external wastegate EBC setup differences?

#1

FD pro licensed driver

Thread Starter

iTrader: (3)

Join Date: Feb 2006

Location: Renton/Bellevue/Seattle WA

Posts: 2,897

Likes: 0

Received 2 Likes

on

2 Posts

external wastegate EBC setup differences?

Hello. I am having some issues with my boost right now. I am using the haltech closed loop boost control that I am about to ditch as soon as I figure some stuff out.

I am using method one in the diagrams below.

Currently my wastegate is still getting pushed open a little (I don't know how since the top valve should be shut) and I want to switch to method 2.

My question is, why is method 2 high boost, and what is the negative to doing it that way? What psi is "high boost"? I am currently running ~11.5-12 psi.

I have a tial 38mm wategate with 7 lb spring (and there is about a 1.5 psi drop between the turbo and the lim, so my WG opens at about 5 psi. (I am getting WG pressure from the turbo, and my haltech is getting pressure readings from behind the throttle body.)

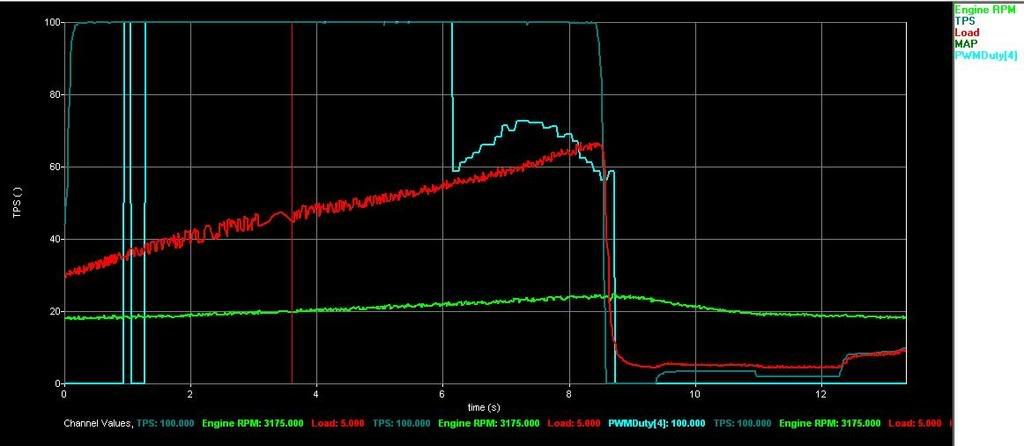

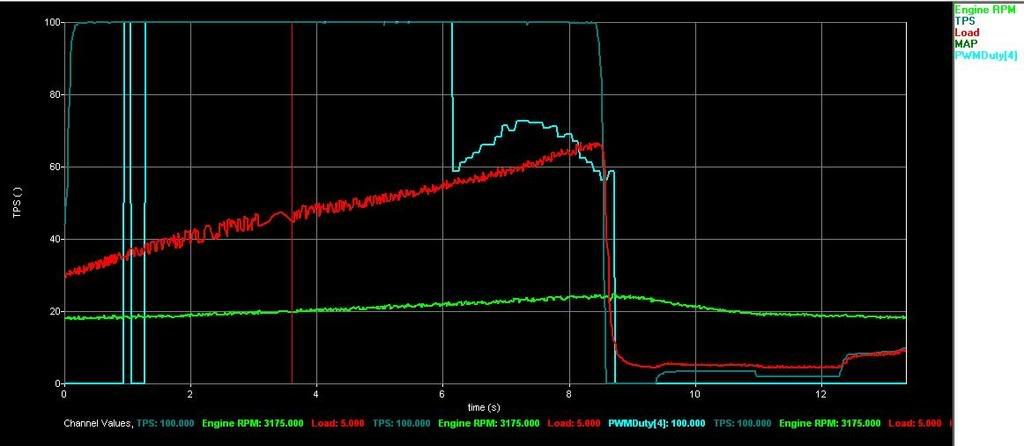

The reason I think/know my wastegate is opening is because of this last experimental pull I did last night. (5th gear for super slow boost build) I noticed that at the ~6 psi that something funky happened. My boost actually fell a full psi.

If there was enough pressure to even open the wastegate a little bit at the wastegate spring's pressure that means something is wrong right? I am going to check my pluming tonight some more, but most likely going to try the method 2 if there isn't a specific reason I shouldn't?

I have a theory that maybe method one leaves just a little bit of play on the top port, since the air can still compress a little and allow the WG valve to move. I am using basically 3 ft of fuel injected fuel hose for now, so maybe it is just leaving too much air to be compressed instead of forcing the valve shut?

Any insight is welcome.

Thanks

~Tweak

(PS) and I made a huge breakthrough in my own head. I was super confused why the solenoid kept going full duty cycle at 1.5 psi and then would drop down. I was under the impression that the valve would increase duty cycle WHEN I want the solenoid to switch, but instead it looks like it is supposed to click it SHUT when you go into boost, and slowly turn off the valve's duty cycle when it wants to open the gate. Pretty weird, I'm not quite sure why yet, maybe its easier to de-energize a coil, that to energize it quickly?

I am using method one in the diagrams below.

Currently my wastegate is still getting pushed open a little (I don't know how since the top valve should be shut) and I want to switch to method 2.

My question is, why is method 2 high boost, and what is the negative to doing it that way? What psi is "high boost"? I am currently running ~11.5-12 psi.

I have a tial 38mm wategate with 7 lb spring (and there is about a 1.5 psi drop between the turbo and the lim, so my WG opens at about 5 psi. (I am getting WG pressure from the turbo, and my haltech is getting pressure readings from behind the throttle body.)

The reason I think/know my wastegate is opening is because of this last experimental pull I did last night. (5th gear for super slow boost build) I noticed that at the ~6 psi that something funky happened. My boost actually fell a full psi.

If there was enough pressure to even open the wastegate a little bit at the wastegate spring's pressure that means something is wrong right? I am going to check my pluming tonight some more, but most likely going to try the method 2 if there isn't a specific reason I shouldn't?

I have a theory that maybe method one leaves just a little bit of play on the top port, since the air can still compress a little and allow the WG valve to move. I am using basically 3 ft of fuel injected fuel hose for now, so maybe it is just leaving too much air to be compressed instead of forcing the valve shut?

Any insight is welcome.

Thanks

~Tweak

(PS) and I made a huge breakthrough in my own head. I was super confused why the solenoid kept going full duty cycle at 1.5 psi and then would drop down. I was under the impression that the valve would increase duty cycle WHEN I want the solenoid to switch, but instead it looks like it is supposed to click it SHUT when you go into boost, and slowly turn off the valve's duty cycle when it wants to open the gate. Pretty weird, I'm not quite sure why yet, maybe its easier to de-energize a coil, that to energize it quickly?

Last edited by TweakGames; 10-20-08 at 02:30 PM.

#2

FD pro licensed driver

Thread Starter

iTrader: (3)

Join Date: Feb 2006

Location: Renton/Bellevue/Seattle WA

Posts: 2,897

Likes: 0

Received 2 Likes

on

2 Posts

Opps, I'm an idiot. There wouldn't be any extra air to be compressed or anything by the valve on the top wastegate line because the air from the turbo is going to go through the valve and push the top valve down (or hopefully with the same force as the air pushing the bottom up) so that it won't move.

Hmmm... I wonder what's going on here..... :/

Hmmm... I wonder what's going on here..... :/

#3

I have a tial 38mm wategate with 7 lb spring (and there is about a 1.5 psi drop between the turbo and the lim, so my WG opens at about 5 psi.

#6

the high energy of the rotary exhaust is pushing the spring open. it is bleeding exhaust as soon as you load the engine down. Therefore it is not creeping (never gets enough exhaust to spin the wheel up) but it is also laggy. That's the theory. A tial 38 with a 7psi spring is what I have run on turbo civics. The other problem could be that you don't have your valve seat ("fire ring") installed correctly)

Vent your wastegate to atmosphere. you should hear it opening really early if it is cracking too soon due to the spring. I'll put it to you this way: I don't know of anyone who runs a Tial 38 on a rotary. I mean there's probably somebody somewhere who does it, but it's not an accepted practice for a reason.

Vent your wastegate to atmosphere. you should hear it opening really early if it is cracking too soon due to the spring. I'll put it to you this way: I don't know of anyone who runs a Tial 38 on a rotary. I mean there's probably somebody somewhere who does it, but it's not an accepted practice for a reason.

Last edited by arghx; 10-21-08 at 12:41 AM.

Trending Topics

#8

^ It's the cheapest solution to try. Then run straight atmospheric pressure to the side port (eliminate the boost controller completely for now) for a while and datalog your boost curve. I ran the HKS 40mm on an FC HKS log manifold and it creeped past the 10psi spring, although the HKS FC mani only bleeds exhaust off one runner. As the weather gets cold you will see if the Tial 38 can keep you from creeping. It should reach spring pressure in your logs and stay there with only very very minor fluctuation.

Last edited by arghx; 10-21-08 at 12:48 AM.

#11

FD pro licensed driver

Thread Starter

iTrader: (3)

Join Date: Feb 2006

Location: Renton/Bellevue/Seattle WA

Posts: 2,897

Likes: 0

Received 2 Likes

on

2 Posts

Update : I poured soupy water all over my exhaust manifold and shot compressed air into my muffler. TONS of bubbles. :/

It turned out that my manifold was warped pretty good on one side, so I took a bench sander to it for a good 4 hours. Smooth and perfectly flat now.

Smooth and perfectly flat now.

( I used two methods to get flatness if anybody is interested. I had a flat ruler, a round flat metal rod, and a dark blue marker. At first I just colored in the flange with the blue marker and then did a quick general sanding with the bench sander. That showed me pretty much where all the high and low spots where. (high spots sanded away, and the low spots had blue left.) Then I used the flat edge and flat round bar of metal to get it even loser to perfect as I got it close enough to where all the blue would disappear.)

It took some time but I got it flat. While I had the manifold off I decided to wrap it with my fiberglass wrap. I tightened all my turbo and wastegate bolts, and put it back on with a stock metal gasket. At first I had some weird, (no clue how it got there) hard somewhat paper/plastic gasket. I put the thick metal on on there and tightened everything as hard as I could.

Now the car is MUCH quieter, the exhaust sounds much better coming out the rear, I have no exhaust smell, AND I get boost a LOT sooner! I can actually look at my tach after I hit full boost now. Much nicer to drive hitting boost earlier than redline and max psi hitting at the same time. Anyways, I was able to do a lot of pulls today, and it is MUCH better. Thanks for all that have helped. I still need to upgrade to larger exhaust DP, and muffler. The n1 seems pretty restrictive. :/

Anyways, I was able to do a lot of pulls today, and it is MUCH better. Thanks for all that have helped. I still need to upgrade to larger exhaust DP, and muffler. The n1 seems pretty restrictive. :/

Again! Thanks. I <3 my car more and more every day.

lol

~Tweak

It turned out that my manifold was warped pretty good on one side, so I took a bench sander to it for a good 4 hours.

Smooth and perfectly flat now.

Smooth and perfectly flat now. ( I used two methods to get flatness if anybody is interested. I had a flat ruler, a round flat metal rod, and a dark blue marker. At first I just colored in the flange with the blue marker and then did a quick general sanding with the bench sander. That showed me pretty much where all the high and low spots where. (high spots sanded away, and the low spots had blue left.) Then I used the flat edge and flat round bar of metal to get it even loser to perfect as I got it close enough to where all the blue would disappear.)

It took some time but I got it flat. While I had the manifold off I decided to wrap it with my fiberglass wrap. I tightened all my turbo and wastegate bolts, and put it back on with a stock metal gasket. At first I had some weird, (no clue how it got there) hard somewhat paper/plastic gasket. I put the thick metal on on there and tightened everything as hard as I could.

Now the car is MUCH quieter, the exhaust sounds much better coming out the rear, I have no exhaust smell, AND I get boost a LOT sooner! I can actually look at my tach after I hit full boost now. Much nicer to drive hitting boost earlier than redline and max psi hitting at the same time.

Anyways, I was able to do a lot of pulls today, and it is MUCH better. Thanks for all that have helped. I still need to upgrade to larger exhaust DP, and muffler. The n1 seems pretty restrictive. :/

Anyways, I was able to do a lot of pulls today, and it is MUCH better. Thanks for all that have helped. I still need to upgrade to larger exhaust DP, and muffler. The n1 seems pretty restrictive. :/ Again! Thanks. I <3 my car more and more every day.

lol

~Tweak

#12

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

All ICs cause a pressure drop thus the pressure near the TB will be lower than before the IC. If you take your WG and EBC pressure source after the IC, your system will work better as it will be using the same pressure source and will not have a pressure differntial. This will help your problem even with the 7psi WG spring.

Most EBC instructions do not memention this.

Most EBC instructions do not memention this.

#13

FD pro licensed driver

Thread Starter

iTrader: (3)

Join Date: Feb 2006

Location: Renton/Bellevue/Seattle WA

Posts: 2,897

Likes: 0

Received 2 Likes

on

2 Posts

All ICs cause a pressure drop thus the pressure near the TB will be lower than before the IC. If you take your WG and EBC pressure source after the IC, your system will work better as it will be using the same pressure source and will not have a pressure differntial. This will help your problem even with the 7psi WG spring.

Most EBC instructions do not memention this.

Most EBC instructions do not memention this.

Also I think that my IC is only dropping my pressure .6 psi. When I look at my Haltech with the car off I am at -1.4 psi. My haltech says I am at 5 psi when I am on just my spring, and the spring is supposed to be 7 psi. The wastegate is getting it's source pre-IC as mentioned above.. I don't remember where I was going with this... but yeah, 1/2 psi isn't that bad of a drop lol. I guess that assumes that the wastegate spring is exactly 7 psi, and that my wastegate isn't being blown open... I will do a few more logged runs tonight. My general boost is a LOT better, but I still notice it goes SUPER fast from 0-5 psi, then hesitates, then climbs (slower than from 0-5) up to 12. I would think that it would want to spike up fast, but maybe I am wrong.

Also, thank you for your input.

Last edited by TweakGames; 10-27-08 at 05:29 PM.

#14

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

It has not been proven that your exhaust is forcing the WG open.

My original wg spring was 7psi and it did not stop me from running 15psi boost and making it by 3800 but mine was a 46mm Tial. I went to a 10lb spring to increase spoolup by about 200 rpm.

After all the EBC controlls boost by controlling the pressure on top of the WG.

My original wg spring was 7psi and it did not stop me from running 15psi boost and making it by 3800 but mine was a 46mm Tial. I went to a 10lb spring to increase spoolup by about 200 rpm.

After all the EBC controlls boost by controlling the pressure on top of the WG.

#15

FD pro licensed driver

Thread Starter

iTrader: (3)

Join Date: Feb 2006

Location: Renton/Bellevue/Seattle WA

Posts: 2,897

Likes: 0

Received 2 Likes

on

2 Posts

It has not been proven that your exhaust is forcing the WG open.

My original wg spring was 7psi and it did not stop me from running 15psi boost and making it by 3800 but mine was a 46mm Tial. I went to a 10lb spring to increase spoolup by about 200 rpm.

After all the EBC controlls boost by controlling the pressure on top of the WG.

My original wg spring was 7psi and it did not stop me from running 15psi boost and making it by 3800 but mine was a 46mm Tial. I went to a 10lb spring to increase spoolup by about 200 rpm.

After all the EBC controlls boost by controlling the pressure on top of the WG.

#16

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

I doubt that the WG valve seat is leaking and thus allowing exhaust to escape.

If you do have a leak, then it might be in the WG internal seal. If this happens, then your EBC will not properly controll boost. You would have to pressurize the control hoses to listen for WG leaks. This has happend to a friend and some others here on the forum.

Some boost controllers are more difficult to properly setup to accurately control boost. Most have a "GAIN" feature that allows faster spoolup at the risk that with too much gain you will get an initial boost spike. My setup will not spike but with too much gain boost starts to run higher as if I had increased the "RATIO".

All WGs will start to open sooner than the spring pressure. Even when you adjust "GAIN". That is why a 10lb spring will build boost a little sooner than a 7lb one. Best to run a sping near you lowest planned running boost.

I have 10lb spring which gives me 11psi boost minimun. I normally run this to get better mileage then when boost is set to 16psi. At 16 it builds so fast.

An undersize WG will cause boost creap.

If you do have a leak, then it might be in the WG internal seal. If this happens, then your EBC will not properly controll boost. You would have to pressurize the control hoses to listen for WG leaks. This has happend to a friend and some others here on the forum.

Some boost controllers are more difficult to properly setup to accurately control boost. Most have a "GAIN" feature that allows faster spoolup at the risk that with too much gain you will get an initial boost spike. My setup will not spike but with too much gain boost starts to run higher as if I had increased the "RATIO".

All WGs will start to open sooner than the spring pressure. Even when you adjust "GAIN". That is why a 10lb spring will build boost a little sooner than a 7lb one. Best to run a sping near you lowest planned running boost.

I have 10lb spring which gives me 11psi boost minimun. I normally run this to get better mileage then when boost is set to 16psi. At 16 it builds so fast.

An undersize WG will cause boost creap.

Last edited by cewrx7r1; 10-29-08 at 02:38 PM.

#17

FD pro licensed driver

Thread Starter

iTrader: (3)

Join Date: Feb 2006

Location: Renton/Bellevue/Seattle WA

Posts: 2,897

Likes: 0

Received 2 Likes

on

2 Posts

Thanks for that. Pretty common knowledge things there, but I am using the haltech boost controller and switching to the ams-500 so things are a little different for me. Anyways, good try, I will just have to figure this out on my own.

Thanks.

The problem I am having just to clarify is that although my EBC isn't closing my top port, my wastegate is still opening a little after my spring pressure. Like the above picture shows, at the 5 psi mark, even though the top port is still getting full pressure I get a drop in psi (assuming because my wastegate is being pushed open. I will have to figure out a way to do some more tests while I am waiting for my 11.1 lb spring to come in.

Thanks.

The problem I am having just to clarify is that although my EBC isn't closing my top port, my wastegate is still opening a little after my spring pressure. Like the above picture shows, at the 5 psi mark, even though the top port is still getting full pressure I get a drop in psi (assuming because my wastegate is being pushed open. I will have to figure out a way to do some more tests while I am waiting for my 11.1 lb spring to come in.

Last edited by TweakGames; 10-29-08 at 02:53 PM.

Thread

Thread Starter

Forum

Replies

Last Post