making turbo manifold

#1

Full Member

Thread Starter

Join Date: Nov 2007

Location: NJ

Posts: 117

Likes: 0

Received 0 Likes

on

0 Posts

making turbo manifold

I have been fabbing my own t4 divided turbo manifold. I have been using all the good info on here. It is definitely a task. I was using a miter saw with a chop for the cuts. My saw just died on me and I wanted to know if buying a chop saw was the best thing to get to make the cuts? I was wondering what kind of tool/tools are generally used for cutting the wastegate runner holes in the main runners?? thanks

#2

*** Bless The USA

iTrader: (8)

Join Date: Jan 2007

Location: Saint Louis / Illinois

Posts: 7,139

Received 0 Likes

on

0 Posts

I have a Hitachi Mitre saw that I used to make mine but they aren't build for that kind of work so you're better off getting a chop saw.

I'd like to know about cutting the holes for the wastegate runners as well since I'll be doing that this weekend.

I'd like to know about cutting the holes for the wastegate runners as well since I'll be doing that this weekend.

#3

Full Member

Thread Starter

Join Date: Nov 2007

Location: NJ

Posts: 117

Likes: 0

Received 0 Likes

on

0 Posts

just went out and got one..cut 3.5 inch piece of stainless pipe in like 5 seconds.

speaking of manifolds I also wanted to know how low of boost you can run in theory if you have a streetport, decent manifold with ~11 inch runners, a bw s300 with 61 wheel, and a 44mm wg with good plumbing. I have a 5 psi spring and a 1 bar spring. I need to upgrade some other things before i put down 400 whp in my fb so I wanted to run low boost.

with the wg holes in the manifold runners.. would a carbide bit with a die grinder be able to remove enough material efficiently? thanks

speaking of manifolds I also wanted to know how low of boost you can run in theory if you have a streetport, decent manifold with ~11 inch runners, a bw s300 with 61 wheel, and a 44mm wg with good plumbing. I have a 5 psi spring and a 1 bar spring. I need to upgrade some other things before i put down 400 whp in my fb so I wanted to run low boost.

with the wg holes in the manifold runners.. would a carbide bit with a die grinder be able to remove enough material efficiently? thanks

#7

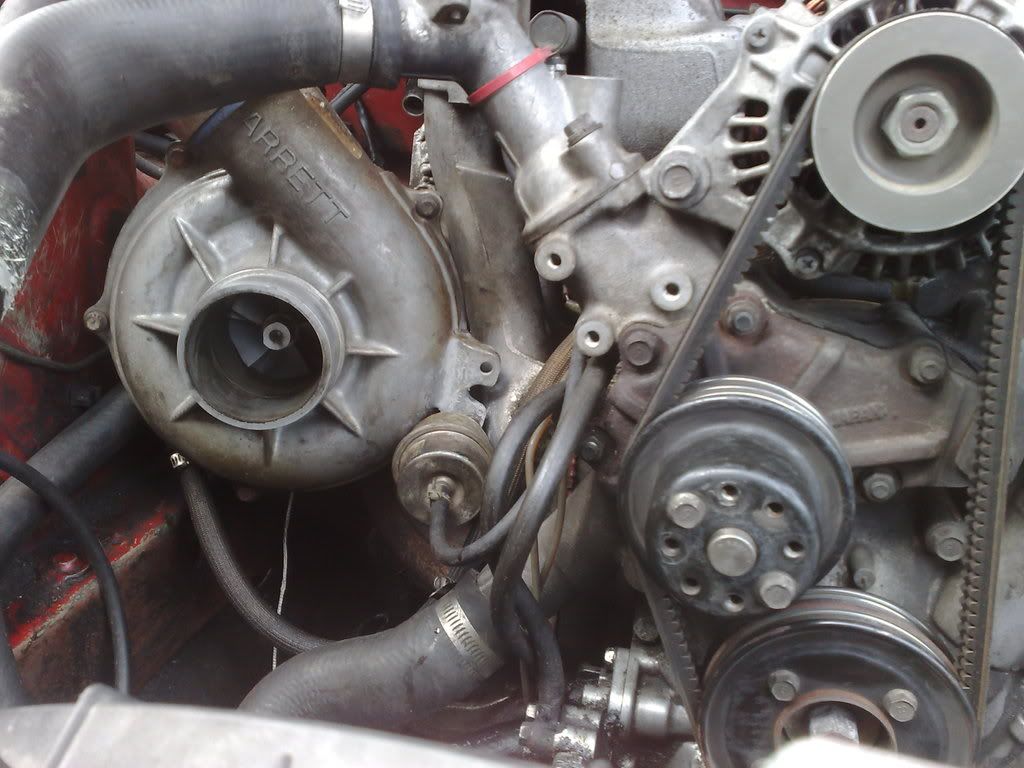

Me and a fellow fourm member who may prefer to remain anynomus built one for my car in an afternood with a $60 junkyard turbo, $40 in 14 ga mandrel bent exhaust pipe a sawzaw, and a recycled racing beat flange.

I'm not sure all of what its capabe yet, but due to poor tuning the EGT's have gotten hot enough to turn exhaust sleves into this:

and the manifold/turbo stayed together. it does have a reinforcing bar that connects the flange to the exhaust housing.

I'm not sure all of what its capabe yet, but due to poor tuning the EGT's have gotten hot enough to turn exhaust sleves into this:

and the manifold/turbo stayed together. it does have a reinforcing bar that connects the flange to the exhaust housing.

Trending Topics

#8

EGT's went out of control because that is a TINY TURBO. Theres a reason why you see a lot of "THAT TURBO IS TOO SMALL FOR A ROTARY" on here from guys who know what their doing. Tiny turbines (T25, T3) are plain just too damn small to contain the heat from a boosted rotary. It make the EGT's skyrocket even when running pig *** rich which intern kills power (and engines).

Looks like a fun afternoon with too many beers project lol. I'd prefer to remain anonymous too lol. Please don't take offense to this, it looks like it was just messing around anyway right?

~Mike..............

Looks like a fun afternoon with too many beers project lol. I'd prefer to remain anonymous too lol. Please don't take offense to this, it looks like it was just messing around anyway right?

~Mike..............

#9

Registered shy guy

iTrader: (1)

Join Date: Jul 2007

Location: tewksbury, ma

Posts: 1,436

Likes: 0

Received 0 Likes

on

0 Posts

iam going to be making my own mani for my to4b thats comming in the mail. i know what to do on the fab side of this since its close to what i do for work. but what type of tubing should i buy?

#10

Rotary Enthusiast

.

.Chris

p.s. you can get the at www.mcmaster.com

Last edited by ChrisRX8PR; 08-08-08 at 09:33 AM.

#12

EGT's went out of control because that is a TINY TURBO. Theres a reason why you see a lot of "THAT TURBO IS TOO SMALL FOR A ROTARY" on here from guys who know what their doing. Tiny turbines (T25, T3) are plain just too damn small to contain the heat from a boosted rotary. It make the EGT's skyrocket even when running pig *** rich which intern kills power (and engines).

Looks like a fun afternoon with too many beers project lol. I'd prefer to remain anonymous too lol. Please don't take offense to this, it looks like it was just messing around anyway right?

~Mike..............

Looks like a fun afternoon with too many beers project lol. I'd prefer to remain anonymous too lol. Please don't take offense to this, it looks like it was just messing around anyway right?

~Mike..............

#15

Rotary Enthusiast

Chris

#16

Registered shy guy

iTrader: (1)

Join Date: Jul 2007

Location: tewksbury, ma

Posts: 1,436

Likes: 0

Received 0 Likes

on

0 Posts

i know you can weld mild steal to it with those rods, i am a tig welder after all. iam just stuck in work mode. i weld ss all day long in the bio field plus all the other crap my work makes. i was thinking of the ozone generators i was making a few weeks ago, and half way done they deiced they didnt want to take the chance of welding mild steel to stainless. so i had to grind out my weld and insert a threaded part . but thats because ozone is so deadly one leak can kill alot of people real fast.

if the weld cracks on a mani no one will die so i guess ill just do that. the only problem i have is that i need to figure a way to tack ss to mild steel with a mig gun so i can bring it to my work to weld up on a week end. since iam broke and cant just buy my own tig welder.

if the weld cracks on a mani no one will die so i guess ill just do that. the only problem i have is that i need to figure a way to tack ss to mild steel with a mig gun so i can bring it to my work to weld up on a week end. since iam broke and cant just buy my own tig welder.

#17

Rotary Enthusiast

i know you can weld mild steal to it with those rods, i am a tig welder after all. iam just stuck in work mode. i weld ss all day long in the bio field plus all the other crap my work makes. i was thinking of the ozone generators i was making a few weeks ago, and half way done they deiced they didnt want to take the chance of welding mild steel to stainless. so i had to grind out my weld and insert a threaded part . but thats because ozone is so deadly one leak can kill alot of people real fast.

if the weld cracks on a mani no one will die so i guess ill just do that. the only problem i have is that i need to figure a way to tack ss to mild steel with a mig gun so i can bring it to my work to weld up on a week end. since iam broke and cant just buy my own tig welder.

if the weld cracks on a mani no one will die so i guess ill just do that. the only problem i have is that i need to figure a way to tack ss to mild steel with a mig gun so i can bring it to my work to weld up on a week end. since iam broke and cant just buy my own tig welder.

I see what you are saying.

As for the tacking, I've used both regular ss wire and steel wire to tack stainless to mild steel with a mig. They both work fine....you will weld over tacks anyways. On a good note if you get good metal penetration the weld will not crack. I've made at least 20 three runner turbo manifolds for 13B's(Renesis) with this exact piping I recommended and with this method most of which are driven everyday and have had no feedback of any one of them cracking or breaking so go for it

like you said, at least no one will die if one weld cracks

like you said, at least no one will die if one weld cracks

If you are still worried about SS, mcmaster.com also sells this exact same piping in cast iron

Good luck!

Chris

#18

Registered shy guy

iTrader: (1)

Join Date: Jul 2007

Location: tewksbury, ma

Posts: 1,436

Likes: 0

Received 0 Likes

on

0 Posts

i dont do much mild steel to ss tig welding so this mite be a dumb question.

i was just going to tack weld it then bring it to work and purge it with argon. will i be able to fuse it like normal or do i have to use the 308 rod? cause normal when i weld mani in my trade we wont use wire. we set the inside purge pressure to about 10 psi or so(thats what it reads on the mag reader so who know what the psi really is.) when fully penetrating fuse welding this stops the weld from blowing a hole and falling in, if you set it two high the fuse weld will bulge up or blow out while welding. but if you set it just right the pipe will be smooth where the weld is on the inside ie no concave or convex weld. does that make sense to any one lol.

i was just going to tack weld it then bring it to work and purge it with argon. will i be able to fuse it like normal or do i have to use the 308 rod? cause normal when i weld mani in my trade we wont use wire. we set the inside purge pressure to about 10 psi or so(thats what it reads on the mag reader so who know what the psi really is.) when fully penetrating fuse welding this stops the weld from blowing a hole and falling in, if you set it two high the fuse weld will bulge up or blow out while welding. but if you set it just right the pipe will be smooth where the weld is on the inside ie no concave or convex weld. does that make sense to any one lol.

#19

Rotary Enthusiast

i dont do much mild steel to ss tig welding so this mite be a dumb question.

i was just going to tack weld it then bring it to work and purge it with argon. will i be able to fuse it like normal or do i have to use the 308 rod? cause normal when i weld mani in my trade we wont use wire. we set the inside purge pressure to about 10 psi or so(thats what it reads on the mag reader so who know what the psi really is.) when fully penetrating fuse welding this stops the weld from blowing a hole and falling in, if you set it two high the fuse weld will bulge up or blow out while welding. but if you set it just right the pipe will be smooth where the weld is on the inside ie no concave or convex weld. does that make sense to any one lol.

i was just going to tack weld it then bring it to work and purge it with argon. will i be able to fuse it like normal or do i have to use the 308 rod? cause normal when i weld mani in my trade we wont use wire. we set the inside purge pressure to about 10 psi or so(thats what it reads on the mag reader so who know what the psi really is.) when fully penetrating fuse welding this stops the weld from blowing a hole and falling in, if you set it two high the fuse weld will bulge up or blow out while welding. but if you set it just right the pipe will be smooth where the weld is on the inside ie no concave or convex weld. does that make sense to any one lol.

Hope this helps...

Chris

p.s.I set the gas flow at between 15-20lbs(flow not pressure) and the amps at around 70 and it yields really nice predictable welds between the stainless pipes and the same gas but with 100amps between the thick mild steel flanges and the stainless pipes.

#20

Registered shy guy

iTrader: (1)

Join Date: Jul 2007

Location: tewksbury, ma

Posts: 1,436

Likes: 0

Received 0 Likes

on

0 Posts

yeah the purging setup is so the welds on the inside wont discolor and the wont sad ect. its not that hard to do believe it or not.i never purged any thing before i started working at my current job. ill just use filler rod on all my weld and on the flanges ill just fuse from the inside after if i dont get full pen.

speaking of welding, i was at my buddys place today working on our rs turbo capri.

where making a custom upper intake mani for it. i just tacked it up and will be bringing it to work to fully weld it. ill take pic and post it after. we went for a throttle body that was barley 1.5 inside dim to 2.75. maine reason for making a new upper.

speaking of welding, i was at my buddys place today working on our rs turbo capri.

where making a custom upper intake mani for it. i just tacked it up and will be bringing it to work to fully weld it. ill take pic and post it after. we went for a throttle body that was barley 1.5 inside dim to 2.75. maine reason for making a new upper.

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 04:40 PM

Turblown

Vendor Classifieds

0

08-18-15 10:01 PM