FD New Brake Options

#1351

>>No trimming of the springs?

Nope, just make sure to get the right size, and they go right in there behind the piston. Now I did notice that stoptechs calipers had a slight indentation in the caliper where the springs go, it is possible that was there because they knew competition drivers would put springs in, but i am only speculating.

>> Is it a pain to change the pads with the springs pushing the pistons out of the bores all the time?

Nope. I do not have any added issues when replacing pads or do anything different than i did before. You may have to use the old pad to keep the pistons in till you get the new pad in position, but keep i mind the springs are not that strong, so its not like they shoot the pistons out. The friction of the seal alone keeps them from moving very fast.

>> Did you notice any accelerated wear rates?

Nope, nothing that was obvious or notable on my setup, although I can not speak for other setups. I am sure it does affect it to some minimal degree, just not enough to matter with normal race car brake usage :-)

For me, any trade off of the things above would have been well worth it as they made a huge difference. Basically I used to have to 'pump' the pedal between hard cornering to get the pistons seated, now I no longer have to do that at all. I still do the obligatory brake 'tap' to make sure i have pressure, but no longer have to 'pump-pump-tap' to seat the pistons.

Nope, just make sure to get the right size, and they go right in there behind the piston. Now I did notice that stoptechs calipers had a slight indentation in the caliper where the springs go, it is possible that was there because they knew competition drivers would put springs in, but i am only speculating.

>> Is it a pain to change the pads with the springs pushing the pistons out of the bores all the time?

Nope. I do not have any added issues when replacing pads or do anything different than i did before. You may have to use the old pad to keep the pistons in till you get the new pad in position, but keep i mind the springs are not that strong, so its not like they shoot the pistons out. The friction of the seal alone keeps them from moving very fast.

>> Did you notice any accelerated wear rates?

Nope, nothing that was obvious or notable on my setup, although I can not speak for other setups. I am sure it does affect it to some minimal degree, just not enough to matter with normal race car brake usage :-)

For me, any trade off of the things above would have been well worth it as they made a huge difference. Basically I used to have to 'pump' the pedal between hard cornering to get the pistons seated, now I no longer have to do that at all. I still do the obligatory brake 'tap' to make sure i have pressure, but no longer have to 'pump-pump-tap' to seat the pistons.

#1352

Thanks for the info, Damian. Very useful!

I am having the same experience as you had before the springs, namely that I have to pump the pedal with my left foot to close the gap until I feel a little braking bite. This is a big problem when you have less than a second between the exit of a long corner and the entry of the next. (Plus I look like I'm having a seizure with my brake lights coming on before the corner.) But it's somewhat relieving to see that it's not an issue with any particular brake it, but rather something fundamental to the FD.

Your car is pulling higher lateral loads than mine, but IIRC you did change at least your front bearings (hubs) in the recent past. I discovered the tiniest bit of play in my rear bearings, so those are getting changed. But I wanted to be sure that you eliminated bearing flex as the culprit--and that you feel upright flex is the real issue.

For my setup, I'm curious what kind of trade off these springs might bring to a car which is used on the street as well as the track. I'm going to do my next test with new bearings to see how that affects things, and if there is no improvement I will try the springs. But frankly I'm befuddled as to why other people who have tested BBK setups on the track have not noticed the knockback issue. To my knowledge only you, Peter, Andrew, and myself have commented on it.

-ch

For me, any trade off of the things above would have been well worth it as they made a huge difference. Basically I used to have to 'pump' the pedal between hard cornering to get the pistons seated, now I no longer have to do that at all. I still do the obligatory brake 'tap' to make sure i have pressure, but no longer have to 'pump-pump-tap' to seat the pistons.

Your car is pulling higher lateral loads than mine, but IIRC you did change at least your front bearings (hubs) in the recent past. I discovered the tiniest bit of play in my rear bearings, so those are getting changed. But I wanted to be sure that you eliminated bearing flex as the culprit--and that you feel upright flex is the real issue.

For my setup, I'm curious what kind of trade off these springs might bring to a car which is used on the street as well as the track. I'm going to do my next test with new bearings to see how that affects things, and if there is no improvement I will try the springs. But frankly I'm befuddled as to why other people who have tested BBK setups on the track have not noticed the knockback issue. To my knowledge only you, Peter, Andrew, and myself have commented on it.

-ch

#1355

I think other folks get knockback too, but I did start hearing about it more in reference to the StopTech kit when I got it, though I've no reason to think it's worse with it rather than other kits.

My experience is that no one thing is to blame... new wheel bearings helped a little, brand new pads do it less than worn ones, a really good flush/bleed helps, new Hoosiers hurt.

Overall, the root is probably both bearings and upright flex in combination. However, I will say that I prefer a PARTICULARLY high, stiff pedal with immediate action... I'm not sure everyone would be as bothered by it. I've never had to "pump" the pedal... it takes really the smallest of taps. I try to do it at corner exit instead of right before the brake zone.

My experience is that no one thing is to blame... new wheel bearings helped a little, brand new pads do it less than worn ones, a really good flush/bleed helps, new Hoosiers hurt.

Overall, the root is probably both bearings and upright flex in combination. However, I will say that I prefer a PARTICULARLY high, stiff pedal with immediate action... I'm not sure everyone would be as bothered by it. I've never had to "pump" the pedal... it takes really the smallest of taps. I try to do it at corner exit instead of right before the brake zone.

Your car is pulling higher lateral loads than mine, but IIRC you did change at least your front bearings (hubs) in the recent past. I discovered the tiniest bit of play in my rear bearings, so those are getting changed. But I wanted to be sure that you eliminated bearing flex as the culprit--and that you feel upright flex is the real issue.

For my setup, I'm curious what kind of trade off these springs might bring to a car which is used on the street as well as the track. I'm going to do my next test with new bearings to see how that affects things, and if there is no improvement I will try the springs. But frankly I'm befuddled as to why other people who have tested BBK setups on the track have not noticed the knockback issue. To my knowledge only you, Peter, Andrew, and myself have commented on it.

-ch

For my setup, I'm curious what kind of trade off these springs might bring to a car which is used on the street as well as the track. I'm going to do my next test with new bearings to see how that affects things, and if there is no improvement I will try the springs. But frankly I'm befuddled as to why other people who have tested BBK setups on the track have not noticed the knockback issue. To my knowledge only you, Peter, Andrew, and myself have commented on it.

-ch

#1356

I was able to work with Warren/Racing Brake and get DTC-60 pads front and rear for my car, so hopefully within a month I will have the car on track with them and be able to report back differences as compared to HT-10's front and rear. I'm hoping for the things I've been hearing; less rotor wear, more brake torque, and better modulation.

#1357

>>I am having the same experience as you had before the springs, namely that I have to pump the pedal with my left foot to close the gap until I feel a little braking bite. This is a big problem when you have less than a second between the exit of a long corner and the entry of the next.

Exactly!!! :-) heheh

>>But it's somewhat relieving to see that it's not an issue with any particular brake it, but rather something fundamental to the FD.

Well its not just the FD, its any cars hub setup that start to flex to much under hard lateral Gs. Many cars have the knockback issue on stock hubs once they stat pulling decent Gs.

>>Because no one else probably corners with such high G-forces are you guys!

hehe, yeah my car can hit some pretty silly lateral Gs for a production chassy. Even at MAM (very flat track) I am peaking at 1.4ish Gs on many corners according to the traqmate data. Kinda nutty considering I still have a level or 2 I could take the car up in terms of chassy setup for grip.

>>but IIRC you did change at least your front bearings (hubs) in the recent past

yes, but don't confuse that with any of my knockback issues as that came later, typically my front bearings (hubs) toasted prematurely from not cooling the front brakes enough, the HEAT is what kills them (think of all that rotor heat and it goes right into the hub bearing), in addition to taking high lateral load. However, since I properly ducted my fronts, I have not had hub issues in a long while. Back when I was replacing them often, I did NOT have the knockback issues (the car was slower then, less lateral Gs, I wasn't as fast a driver, different brake setup, et, et) so although they probably can be related, in my case it was for other reasons.

>>But I wanted to be sure that you eliminated bearing flex as the culprit--and that you feel upright flex is the real issue.

Yes, I had new front hubs and still had the knockback issue. The real solution, although not really feesable, is to use higher end knuckle/hubs that are built for racing and do not flex, keeping the rotor on its proper plane not mater the Gs.

But, for now, $10 piston springs work great :-)

Exactly!!! :-) heheh

>>But it's somewhat relieving to see that it's not an issue with any particular brake it, but rather something fundamental to the FD.

Well its not just the FD, its any cars hub setup that start to flex to much under hard lateral Gs. Many cars have the knockback issue on stock hubs once they stat pulling decent Gs.

>>Because no one else probably corners with such high G-forces are you guys!

hehe, yeah my car can hit some pretty silly lateral Gs for a production chassy. Even at MAM (very flat track) I am peaking at 1.4ish Gs on many corners according to the traqmate data. Kinda nutty considering I still have a level or 2 I could take the car up in terms of chassy setup for grip.

>>but IIRC you did change at least your front bearings (hubs) in the recent past

yes, but don't confuse that with any of my knockback issues as that came later, typically my front bearings (hubs) toasted prematurely from not cooling the front brakes enough, the HEAT is what kills them (think of all that rotor heat and it goes right into the hub bearing), in addition to taking high lateral load. However, since I properly ducted my fronts, I have not had hub issues in a long while. Back when I was replacing them often, I did NOT have the knockback issues (the car was slower then, less lateral Gs, I wasn't as fast a driver, different brake setup, et, et) so although they probably can be related, in my case it was for other reasons.

>>But I wanted to be sure that you eliminated bearing flex as the culprit--and that you feel upright flex is the real issue.

Yes, I had new front hubs and still had the knockback issue. The real solution, although not really feesable, is to use higher end knuckle/hubs that are built for racing and do not flex, keeping the rotor on its proper plane not mater the Gs.

But, for now, $10 piston springs work great :-)

#1358

Thanks again, Damian. This kind of data is really valuable. We're fortunate to have you blazing the path ahead of us!

If I can't get the knockback under control (with some bearing changes) I'll experiment with the PFC springs next and share my results here.

-ch

If I can't get the knockback under control (with some bearing changes) I'll experiment with the PFC springs next and share my results here.

-ch

#1361

Thunderhill test on Saturday

I'm running four session at Thunderhill on Saturday. This will be a good high-temperature test (forecast is a high of 97 degrees) for the Racing Brake kit. In addition, I'm running a new set of Hawk DTC-70 pads in the front paired with the DTC-60 in the rear for the first time. I'll share my track data after the event. Below are the brakes prepped for testing.

I really encourage others who run at the track to do this kind of thing. It adds about 10 minutes of prep and maybe 20 minutes of additional effort on the post-event teardown. And you can really learn a lot about your car.

-ch

I really encourage others who run at the track to do this kind of thing. It adds about 10 minutes of prep and maybe 20 minutes of additional effort on the post-event teardown. And you can really learn a lot about your car.

-ch

#1363

The methodology is pretty simple. Put the paint at various points on the pads and rotors, and place the strips on the outside face of the body of the calipers. Take readings after a hard session immediately when you get back to the pits. (If you let it sit too long, you'll be measuring the heat soak, not the actual track temps.) You want to see paint temps under 1300 F unless your pads are rated for higher than 1400 F (like the DTC-70). The calipers should never get above 370 F; 330 F is preferable.

-ch

#1365

Thanks for pointing us to the Genesis paint - that stuff is a great help and much better than the indicating paint available from McMaster.

As a reference point, I was at Thunderhill 5/15 and with my stock brakes, ducting system and Carbotech XP10 pads, showed about 1200 deg F rotor temp, with caliper temps not registering on the McMaster-Carr strips (so less than 370 F). I do have stainless steel backing plates to reduce heat transfer to the caliper pistons. With this setup, the XP10s last about two track days.

Ambient temp was 103 deg F, my car has 300 rwhp, and I was turning consistent 2:09 laps in 30 minute sessions (with AIT a scary 74 deg C and water temps of 110 deg C, so probably down on power a fair amount). It will be interesting to compare with what you get. These are about the same temps I saw at Laguna with the same set up, turning about a 1:46 lap.

Have a great time!

#1367

No, sorry, I wasn't clear. The strips are not reversible, but if you don't read them immediately when you come into the pit you may get a false reading. The Alcon engineers don't want to see caliper face temps of 370F as it indicates that the body of the caliper (and the seals, and the fluid) are much hotter than that, which is bad.

However, if you read the strips after sitting in the pit for a few minutes (especially if you don't run a nice cooldown lap) your rotors may still be at over 1000F. Sitting stationary may radiantly heat the caliper face to 370F+ even though the internals are not that hot. Since the strips aren't reversible, now you don't know if the temperature reading was due to on-track temps, or paddock heat soak.

So you just gotta read the temps right when you come in, especially if you didn't have a complete cooldown lap.

This is extra important if you intentionally skip your cooldown lap in order to get accurate tire temperatures and pressures.

-ch

However, if you read the strips after sitting in the pit for a few minutes (especially if you don't run a nice cooldown lap) your rotors may still be at over 1000F. Sitting stationary may radiantly heat the caliper face to 370F+ even though the internals are not that hot. Since the strips aren't reversible, now you don't know if the temperature reading was due to on-track temps, or paddock heat soak.

So you just gotta read the temps right when you come in, especially if you didn't have a complete cooldown lap.

This is extra important if you intentionally skip your cooldown lap in order to get accurate tire temperatures and pressures.

-ch

#1369

Thunderhill test report

I ran my car (details in sig) at Thunderhill yesterday in brutal conditions. Ambient over 100F with unusually high humidity for the region. I ran three sessions for a total of 25 laps around the 3 mile circuit. Thunderhill is not really known as a track that is hard on brakes--lots of medium-speed corners strung together--but it does feature three hard braking zones from over 115 MPH.

I ran a new set of DTC-70 pads up front and DTC-60 in the rear. The performance was very good; I experienced no fade. The DTC compound has incredible bite and is easy to modulate with a smooth release. Threshold braking at 1G+ can be done all day.

Knockback is still an issue, but has improved on my car with some attention to the wheel bearings. To make this any better, I now think that piston springs will be necessary, but I'm getting really used to tapping up after a hard corner, so I'm not sure whether or not I'll go that route with my street car.

As in my previous tests, the front pads wore more aggressively on the leading edge and displayed some top-to-bottom taper on the outboard pads. (Version 2 kit requests: larger piston bore stagger, and stiffer calipers please.) The rear pads wore more evenly, although it seems that the Hawk baking plate flexes a bit; the center of the inboard pads wears somewhat faster than the edges, but I expect this to stabilize as the plate can only bend so much.

I wore about 9% of the front pads and 4% of the rear pads during the day.

I didn't notice a huge difference between the DTC-60 rears and the older HT-10s I had run previously, but if anything I think it's good to move to the compound that Hawk is currently developing. They appeared to wear a bit better and produced less noise on the street (for those of us who drive to the track, this is nice). If anything, I think they were a bit easier to modulate, although to be honest the 'feeling' of the car seems to be mostly set by the characteristics of the front brake pads. Regardless, I won't be going back to the HT-10s.

The temperature paint and strips showed that the rear rotors reached at least 1075F but no more than 1326F. In the images you can see that the rotor edges were much hotter than the center; the rear brakes if anything have too much cooling and thermal inertia, but that's not a problem I'm complaining about. The backing plates of the pads did not even reach 1075F which is well within their 1400F operational zone.

The front pads got hot enough to burn away the paint that Hawk puts on the backing plates (this is normal) so I lost most of the data there. But you can see in the pictures below that the paint is completely gone from the leading edge with just a little residue on the trailing edges. The pain there suggests the pads got up to at least 1075F, well below the 1600F limit.

The DTC pads heat up very quickly and display a very consistent braking force throughout the heat range.

The temperature strip on the caliper only registered 290-330F which surprised me given the extremely high ambient temps. But it just goes to show that track layout is way, way more important than the conditions. Based on this experience, I think you could literally run a 3-day weekend flat out at Thunderhill with this setup without any issues. Not bad for an un-ducted brake system!

The rotors, as before, showed no measurable wear whatsoever. What do they build these things out of? Based on my current rate of wear, I will have to replace them in the year 2046.

I'm looking forward to taking this setup back Laguna--the brake-killer of the west coast--to get some additional data. My feedback on the pads is very positive, and for those with the RB kit (and a similar car configuration to mine) this is a very capable combination.

Some images of the brakes during teardown:

-ch

I ran a new set of DTC-70 pads up front and DTC-60 in the rear. The performance was very good; I experienced no fade. The DTC compound has incredible bite and is easy to modulate with a smooth release. Threshold braking at 1G+ can be done all day.

Knockback is still an issue, but has improved on my car with some attention to the wheel bearings. To make this any better, I now think that piston springs will be necessary, but I'm getting really used to tapping up after a hard corner, so I'm not sure whether or not I'll go that route with my street car.

As in my previous tests, the front pads wore more aggressively on the leading edge and displayed some top-to-bottom taper on the outboard pads. (Version 2 kit requests: larger piston bore stagger, and stiffer calipers please.) The rear pads wore more evenly, although it seems that the Hawk baking plate flexes a bit; the center of the inboard pads wears somewhat faster than the edges, but I expect this to stabilize as the plate can only bend so much.

I wore about 9% of the front pads and 4% of the rear pads during the day.

I didn't notice a huge difference between the DTC-60 rears and the older HT-10s I had run previously, but if anything I think it's good to move to the compound that Hawk is currently developing. They appeared to wear a bit better and produced less noise on the street (for those of us who drive to the track, this is nice). If anything, I think they were a bit easier to modulate, although to be honest the 'feeling' of the car seems to be mostly set by the characteristics of the front brake pads. Regardless, I won't be going back to the HT-10s.

The temperature paint and strips showed that the rear rotors reached at least 1075F but no more than 1326F. In the images you can see that the rotor edges were much hotter than the center; the rear brakes if anything have too much cooling and thermal inertia, but that's not a problem I'm complaining about. The backing plates of the pads did not even reach 1075F which is well within their 1400F operational zone.

The front pads got hot enough to burn away the paint that Hawk puts on the backing plates (this is normal) so I lost most of the data there. But you can see in the pictures below that the paint is completely gone from the leading edge with just a little residue on the trailing edges. The pain there suggests the pads got up to at least 1075F, well below the 1600F limit.

The DTC pads heat up very quickly and display a very consistent braking force throughout the heat range.

The temperature strip on the caliper only registered 290-330F which surprised me given the extremely high ambient temps. But it just goes to show that track layout is way, way more important than the conditions. Based on this experience, I think you could literally run a 3-day weekend flat out at Thunderhill with this setup without any issues. Not bad for an un-ducted brake system!

The rotors, as before, showed no measurable wear whatsoever. What do they build these things out of? Based on my current rate of wear, I will have to replace them in the year 2046.

I'm looking forward to taking this setup back Laguna--the brake-killer of the west coast--to get some additional data. My feedback on the pads is very positive, and for those with the RB kit (and a similar car configuration to mine) this is a very capable combination.

Some images of the brakes during teardown:

-ch

#1372

Chris, thanks for the great write-up.

Those rotors temps look amazingly like the rotors I returned with 5/15 - see pics below. One thing I'd like to correct from my previous post - I put the paint on my rotors prior to a day at Laguna, then went later to Thunderhill 5/15 without re-painting, so it is possible the worst case heat is from my earlier day at Laguna, and not Thill. Since all I care about is the worst case temperature, this was fine for me, but isn't really an apples-to-apples comparison with your test.

I retired my rotors after that day because of the cracking - usually I get about 4-5 track days out of my cheapo $30/pair front rotors. From my previous experience, once the cracks start looking like this (the worst one is about twice as long as that shown) they are likely to propagate all the way through on the next track day.

I am surprised to see such significant cracking on your rotors given the extra thermal mass they have. Maybe it is just the angle of the camera though. How many track days do you have on them?

Those rotors temps look amazingly like the rotors I returned with 5/15 - see pics below. One thing I'd like to correct from my previous post - I put the paint on my rotors prior to a day at Laguna, then went later to Thunderhill 5/15 without re-painting, so it is possible the worst case heat is from my earlier day at Laguna, and not Thill. Since all I care about is the worst case temperature, this was fine for me, but isn't really an apples-to-apples comparison with your test.

I retired my rotors after that day because of the cracking - usually I get about 4-5 track days out of my cheapo $30/pair front rotors. From my previous experience, once the cracks start looking like this (the worst one is about twice as long as that shown) they are likely to propagate all the way through on the next track day.

I am surprised to see such significant cracking on your rotors given the extra thermal mass they have. Maybe it is just the angle of the camera though. How many track days do you have on them?

#1373

I think the short answer is that the cracking is not necessarily bad. When I feel the surface with my fingers, it's perfectly smooth. The cracks are probably a few mils deep--if that--and do not extend to the inner or outer edges of the rotor face. They usually appear after the first or second session, but do not seem to affect performance at all.

Racing Brake has a webpage addresses this--look at the cracks on the rotor in the picture there:

http://www.racingbrake.com/v/main/surface_cracks.asp

In my case, the cracks have not "expand[ed] to catch my fingernail", so I consider it to be normal. I have six track days now on left front rotor and still have yet to see 0.002" worn away, and the braking is very smooth once as long as you don't press the pedal too lightly (in which case there is some vibration from the slots).

Also, this wear is consistent with what GooRoo has seen on his RB rear rotors. I think there is an image of that earlier in this ever-increasing thread.

On your discarded rotors, how much of the friction surface was removed by the brakes? I don't see a lip or groove, so I'm betting not that much. They might be good for more miles, although far be it from me to recommend that.

-ch

#1374

Ah, found GooRoo's post here: https://www.rx7club.com/showpost.php...postcount=1121

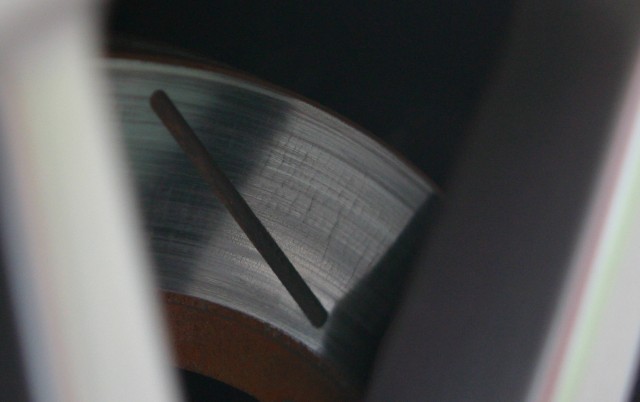

Here's the pic of his rear rotor:

According to his post, he had run 15 track days (56 sessions) on the rear rotors. So far, no issues from the cracks. Any update, GooRoo?

-ch

Here's the pic of his rear rotor:

According to his post, he had run 15 track days (56 sessions) on the rear rotors. So far, no issues from the cracks. Any update, GooRoo?

-ch

#1375

Senior Member

iTrader: (10)

Join Date: Oct 2002

Location: Greensboro, NC

Posts: 463

Likes: 0

Received 0 Likes

on

0 Posts

I've gone through a few itterations on my FD - currently running Stoptech fronts and the stock single piston rears, (which for all the kits out there, they run the stock caliper - either as delivered, or with the "99" stock setup).

I'm fairly sure that at least half, if not more of the required "pedal pumping" at the track is because of those rear brakes,(a very crappy design in my opinion).

What options do I have for a fixed rear caliper? Yes, I realize that I'll likely lose any parking brake option, however, the movement of that rear brake when not under pressure is significant. I rebuilt the calipers and that was a minor at best improvement,(the new "dust" seal around the locating bolts).

I saw there are some wilwood setups using a widefoot bracket. Any other options? I haven't sat down and done the math computations for the effective piston size I'd need to match up to keep the balance,(its been a while, but I seem to remember that on a sliding setup, you need to double the piston size to take into account it is acting on both sides if you want to compare it to a fixed 2 or 4 piston setup). The old 300zx rears or the current STi and Evo rear brakes are considerations.

-Bob

I'm fairly sure that at least half, if not more of the required "pedal pumping" at the track is because of those rear brakes,(a very crappy design in my opinion).

What options do I have for a fixed rear caliper? Yes, I realize that I'll likely lose any parking brake option, however, the movement of that rear brake when not under pressure is significant. I rebuilt the calipers and that was a minor at best improvement,(the new "dust" seal around the locating bolts).

I saw there are some wilwood setups using a widefoot bracket. Any other options? I haven't sat down and done the math computations for the effective piston size I'd need to match up to keep the balance,(its been a while, but I seem to remember that on a sliding setup, you need to double the piston size to take into account it is acting on both sides if you want to compare it to a fixed 2 or 4 piston setup). The old 300zx rears or the current STi and Evo rear brakes are considerations.

-Bob