RENESISFD's Robust Build: Powered by Pepperoni Pizza and Chikken Nuggets

#452

Wastegate John

Thread Starter

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

Are you using those Russell push-on adapters at your stock Feed/Return hardlines by the firewall too? I currently just have my -6AN rubber fuel hoses triple clamped to the stock hardlines, I might switch to these.

These should be the newer versions to the plastic clips:

Russell 644110 Russell Push-On EFI Fittings For Late Model EFI

Old Left, New Right

http://targamiata.com/images_lrg/img_8809.jpg

These should be the newer versions to the plastic clips:

Russell 644110 Russell Push-On EFI Fittings For Late Model EFI

Old Left, New Right

http://targamiata.com/images_lrg/img_8809.jpg

.

.The fittings I linked to will not work with the stock connection at the firewall. The flex fuel sensor is designed to work with GM push lock fittings.

Last edited by RENESISFD; 02-26-13 at 09:45 PM.

#460

Very cool swirl tank setup. Why two pumps (in the pot) instead of one? I know there's always the debate about, "well what happens when one pump fails?". Seems like its easier to build in a fail-safe with only 1 pump to worry about instead of two.

Sorry if you already answered that.

Sorry if you already answered that.

#461

Wastegate John

Thread Starter

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

The reason for 2 pumps is flow. I will be running e-85. I eventually plan to run more than 25psi for fun so I will need the fuel.

If one fails I have a fuel pressure sensor coupled with my ECU and engine protection parameters that will save my motor. AEM can do this as well . The 044 pumps also have built in check valves. The car will still run and still be capable of 400whp on just one pump.

. The 044 pumps also have built in check valves. The car will still run and still be capable of 400whp on just one pump.

There will also be one pump (044) in the tank feeding the swirl pot.

If one fails I have a fuel pressure sensor coupled with my ECU and engine protection parameters that will save my motor. AEM can do this as well

There will also be one pump (044) in the tank feeding the swirl pot.

#463

Wastegate John

Thread Starter

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

Imo, the large pumps are more prone to failing, I have seen a few threads of those high output pumps failing. Plus from what I understand they are LOUD because they are external. With my setup I can always make it home even if one goes bad.

I really think the concern of the dual pumps failing is a problem that should not be much of a concern with the modern ecus. Most of the time even the large single pumps seem to fail slowly and if not caught in time will eventually be unable to keep up the flow and could possibly cost a motor. But for this reason and a few others, that's why I spent a ton of money on a stainless fuel pressure sensor and had it wired into the Haltech.

I really think the concern of the dual pumps failing is a problem that should not be much of a concern with the modern ecus. Most of the time even the large single pumps seem to fail slowly and if not caught in time will eventually be unable to keep up the flow and could possibly cost a motor. But for this reason and a few others, that's why I spent a ton of money on a stainless fuel pressure sensor and had it wired into the Haltech.

#464

Wastegate John

Thread Starter

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

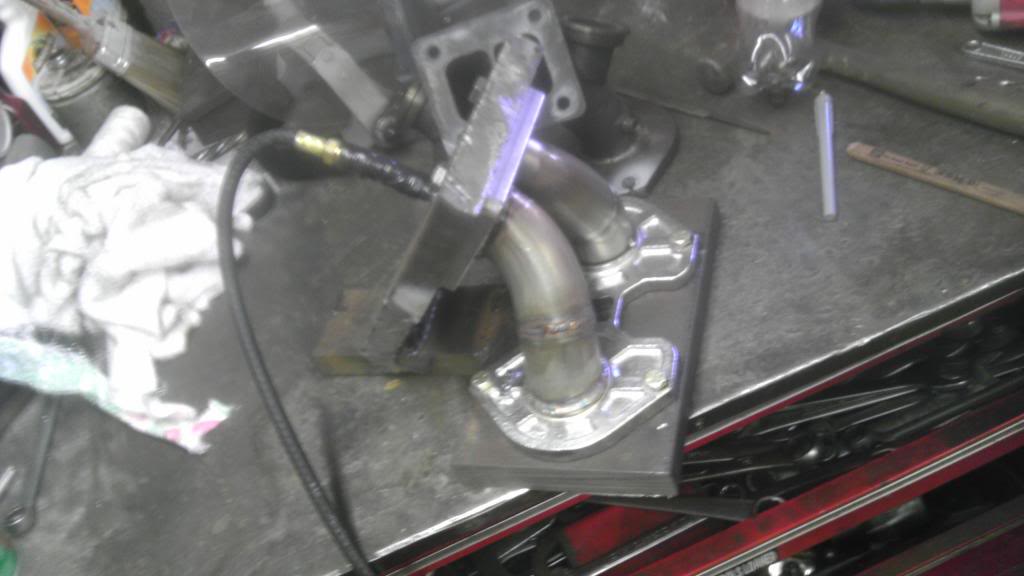

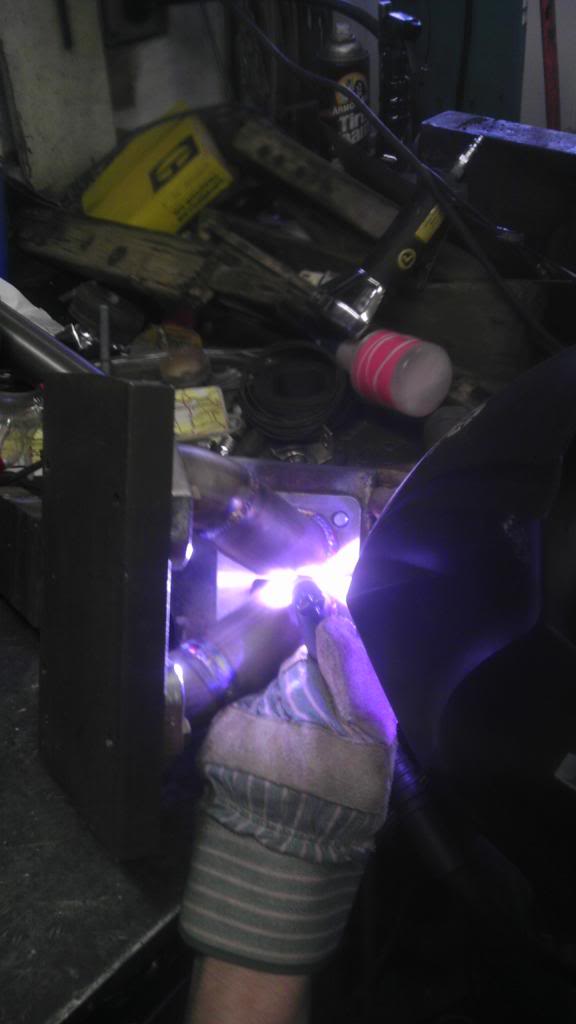

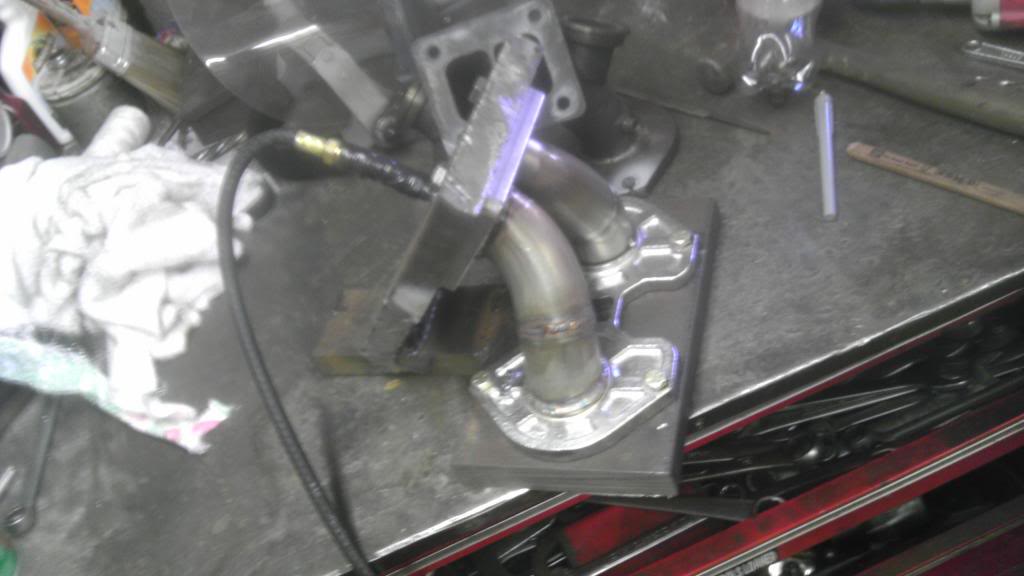

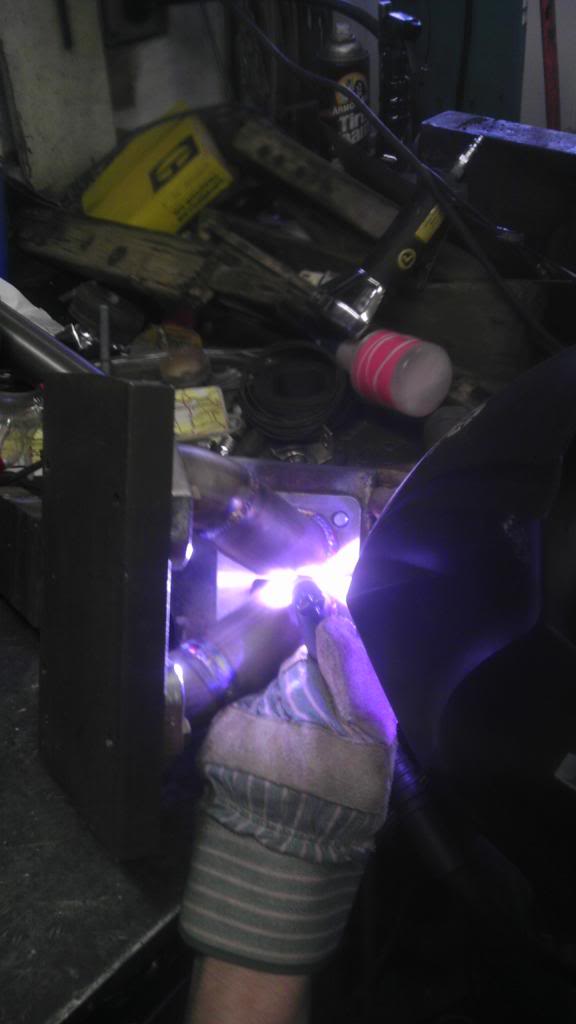

Made some progress this weekend.

Matt and I made the manifold.

As you can see, my wastegates wont do much good, I need to drill the holes for the wastegate dumps.

Matt and I made the manifold.

As you can see, my wastegates wont do much good, I need to drill the holes for the wastegate dumps.

#465

RX-7 Bad Ass

iTrader: (55)

All I know is you best hurry it up, DGRR is around the corner!

Lookin' good man!

Dale

Lookin' good man!

Dale

#468

Wastegate John

Thread Starter

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

I know it is coming up quick and I still have a TON to do.

I used stainless flanges this time as well as thicker tubing. The previous manifold only used stainless tubing and mild steel flanges. The design is slightly different with the exhaust entrance into the turbo flange being smoother and more direct. This was also a practice run making a manifold using a welding jig. We also backpurge welded the entire manifold.

Looks like we have a winner. Yes the manifold is full stainless, the previous one only had stainless tubing.

Last edited by RENESISFD; 03-11-13 at 11:41 AM.

#470

Wastegate John

Thread Starter

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

Well it provides for a MUCH cleaner weld, It is also stronger.

The previous manifold was not backpurged, I cleaned the sugaring out with a porting tool but also removed the base material causing the manifold to crack. I did not want the same problem again. Trust me, it is much better to backpurge it and not waste your time having to clean it up later. Do it right the first time, not like me. haha

The previous manifold was not backpurged, I cleaned the sugaring out with a porting tool but also removed the base material causing the manifold to crack. I did not want the same problem again. Trust me, it is much better to backpurge it and not waste your time having to clean it up later. Do it right the first time, not like me. haha

#475

Well it provides for a MUCH cleaner weld, It is also stronger.

The previous manifold was not backpurged, I cleaned the sugaring out with a porting tool but also removed the base material causing the manifold to crack. I did not want the same problem again. Trust me, it is much better to backpurge it and not waste your time having to clean it up later. Do it right the first time, not like me. haha

The previous manifold was not backpurged, I cleaned the sugaring out with a porting tool but also removed the base material causing the manifold to crack. I did not want the same problem again. Trust me, it is much better to backpurge it and not waste your time having to clean it up later. Do it right the first time, not like me. haha