Pre-swirl shown to reduce turbo lag up to 26%

#1

Pre-swirl shown to reduce turbo lag up to 26%

http://turbo-moteurs.cnam.fr/publica...pdf/EUROT5.PDF

I just stumbled on this interesting paper on a subject I had never heard of before.

Something as simple as a 90 degree bend just before the turbo inlet can help speed spool by introducing pre-swirl and something a little more specialized like Peugeot's 12 blade radial inlet can boost spool by 26% at throttle positions over 40%.

Note, compressor maps are provided for some configurations and some do show more negative impact overall flow rate, but the most effective ones actually have less impact on overall flow.

I just stumbled on this interesting paper on a subject I had never heard of before.

Something as simple as a 90 degree bend just before the turbo inlet can help speed spool by introducing pre-swirl and something a little more specialized like Peugeot's 12 blade radial inlet can boost spool by 26% at throttle positions over 40%.

Note, compressor maps are provided for some configurations and some do show more negative impact overall flow rate, but the most effective ones actually have less impact on overall flow.

The following users liked this post:

mr2peak (11-11-22)

#4

A few things to note:

1. adding bends to your turbo inlet increases restriction. Restriction increases the pressure ratio of the turbo, making it work harder.

2. adding vanes they are talking about in front of the turbo increases restriction

3. they did not experimentally prove better spool on a firing engine. What they did was test different setups on a gas stand at steady state conditions. Then they calculated a predicted improvement of turbocharger acceleration in a transient, on a gas stand.

That kind of stuff doesn't work well on a firing engine. Look at all the advanced boosting concepts going into production right now or sitting in advanced engineering at the major turbo suppliers. They're multi stage systems (compound turbos for example) and other weird concepts like you see on the Ford 6.4 diesel. Ported shrouds are used on diesels and in the aftermarket. Pre-swirl type systems look good on gas stands but they don't work well on firing engines.

1. adding bends to your turbo inlet increases restriction. Restriction increases the pressure ratio of the turbo, making it work harder.

2. adding vanes they are talking about in front of the turbo increases restriction

3. they did not experimentally prove better spool on a firing engine. What they did was test different setups on a gas stand at steady state conditions. Then they calculated a predicted improvement of turbocharger acceleration in a transient, on a gas stand.

That kind of stuff doesn't work well on a firing engine. Look at all the advanced boosting concepts going into production right now or sitting in advanced engineering at the major turbo suppliers. They're multi stage systems (compound turbos for example) and other weird concepts like you see on the Ford 6.4 diesel. Ported shrouds are used on diesels and in the aftermarket. Pre-swirl type systems look good on gas stands but they don't work well on firing engines.

#6

A few things to note:

1. adding bends to your turbo inlet increases restriction. Restriction increases the pressure ratio of the turbo, making it work harder.

Indeed, the paper did note this. Still, it doesn't take much imagination to figure out a way to decrease the restriction. Take the 12 blade radial pre-rotator, now create a truncated center diffuser with a butterfly valve in it opened with an internal wastegate actuator and a filter extension off the front. Now you have a dual path inlet. A radial path for pre-swirl during spool up and then additional direct path in the form of a velocity stack in front of the compressor at full boost.

If you wanted to get fancy you could use airfoils and a swash plate to vary the pitch like (or taken right off) the Ford 6.0 turbo VGT or a sliding varied pitch arrangement like the Cummins VGT in the radial inlet path. Tell me, how many CFM do those exhaust sides flow?

You now have

2. adding vanes they are talking about in front of the turbo increases restriction

A very minor restriction in the 12 blade radial model as the airfoils are not directly in front of the compressor, but arranged at the periphery with a large inlet area.

You can clearly see what a restriction some of the lesser systems are on the compressor maps shown as some limit the total compressor mass flow.

3. they did not experimentally prove better spool on a firing engine. What they did was test different setups on a gas stand at steady state conditions. Then they calculated a predicted improvement of turbocharger acceleration in a transient, on a gas stand.

You are wrong and need to read it more carefully. The first part of the paper explored the various pre-swirl designs on a gas stand and the second part took the best performing 12 blade radial and ran it on a test engine with dyno loading.

ENGINE TEST BENCH EXPERIMENTS.

Now, we present some experimental resu

lts obtained with the 12 blades radial pre-

rotator operating with a Peugeot turbocharged

petrol engine, 2 litres capacity. The KKK k16

model and the 12 blades radial pre-rotator are shown on the figure 8.

The methodology of experiments stands as follows:

At constant engine rotational speed and engine

load (the torque), we test nine different

inclinations of the inlet guide vanes . Theses e

xperiments are made for five different values of

the torque and for six values of the engine rotational speed.

It is the table derived from these results that I pulled the 26% decrease in spool time (over 40% throttle).

This is exaclty what we are looking for in the real world. Mash the gas pedal at 3,500rpm and have full boost in .67 seconds instead of .91 seconds as their test show.

That kind of stuff doesn't work well on a firing engine. Look at all the advanced boosting concepts going into production right now or sitting in advanced engineering at the major turbo suppliers. They're multi stage systems (compound turbos for example) and other weird concepts like you see on the Ford 6.4 diesel. Ported shrouds are used on diesels and in the aftermarket. Pre-swirl type systems look good on gas stands but they don't work well on firing engines.

Sorry, your wrong.

I remember back in '99 or 2000 when I seized on the idea for a hybrid turbo with a highspeed alternator/motor between the turbine and compressor for use on the then new Honda Insight. Generate current from the alternator to slow the compressor instead of a wastegate to control boost and use it as a motor to keep a constant compressor rpm to spool/preserve boost. I looked online in the patents and it was already patented.

Just now 15 years later in Formula 1 we are finally seeing this simple electric hybrid turbo system implemented, not even available to the consumer yet.

Another example- Nissan used ceramic exhaust wheels since the late '80s in production cars and they were crap. Now with some material and production tweeks 25 years later they are the new hot sh*t in Borg Warners EFR line of aftermarket turbos.

Its possible it is the same with this. This research resulted in a patent by Peugeot and nobody has decided it was worth it to pay them to produce it as there were other venues to pursue (direct injection/higher compression, variable compression, variable geometry turbos).

The difference I see with this technology is it would be very easy to implement for us hobbyists who do not need to pay to use the patent.

1. adding bends to your turbo inlet increases restriction. Restriction increases the pressure ratio of the turbo, making it work harder.

Indeed, the paper did note this. Still, it doesn't take much imagination to figure out a way to decrease the restriction. Take the 12 blade radial pre-rotator, now create a truncated center diffuser with a butterfly valve in it opened with an internal wastegate actuator and a filter extension off the front. Now you have a dual path inlet. A radial path for pre-swirl during spool up and then additional direct path in the form of a velocity stack in front of the compressor at full boost.

If you wanted to get fancy you could use airfoils and a swash plate to vary the pitch like (or taken right off) the Ford 6.0 turbo VGT or a sliding varied pitch arrangement like the Cummins VGT in the radial inlet path. Tell me, how many CFM do those exhaust sides flow?

You now have

2. adding vanes they are talking about in front of the turbo increases restriction

A very minor restriction in the 12 blade radial model as the airfoils are not directly in front of the compressor, but arranged at the periphery with a large inlet area.

You can clearly see what a restriction some of the lesser systems are on the compressor maps shown as some limit the total compressor mass flow.

3. they did not experimentally prove better spool on a firing engine. What they did was test different setups on a gas stand at steady state conditions. Then they calculated a predicted improvement of turbocharger acceleration in a transient, on a gas stand.

You are wrong and need to read it more carefully. The first part of the paper explored the various pre-swirl designs on a gas stand and the second part took the best performing 12 blade radial and ran it on a test engine with dyno loading.

ENGINE TEST BENCH EXPERIMENTS.

Now, we present some experimental resu

lts obtained with the 12 blades radial pre-

rotator operating with a Peugeot turbocharged

petrol engine, 2 litres capacity. The KKK k16

model and the 12 blades radial pre-rotator are shown on the figure 8.

The methodology of experiments stands as follows:

At constant engine rotational speed and engine

load (the torque), we test nine different

inclinations of the inlet guide vanes . Theses e

xperiments are made for five different values of

the torque and for six values of the engine rotational speed.

It is the table derived from these results that I pulled the 26% decrease in spool time (over 40% throttle).

This is exaclty what we are looking for in the real world. Mash the gas pedal at 3,500rpm and have full boost in .67 seconds instead of .91 seconds as their test show.

That kind of stuff doesn't work well on a firing engine. Look at all the advanced boosting concepts going into production right now or sitting in advanced engineering at the major turbo suppliers. They're multi stage systems (compound turbos for example) and other weird concepts like you see on the Ford 6.4 diesel. Ported shrouds are used on diesels and in the aftermarket. Pre-swirl type systems look good on gas stands but they don't work well on firing engines.

Sorry, your wrong.

I remember back in '99 or 2000 when I seized on the idea for a hybrid turbo with a highspeed alternator/motor between the turbine and compressor for use on the then new Honda Insight. Generate current from the alternator to slow the compressor instead of a wastegate to control boost and use it as a motor to keep a constant compressor rpm to spool/preserve boost. I looked online in the patents and it was already patented.

Just now 15 years later in Formula 1 we are finally seeing this simple electric hybrid turbo system implemented, not even available to the consumer yet.

Another example- Nissan used ceramic exhaust wheels since the late '80s in production cars and they were crap. Now with some material and production tweeks 25 years later they are the new hot sh*t in Borg Warners EFR line of aftermarket turbos.

Its possible it is the same with this. This research resulted in a patent by Peugeot and nobody has decided it was worth it to pay them to produce it as there were other venues to pursue (direct injection/higher compression, variable compression, variable geometry turbos).

The difference I see with this technology is it would be very easy to implement for us hobbyists who do not need to pay to use the patent.

#7

arghx, do you have access to the more recent SAE papers?

Such as last years-

2013-01-0934

Potentials of Variable Compressor Pre Swirl Devices in Consideration of Different Sealing Concepts

The abstract claims are interesting-

An extended compressor map with partial higher compressor efficiency of up to 2% was detected. The outcome of this is an increase of up to 6% in low end torque, found on engine test bench. This effect could also be validated in 1D simulation.

I would love to read this to see if the gains they found are possible with as simple a device as was shown in the paper I initially found.

Variable pre-swirl sounds like it would be more complex. Possibly a compressor rpm input or MAP input and a linear actuator on a variable vane radial swirl inducer (like Ford 6.0 hotside). Still, could be "advanced hobby" level.

Such as last years-

2013-01-0934

Potentials of Variable Compressor Pre Swirl Devices in Consideration of Different Sealing Concepts

The abstract claims are interesting-

An extended compressor map with partial higher compressor efficiency of up to 2% was detected. The outcome of this is an increase of up to 6% in low end torque, found on engine test bench. This effect could also be validated in 1D simulation.

I would love to read this to see if the gains they found are possible with as simple a device as was shown in the paper I initially found.

Variable pre-swirl sounds like it would be more complex. Possibly a compressor rpm input or MAP input and a linear actuator on a variable vane radial swirl inducer (like Ford 6.0 hotside). Still, could be "advanced hobby" level.

Trending Topics

#8

You are right. They did run it on a firing engine. But they didn't run the firing engine in an actual transient. They ran it at steady state with different guide vanes at a very high speed for measuring (3500rpm). Then they figured out how much the initial turbo speed changed. Using the inertia and a compressor power calculation, they back calculated how much the acceleration should increase. What they didn't comment on is the increase in pressure ratio resulting from having a big restriction in front of the turbo. That ultimately can limit peak power. Something's gotta give.

I say this because I deal with step-load transient tests on a regular basis. They're not very "real world" representative tests. You hold the engine dyno fixed at a particular speed, like 1500rpm, and then you command full accelerator. Depending how you the gains are tuned on the dyno controller, the engine speed will overshoot to some degree and then be clamped back down when the brake kicks in. It's the equivalent of driving up a hill locked in top gear with a trailer on back and flooring it. It's a very rough metric for how the engine actually drives in a car.

The normal metric is time to 90% of rated steady-state torque. It's a lab number. Changing the initial turbo speed can help with that. If you sweep wastegate position you can raise the initial turbo speed.

The Borg Warner EFR turbos are ceramic ball bearing with Titanium Aluminide turbine wheels.

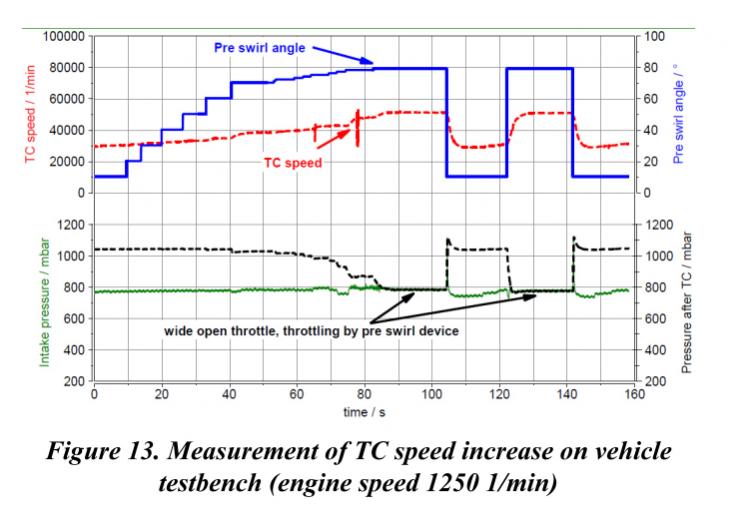

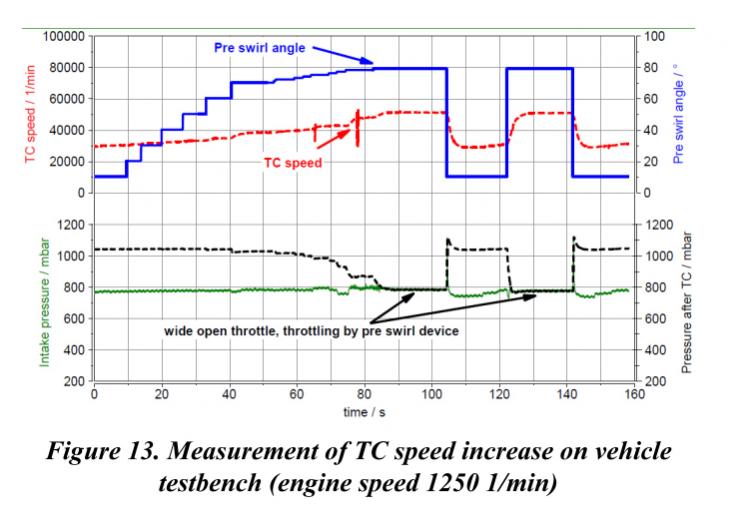

I have the paper you are referring to. It uses a variable swirl device, and there is data showing an increase in low end torque (1250 rpm) on a turbo DI engine which presumably was surge-limited at low speeds. However the variable swirl device functions as a throttle and needs to be controlled as such (now you're coordinating two throttles). There is a section on vehicle results which explains this.

The other thing to keep in mind is that the gains in low end torque are only if the low end torque is limited by surge or inertia of the wheel. If the limit is turbine power, pre-swirl isn't going to do it. If you run at steady-state peak load at low speed on an engine (engine dyno, or uphill towing scenario at top gear), turbine power is what limits you if you're not surging. Initial turbine speed doesn't matter. Of course that assumes the engine doesn't have a knock problem, and low speed/high load is very dangerous for knock and preignition. If you need to get more turbine power you have to retard spark, or do something to the turbine housing (smaller A/R or whatever) that would increase backpressure at high speeds. It always comes down to a low end/high end output balancing act.

No matter how you implement it, there are consequences for putting something in front of the turbo inlet. Any time you try to direct air you introduce a restriction. It's the same thing with intake port design on a piston engine. There's always a tradeoff.

I say this because I deal with step-load transient tests on a regular basis. They're not very "real world" representative tests. You hold the engine dyno fixed at a particular speed, like 1500rpm, and then you command full accelerator. Depending how you the gains are tuned on the dyno controller, the engine speed will overshoot to some degree and then be clamped back down when the brake kicks in. It's the equivalent of driving up a hill locked in top gear with a trailer on back and flooring it. It's a very rough metric for how the engine actually drives in a car.

The normal metric is time to 90% of rated steady-state torque. It's a lab number. Changing the initial turbo speed can help with that. If you sweep wastegate position you can raise the initial turbo speed.

The Borg Warner EFR turbos are ceramic ball bearing with Titanium Aluminide turbine wheels.

I have the paper you are referring to. It uses a variable swirl device, and there is data showing an increase in low end torque (1250 rpm) on a turbo DI engine which presumably was surge-limited at low speeds. However the variable swirl device functions as a throttle and needs to be controlled as such (now you're coordinating two throttles). There is a section on vehicle results which explains this.

The other thing to keep in mind is that the gains in low end torque are only if the low end torque is limited by surge or inertia of the wheel. If the limit is turbine power, pre-swirl isn't going to do it. If you run at steady-state peak load at low speed on an engine (engine dyno, or uphill towing scenario at top gear), turbine power is what limits you if you're not surging. Initial turbine speed doesn't matter. Of course that assumes the engine doesn't have a knock problem, and low speed/high load is very dangerous for knock and preignition. If you need to get more turbine power you have to retard spark, or do something to the turbine housing (smaller A/R or whatever) that would increase backpressure at high speeds. It always comes down to a low end/high end output balancing act.

No matter how you implement it, there are consequences for putting something in front of the turbo inlet. Any time you try to direct air you introduce a restriction. It's the same thing with intake port design on a piston engine. There's always a tradeoff.

#10

Yes, you have it right WANKfactor.

Guide vanes in the turbo inlet initiate the rotation of the intake charge so there is less work for the compressor wheel to do and it can accelerate (spool) faster.

Since the rate of spool is exponential small initial improvements have a larger cumulative effect.

Even just a bend in the turbo inlet duct can have some small effect.

Guide vanes in the turbo inlet initiate the rotation of the intake charge so there is less work for the compressor wheel to do and it can accelerate (spool) faster.

Since the rate of spool is exponential small initial improvements have a larger cumulative effect.

Even just a bend in the turbo inlet duct can have some small effect.

#13

I might mess around with a dual path intake with one path for pre-swirl on my next set up.

I had bought an EFR 7670 which wouldn't need any help for spool, but sold that and am thinking about an EFR 9180 on which I will be trying whatever I can to get it to spool.

So far I am thinking of using a stock 3rd gen sequential manifold with an adapter plate under my divided tubular SS manifold for a S4 TII (ish) Dual Scroll (higher initial exhaust velocity/EMP) and dual path inlet with pre-swirl.

The rotary and turbo combination I use may not follow the pre-swirl paper's findings, but it would be fun to datalog and see if pre-swirl helps spool at all over just a minimal restriction intake (current set up is 3" to 6" velocity stack to a 6" inlet 12" long truck filter).

If I was able to increase spool with pre-swirl for 3,500rpm 5th gear pulls like the papers findings it would be great.

I wouldn't mind if 5th was a bit snappier no matter what turbo I end up using.

I had bought an EFR 7670 which wouldn't need any help for spool, but sold that and am thinking about an EFR 9180 on which I will be trying whatever I can to get it to spool.

So far I am thinking of using a stock 3rd gen sequential manifold with an adapter plate under my divided tubular SS manifold for a S4 TII (ish) Dual Scroll (higher initial exhaust velocity/EMP) and dual path inlet with pre-swirl.

The rotary and turbo combination I use may not follow the pre-swirl paper's findings, but it would be fun to datalog and see if pre-swirl helps spool at all over just a minimal restriction intake (current set up is 3" to 6" velocity stack to a 6" inlet 12" long truck filter).

If I was able to increase spool with pre-swirl for 3,500rpm 5th gear pulls like the papers findings it would be great.

I wouldn't mind if 5th was a bit snappier no matter what turbo I end up using.

#14

This is interesting to me because it is opposite of what you find in electric fans for air movement and any type of dust collection etc. Basically if the air entering the fan is pre rotated it makes the fun pull less cfm, studies show that if the air is ran thru a "straightener" and not turbulent, the fan is more efficient and cfms go up dramatically. Of course this is a steady running low h.p. motor so how it correlates, if at all I couldn't tell you. The other benefit is a large drop in noise level, which is nice when im in the shop all day.

#15

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

Maybe placing your turbo inlet water/meth injection jet at the same angle that the air swirls would do the same thing?

It could be done if there is a pipe between the turbo and air filter. Too much trouble for me do deal with and test!

It could be done if there is a pipe between the turbo and air filter. Too much trouble for me do deal with and test!

#16

Full Member

iTrader: (1)

its interesting because I had this idea due to dealing with jet engines at work. where preswirl is necessary with the air being forced in there due to the speed of the aircraft. prevents stalling and whatnot(no expert on physics or anything, just familiar with the tech). turns out you guys have been thinking about it since before I was in the 7 game.. haha. anyways, how would an inlet pipe with multiple swirled grooves on the inside do? I don't think itd be restrictive like guide veins, but it would also swirl a lesser percentage of the air in the inlet.

any thoughts?

also, any advances in this tech lately?

Carrington

any thoughts?

also, any advances in this tech lately?

Carrington

Last edited by atsugiT2; 10-07-16 at 09:13 AM. Reason: typo.

#19

Rotary Enthusiast

You're a weird one rx8, strange way to bump a 7 year old thread

#20

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,778

Received 2,564 Likes

on

1,824 Posts

#21

Rotary Enthusiast

What did you write before you edited your comment? Something about there always being more hot air? Please post it again I want some help decoding it. I wish I had saved it, it was an RX8 masterpiece as always

#22

oh, I have something much better for you to put in your heart full of iniquitous imaginations to ponder upon, let your feet be swift in running to this mischief instead:

That which is born of the flesh is flesh, and that which is born of the spirit is spirit. You are of the world; you know the world, you speak of the world, and the world hears you, but we are of the spirit; you neither know us nor hear us.

.

That which is born of the flesh is flesh, and that which is born of the spirit is spirit. You are of the world; you know the world, you speak of the world, and the world hears you, but we are of the spirit; you neither know us nor hear us.

.

#23

Rotary Enthusiast

Hey man, I came here to talk about RX7's. I did not come here to be judged by someone else's god.

#24

Old [Sch|F]ool

This is old news even from the OP's time.

Pour water in a funnel. Notice that when it starts swirling, flow out of the funnel slows down. This is because the water's speed is angular rather than straight down through.

If you put a little vane in the funnel to keep the fluid moving straight, it empties much faster.

The same thing happens with a turbo compressor.... the air in the inlet starts spinning in the same direction as the turbo, which makes the turbo less efficient at moving air into itself. A simple vane across the turbo inlet, as close as practical to the wheel, will increase response and mass flow by a remarkable margin.

I don't know about "pre swirl", that would seem to require adding energy, and adding energy usually can be beneficial in other ways.

I do like the idea of a sharp bend before the compressor inlet, though.

Pour water in a funnel. Notice that when it starts swirling, flow out of the funnel slows down. This is because the water's speed is angular rather than straight down through.

If you put a little vane in the funnel to keep the fluid moving straight, it empties much faster.

The same thing happens with a turbo compressor.... the air in the inlet starts spinning in the same direction as the turbo, which makes the turbo less efficient at moving air into itself. A simple vane across the turbo inlet, as close as practical to the wheel, will increase response and mass flow by a remarkable margin.

I don't know about "pre swirl", that would seem to require adding energy, and adding energy usually can be beneficial in other ways.

I do like the idea of a sharp bend before the compressor inlet, though.

Thread

Thread Starter

Forum

Replies

Last Post

Anthrax Mike

1st Generation Specific (1979-1985)

5

11-27-05 07:29 PM