No start after rebuild. no spark. no rpm. need help

#1

Senior Member

Thread Starter

iTrader: (3)

Join Date: Mar 2006

Location: Hawthorne, CA

Posts: 382

Likes: 0

Received 0 Likes

on

0 Posts

93 R1 with AEM v1

Just finished rebuilding my fd after a exhaust sleeve failure. Put it back in and rewired it back up. nothing.... pulled a plug and grounded it and tried to crank and no spark. So I checked all my fuses and relays and everything is good. I have the efi fuse click like it should when I turn the key and even get fuel pressure.

Then I noticed I'm not getting any rpm signal. ok checked both crank angle sensor. The inner one seamed to work when I connected a ground to the sensor. Magnetic pickup basically. It even clicked on the fuel pump. cool that ones good.

Checked the outer cas and didn't see the fuel pump set on. I'm not sure if it will or not but the inner one did. So I was like maybe its the wiring. I ran a jumper from the ecu to both wires and had continuity from the ecu to the plug. thought it might be the sensor so I switched it to the inner sensor and tested the sensor and it worked just like the other one.

If I'm not mistaken the outer crank angle sensor is suppose to give the rpm signal. Also if its not working I believe it wont send fuel or spark. In thus is the problem. If I'm getting good good continuity up to the sensor but its not picking it up for some reason and I'm not sure why. I know the sensor is good but its not wanting to trigger to the ecu.

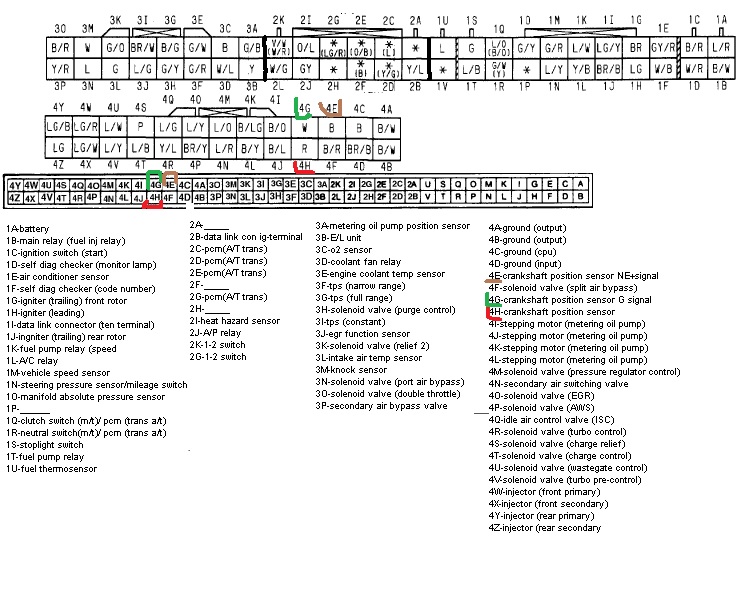

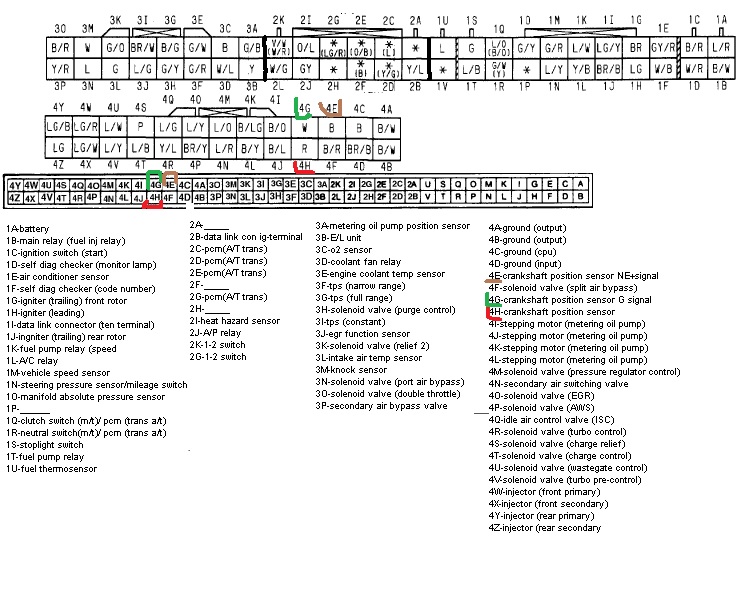

I jumped 4g (g signal) and 4h (crank signal). I did this because it was the same wires colors that the connector was and had continuity between the wires. Just need to be double checked that those are the right ones I should have jumped.

I'm kinda at a loss so I figured some one might have had the same problem I've had. or at least figure out what the next step is.

Please help

Just finished rebuilding my fd after a exhaust sleeve failure. Put it back in and rewired it back up. nothing.... pulled a plug and grounded it and tried to crank and no spark. So I checked all my fuses and relays and everything is good. I have the efi fuse click like it should when I turn the key and even get fuel pressure.

Then I noticed I'm not getting any rpm signal. ok checked both crank angle sensor. The inner one seamed to work when I connected a ground to the sensor. Magnetic pickup basically. It even clicked on the fuel pump. cool that ones good.

Checked the outer cas and didn't see the fuel pump set on. I'm not sure if it will or not but the inner one did. So I was like maybe its the wiring. I ran a jumper from the ecu to both wires and had continuity from the ecu to the plug. thought it might be the sensor so I switched it to the inner sensor and tested the sensor and it worked just like the other one.

If I'm not mistaken the outer crank angle sensor is suppose to give the rpm signal. Also if its not working I believe it wont send fuel or spark. In thus is the problem. If I'm getting good good continuity up to the sensor but its not picking it up for some reason and I'm not sure why. I know the sensor is good but its not wanting to trigger to the ecu.

I jumped 4g (g signal) and 4h (crank signal). I did this because it was the same wires colors that the connector was and had continuity between the wires. Just need to be double checked that those are the right ones I should have jumped.

I'm kinda at a loss so I figured some one might have had the same problem I've had. or at least figure out what the next step is.

Please help

#3

Senior Member

Thread Starter

iTrader: (3)

Join Date: Mar 2006

Location: Hawthorne, CA

Posts: 382

Likes: 0

Received 0 Likes

on

0 Posts

I'm more or less wondering the function of the outer cas. and if it triggered would the fuel pump kick in. and im not sure if its an aem problem. It would be the same problem aem or not.

#4

Senior Member

Thread Starter

iTrader: (3)

Join Date: Mar 2006

Location: Hawthorne, CA

Posts: 382

Likes: 0

Received 0 Likes

on

0 Posts

So after checking out the 4e crank ne signal. I'm not getting any signal from the ecu. I did change to a different front cover does any one know if different year front covers don't line up with a 93 pulley wheel. This might explain why it's not wanting to signal to it.

#6

Senior Member

Thread Starter

iTrader: (3)

Join Date: Mar 2006

Location: Hawthorne, CA

Posts: 382

Likes: 0

Received 0 Likes

on

0 Posts

Mehh figured it out. Apparently there's only suppose to be a gap between the. Crank sensor and the wheel by 3 mm. Mine was Chillen about 10 mm away from it. It picked up signal and immediately and started sparking now for my dead battery I have to replace since I've cranked and cranked on. I fixed it with 3 copper washers.

#7

yes, the air gap is very important. but the real question is how did the pulley set wind up so far away from the sensors.. i have never had to shim them in such a way, if the pulleys are OEM and bolted on properly i hate to think of the next possible problem.

you did check the endplay and paid attention to the front thrust stack orientations i hope. if the thrust stack was improperly assembled then you will destroy the engine in a matter of a few minutes of running it.

you did check the endplay and paid attention to the front thrust stack orientations i hope. if the thrust stack was improperly assembled then you will destroy the engine in a matter of a few minutes of running it.

Last edited by RotaryEvolution; 02-01-14 at 04:35 PM.

Trending Topics

#9

yes, the air gap is very important. but the real question is how did the pulley set wind up so far away from the sensors.. i have never had to shim them in such a way, if the pulleys are OEM and bolted on properly i hate to think of the next possible problem.

you did check the endplay and paid attention to the front thrust stack orientations i hope. if the thrust stack was improperly assembled then you will destroy the engine in a matter of a few minutes of running it.

you did check the endplay and paid attention to the front thrust stack orientations i hope. if the thrust stack was improperly assembled then you will destroy the engine in a matter of a few minutes of running it.

I'm with Rotary Evolution, there is something wrong there.

#10

Senior Member

Thread Starter

iTrader: (3)

Join Date: Mar 2006

Location: Hawthorne, CA

Posts: 382

Likes: 0

Received 0 Likes

on

0 Posts

yes, the air gap is very important. but the real question is how did the pulley set wind up so far away from the sensors.. i have never had to shim them in such a way, if the pulleys are OEM and bolted on properly i hate to think of the next possible problem.

you did check the endplay and paid attention to the front thrust stack orientations i hope. if the thrust stack was improperly assembled then you will destroy the engine in a matter of a few minutes of running it.

you did check the endplay and paid attention to the front thrust stack orientations i hope. if the thrust stack was improperly assembled then you will destroy the engine in a matter of a few minutes of running it.

#11

Senior Member

Thread Starter

iTrader: (3)

Join Date: Mar 2006

Location: Hawthorne, CA

Posts: 382

Likes: 0

Received 0 Likes

on

0 Posts

when the motor was put together buy the previous owner he used a 20b housing. there pretty much the same but the exhaust sleeve is different. you have to trim part of the housings down to fit the fd sleeve in. the problem was that the previous builder either used the wrong dowel pin or didnt make it long enough. the sleeve got loose and rattled so much that it got a hairline crack in it. the hair line crack broke over prob 15000 miles or so sending part of the exhaust sleeve back into the motor causing a apex failure and trashing the rotor housing. I can take some pics if you would like.

#12

Sponsor

iTrader: (41)

when the motor was put together buy the previous owner he used a 20b housing. there pretty much the same but the exhaust sleeve is different. you have to trim part of the housings down to fit the fd sleeve in. the problem was that the previous builder either used the wrong dowel pin or didnt make it long enough. the sleeve got loose and rattled so much that it got a hairline crack in it. the hair line crack broke over prob 15000 miles or so sending part of the exhaust sleeve back into the motor causing a apex failure and trashing the rotor housing. I can take some pics if you would like.

Thread

Thread Starter

Forum

Replies

Last Post