work to service but really how often will I be pulling it out?

rack out

this crossmember has the poly bushings in it, but also an 3 hole rack in it. Have a 2 hole for simplified plumbing (though I could just block the otters hole on a 3 hole but this is tidier)

was painted black from before, gave it a quick wipe clean and put it together with the poly rack bushings

Getting the power steering lines in and connected was sure a hassle. Feel like the cradle could be better here..

routed the wire for the wiper motor

I didnít want to see the wires but I also didnít want them in the way of the assembly or in a spot they would let water into the cabin

worth mentioning that if I need to remove the wire it now involves de pinning the connector to fit through the hole. More work to service but really how often will I be pulling it out?

#158

Senior Member

Thread Starter

Wanted to fill with water and bleed the coolant and power steering but needed a working gauge to see what the thermostat is doing

I bought a low t stat and it opens at like 70*, but the low speed fan doesnít come on until like 93* so Iíll need to get a programmer to change thatÖ but it keeps it cool idling on stands

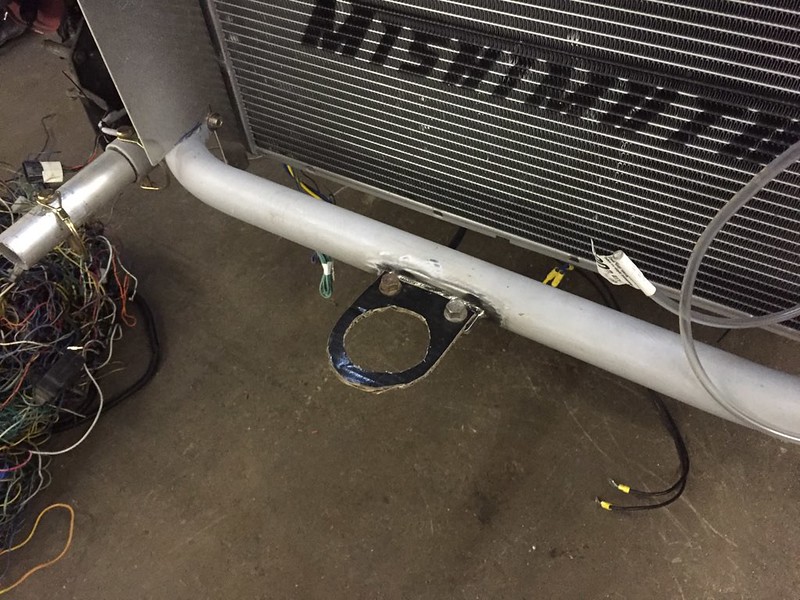

put a jack point and tow hook mount up front

then painted my splitter black and coated it with this awesome clear stuff (which i spilled the remainder of immediately after this photo)

Was a good suggestion on Johnoís part.

The idea here is I can slip a pipe into the jack point and lift the front easier. Its pretty tricky getting a jack under with all the aero on

I bought a low t stat and it opens at like 70*, but the low speed fan doesnít come on until like 93* so Iíll need to get a programmer to change thatÖ but it keeps it cool idling on stands

put a jack point and tow hook mount up front

then painted my splitter black and coated it with this awesome clear stuff (which i spilled the remainder of immediately after this photo)

Was a good suggestion on Johnoís part.

The idea here is I can slip a pipe into the jack point and lift the front easier. Its pretty tricky getting a jack under with all the aero on

#159

Senior Member

Thread Starter

Found a place and a way to hold the rear running wiring connectors that I like. Need to weld in the nits but I’ll wait until everything else is removed.

somewhere in there I mocked up a switch panel in the ash tray. 5 switches is too many, space is tight and I’ll probably be soldering onto the switches,.

4 seems just right

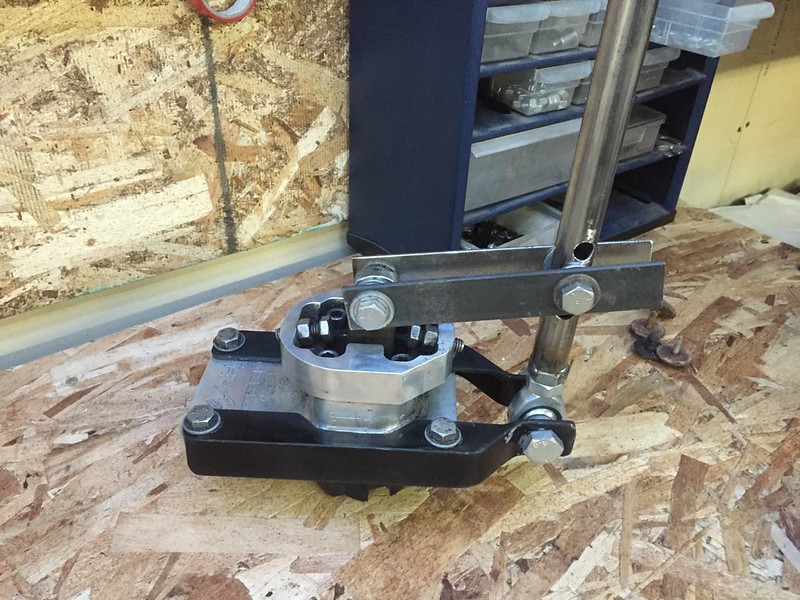

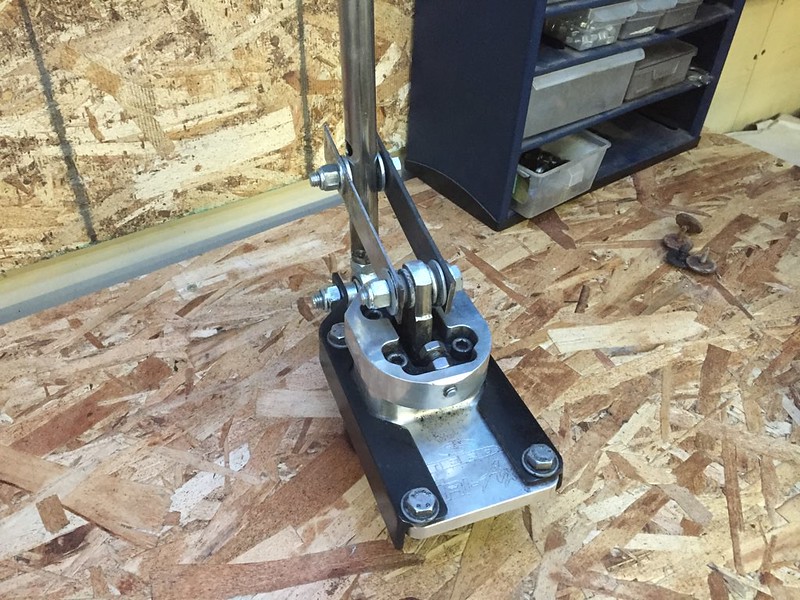

Picked these up to make sway bar end links some day in the future

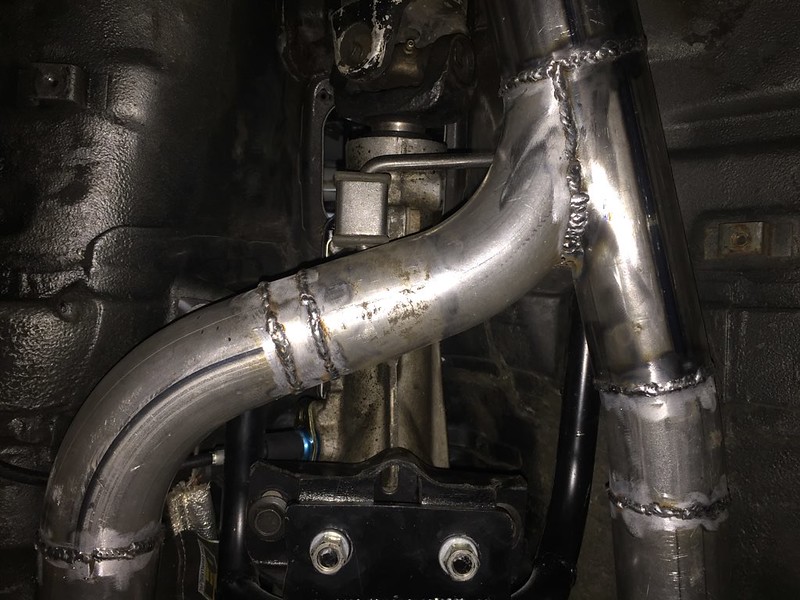

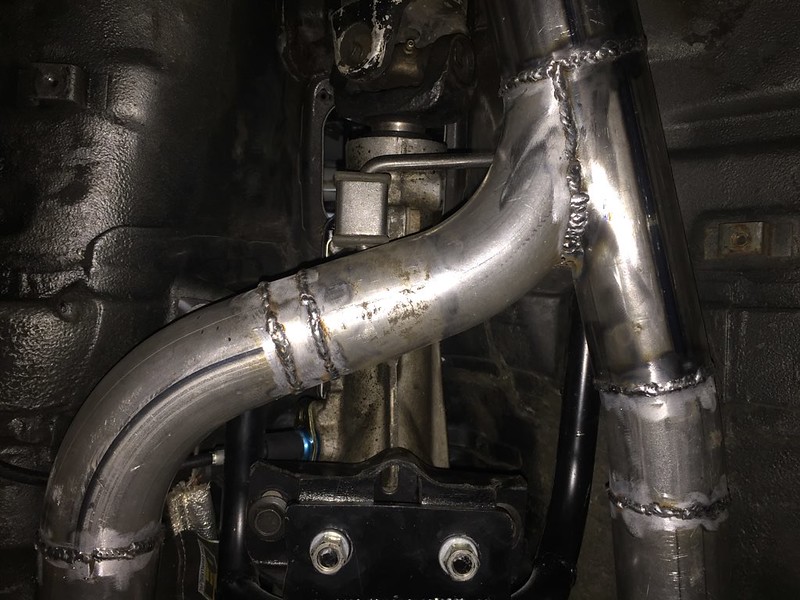

next was the exhaust. Shout out to Neil for letting me borrow his chop saw. This is at least the 3rd time redoing this exhaust haha

with the clutch slave out of the way i could get it good and tucked up

somewhere in there I mocked up a switch panel in the ash tray. 5 switches is too many, space is tight and I’ll probably be soldering onto the switches,.

4 seems just right

Picked these up to make sway bar end links some day in the future

next was the exhaust. Shout out to Neil for letting me borrow his chop saw. This is at least the 3rd time redoing this exhaust haha

with the clutch slave out of the way i could get it good and tucked up

#160

Senior Member

Thread Starter

added a little keeper so that the flange doesnít fall down. the one side the 02 is right there, but this makes the other side easier

much better place than before when it was hitting the front U jointÖ.

I cut off the old flange on the stainless axle back I had

much better place than before when it was hitting the front U jointÖ.

I cut off the old flange on the stainless axle back I had

#161

Senior Member

Thread Starter

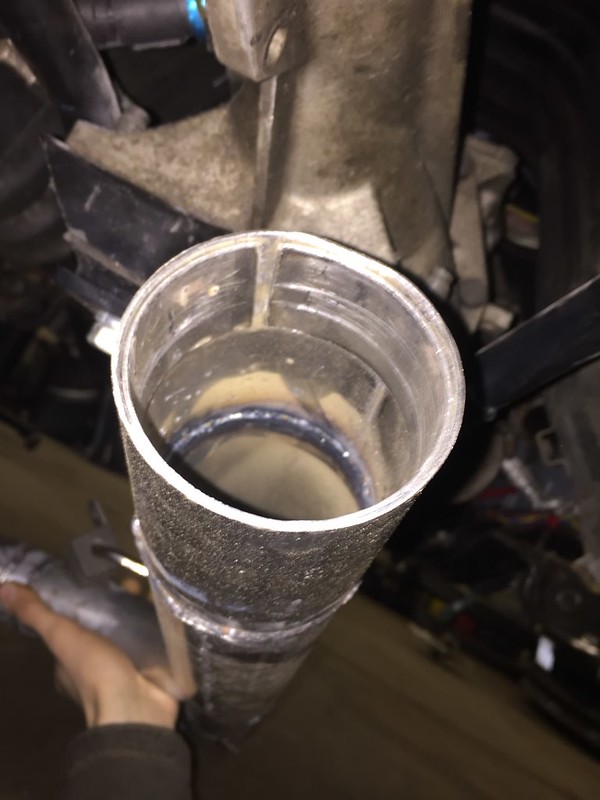

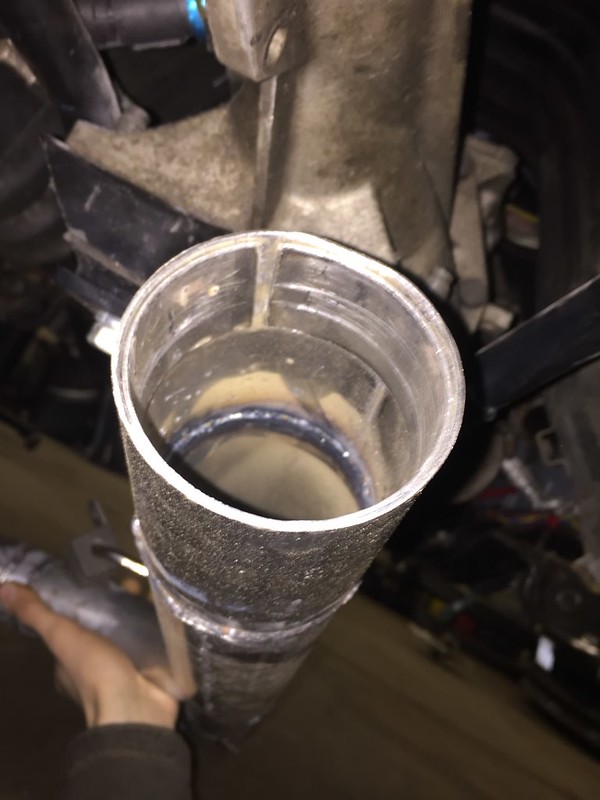

I wanted to use slip joints again, as that are easy and low profile. They can also handle mild - stainless transition

never that easy though, Had to shim it a little

sits as high up as it can. It dips below the frame rail to go under the rear subframe but I can’t do a lot about that… This is much better than last time though and should scrape less

got these sweet lights from china, they were like $25 cdn shipped and i got 15 off because the one was missing a charger cover and a cover on the top light. But they are super bright, light, magnetic and have a hook. charge over USB too

played around with my new crimpers and got the senders ready to go

After 3 tries to bleed the coolant, it finally did. Runs well once bled, power steering calmed down after a bit too. this is peace of mind for me and to hear the exhaust roar without fear of cooking something was nice. debugged a broken wire in the alternator harness and its basically ready to drive. But more things to do first

never that easy though, Had to shim it a little

sits as high up as it can. It dips below the frame rail to go under the rear subframe but I can’t do a lot about that… This is much better than last time though and should scrape less

got these sweet lights from china, they were like $25 cdn shipped and i got 15 off because the one was missing a charger cover and a cover on the top light. But they are super bright, light, magnetic and have a hook. charge over USB too

played around with my new crimpers and got the senders ready to go

After 3 tries to bleed the coolant, it finally did. Runs well once bled, power steering calmed down after a bit too. this is peace of mind for me and to hear the exhaust roar without fear of cooking something was nice. debugged a broken wire in the alternator harness and its basically ready to drive. But more things to do first

#162

Senior Member

Thread Starter

made a kinda big purchase for something that I’ve wanted for a long time, my own tire machine.

buddy got a new fancier on and gave me his for a good deal. Pulled the tire tire off the broken wheel (long story short, its cracked deep through and not by my doing but i aint mad about it)

its now a trophy/cable holder lol

for my birthday recently my fiancť spoiled me by adding another member to the milwaukee family. This thing is sweet and super powerful.

made fender holders to keep the fenders out where they should be and tighten the gap between them and the front bumper.

its the little things I love

buddy got a new fancier on and gave me his for a good deal. Pulled the tire tire off the broken wheel (long story short, its cracked deep through and not by my doing but i aint mad about it)

its now a trophy/cable holder lol

for my birthday recently my fiancť spoiled me by adding another member to the milwaukee family. This thing is sweet and super powerful.

made fender holders to keep the fenders out where they should be and tighten the gap between them and the front bumper.

its the little things I love

#163

Senior Member

Thread Starter

somewhere in there we got a shop doggo

her name is Roxy and sheís a perfect shop doggo because sheís 11 and basically deaf and blind so not much phases her

And here we are, basically ready to start tearing it apart to paint the underside and interior and engine bay.

I start 3rd term school on monday so Iím on target for where I wanted to be. Theres a local show iíd really like to make but its june 10th, so I have a lot of work to do to make that as itíll need to be fully painted and assembled for thatÖ

her name is Roxy and sheís a perfect shop doggo because sheís 11 and basically deaf and blind so not much phases her

And here we are, basically ready to start tearing it apart to paint the underside and interior and engine bay.

I start 3rd term school on monday so Iím on target for where I wanted to be. Theres a local show iíd really like to make but its june 10th, so I have a lot of work to do to make that as itíll need to be fully painted and assembled for thatÖ

#164

Rotary Freak

I really like what you did with the switches in the ashtray. I may do something similar if I need to add switches in my car (I really hate seeing switches that aren't in OEM locations, so concealing them in the ashtray is a nice alternative).

#165

Senior Member

Thread Starter

they will be controlling the strobes and underglow etc, so not stuff I want out in the open anyway lol. I had to trim the bottom of the ashtray in my last chassis to clear the shifter, so this has a second purpose as well. Just need to get some abs plastic and glue it in instead of the aluminum mock up piece

#168

Senior Member

Thread Starter

Well as per my usual its been far too long. This is largely due to my work pace, Iíve been pretty bad at taking pics of everything. Some details are minor and some details are in my opinion worth sharing and I have pics of most of those.

we left off with it basically ready to be stripped for paint.

this was after about 8 hours, basically down to the engine and subframes.

took a minute to put tires on the RPF1ís as well

these are 225/40ís on a 9.5 and they are more stretched than I thought. looks like a 10Ē wheelÖ but i like it

once it was stripped down there was a handful of tasks still to be done that I was waiting to do once most stuff was out of the way.

This is the other half of the oil filter relocation kit that wasnít really working out. I had bought an adapter from transdapt to make the thread something more common, and that combined with a part from the other oil filter pedestal make it work for a spin on fuel filter. A long time ago I had the idea to use a spin on can, they are huge media area and very small micron (10 and less) and $7 for a replacement.

but where to fit it

Where I settled on was above the diff. Safe from a rear ender, safe from an axle breaking. Ideally Iíd prefer the filter closer to the rail, but I also didnít like any of the places that it could physically fit, either it be in the way of something else or proximity to the ground or exhaust. I can change it without removing anything, just have to jack the car up. I believe FD rx7ís have their filters in a similar place. Thankfully with a filter this size its not something I have to change often. And theres ports for a fuel pressure and temperature senders if I ever want.

we left off with it basically ready to be stripped for paint.

this was after about 8 hours, basically down to the engine and subframes.

took a minute to put tires on the RPF1ís as well

these are 225/40ís on a 9.5 and they are more stretched than I thought. looks like a 10Ē wheelÖ but i like it

once it was stripped down there was a handful of tasks still to be done that I was waiting to do once most stuff was out of the way.

This is the other half of the oil filter relocation kit that wasnít really working out. I had bought an adapter from transdapt to make the thread something more common, and that combined with a part from the other oil filter pedestal make it work for a spin on fuel filter. A long time ago I had the idea to use a spin on can, they are huge media area and very small micron (10 and less) and $7 for a replacement.

but where to fit it

Where I settled on was above the diff. Safe from a rear ender, safe from an axle breaking. Ideally Iíd prefer the filter closer to the rail, but I also didnít like any of the places that it could physically fit, either it be in the way of something else or proximity to the ground or exhaust. I can change it without removing anything, just have to jack the car up. I believe FD rx7ís have their filters in a similar place. Thankfully with a filter this size its not something I have to change often. And theres ports for a fuel pressure and temperature senders if I ever want.

#169

Senior Member

Thread Starter

anyway completely stripped down

while theres gussets on the A pillar, there wasnít anything on the rear of the car. So I added a plate above the rear of the main hoop. I drilled holes for the bolts that hold the sunroof in as a last resort but I donít think that the sunroof frame will ever come out.

Came to the realization that I didnít have pinch welds, and while when doing the rust repair and such I decided I didnít want to bother but I realized that if my frame ever needs to be straightened they will need a way to grab the frame. Its also ideal for jack stands, something FC pinch welds arenít

One thing I hadnít done yet was trim my good dash to fit the car. I made templates for it based off the first dash I over cut (for ease of removal) so I could get It as perfect as possible.

I took the skin off the dash frame and trimmed the frame separately

then the dash skin

#170

Senior Member

Thread Starter

Im sure I could have gotten it even better than that with a 3rd try but oh well

prepping for paint includes the garage too, we have a compressor with a 40 or so gallon tank. While that may cut it it will be hard to keep up with the demand of a HVLP gun. In the back of the garage theres a huge 100 gallon or something tank but it doesnít have a motor. My plan was to use the little one to feed the big one (with some cool down time in-between filling it) and also build an air cooler/water trap to prevent anything from getting into the paint.

a rather frustrating almost $150 later, I had a diy water trap.

#171

Senior Member

Thread Starter

While I’m spending money…. this is about $700 in paint supplies lol

but short of black primer its everything I need to paint the underside, engine bay, interior and exterior and have some leftovers for repainting aero parts I’m sure to destroy

dragged it outside to pressure wash it before starting sanding

given how sketchy the car was sitting, i wasn’t super comfortable getting right under it to scrub the dirt. So it was kinda a waste of time lol. Got the surface stuff but the real grime needed more attention

for example

Put up the poly plastic walls, bought some pizza and had the vibes boys over for some sanding. Obviously we listened to Darude Sandstorm. Shoutout to Mitch, Jordan, Kris, Tito for 15 minutes and Eli for the help (also Eli for ditching his gf lol)

#172

Senior Member

Thread Starter

But in one night, including a lot of goofing off we got like 80% of the car sanded. I had to spend some extra effort in the engine bay due to brushing on primer. Mitch will be the first to tell you this.

[mg]https://farm2.staticflickr.com/1813/42957881921_1e0fe04c2e_c.jpg[/img]

Everyone seems to fill the gaps and such in Bondo, especially where theres room for the engine bay to flex it always cracks. I chose to use some 2 part epoxy filler, and maaaaaaaan does this stuff suck to sand. I thought it would take all of an evening to sand it once it hardened but it was like 3. Might have been easier if i went with rigid type instead of semi-rigid but i doubt it. sanding “innies” isn’t fun either.

Somewhere in there I applied seam sealer to all the seams I either created or grinded. Was really rushing to get stuff done before painting so I didn’t really take pics

My fiancť (who I did not unfortunately get a picture of while working) and my sister came out to help sand around this part. My sister is an auto painter by trade, so it was a huge help having her advice and expertise throughout the entire process. She laid down a final layer of primer on the cage and engine bay.

#175

Senior Member

Thread Starter

Colour is Mazda Stormy Blue Mica. Came on RX8ís and NC miataís. Its usually more black but i kinda goofed and used a lighter colour primer than intended so It looks a bit purple. especially in the spots with less coverage. She sprayed 2 coats of gloss black in the interior, 1 thick one on the underside (the undercoating just soaked it up), and 3 coats on the bay. Have to give it up to my sister, She was painting from about 6 pm until midnight. And hindsight being 20/20, a hat was not enough to keep paint out of her hair.

I left it for the rest of the weekend (we painted on friday) and came back monday to scuff and spray bedliner onto the wheel wells.

This worked really good on the last chassis and texture just covers up so many imperfections haha

full force reassembly, can finally get all this stuff I have had on shelves for ages off of them

Painted my front brake lines. people before would always ask me where the brake lines were, they are basically invisible now lol