Weird AC problem

#1

Make an assessment...

Thread Starter

iTrader: (3)

Weird AC problem

I reinstalled my AC last year and it worked great. Now it's not working but I figured it just had a leak, so I jumped the connector for the refrigerant pressure switch and turned AC on and it worked. I turned the AC off and removed the jumper and the compressor kicked on again. Now it will only shut off if I keep the jumper in the connector. I did this a few years ago and it worked and I never had any issues like this. If I connect the pressure switch again, the compressor stays on whether the AC is turned on or not. The only time it works normally is if I have the refrigerant pressure switch connector jumped. As soon as I turn on the car, the compressor is on unless I have the jumper in the pressure switch connector. This makes no sense to me since closing the circuit (the switch seeing refrigerant pressure) should be turning the compressor on instead of off. I am completely lost on this one, does anyone have any ideas? It worked fine last fall when I last used AC, and assuming it's low on refrigerant, it was working fine up until this as well.

In short...

It works normally only if I have a jumper in the refrigerant pressure switch connector.

The compressor is on constantly if everything is connected like it should be, OR if the pressure switch wiring isn't connected at all.

In short...

It works normally only if I have a jumper in the refrigerant pressure switch connector.

The compressor is on constantly if everything is connected like it should be, OR if the pressure switch wiring isn't connected at all.

#3

RX-7 Bad Ass

iTrader: (55)

Sounds like an electrical issue. The compressor's electrical connector gets 12v to engage the compressor, I would go through the components and see if you have a wiring problem or one of the sensors in the system is flaky.

This isn't common as far as I know, you'll need to get the shop manual out and step through the troubleshooting on the electrical side.

Most likely the mechanical parts of the Ac system are OK.

Dale

This isn't common as far as I know, you'll need to get the shop manual out and step through the troubleshooting on the electrical side.

Most likely the mechanical parts of the Ac system are OK.

Dale

#4

Make an assessment...

Thread Starter

iTrader: (3)

Sounds like an electrical issue. The compressor's electrical connector gets 12v to engage the compressor, I would go through the components and see if you have a wiring problem or one of the sensors in the system is flaky.

This isn't common as far as I know, you'll need to get the shop manual out and step through the troubleshooting on the electrical side.

Most likely the mechanical parts of the Ac system are OK.

Dale

This isn't common as far as I know, you'll need to get the shop manual out and step through the troubleshooting on the electrical side.

Most likely the mechanical parts of the Ac system are OK.

Dale

#5

Racecar - Formula 2000

I'm no expert on this particular system, but there are usually a few relays that enable the compressor. I'd start looking at any of those to see if one is stuck in the "on" (triggers compressor) position permanently. Since jumping the pressure switch makes it work properly, I'd start in that circuit.

#6

Make an assessment...

Thread Starter

iTrader: (3)

I'm no expert on this particular system, but there are usually a few relays that enable the compressor. I'd start looking at any of those to see if one is stuck in the "on" (triggers compressor) position permanently. Since jumping the pressure switch makes it work properly, I'd start in that circuit.

Since jumping the connector makes the system work properly, and there is nothing between that connector and the compressor, I would think the problem lies somewhere in the wiring there, but who the hell knows lol.

#7

Racecar - Formula 2000

There is the AC relay in the block of relays at the front of the car, and I'm going to check that one just to make sure, but it's before the connector that I jumped so I'm not sure if it would make a difference. But I'm going to check it anyway.

Since jumping the connector makes the system work properly, and there is nothing between that connector and the compressor, I would think the problem lies somewhere in the wiring there, but who the hell knows lol.

Since jumping the connector makes the system work properly, and there is nothing between that connector and the compressor, I would think the problem lies somewhere in the wiring there, but who the hell knows lol.

Last edited by DaveW; 04-15-20 at 05:35 PM. Reason: added details

Trending Topics

#8

Make an assessment...

Thread Starter

iTrader: (3)

I tested the relay and it's opening and closing with power. I did notice that the relay is activating right away when the car turns on, and clicks every time I jump the pressure connector, but all that makes sense.

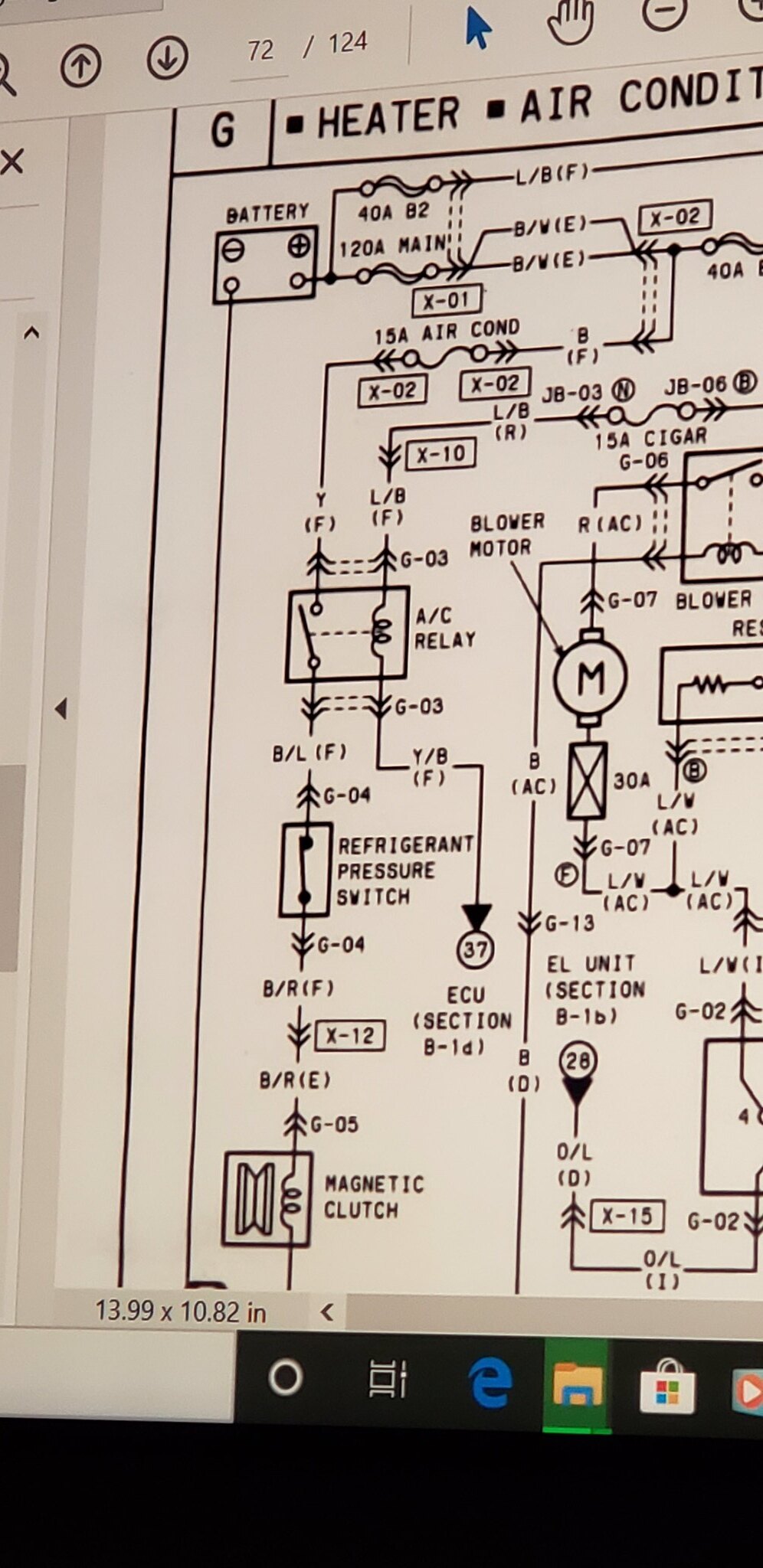

I did some continuity checks and I'm even more confused now lol. According to the wiring diagram, power goes through the AC relay (once it's closed) to the pressure switch (G-04), then through X-12 (one of the two gray connectors near the diagnostic box) and to the magnetic clutch. I checked between X-12 and the connector that goes to the compressor harness, and it had continuity. I checked from the relay to the pressure switch connector and had continuity the first time, and none when I checked a few minutes later. I checked between the pressure switch connector and X-12 and had no continuity there either. But obviously it has continuity once the car is running or the compressor wouldn't be kicking on.

A couple years ago before my AC was working I was checking things that Chris Ludwig told me to try (he built my harness and installed the ECU) and I had to ground one of the wires coming out of the ECU and it would turn on the compressor, so I'm wondering if maybe I grounded that wire somehow when I made the mount for the ECU recently and it's automatically engaging the compressor clutch. I'm also wondering if mice chewed on the starter harness. I just can't figure out how power is getting through the open pressure switch connector, that makes me think it has to be past that in the starter harness. However, if that was the case, jumping the pressure switch connector wouldn't make it operate properly again, I wouldn't think.

I called a local friend and fellow FD owner who is an electrical engineer and he's going to look into it too.

I was also having an issue with the battery not charging and thought the alternator was going bad, but upon further inspection I found one of the wires to the alternator connector had broken. I doubt this is related to the AC problem, but that would be really awesome if it was LOL.

I did some continuity checks and I'm even more confused now lol. According to the wiring diagram, power goes through the AC relay (once it's closed) to the pressure switch (G-04), then through X-12 (one of the two gray connectors near the diagnostic box) and to the magnetic clutch. I checked between X-12 and the connector that goes to the compressor harness, and it had continuity. I checked from the relay to the pressure switch connector and had continuity the first time, and none when I checked a few minutes later. I checked between the pressure switch connector and X-12 and had no continuity there either. But obviously it has continuity once the car is running or the compressor wouldn't be kicking on.

A couple years ago before my AC was working I was checking things that Chris Ludwig told me to try (he built my harness and installed the ECU) and I had to ground one of the wires coming out of the ECU and it would turn on the compressor, so I'm wondering if maybe I grounded that wire somehow when I made the mount for the ECU recently and it's automatically engaging the compressor clutch. I'm also wondering if mice chewed on the starter harness. I just can't figure out how power is getting through the open pressure switch connector, that makes me think it has to be past that in the starter harness. However, if that was the case, jumping the pressure switch connector wouldn't make it operate properly again, I wouldn't think.

I called a local friend and fellow FD owner who is an electrical engineer and he's going to look into it too.

I was also having an issue with the battery not charging and thought the alternator was going bad, but upon further inspection I found one of the wires to the alternator connector had broken. I doubt this is related to the AC problem, but that would be really awesome if it was LOL.

#9

Make an assessment...

Thread Starter

iTrader: (3)

I did a bit more troubleshooting tonight. The relay is clicking as soon as power is applied, so I checked it out and it is getting a ground as soon as the car is running, and the ECU is what supplies that ground. With the key off, the ground wire of the AC relay is reading continuity to ground, but there is about 139 ohms(?) of resistance, and with the key on it gets about 230 ohms of resistance. But when I check terminal 1L at the ECU connector, it doesn't show that it's grounding at all with the key either off or turned to accessory. I haven't tried it with the car on yet because it's getting late and I don't wanna be a dick to the neighbors.

Either way, I still can't see how any of that matters because there shouldn't be any way for the compressor to get power since the circuit is open at the pressure switch connector. Unless the wires are burned together somewhere in the bundle and it's completing the circuit that way, in addition to the AC relay getting ground right away.

Either way, I still can't see how any of that matters because there shouldn't be any way for the compressor to get power since the circuit is open at the pressure switch connector. Unless the wires are burned together somewhere in the bundle and it's completing the circuit that way, in addition to the AC relay getting ground right away.

Last edited by speedjunkie; 04-23-20 at 01:13 AM.

#10

Either way, I still can't see how any of that matters because there shouldn't be any way for the compressor to get power since the circuit is open at the pressure switch connector. Unless the wires are burned together somewhere in the bundle and it's completing the circuit that way, in addition to the AC relay getting ground right away.

The following users liked this post:

alexdimen (04-23-20)

#11

Good call on the switch logic.

What are your high/low side Freon pressures? Static and running? Static should be a bit above ambient temp.

Since the compressor stays on and requires 12V to turn off... Could be a mechanical problem with the clutch? Can you post up some pics of the compressor and switch? How about a video of the compressor acting weird?

What are your high/low side Freon pressures? Static and running? Static should be a bit above ambient temp.

Since the compressor stays on and requires 12V to turn off... Could be a mechanical problem with the clutch? Can you post up some pics of the compressor and switch? How about a video of the compressor acting weird?

Last edited by alexdimen; 04-23-20 at 08:36 AM.

#12

Make an assessment...

Thread Starter

iTrader: (3)

I'd have to check the FD wiring diagram, but in the FC that pressure switch is normally closed, not NO, so it would pass current until the pressure in the system falls below its set pressure. That switch is there to prevent the compressor from running in the event that too much of the refrigerant (and oil charge with it) leaks out. On newer cars that run R134, they typically use a NC "trinary" pressure switch that cuts power if the pressure gets too low OR too high.

The 93 diagram page Z-68

94 diagram page Z-68

94 diagram page Z-70

I checked the pressure switch and it's reading open right now, which obviously would indicate a low charge, and it also explains why it doesn't matter if the connector is connected to it or not since it will be an open circuit either way. But what it doesn't explain is why the compressor still kicks on when there is supposed to be no completed circuit for it to receive power AND that it does so without the AC being turned on. When I was troubleshooting a few years ago and again a few days ago before this issue, I jumped the connector for the switch to show it as normally closed and that's when the AC would work properly, and even now it works properly when the connector is jumped. I would think maybe something happened with the ECU and it's just providing ground for the relay automatically for some reason, but that still doesn't explain how power is getting to the compressor clutch with an opening in the circuit. The only thing I can conclude is there are some bad wires in the front harness.

On the other hand, it looks like if I charge the system again, the compressor should turn off until I want it on haha. But if it loses that charge, the compressor would kick on no matter what.

Good call on the switch logic.

What are your high/low side Freon pressures? Static and running? Static should be a bit above ambient temp.

Since the compressor stays on and requires 12V to turn off... Could be a mechanical problem with the clutch? Can you post up some pics of the compressor and switch? How about a video of the compressor acting weird?

What are your high/low side Freon pressures? Static and running? Static should be a bit above ambient temp.

Since the compressor stays on and requires 12V to turn off... Could be a mechanical problem with the clutch? Can you post up some pics of the compressor and switch? How about a video of the compressor acting weird?

That's possible I guess. I wouldn't rule out anything at this point. I'll post those pics and video tomorrow night or this weekend.

Thank you all for your help so far!

#13

If your compressor is spinning with no power to the clutch wire I would think it's gotta be a mechanical failure or trash in the clutch. Just doesn't make any sense that it could spin without 12V to it.

I would be wary of running the compressor flat out. You want the compressor to be able to cycle based on that low pressure switch and the thermoswitch in the evaporator box. The system uses those switches to regulate temperature and pressure.

Let us know what you find.

I would be wary of running the compressor flat out. You want the compressor to be able to cycle based on that low pressure switch and the thermoswitch in the evaporator box. The system uses those switches to regulate temperature and pressure.

Let us know what you find.

#14

#15

Make an assessment...

Thread Starter

iTrader: (3)

If your compressor is spinning with no power to the clutch wire I would think it's gotta be a mechanical failure or trash in the clutch. Just doesn't make any sense that it could spin without 12V to it.

I would be wary of running the compressor flat out. You want the compressor to be able to cycle based on that low pressure switch and the thermoswitch in the evaporator box. The system uses those switches to regulate temperature and pressure.

Let us know what you find.

I would be wary of running the compressor flat out. You want the compressor to be able to cycle based on that low pressure switch and the thermoswitch in the evaporator box. The system uses those switches to regulate temperature and pressure.

Let us know what you find.

I don't ever plan to run the compressor flat out. I really want all this to work normally, and presumably it would work normally if the system was charged with the proper amount so the pressure switch would close, as indicated by it working normally when I jump the pressure switch connector. However, since the clutch engages without jumping the connector, that would still be a problem I want fixed before charging the system and calling it good.

I'm planning on hooking up the gauges this afternoon and see what the pressures look like.

Yup, Speedjunkie should just disconnect the compressor's electrical connector while it's running - if the compressor clutch doesn't disengage itself, it's a verified mechanical problem. I experienced this same problem with a remanufactured compressor that I got to restore my FC's A/C. It worked normally for about a week after installing it, then the clutch just mechanically locked up somehow and ran the compressor all the time without any power applied. Compressor vendor let me return it under warranty, and the replacement has been working fine for 3 years now.

#16

Make an assessment...

Thread Starter

iTrader: (3)

Ok here are some videos. Sorry, I was filming and trying to do other things. I have absolutely nothing in my system, reading zero on both gauges. And I think part of the issue might be coming from the ECU, because terminal 1L on the stock ECU connector is reading as grounded, although it has about 32 ohms resistance. But that was with the AC relay disconnected. I don't read ground on that wire unless the car is running so I guess that wire isn't grounding out like I previously thought was a possibility.

That still doesn't answer how the clutch is getting power. While the car was running and the clutch was engaged, I unplugged the wire going to the compressor and it disengaged. So I guess it's not a mechanical problem with that.

I just tried something else too. I'm jumping the pressure switch with a piece of safety wire. I touched that safety wire to the chassis while it was in the connector and the clutch engaged again. I'm not sure what that tells me lol, but I figured I'd try it to see what happened. I think I'm gonna pull the front harness out a bit and unwrap it and check for damage.

That still doesn't answer how the clutch is getting power. While the car was running and the clutch was engaged, I unplugged the wire going to the compressor and it disengaged. So I guess it's not a mechanical problem with that.

I just tried something else too. I'm jumping the pressure switch with a piece of safety wire. I touched that safety wire to the chassis while it was in the connector and the clutch engaged again. I'm not sure what that tells me lol, but I figured I'd try it to see what happened. I think I'm gonna pull the front harness out a bit and unwrap it and check for damage.

#17

Make an assessment...

Thread Starter

iTrader: (3)

I was just talking with one of my buddies that also has a 94 (and apparently knows the wiring much better than I do) and he said that according to the 94 wiring diagram, the compressor would get 12v any time the ECU provides a ground at 1L, which would make sense in my situation. So maybe my only issue is the ECU providing that ground when it's not supposed to. I kinda hope that's the case, but I'm also afraid that I may have messed up a very expensive ECU lol. But if that's the issue, at least I would know what it was.

#18

So, from video 1 I would say everything is working as normal. Is it possible you had a misunderstanding of the pressure switch?

- The ECU is providing a ground for the relay thru pin 1L when you hit the AC switch. Good.

- By jumping the pressure switch you are completing the circuit as though you had a full freon charge. (which you don't, but you are simulating with the jump). Good.

- The cltuch engages and compressor turns with relay on and pressure switch jumped. Good.

Am I missing something? Maybe I am misunderstanding...

Video 2 and 3 may just be the result of the ECU bumping idle up for AC.

Video 4 - Bingo. Well, now you have to find the leak. I'm not sure how 152 compares to 134 refrigerant, but I had a hard time keeping 134 in my r12 car. The main culprit was the port adapter fittings. I could not find a set that sealed well, though I was willing to pay. I eventually ditched the adapters and just bought some R12 off ebay. I won't get into the fiasco of trying to get ES12 junk to work (spoiler: it doesn't). TLDR; check or ditch your 134 port adapters if you have them

- The ECU is providing a ground for the relay thru pin 1L when you hit the AC switch. Good.

- By jumping the pressure switch you are completing the circuit as though you had a full freon charge. (which you don't, but you are simulating with the jump). Good.

- The cltuch engages and compressor turns with relay on and pressure switch jumped. Good.

Am I missing something? Maybe I am misunderstanding...

Video 2 and 3 may just be the result of the ECU bumping idle up for AC.

Video 4 - Bingo. Well, now you have to find the leak. I'm not sure how 152 compares to 134 refrigerant, but I had a hard time keeping 134 in my r12 car. The main culprit was the port adapter fittings. I could not find a set that sealed well, though I was willing to pay. I eventually ditched the adapters and just bought some R12 off ebay. I won't get into the fiasco of trying to get ES12 junk to work (spoiler: it doesn't). TLDR; check or ditch your 134 port adapters if you have them

#19

So, from video 1 I would say everything is working as normal. Is it possible you had a misunderstanding of the pressure switch?

- The ECU is providing a ground for the relay thru pin 1L when you hit the AC switch. Good.

- By jumping the pressure switch you are completing the circuit as though you had a full freon charge. (which you don't, but you are simulating with the jump). Good.

- The cltuch engages and compressor turns with relay on and pressure switch jumped. Good.

Am I missing something? Maybe I am misunderstanding...

Video 2 and 3 may just be the result of the ECU bumping idle up for AC.

Video 4 - Bingo. Well, now you have to find the leak. I'm not sure how 152 compares to 134 refrigerant, but I had a hard time keeping 134 in my r12 car. The main culprit was the port adapter fittings. I could not find a set that sealed well, though I was willing to pay. I eventually ditched the adapters and just bought some R12 off ebay. I won't get into the fiasco of trying to get ES12 junk to work (spoiler: it doesn't). TLDR; check or ditch your 134 port adapters if you have them

- The ECU is providing a ground for the relay thru pin 1L when you hit the AC switch. Good.

- By jumping the pressure switch you are completing the circuit as though you had a full freon charge. (which you don't, but you are simulating with the jump). Good.

- The cltuch engages and compressor turns with relay on and pressure switch jumped. Good.

Am I missing something? Maybe I am misunderstanding...

Video 2 and 3 may just be the result of the ECU bumping idle up for AC.

Video 4 - Bingo. Well, now you have to find the leak. I'm not sure how 152 compares to 134 refrigerant, but I had a hard time keeping 134 in my r12 car. The main culprit was the port adapter fittings. I could not find a set that sealed well, though I was willing to pay. I eventually ditched the adapters and just bought some R12 off ebay. I won't get into the fiasco of trying to get ES12 junk to work (spoiler: it doesn't). TLDR; check or ditch your 134 port adapters if you have them

When I restored the A/C my FC, which is running the R152 duster gas, I changed out all the O-rings to the green HBNR types, new receiver/dryer, new expansion valve and new R134 type service fittings, but I didn't bother swapping out the 30+ year old hoses. Depending on how often I use the A/C, I'll typically get a full summer season out of it before it needs a recharge. Tried hunting down for leaks using UV dye & black lights, and even rented one of those expensive electronic leak detectors - had zero luck finding any leaks, even at the service fittings, so I'm convinced the stuff is just permeating out of the hoses over time. Since duster gas is so cheap, I just evacuate the system & do a full charge each year. If I can find a local shop that can crimp A/C hoses for a reasonable fee, I might make a set of new hoses to see if it solves the problem.

#20

Interesting. I thought 152 was supposed to be the perfect substitute!

I think the FD actually has the new type barrier hoses. Even the 93. It says something to that effect in the 93 service manual IIRC. I seem to remember a diagram with hose construction showing the barrier. Personally it was the fitting adapters for me. Could be hoses for others.

I think the FD actually has the new type barrier hoses. Even the 93. It says something to that effect in the 93 service manual IIRC. I seem to remember a diagram with hose construction showing the barrier. Personally it was the fitting adapters for me. Could be hoses for others.

#21

Make an assessment...

Thread Starter

iTrader: (3)

So, from video 1 I would say everything is working as normal. Is it possible you had a misunderstanding of the pressure switch?

- The ECU is providing a ground for the relay thru pin 1L when you hit the AC switch. Good.

- By jumping the pressure switch you are completing the circuit as though you had a full freon charge. (which you don't, but you are simulating with the jump). Good.

- The cltuch engages and compressor turns with relay on and pressure switch jumped. Good.

Am I missing something? Maybe I am misunderstanding...

Video 2 and 3 may just be the result of the ECU bumping idle up for AC.

Video 4 - Bingo. Well, now you have to find the leak. I'm not sure how 152 compares to 134 refrigerant, but I had a hard time keeping 134 in my r12 car. The main culprit was the port adapter fittings. I could not find a set that sealed well, though I was willing to pay. I eventually ditched the adapters and just bought some R12 off ebay. I won't get into the fiasco of trying to get ES12 junk to work (spoiler: it doesn't). TLDR; check or ditch your 134 port adapters if you have them

- The ECU is providing a ground for the relay thru pin 1L when you hit the AC switch. Good.

- By jumping the pressure switch you are completing the circuit as though you had a full freon charge. (which you don't, but you are simulating with the jump). Good.

- The cltuch engages and compressor turns with relay on and pressure switch jumped. Good.

Am I missing something? Maybe I am misunderstanding...

Video 2 and 3 may just be the result of the ECU bumping idle up for AC.

Video 4 - Bingo. Well, now you have to find the leak. I'm not sure how 152 compares to 134 refrigerant, but I had a hard time keeping 134 in my r12 car. The main culprit was the port adapter fittings. I could not find a set that sealed well, though I was willing to pay. I eventually ditched the adapters and just bought some R12 off ebay. I won't get into the fiasco of trying to get ES12 junk to work (spoiler: it doesn't). TLDR; check or ditch your 134 port adapters if you have them

With the pressure switch jumped, it works as normal though, yes. You are correct on that.

The port adapter fittings you're talking about is to adapt the lines from R12 to R134a so it can be charged? Interesting. I guess I'll remove them when I'm finished charging the system. Thanks!

R134 and R152 molecules are smaller than R12 molecules. The difference is significant enough such that the seals and hoses in R134 systems were changed over to different materials to help seal & contain the refrigerant better. So for an R134 system (and R152/duster gas if that's what you're using) you should swap out all your O-rings and seals to the HBNR (green) types, and use a "barrier" hose that is designed for the stuff as well. Rarely does any one doing R12 to R134 conversions bother to do this, but it's the physics of the problem.

When I restored the A/C my FC, which is running the R152 duster gas, I changed out all the O-rings to the green HBNR types, new receiver/dryer, new expansion valve and new R134 type service fittings, but I didn't bother swapping out the 30+ year old hoses. Depending on how often I use the A/C, I'll typically get a full summer season out of it before it needs a recharge. Tried hunting down for leaks using UV dye & black lights, and even rented one of those expensive electronic leak detectors - had zero luck finding any leaks, even at the service fittings, so I'm convinced the stuff is just permeating out of the hoses over time. Since duster gas is so cheap, I just evacuate the system & do a full charge each year. If I can find a local shop that can crimp A/C hoses for a reasonable fee, I might make a set of new hoses to see if it solves the problem.

When I restored the A/C my FC, which is running the R152 duster gas, I changed out all the O-rings to the green HBNR types, new receiver/dryer, new expansion valve and new R134 type service fittings, but I didn't bother swapping out the 30+ year old hoses. Depending on how often I use the A/C, I'll typically get a full summer season out of it before it needs a recharge. Tried hunting down for leaks using UV dye & black lights, and even rented one of those expensive electronic leak detectors - had zero luck finding any leaks, even at the service fittings, so I'm convinced the stuff is just permeating out of the hoses over time. Since duster gas is so cheap, I just evacuate the system & do a full charge each year. If I can find a local shop that can crimp A/C hoses for a reasonable fee, I might make a set of new hoses to see if it solves the problem.

I swapped over to all new o-rings, the green ones. Although, hopefully they're all sealing well enough. I used what looked to be the proper size and offered a little resistance when putting them together so I would know the o-ring was making contact with both sides of the connection and sealing.

I did swap the soft parts of the lines too. For the compressor to condenser line, I had to since I had to make that line. The line going across the bay from the evaporator to the compressor I did just because I wanted to make sure it was good and would work with the newer refrigerants. Here are the two types of hose that I got.

https://www.autoacfittings.com/13-32...-Ft-AC-08R.htm (#8 reduced barrier hose, for from the compressor to the condenser)

https://www.autoacfittings.com/1-2-G...-Ft-AC-10R.htm (#10 reduced barrier hose, for coming from the evaporator to the compressor)

This link has more info for the hose I used, says it's good for R134a. So hopefully that isn't it.

https://www.continental-industry.com...E-Barrier-4890

And here is the link to my thread about the retrofit if there is any other info you wanna see.

https://www.rx7club.com/3rd-generati...-vmic-1137819/

I used R134a ester oil with dye so I'm planning to check for leaks this time. I would think there has to be something pretty substantial, or maybe the hoses I got weren't suited for R152. That would really suck lol. I bought a crimp kit because I couldn't find anyone to crimp them for me, even the guy that did them last time. However, you'd still need the parts to crimp and to get them welded onto the fittings you have, assuming the FC AC lines are similar to the FD's. It would probably still be worth doing, even though duster is so cheap. At least you wouldn't have to do it every year. But I might have to also.

The connection at the condenser on the line from the compressor MIGHT be the culprit, but I'm not sure about that either. You can see the pics at the bottom of the first post in my thread. The inlet in the condenser is squared off at the bottom, as is the RX-8 fitting. But the fitting I'm using is angled at the bottom. However, I would imagine the hole is still lined up for the most part and the o-ring I used fit pretty tight, so I don't think it would be an issue, but it is something I wondered about. It's the only line I could find that would work though, the way the line was shaped.

When you do your full recharge each year, I'm guessing you pull a vacuum and add all the oil you need again, including the oil in the compressor?

Interesting. I thought 152 was supposed to be the perfect substitute!

I think the FD actually has the new type barrier hoses. Even the 93. It says something to that effect in the 93 service manual IIRC. I seem to remember a diagram with hose construction showing the barrier. Personally it was the fitting adapters for me. Could be hoses for others.

I think the FD actually has the new type barrier hoses. Even the 93. It says something to that effect in the 93 service manual IIRC. I seem to remember a diagram with hose construction showing the barrier. Personally it was the fitting adapters for me. Could be hoses for others.

I swapped the hoses just in case. I assumed they were only good for R12.

Last edited by speedjunkie; 04-28-20 at 12:14 AM.

#22

I swapped over to all new o-rings, the green ones. Although, hopefully they're all sealing well enough. I used what looked to be the proper size and offered a little resistance when putting them together so I would know the o-ring was making contact with both sides of the connection and sealing.

I did swap the soft parts of the lines too. For the compressor to condenser line, I had to since I had to make that line. The line going across the bay from the evaporator to the compressor I did just because I wanted to make sure it was good and would work with the newer refrigerants. Here are the two types of hose that I got.

https://www.autoacfittings.com/13-32...-Ft-AC-08R.htm (#8 reduced barrier hose, for from the compressor to the condenser)

https://www.autoacfittings.com/1-2-G...-Ft-AC-10R.htm (#10 reduced barrier hose, for coming from the evaporator to the compressor)

This link has more info for the hose I used, says it's good for R134a. So hopefully that isn't it.

https://www.continental-industry.com...E-Barrier-4890

And here is the link to my thread about the retrofit if there is any other info you wanna see.

https://www.rx7club.com/3rd-generati...-vmic-1137819/

I used R134a ester oil with dye so I'm planning to check for leaks this time. I would think there has to be something pretty substantial, or maybe the hoses I got weren't suited for R152. That would really suck lol. I bought a crimp kit because I couldn't find anyone to crimp them for me, even the guy that did them last time. However, you'd still need the parts to crimp and to get them welded onto the fittings you have, assuming the FC AC lines are similar to the FD's. It would probably still be worth doing, even though duster is so cheap. At least you wouldn't have to do it every year. But I might have to also.

The connection at the condenser on the line from the compressor MIGHT be the culprit, but I'm not sure about that either. You can see the pics at the bottom of the first post in my thread. The inlet in the condenser is squared off at the bottom, as is the RX-8 fitting. But the fitting I'm using is angled at the bottom. However, I would imagine the hole is still lined up for the most part and the o-ring I used fit pretty tight, so I don't think it would be an issue, but it is something I wondered about. It's the only line I could find that would work though, the way the line was shaped.

I did swap the soft parts of the lines too. For the compressor to condenser line, I had to since I had to make that line. The line going across the bay from the evaporator to the compressor I did just because I wanted to make sure it was good and would work with the newer refrigerants. Here are the two types of hose that I got.

https://www.autoacfittings.com/13-32...-Ft-AC-08R.htm (#8 reduced barrier hose, for from the compressor to the condenser)

https://www.autoacfittings.com/1-2-G...-Ft-AC-10R.htm (#10 reduced barrier hose, for coming from the evaporator to the compressor)

This link has more info for the hose I used, says it's good for R134a. So hopefully that isn't it.

https://www.continental-industry.com...E-Barrier-4890

And here is the link to my thread about the retrofit if there is any other info you wanna see.

https://www.rx7club.com/3rd-generati...-vmic-1137819/

I used R134a ester oil with dye so I'm planning to check for leaks this time. I would think there has to be something pretty substantial, or maybe the hoses I got weren't suited for R152. That would really suck lol. I bought a crimp kit because I couldn't find anyone to crimp them for me, even the guy that did them last time. However, you'd still need the parts to crimp and to get them welded onto the fittings you have, assuming the FC AC lines are similar to the FD's. It would probably still be worth doing, even though duster is so cheap. At least you wouldn't have to do it every year. But I might have to also.

The connection at the condenser on the line from the compressor MIGHT be the culprit, but I'm not sure about that either. You can see the pics at the bottom of the first post in my thread. The inlet in the condenser is squared off at the bottom, as is the RX-8 fitting. But the fitting I'm using is angled at the bottom. However, I would imagine the hole is still lined up for the most part and the o-ring I used fit pretty tight, so I don't think it would be an issue, but it is something I wondered about. It's the only line I could find that would work though, the way the line was shaped.

When you do your full recharge each year, I'm guessing you pull a vacuum and add all the oil you need again, including the oil in the compressor?

I wonder if there ever will be a perfect substitute, but even now I think R152 is about as close as it comes. I was seeing 25F air from the vents last summer lol. Although I couldn't run it like that for long before the system would freeze up, so I'd keep the temp control just a little bit into the blue and it would work fine.

I swapped the hoses just in case. I assumed they were only good for R12.

I wonder if there ever will be a perfect substitute, but even now I think R152 is about as close as it comes. I was seeing 25F air from the vents last summer lol. Although I couldn't run it like that for long before the system would freeze up, so I'd keep the temp control just a little bit into the blue and it would work fine.

I swapped the hoses just in case. I assumed they were only good for R12.

#24

Make an assessment...

Thread Starter

iTrader: (3)

R152 & R12 share similar characteristics (i.e. the pressure/temp curve characteristics that I don't understand) WRT how they behave as refrigerants, but that's pretty much where the similarities end. As far as physical molecule sizes, chemistry, sealing & lube requirements, R152 is more similar to R134 than R12, which is why you use the green HBNR O-rings and such. Ester lube is compatible with both R152 and R134, and it doesn't have any nasty reactions to small amounts of left over mineral oil when converting from an old R12 system that used mineral oil.

Sound like you did all the right things, but it must be leaking from somewhere. Hopefully it will be easy to find. FWIW, testing for leaks just by holding a vacuum is often inconclusive. Better to test with the system fully charged and operating while you look for leaks via UV light/dye or an electronic gas detector. My FC system, which technically leaks albeit very slowly, can hold a vacuum rock solid overnight. Good info in those links, I'll be borrowing that for when I do my FD's A/C system.

I don't add any oil when I evac & recharge each year; when done correctly hardly any oil gets removed from the system. For evac & recharge service, first I'll hook up the manifold gauges, and then just barely crack open the 2 valves, letting the low & high sides very slowly discharge thru the yellow hose. I'll have a white paper towel positioned over the yellow hose discharge port so I can gauge how much oil is coming out - with the dye in the system, it's easy to tell, and when done right, hardly any oil comes out with the gas. Once that's done, I'll pull a vacuum, see if it holds for an hour or two and then do a full recharge with the R152A. Note that since there's very little gas left in the system after you discharge it, the vacuum pump won't be able to pull much if any oil out with the remaining gas in the system. The 1st can of R152 goes in as a liquid (can upside down), with the A/C system off - it all gets sucked in by vacuum. Then start the car & run the A/C at max/recirc, windows open, RPMs ~2500, and charge with 2nd can as a gas. For my FC, it typically takes almost a full 2nd can to get to the point where the air temp out of the vents bottoms out at around 5~7*C, and much of this depends on the ambient temp conditions too.

Oooh that's a good call. That's something I didn't do last time.

Thanks guys!

#25

Make an assessment...

Thread Starter

iTrader: (3)

I just tried something Chris Ludwig suggested to see if the ECU was at fault. I pulled the 1L terminal from the connector so the ECU couldn't provide ground and started the car (on my ECU it's terminal 2A but it goes straight to 1L on the stock connector). It didn't ground, so it's coming from the ECU. At first I thought it grounded but I just realized I was an idiot and checked continuity at the wrong place, across the same wire instead of from the terminal to chassis ground lol.

Last edited by speedjunkie; 04-30-20 at 09:20 PM.