94 Build... GT35R, RE Vmount and a whole lot more............ NOW WITH PISTONS!!

#451

I have a question....... e85 and your Push-loc lines? Is there going to be a problem with the hose and the e85 eating away at it? I wanted to run e85 at the track but the closest station is about 70 miles away. Either way I was still going to install the flex fuel sensor...but I have all push-loc lines as well and was wondering if I'd run into a problem with the hose specifically as some people have said it will degrade the hose and eventually eat through it. Haven't done much research on it......but maybe you have?

#452

I have a question....... e85 and your Push-loc lines? Is there going to be a problem with the hose and the e85 eating away at it? I wanted to run e85 at the track but the closest station is about 70 miles away. Either way I was still going to install the flex fuel sensor...but I have all push-loc lines as well and was wondering if I'd run into a problem with the hose specifically as some people have said it will degrade the hose and eventually eat through it. Haven't done much research on it......but maybe you have?

Also keep in mind that Teflon lined hoses generally require different fittings since the liner is easier to tear/damage. Maybe this is what was jacobcartmill was referring to with Oetiker clamps damaging hoses?

#453

I have a question....... e85 and your Push-loc lines? Is there going to be a problem with the hose and the e85 eating away at it? I wanted to run e85 at the track but the closest station is about 70 miles away. Either way I was still going to install the flex fuel sensor...but I have all push-loc lines as well and was wondering if I'd run into a problem with the hose specifically as some people have said it will degrade the hose and eventually eat through it. Haven't done much research on it......but maybe you have?

If I planned to run E85, I would utilize hard lines as much as possible, and use E85 approved flexible hose in the limited places it was needed.

I've read that the AQP is some of the toughest hose for E85 (for non-teflon), that it's rated for in tank usage and can handle just about every fluid. They even have a high pressure version for brake lines but I have read that on the Turbo Buick forums that E85 causes the lines to harden up and dry out in as little as one year. It's best to use a Teflon lined hose to be certain the lines can handle alcohol long-term. Now this also brings up the idea that you should also check your injector o-rings and FPR can handle ethanol.

Also keep in mind that Teflon lined hoses generally require different fittings since the liner is easier to tear/damage. Maybe this is what was jacobcartmill was referring to with Oetiker clamps damaging hoses?

Also keep in mind that Teflon lined hoses generally require different fittings since the liner is easier to tear/damage. Maybe this is what was jacobcartmill was referring to with Oetiker clamps damaging hoses?

One thing is for sure, that hose is tough as hell. It takes repeated strikes with a razor blade knife to open it up.

#454

UPDATE TIME

I got a good bid done this weekend.

Fire Sleeve

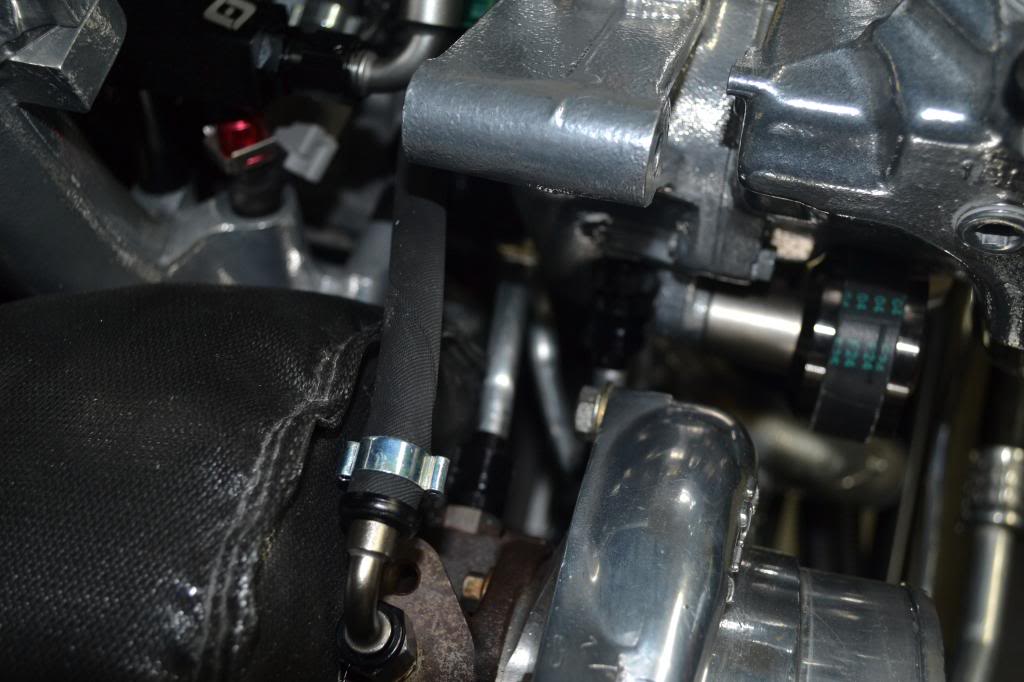

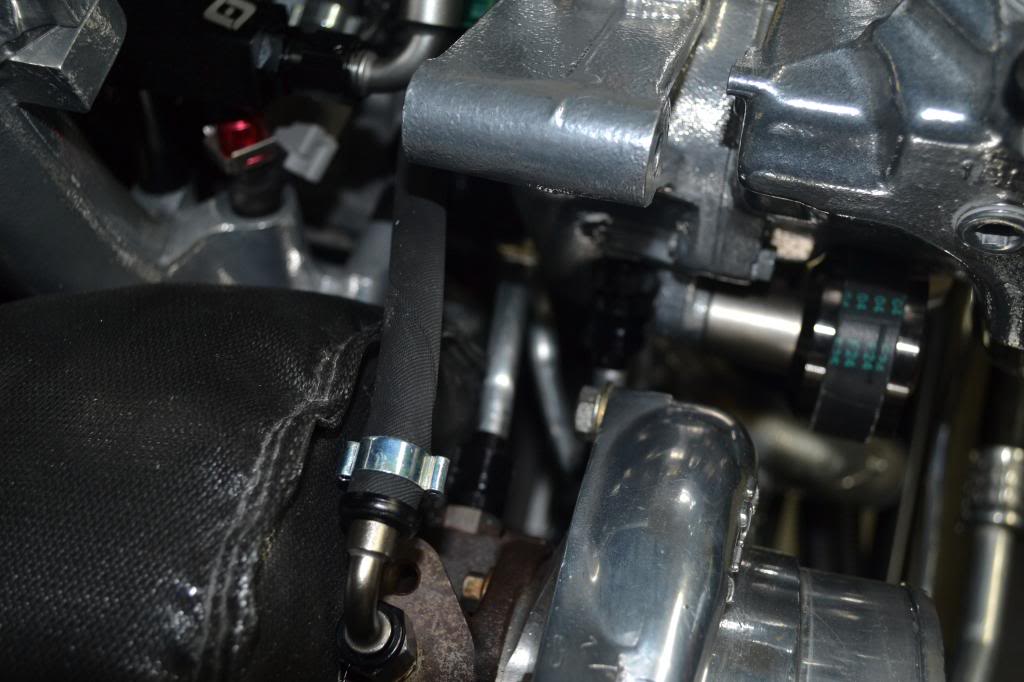

I used DEI fire sleeve on the harness as it goes over the downpipe. A no-brainer really. As suggested, I also coated the wastegate vacuum lines with Fire Flex hose to keep things happy in the oven.

Hard Lines

I decided awhile ago to utilize hard lines for the turbo coolant. After removing my standard coolant lines from my last setup, they were really crispy. Even while being covered with DEI sleeve, they just didn't like it. With this, I got my first go with flaring and installing hard lines. A little trial and error, but it turned out well.

Tank Installed, WI and MAC solenoid wiring tucked!!

Using the same method, I put the wiring through the fenderwell and kept everything hidden. I repolished my tank, and got it bolted up. Looking sharp.

With the installation of my tank, I also rewired my level sensor LED. When the tank gets to 1/3, the LED shines bright and lets me know. I obviously check the tank periodically, but it's nice insurance.

I also incorporated a boost switch. By killing power to the MAC solenoid, I run wastegate pressure, which will be 14lbs. Otherwise, it should push hard at 25lbs. I used the OEM fog light switch I ordered from Ray. I plan to get a small circular sticker in black and white. A little smiley face should do it.

PLX Integration

I got the gauge, pod, and integration board installed and rocking. I LOVE IT! The DM100 allows me to edit so much. Colors, backgrounds, and pretty much any useable metric the ECU sees. As the ECU pulls my EGTs, and AFRs from the Innovative products, it slaps it up for me to view. Very pleased with it. The Adaptronic integration board is pretty raw. With no actual case, I gave it a good wrap with packing tape. This allowed me to mount it to the PLX module, and run my serial data cables to the ECU. I admit, the ECU pocked is getting REALLY busy, but its all solid.

I got a good bid done this weekend.

Fire Sleeve

I used DEI fire sleeve on the harness as it goes over the downpipe. A no-brainer really. As suggested, I also coated the wastegate vacuum lines with Fire Flex hose to keep things happy in the oven.

Hard Lines

I decided awhile ago to utilize hard lines for the turbo coolant. After removing my standard coolant lines from my last setup, they were really crispy. Even while being covered with DEI sleeve, they just didn't like it. With this, I got my first go with flaring and installing hard lines. A little trial and error, but it turned out well.

Tank Installed, WI and MAC solenoid wiring tucked!!

Using the same method, I put the wiring through the fenderwell and kept everything hidden. I repolished my tank, and got it bolted up. Looking sharp.

With the installation of my tank, I also rewired my level sensor LED. When the tank gets to 1/3, the LED shines bright and lets me know. I obviously check the tank periodically, but it's nice insurance.

I also incorporated a boost switch. By killing power to the MAC solenoid, I run wastegate pressure, which will be 14lbs. Otherwise, it should push hard at 25lbs. I used the OEM fog light switch I ordered from Ray. I plan to get a small circular sticker in black and white. A little smiley face should do it.

PLX Integration

I got the gauge, pod, and integration board installed and rocking. I LOVE IT! The DM100 allows me to edit so much. Colors, backgrounds, and pretty much any useable metric the ECU sees. As the ECU pulls my EGTs, and AFRs from the Innovative products, it slaps it up for me to view. Very pleased with it. The Adaptronic integration board is pretty raw. With no actual case, I gave it a good wrap with packing tape. This allowed me to mount it to the PLX module, and run my serial data cables to the ECU. I admit, the ECU pocked is getting REALLY busy, but its all solid.

#455

BLING BLING

I've been biding my time on a few "looks" parts. So I bit the bullet and picked up some polished door sills and JDM Tails. Very pleased with both!!

Walbro E85 Pump

Feeling that the dual Stealth setup might be overkill, I opted for the Walbro E85 pump. Flowing more than the 400, it should supply my needs perfectly. I am on the interest list for the TNT baffle Group Buy, so it will be a nice compliment to the setup. It is noticeably louder than the Stealths, but the 4" exhaust will probably drown it out.

Tablet Mods

I ended up taking EVERYTHING apart and notching the rear frame of the double din. This allows me to access the power button with a small pin if the tablet dies. I don't drive the car a whole lot, so this will come in handy. The notch is barely noticeable and it really turned out better than I anticipated. I now just need to find or make a trim piece to fill in the gap with the outer skin and the screen. It works great!!

I've been biding my time on a few "looks" parts. So I bit the bullet and picked up some polished door sills and JDM Tails. Very pleased with both!!

Walbro E85 Pump

Feeling that the dual Stealth setup might be overkill, I opted for the Walbro E85 pump. Flowing more than the 400, it should supply my needs perfectly. I am on the interest list for the TNT baffle Group Buy, so it will be a nice compliment to the setup. It is noticeably louder than the Stealths, but the 4" exhaust will probably drown it out.

Tablet Mods

I ended up taking EVERYTHING apart and notching the rear frame of the double din. This allows me to access the power button with a small pin if the tablet dies. I don't drive the car a whole lot, so this will come in handy. The notch is barely noticeable and it really turned out better than I anticipated. I now just need to find or make a trim piece to fill in the gap with the outer skin and the screen. It works great!!

#461

If one cannot reroute the harness, I would at least put one of these between the downpipe & the coolant lines/wiring harness;

TurboSource 12 x 12 Inconel Sheet - Turblown Engineering

When does the car dyno? It has to be super close!

TurboSource 12 x 12 Inconel Sheet - Turblown Engineering

When does the car dyno? It has to be super close!

#462

If one cannot reroute the harness, I would at least put one of these between the downpipe & the coolant lines/wiring harness;

TurboSource 12 x 12 Inconel Sheet - Turblown Engineering

When does the car dyno? It has to be super close!

TurboSource 12 x 12 Inconel Sheet - Turblown Engineering

When does the car dyno? It has to be super close!

I re-sheduled my dyno day for Aug 23rd. This should give me plenty of time to get the Vmount installed, drive the car for a week or so, and work out any small issues. The CCBBQ is the 31st, so I am hoping to drive the car up. All of this is tentative of course. If I run into major issues, or have problems, then obviously I won't be ready. I'm trying to keep my timeline open and not rush anything.

#464

The 4 parameter view is excellent. I dialed in the color to perfectly match the OEM. I can see how two DM-100s would be advantageous. Fortunatly, I have Adaptive Tuner to display some of the critical stuff as well. Nonetheless, I am hooked.

#467

With all this talk of heat, I was thinking of a shield as well. I like the inconel stuff. Though pricey, it seems to be the very best option. For the meth tank I was using the OEM ABS shield. It's a little ugly for this revamp though. My plan was to use a nice uniform sheet of aluminum and have it ceramic coated. I may consider the inconel sheet there as well.

I re-sheduled my dyno day for Aug 23rd. This should give me plenty of time to get the Vmount installed, drive the car for a week or so, and work out any small issues. The CCBBQ is the 31st, so I am hoping to drive the car up. All of this is tentative of course. If I run into major issues, or have problems, then obviously I won't be ready. I'm trying to keep my timeline open and not rush anything.

I re-sheduled my dyno day for Aug 23rd. This should give me plenty of time to get the Vmount installed, drive the car for a week or so, and work out any small issues. The CCBBQ is the 31st, so I am hoping to drive the car up. All of this is tentative of course. If I run into major issues, or have problems, then obviously I won't be ready. I'm trying to keep my timeline open and not rush anything.

those inconel shiels are nice, but i'm not sure they're 10x the price nice.

we made this shield the night before the HPDE and we screwed up sticking the foil on and had to re-do it, so it looks terrible here, but here's what we did:

you can get a .063 12"x12" aluminum sheet on amazon for 14$ and make a few smaller shields for whatever (we used the whole sheet for the LIM shield thing pictured)

#468

^ Thanks!

I see what you mean. I ordered a few parts to get it sorted. I also moved the harness up between the two coolant outputs instead of on the bottom. It definitely gave it a little more space without "stretching" anything.

Nonetheless, my HeatShield parts to help combat heat are on their way...

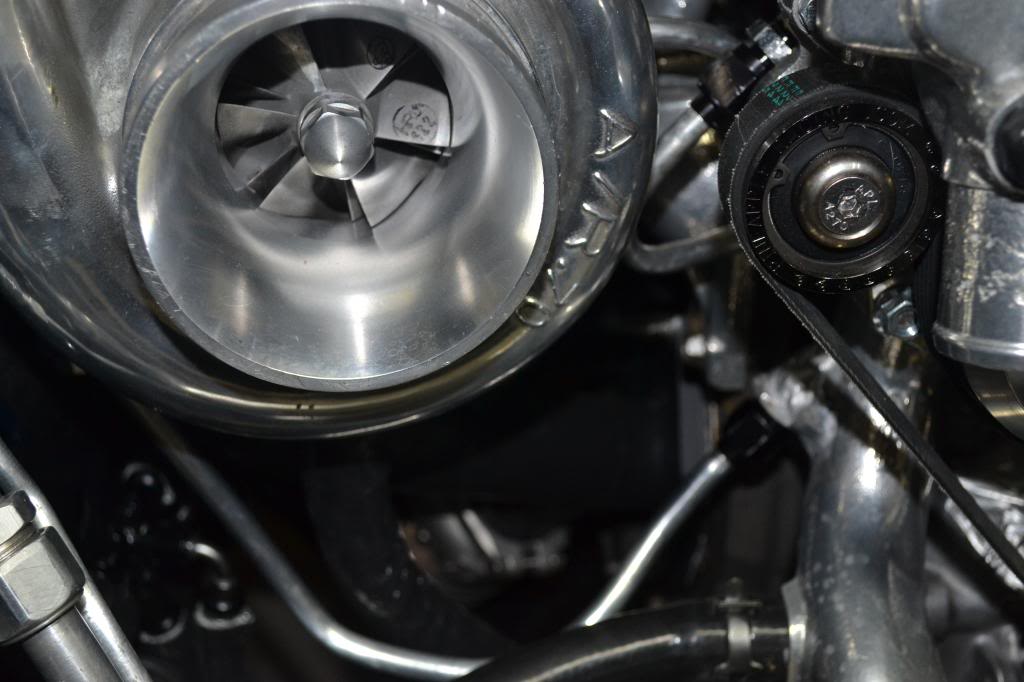

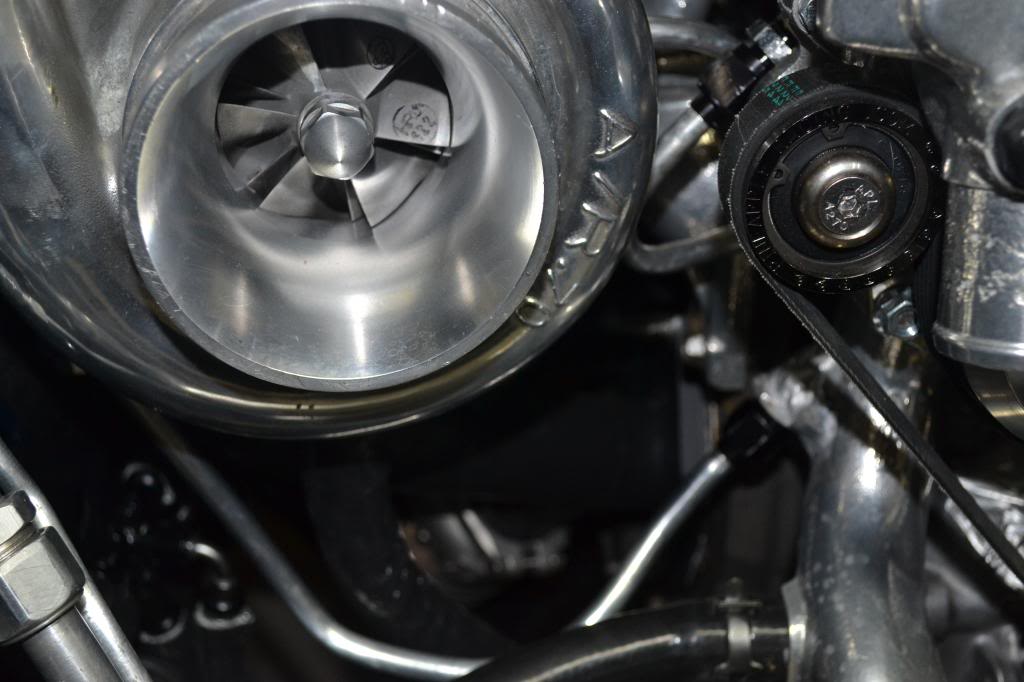

I plan to wrap the downpipe with this. 1800 degree constant, 2200 degree intermittent.

I will also use 2 of these 6" x 14" shields to guard the WI tank and harness.

And I'll use the sleeving for the coolant line.

Being that I like things to match, I had to get a different blanket

I see what you mean. I ordered a few parts to get it sorted. I also moved the harness up between the two coolant outputs instead of on the bottom. It definitely gave it a little more space without "stretching" anything.

Nonetheless, my HeatShield parts to help combat heat are on their way...

I plan to wrap the downpipe with this. 1800 degree constant, 2200 degree intermittent.

I will also use 2 of these 6" x 14" shields to guard the WI tank and harness.

And I'll use the sleeving for the coolant line.

Being that I like things to match, I had to get a different blanket

#469

very nice! i'm partial to the DEI stuff so far, as it's worked for me (and most is available on amazon prime, and i'm impatient)  but this stuff may be a little higher quality. i like. i'm a big advocate of heat shielding and protection, as our engine bays get hell hot, especially when you get a single turbo mounted up higher in the engine bay.

but this stuff may be a little higher quality. i like. i'm a big advocate of heat shielding and protection, as our engine bays get hell hot, especially when you get a single turbo mounted up higher in the engine bay.

i'm not really a fan of the turbo blankets now though, as i caught one on fire when i sprung an oil leak at the turbo oil feed line (eek!). i'm personally going to do the stainless steel cooking pot shield like TheAsset guy did. looks super slick and is high quality food grade stainless.

very nice though. i'm looking forward to some more updates.

but this stuff may be a little higher quality. i like. i'm a big advocate of heat shielding and protection, as our engine bays get hell hot, especially when you get a single turbo mounted up higher in the engine bay.

but this stuff may be a little higher quality. i like. i'm a big advocate of heat shielding and protection, as our engine bays get hell hot, especially when you get a single turbo mounted up higher in the engine bay.i'm not really a fan of the turbo blankets now though, as i caught one on fire when i sprung an oil leak at the turbo oil feed line (eek!). i'm personally going to do the stainless steel cooking pot shield like TheAsset guy did. looks super slick and is high quality food grade stainless.

very nice though. i'm looking forward to some more updates.

#470

very nice! i'm partial to the DEI stuff so far, as it's worked for me (and most is available on amazon prime, and i'm impatient)  but this stuff may be a little higher quality. i like. i'm a big advocate of heat shielding and protection, as our engine bays get hell hot, especially when you get a single turbo mounted up higher in the engine bay.

but this stuff may be a little higher quality. i like. i'm a big advocate of heat shielding and protection, as our engine bays get hell hot, especially when you get a single turbo mounted up higher in the engine bay.

i'm not really a fan of the turbo blankets now though, as i caught one on fire when i sprung an oil leak at the turbo oil feed line (eek!). i'm personally going to do the stainless steel cooking pot shield like TheAsset guy did. looks super slick and is high quality food grade stainless.

very nice though. i'm looking forward to some more updates.

but this stuff may be a little higher quality. i like. i'm a big advocate of heat shielding and protection, as our engine bays get hell hot, especially when you get a single turbo mounted up higher in the engine bay.

but this stuff may be a little higher quality. i like. i'm a big advocate of heat shielding and protection, as our engine bays get hell hot, especially when you get a single turbo mounted up higher in the engine bay.i'm not really a fan of the turbo blankets now though, as i caught one on fire when i sprung an oil leak at the turbo oil feed line (eek!). i'm personally going to do the stainless steel cooking pot shield like TheAsset guy did. looks super slick and is high quality food grade stainless.

very nice though. i'm looking forward to some more updates.

Blankets are always a big toss up. I have heard of them catching on fire, as you experienced, as well as killing turbos due to heat soak. Personally, I have ran a blanket on every turbo car or setup I have owned with no issues. I can always tell a difference in spool too. I was looking at Turblown's housing inconel shields and almost went that route though.

You aren't kidding! I did a little research on the iconel stuff. From what I see, it is pretty much the best heat shielding money can buy. Much this comes from its efficiency at extreme temperatures. For standard shielding locations, and lower down the exhaust track, I can definitely see it not being completely necessary. I opted for the 900 deg shields.

#471

Fixed the wheelhop

iTrader: (9)

Join Date: Nov 2001

Location: St. Petersburg, FL

Posts: 486

Likes: 0

Received 0 Likes

on

0 Posts

Awesome stuff man! It had been a while since I've seen your build thread, real quality work as always! And yeah, I'd double or triple wrap that harness next to the downpipe, and heat shield it.

#472

Just a few small things today.

- Reclocking midpipe flange. The big Greddy almost bolted up to the downpipe. The angle is about 1 1/8" off on one side. Instead of messing with the downpipe, I just had the midpipe modified. I should have it back in a few days. Then the exhaust will be completely done.

- Refitted oil cooler fittings to eliminate small oil drips. Added new washers and teflon tape. Not sure why I didn't use teflon the first time, but it is all good now.

- Changed the oil

- Added finishing tape to fire sleeve on wastegate lines

- Tightened turbo coolant lines down more. I was a little apprehensive, but after looking at the tube nut, sleeve, and flares, I can see that the fittings are meant to lock down completely. No weirdness, just nice and snug.

- Tested ECU Aux outputs

I ran into an issue with Aux 4. It is setup to activate my water injection solenoid. As of now, it doesn't do anything. Every other aux port works perfectly. My "spring pressure" switch I setup works perfect. Idle valve snaps, and fan relays snap.

I posted up a thread on the Adaptronic Forum on troubleshooting the Aux 4. Not a big deal. Worst case scenario is something is fried in the ECU.

- Reclocking midpipe flange. The big Greddy almost bolted up to the downpipe. The angle is about 1 1/8" off on one side. Instead of messing with the downpipe, I just had the midpipe modified. I should have it back in a few days. Then the exhaust will be completely done.

- Refitted oil cooler fittings to eliminate small oil drips. Added new washers and teflon tape. Not sure why I didn't use teflon the first time, but it is all good now.

- Changed the oil

- Added finishing tape to fire sleeve on wastegate lines

- Tightened turbo coolant lines down more. I was a little apprehensive, but after looking at the tube nut, sleeve, and flares, I can see that the fittings are meant to lock down completely. No weirdness, just nice and snug.

- Tested ECU Aux outputs

I ran into an issue with Aux 4. It is setup to activate my water injection solenoid. As of now, it doesn't do anything. Every other aux port works perfectly. My "spring pressure" switch I setup works perfect. Idle valve snaps, and fan relays snap.

I posted up a thread on the Adaptronic Forum on troubleshooting the Aux 4. Not a big deal. Worst case scenario is something is fried in the ECU.

#474

I sure hope so man. The car has really deserved this. After making the decision to repaint it, I knew that it was time to really bring it up to par. Though I never had the intentions to get a car in a feature magazine, I definitely put it in my mind as a possibility.