eage8's SSM/HPDE FC Turbo

#401

Here is the best pictures I have of the tip:

And yes, that's a cusco lower arm bar. It really close to the new wastegate dump pipe which I didn't really expect

#402

Rotary Enthusiast

iTrader: (1)

I know it also matters on the height of your car, but I was curious on which subframe bushings you are using. Do you have a measurement from subframe to chasis? I'm really debating on buying the gauge, but I'm also going to have my rear end out, and I am thinking about turning down the bushings a little. When I made my subframe bushings, I copied stock measurements, butmy car was jacked up, so I don't know if the weight of the rear end was sagging the bushing, something I didn't think about at the time

#403

I know it also matters on the height of your car, but I was curious on which subframe bushings you are using. Do you have a measurement from subframe to chasis? I'm really debating on buying the gauge, but I'm also going to have my rear end out, and I am thinking about turning down the bushings a little. When I made my subframe bushings, I copied stock measurements, butmy car was jacked up, so I don't know if the weight of the rear end was sagging the bushing, something I didn't think about at the time

ride height doesn't matter a whole lot with bump steer... it just matters were the starting point of the curve is. so if I went 1 inch lower in the back it would just be this:

droop:

-2" 0.008"

-1.5" 0.000"

-0.5" -0.001

0" -0.000

bump:

0.5" 0.003

1" -0.002

still thousandths of an inch...

#404

Rotary Enthusiast

iTrader: (1)

I have MMR UHMW subframe bushings (like delrin). They're close enough to stock height for it not to matter much.

ride height doesn't matter a whole lot with bump steer... it just matters were the starting point of the curve is. so if I went 1 inch lower in the back it would just be this:

droop:

-2" 0.008"

-1.5" 0.000"

-0.5" -0.001

0" -0.000

bump:

0.5" 0.003

1" -0.002

still thousandths of an inch...

ride height doesn't matter a whole lot with bump steer... it just matters were the starting point of the curve is. so if I went 1 inch lower in the back it would just be this:

droop:

-2" 0.008"

-1.5" 0.000"

-0.5" -0.001

0" -0.000

bump:

0.5" 0.003

1" -0.002

still thousandths of an inch...

I told him about your findings on the front though. Our fc use a very similar front suspension to the e46 m3s we see everyday. We have weight scales and alignment machine. I don't see why not to get a bump steer gauge. We could probably charge people for the service, but I don't know how long it would take vs how much we could charge

#405

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,890

Received 2,638 Likes

on

1,868 Posts

I talked to my boss about the bump steer gauge and he figured I was trying to use it for myself. lol!

I told him about your findings on the front though. Our fc use a very similar front suspension to the e46 m3s we see everyday. We have weight scales and alignment machine. I don't see why not to get a bump steer gauge. We could probably charge people for the service, but I don't know how long it would take vs how much we could charge

I told him about your findings on the front though. Our fc use a very similar front suspension to the e46 m3s we see everyday. We have weight scales and alignment machine. I don't see why not to get a bump steer gauge. We could probably charge people for the service, but I don't know how long it would take vs how much we could charge

#406

Modified my AWR extended roll center ball joints... hopefully these won't break in half this time:

I drilled out the pinch area to 3/4" (19mm) (which took way longer than I thought it would for just 1mm larger). I notched a 3/4" grade 8 bolt and hammered it through the top and pinched it in place.

the bearing spacers and bolt length need tweaking...

I drilled out the pinch area to 3/4" (19mm) (which took way longer than I thought it would for just 1mm larger). I notched a 3/4" grade 8 bolt and hammered it through the top and pinched it in place.

the bearing spacers and bolt length need tweaking...

#411

Still making slow progress on the car...

Both modified roll center ball joints are done:

clearanced the bearing spacers a bit for more articulation:

Replaced both rear calipers and brake lines... hopefully this allows me to get a bit more rear brake out of the car. one of the rotors was rusty on half of the inside of the rotor, so it wasn't working right....

Sneak preview of new front coilovers:

Both modified roll center ball joints are done:

clearanced the bearing spacers a bit for more articulation:

Replaced both rear calipers and brake lines... hopefully this allows me to get a bit more rear brake out of the car. one of the rotors was rusty on half of the inside of the rotor, so it wasn't working right....

Sneak preview of new front coilovers:

#413

got some stuff done tonight.

first, I weighed the new exhaust:

coated divorced wastegate downpipe is 11.6 lbs.

the rest of the exhaust is 20.2 lbs.

totaling 31.8 lbs. over 41 lbs lighter than my old 3" racing beat exhaust.

looks like the v-band is leaking a bit...

anyone know a good way to fix that that doesn't require resurfacing...

I also think I have an exhaust leak at the new turbo back plate, so I'm going to try to make a copper gasket for it. I got a sheet of 0.043" copper and went to town:

It probably would have turned out better if I started off using the KSP back plate as a refference instead of the stock back plate (which is a different shape) but it's good enough.

first, I weighed the new exhaust:

coated divorced wastegate downpipe is 11.6 lbs.

the rest of the exhaust is 20.2 lbs.

totaling 31.8 lbs. over 41 lbs lighter than my old 3" racing beat exhaust.

looks like the v-band is leaking a bit...

anyone know a good way to fix that that doesn't require resurfacing...

I also think I have an exhaust leak at the new turbo back plate, so I'm going to try to make a copper gasket for it. I got a sheet of 0.043" copper and went to town:

It probably would have turned out better if I started off using the KSP back plate as a refference instead of the stock back plate (which is a different shape) but it's good enough.

#416

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,890

Received 2,638 Likes

on

1,868 Posts

#417

anyone know a good way to fix that that doesn't require resurfacing...

I have seen where people cut out a circle of high temp gasket material from McMaster-Carr to fit warped V-band flanges. Its a fragile, flaky material, forget the name.

I warped the first v-band flange when I re-made my 3.5" turbo back single for my hybrid turbo by welding it continuously around. I found out I had to weld a 1" section and then a 1" section opposite the that and so on as I didn't have a giant heat sink attached to the exhaust.

You can put some abrasive between the flanges and assemble with the band loosely and fiddle it back and forth while watching TV or something if it isn't too far off.

I also think I have an exhaust leak at the new turbo back plate, so I'm going to try to make a copper gasket for it. I got a sheet of 0.043" copper and went to town:

I tried the copper gasket thing too at the back plate and it won't last too long racing. In the areas between bolts it will get pushed out when it is soft from heat and even elongate the holes from being pushed out.

For a long time I kept using a stack of 3 there, but eventually just got everything flat enough to work with no gasket.

I would try 3-5 layers of thin stainless sheetmetal for the turbo backplate.

I have had great luck using the stock S5 gaskets even with the centers ported out for my manifold/turbo and turbo/downpipe where the copper ones I made failed here too racing.

I have seen where people cut out a circle of high temp gasket material from McMaster-Carr to fit warped V-band flanges. Its a fragile, flaky material, forget the name.

I warped the first v-band flange when I re-made my 3.5" turbo back single for my hybrid turbo by welding it continuously around. I found out I had to weld a 1" section and then a 1" section opposite the that and so on as I didn't have a giant heat sink attached to the exhaust.

You can put some abrasive between the flanges and assemble with the band loosely and fiddle it back and forth while watching TV or something if it isn't too far off.

I also think I have an exhaust leak at the new turbo back plate, so I'm going to try to make a copper gasket for it. I got a sheet of 0.043" copper and went to town:

I tried the copper gasket thing too at the back plate and it won't last too long racing. In the areas between bolts it will get pushed out when it is soft from heat and even elongate the holes from being pushed out.

For a long time I kept using a stack of 3 there, but eventually just got everything flat enough to work with no gasket.

I would try 3-5 layers of thin stainless sheetmetal for the turbo backplate.

I have had great luck using the stock S5 gaskets even with the centers ported out for my manifold/turbo and turbo/downpipe where the copper ones I made failed here too racing.

#418

I tried the copper gasket thing too at the back plate and it won't last too long racing. In the areas between bolts it will get pushed out when it is soft from heat and even elongate the holes from being pushed out.

For a long time I kept using a stack of 3 there, but eventually just got everything flat enough to work with no gasket.

I would try 3-5 layers of thin stainless sheetmetal for the turbo backplate.

I have had great luck using the stock S5 gaskets even with the centers ported out for my manifold/turbo and turbo/downpipe where the copper ones I made failed here too racing.

For a long time I kept using a stack of 3 there, but eventually just got everything flat enough to work with no gasket.

I would try 3-5 layers of thin stainless sheetmetal for the turbo backplate.

I have had great luck using the stock S5 gaskets even with the centers ported out for my manifold/turbo and turbo/downpipe where the copper ones I made failed here too racing.

I've been using stock gaskets for everything else and they seem to hold up fine, so I don't change them. except the 1 stock manifold to turbo gasket I blew up when my engine blew which I'm still confused about how that happened....

I was thinking about using some permetex exhaust sealer stuff for the v-band and the slip joint on my rear muffler... it says it's good to up to 2000*F which should be fine that far down the exhaust....

Exhaust System Repair : Permatex® Muffler & Tailpipe Sealer

#419

How thick was the copper you were using, and how thick was the stainless?

The thickest copper I used was 1/8" gasket for turbo manifold to turbo and turbo to downpipe.

I had better luck actually with 3 sheets of very thin copper at the turbo to downpipe junction that I could cut with scissors.

It finally dawned on me that I could use the stock S5 stainless gaskets for turbo manifold to turbo and turbo to downpipe by just porting the inside bigger to match my runners/downpipe.

I did not notice any ill effects from removing the stock "fire ring" by porting them larger.

I haven't tried any stainless besides stock S5 multilayer, but I feel certain it would work fine.

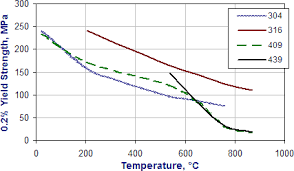

From what I observed of the copper the failure point was that the yield strength at "normal" operating temperature was low enough to be deformed by exhaust pressure. The thicker the copper the worse as there was more area exposed for the exhaust pressure to push against.

Stainless retains its yield strength at elevated temperatures, so I have no doubt that even very thin stainless gaskets stacked will work great.

The thickest copper I used was 1/8" gasket for turbo manifold to turbo and turbo to downpipe.

I had better luck actually with 3 sheets of very thin copper at the turbo to downpipe junction that I could cut with scissors.

It finally dawned on me that I could use the stock S5 stainless gaskets for turbo manifold to turbo and turbo to downpipe by just porting the inside bigger to match my runners/downpipe.

I did not notice any ill effects from removing the stock "fire ring" by porting them larger.

I haven't tried any stainless besides stock S5 multilayer, but I feel certain it would work fine.

From what I observed of the copper the failure point was that the yield strength at "normal" operating temperature was low enough to be deformed by exhaust pressure. The thicker the copper the worse as there was more area exposed for the exhaust pressure to push against.

Stainless retains its yield strength at elevated temperatures, so I have no doubt that even very thin stainless gaskets stacked will work great.

#420

I was thinking about using some permetex exhaust sealer stuff for the v-band and the slip joint on my rear muffler

I have used this product before to seal the turbo to turbo backplate.

Just know that it is basically just refractory brick mortar.

It will be a mess to break the joint apart and chip, wire wheel and curse the cured mortar off when you want to reassemble the joint.

#421

So I finished up resealing the exhaust... hopefully it makes it a bit more quiet.

from the front to the back.

- found some loose manifold bolts and tightened them up

- re-sealed EGT probes. permetex muffler sealer on the threads going into the manifold and 2600*F anti-seize on the threads clamping the probes in.

- made a copper gasket for the turbo back plate (see above)

- made a copper gasket for the v-band...

Here is a picture of the v-band gasket... we'll see if it works not so sure it will...

not so sure it will...

The DC regoin National ProSolo autocross is this coming weekend so my suspension is going to be super close, hopefully I get it in time.

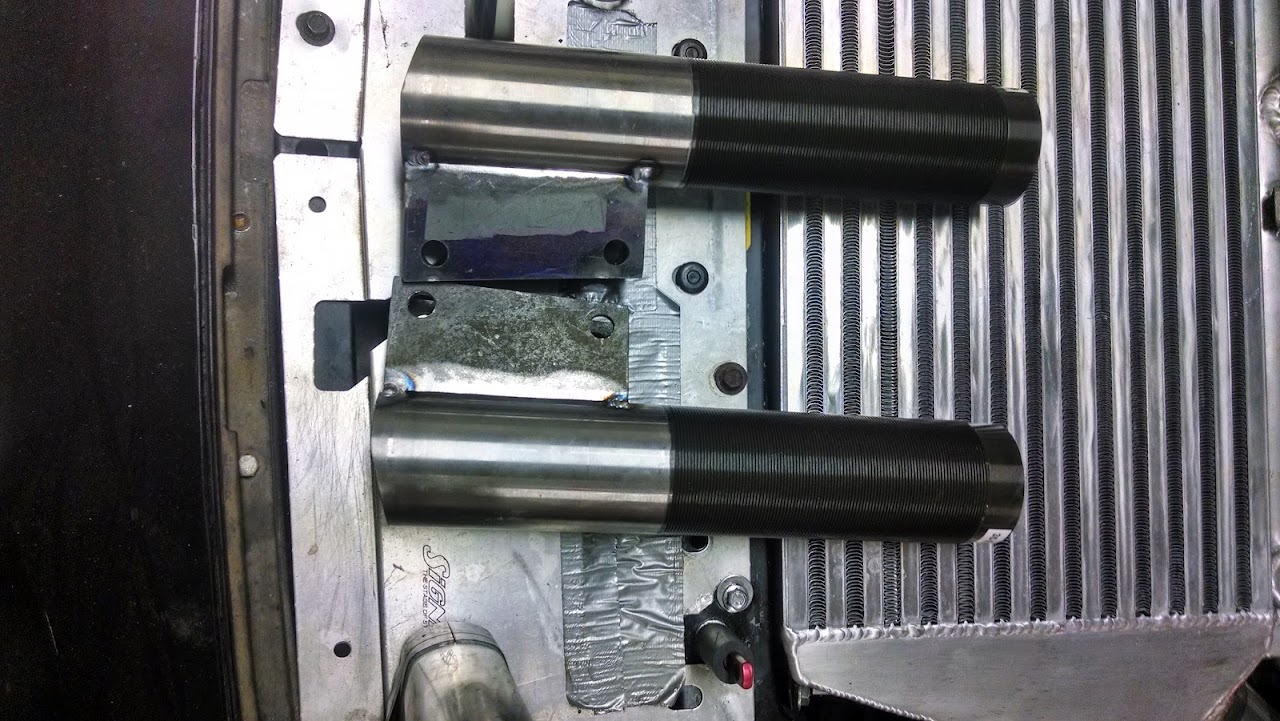

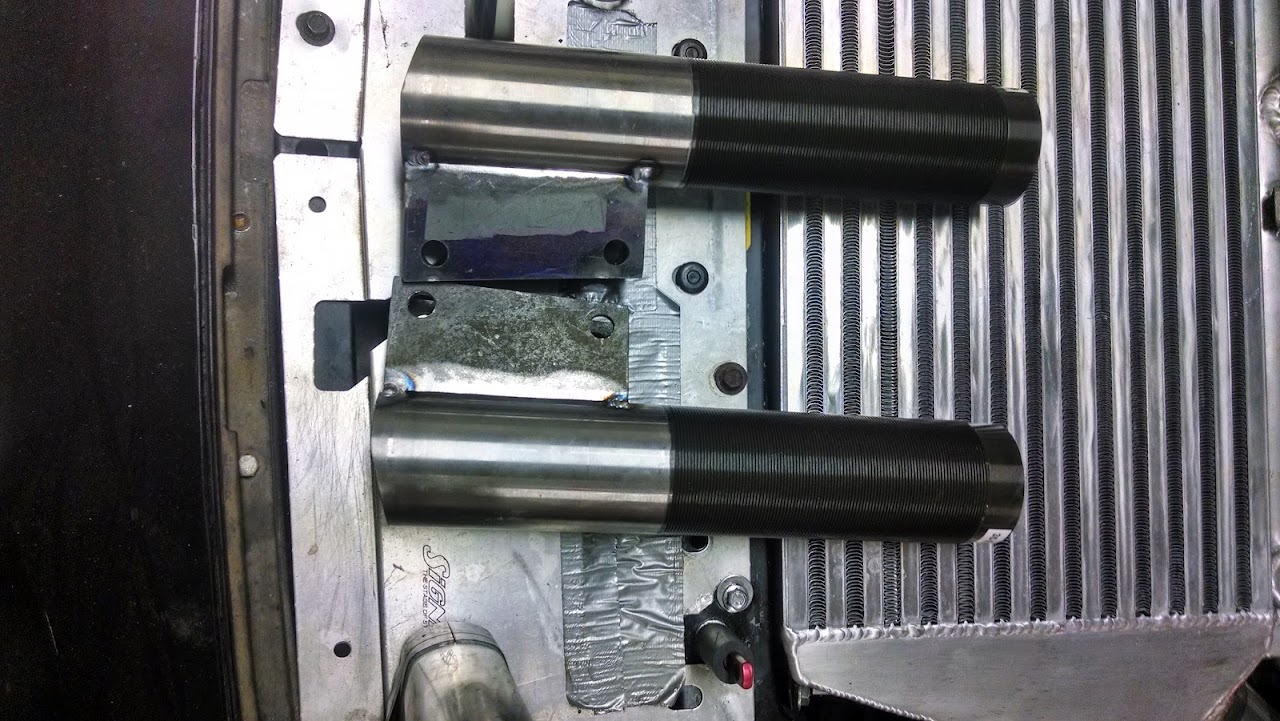

I had my suspension re-valver send me the bilstein strut tubes ahead of time so I could weld ears to them. My friend's CNC machine is broken, so the ears don't look as nice as they did on my old bilsteins (we used a band saw to cut them out), but after taking this picture I ground down the sharp corners and they actually look pretty decent considering:

I dropped them off this morning at the welders to have them fully welded up (my friend doesn't weld suspension stuff for liability reasons)

I also drilled out my stock rear damper mounting stud so I could thread it for a 1/2" bolt. This is a bit sketchy since not all of the M12 threads get drilled out, but it's what AWR does so I'm pretty sure it'll be fine (they've run them on both their and mazdatrix's EP race cars).

the first one (right) didn't turn out very well... I drilled it out to tap 1/2"-20 and then it instantly ruined my tap, so I just tapped it 1/2"-13... the problem with that is the pilot hole for -20 is a bit bigger than the one for -13 so I have even less thread engagement... but it should hold up for one race before I get another one to redo it. The second one (left) I pilot drilled 2 sizes smaller (one size smaller that recommended) and it turned out great, but I did loose 1 tap wrench in the process:

so today I went to sears and bought something a bit more sturdy and finished the job

from the front to the back.

- found some loose manifold bolts and tightened them up

- re-sealed EGT probes. permetex muffler sealer on the threads going into the manifold and 2600*F anti-seize on the threads clamping the probes in.

- made a copper gasket for the turbo back plate (see above)

- made a copper gasket for the v-band...

Here is a picture of the v-band gasket... we'll see if it works

not so sure it will...

not so sure it will...

The DC regoin National ProSolo autocross is this coming weekend so my suspension is going to be super close, hopefully I get it in time.

I had my suspension re-valver send me the bilstein strut tubes ahead of time so I could weld ears to them. My friend's CNC machine is broken, so the ears don't look as nice as they did on my old bilsteins (we used a band saw to cut them out), but after taking this picture I ground down the sharp corners and they actually look pretty decent considering:

I dropped them off this morning at the welders to have them fully welded up (my friend doesn't weld suspension stuff for liability reasons)

I also drilled out my stock rear damper mounting stud so I could thread it for a 1/2" bolt. This is a bit sketchy since not all of the M12 threads get drilled out, but it's what AWR does so I'm pretty sure it'll be fine (they've run them on both their and mazdatrix's EP race cars).

the first one (right) didn't turn out very well... I drilled it out to tap 1/2"-20 and then it instantly ruined my tap, so I just tapped it 1/2"-13... the problem with that is the pilot hole for -20 is a bit bigger than the one for -13 so I have even less thread engagement... but it should hold up for one race before I get another one to redo it. The second one (left) I pilot drilled 2 sizes smaller (one size smaller that recommended) and it turned out great, but I did loose 1 tap wrench in the process:

so today I went to sears and bought something a bit more sturdy and finished the job

#422

This may be a dumb question, but why did you drill out the rear lower dampener stud? Did you want to veg a more common sized bolt in there?

Also, kind of a side note. You may have a leak on the v band if it wasnt welded properly. The way I did mine was by tack welding everything first, then assemble the v band outside of the car so that when you weld it it so t warp. I then let it cool down over night just to make sure.

Also, kind of a side note. You may have a leak on the v band if it wasnt welded properly. The way I did mine was by tack welding everything first, then assemble the v band outside of the car so that when you weld it it so t warp. I then let it cool down over night just to make sure.

#423

This may be a dumb question, but why did you drill out the rear lower dampener stud? Did you want to veg a more common sized bolt in there?

Also, kind of a side note. You may have a leak on the v band if it wasnt welded properly. The way I did mine was by tack welding everything first, then assemble the v band outside of the car so that when you weld it it so t warp. I then let it cool down over night just to make sure.

Also, kind of a side note. You may have a leak on the v band if it wasnt welded properly. The way I did mine was by tack welding everything first, then assemble the v band outside of the car so that when you weld it it so t warp. I then let it cool down over night just to make sure.

and yeah, we welded one of the v-bands with the v-band assembled, but because the downpipe was on the car already for mock-up we welded the other half on the bench... if the copper doesn't work I'll throw some muffler sealant or copper RTV or something on it

#424

Hey just saw something interesting in the latest Fastrack:

The "not sports car based" wording is red-lined.

Some background.. In the summer of 2012, I wrote a letter (9335) to the SEB asking for clarification on the terminology "sports car based", and whether or not the 2nd gen RX7 is excluded from SM. They did after all come from the factory with 4 seats and 4 seatbelts (some anyway).

Here is their response from the November 2012 Fastrack:

They didn't answet the question at all, but I just gave up at that point.

With the new rule change (2015 I'm guessing?), the FC should be in SM, unless specifically excluded in Appendix A. I don't see any wording, aside from "sports car based", that suggests otherwise.

I imagine that if this is persued further with more letters, they would just add the car to the exlusion list, but for the time being I would think you are safe to run SM.

Street Modified

#12753 Eliminate 16.0.B & 16.0.C

The SMAC recommends the following change to 16.0.C:

“All sedans/coupes (models which were originally equipped with a minimum of four seats and four factory seat belts, not sports car based).”

Comment: This removes subjective words from the eligibility requirements from SM and makes it clear that Appendix A controls vehicle eligibility in classes for the category.

#12753 Eliminate 16.0.B & 16.0.C

The SMAC recommends the following change to 16.0.C:

“All sedans/coupes (models which were originally equipped with a minimum of four seats and four factory seat belts, not sports car based).”

Comment: This removes subjective words from the eligibility requirements from SM and makes it clear that Appendix A controls vehicle eligibility in classes for the category.

Some background.. In the summer of 2012, I wrote a letter (9335) to the SEB asking for clarification on the terminology "sports car based", and whether or not the 2nd gen RX7 is excluded from SM. They did after all come from the factory with 4 seats and 4 seatbelts (some anyway).

Here is their response from the November 2012 Fastrack:

Not Recommended:

Street Modified

#9335; RX-7 in SM, seating interpretation. Per the SMAC, the 2nd Gen RX-7 is pretty clearly sports car based in manufacturer literature, and it closely fits the 2+2 example used in the rulebook for Datsun Z cars which are in SSM.

Street Modified

#9335; RX-7 in SM, seating interpretation. Per the SMAC, the 2nd Gen RX-7 is pretty clearly sports car based in manufacturer literature, and it closely fits the 2+2 example used in the rulebook for Datsun Z cars which are in SSM.

With the new rule change (2015 I'm guessing?), the FC should be in SM, unless specifically excluded in Appendix A. I don't see any wording, aside from "sports car based", that suggests otherwise.

I imagine that if this is persued further with more letters, they would just add the car to the exlusion list, but for the time being I would think you are safe to run SM.

#425

Hey just saw something interesting in the latest Fastrack:

The "not sports car based" wording is red-lined.

Some background.. In the summer of 2012, I wrote a letter (9335) to the SEB asking for clarification on the terminology "sports car based", and whether or not the 2nd gen RX7 is excluded from SM. They did after all come from the factory with 4 seats and 4 seatbelts (some anyway).

Here is their response from the November 2012 Fastrack:

They didn't answet the question at all, but I just gave up at that point.

With the new rule change (2015 I'm guessing?), the FC should be in SM, unless specifically excluded in Appendix A. I don't see any wording, aside from "sports car based", that suggests otherwise.

I imagine that if this is persued further with more letters, they would just add the car to the exlusion list, but for the time being I would think you are safe to run SM.

The "not sports car based" wording is red-lined.

Some background.. In the summer of 2012, I wrote a letter (9335) to the SEB asking for clarification on the terminology "sports car based", and whether or not the 2nd gen RX7 is excluded from SM. They did after all come from the factory with 4 seats and 4 seatbelts (some anyway).

Here is their response from the November 2012 Fastrack:

They didn't answet the question at all, but I just gave up at that point.

With the new rule change (2015 I'm guessing?), the FC should be in SM, unless specifically excluded in Appendix A. I don't see any wording, aside from "sports car based", that suggests otherwise.

I imagine that if this is persued further with more letters, they would just add the car to the exlusion list, but for the time being I would think you are safe to run SM.

I had emailed them about the same thing a while ago after I saw you mention it somewhere and received pretty much the same response.

Originally Posted by Doug Gill

2+2 cars are specifically ineligible for SM class. Section 16.0.C.1 also says "not sports car based" and the examples list the Datsun Z 2+2 cars as excluded (page 107). The Datsun 280Z 2+2 cars are actually longer than the "regular" 280Z, too, so it could be argued (unsuccessfully) that it's a different car. But the SEB has been adamant that 2+2 models of sports cars are not eligible for SM class.

it's not like it gets me a lot though... just an easier PAX, I'd still have to deal wth the Panda 240 and Godzilla...