BNR turbos: Is this the end for single set up?

#51

Originally posted by Zero R

I would like to see where it is stated you have to have stock turbo's or IC. I would bet , if you could prove your car passed emmisions within the legal requirements you could pass, if I remember correctly it's not that having the part on the car is illegal, only that the parts would need to be proven not to effect your emmisions output. This might require you to get a EO as it is called on those parts, but it could be done and you would be legal.I just don't think it's worth it to most people.

I would like to see where it is stated you have to have stock turbo's or IC. I would bet , if you could prove your car passed emmisions within the legal requirements you could pass, if I remember correctly it's not that having the part on the car is illegal, only that the parts would need to be proven not to effect your emmisions output. This might require you to get a EO as it is called on those parts, but it could be done and you would be legal.I just don't think it's worth it to most people.

http://www.arb.ca.gov/msprog/aftermkt/aftermkt.htm

Legal add-on or modified parts (Executive Order parts)

List of parts granted Executive Orders (EO's) Exempted parts are add-on or modified parts that have undergone an ARB engineering evaluation. If the part or modification is shown to not increase vehicle emissions, it is granted an exemption to emission control system anti-tampering laws. This exemption is called an Executive Order (EO) and allows the modification to be installed on specific emission controlled vehicles. Every Executive Order part or modification has an assigned number that can be verified by Smog Check stations, BAR Referee stations, or by the ARB.

Competition or racing use only parts

Information about uncontrolled vehicles Competition or racing parts are those that have not been proven by their manufacturer to not increase vehicle emissions. These parts are not legal for use on any pollution controlled vehicle. These parts may only be used on closed course racing or competition vehicles or on off-road vehicles manufactured prior to the introduction of emissions control standards (uncontrolled vehicles).

#52

Eats, Sleeps, Dreams Rotary

iTrader: (2)

The dynamic seal might reduce friction to help the turbo spool up faster but the larger amount of heat reduced from what you describe is due to the more efficient compressor wheel. If there is a large amount of friction between the carbon seal and the turbine shaft, the turbo simply won't spin and that's the time you need a turbo overhaul.

Dynamic seal has been around for a while. Turbonetic offers the dynamic seal option on all their turbos.

According to your result, the turbo still works greatly but your concept is not correct. That's all. Not putting anyone down or any product down.

Chuck Huang

Dynamic seal has been around for a while. Turbonetic offers the dynamic seal option on all their turbos.

According to your result, the turbo still works greatly but your concept is not correct. That's all. Not putting anyone down or any product down.

Chuck Huang

Originally posted by SPOautos

Carbon seals have huge amounts of frictions compared to a dynamic seal. What does friction create??? Heat

This is why there havent been any turbos with carbon seals in years and years.

And yea, you are correct that the more efficient wheels also help, but there have been many upgraded twins with different compressor wheels that didnt get the cooling ability that these do. Its bacause all they did was take the stock turbos and fit a new compressor wheel to them. I believe the M2's runn pretty cool as well, they are bb though so they dont have the crap carbon seals.

STEPHEN

Carbon seals have huge amounts of frictions compared to a dynamic seal. What does friction create??? Heat

This is why there havent been any turbos with carbon seals in years and years.

And yea, you are correct that the more efficient wheels also help, but there have been many upgraded twins with different compressor wheels that didnt get the cooling ability that these do. Its bacause all they did was take the stock turbos and fit a new compressor wheel to them. I believe the M2's runn pretty cool as well, they are bb though so they dont have the crap carbon seals.

STEPHEN

Last edited by rotaryextreme; 01-24-03 at 12:52 PM.

#53

Hey, where did my $$$ go?

Join Date: Feb 2001

Location: Bimingham, AL

Posts: 4,413

Likes: 0

Received 0 Likes

on

0 Posts

Yea, I know they both play a part. I've figured since they cool so much better than other upgraded twins I've seen I concluded it was probably due to the dynamic seal. Maybe its just that the other upgraded twins had a poorly choosen compressor wheel. I'm no turbo engineer, I was just going off my assumptions.

Either way, they are much cooler and spool faster than stockers....no matter if its from the seal, compressor wheel, or a combination of the two.

STEPHEN

Either way, they are much cooler and spool faster than stockers....no matter if its from the seal, compressor wheel, or a combination of the two.

STEPHEN

#54

WTB** Very Low Miles 94-95

Join Date: Jul 2001

Location: Tejas

Posts: 3,298

Likes: 0

Received 0 Likes

on

0 Posts

this thread turned funny....

poweraxel...you got any numbers for your twins yet? Your thread has been up for a year or there abouts right?

just wondering. Id love to see the results.

jason

poweraxel...you got any numbers for your twins yet? Your thread has been up for a year or there abouts right?

just wondering. Id love to see the results.

jason

#55

Rotary Enthusiast

Join Date: Feb 2001

Location: In the Sky

Posts: 1,190

Likes: 0

Received 0 Likes

on

0 Posts

artguy:

i dont see how its been a year or so??? that thread was started 12/10/02 if i do my math correctly its been a month and a half.. i wont have that turbo kit for at least until the middle/end of spring due to the nasty weather here. who knows i might just keep my HKS T04R

i dont see how its been a year or so??? that thread was started 12/10/02 if i do my math correctly its been a month and a half.. i wont have that turbo kit for at least until the middle/end of spring due to the nasty weather here. who knows i might just keep my HKS T04R

Originally posted by artguy

this thread turned funny....

poweraxel...you got any numbers for your twins yet? Your thread has been up for a year or there abouts right?

just wondering. Id love to see the results.

jason

this thread turned funny....

poweraxel...you got any numbers for your twins yet? Your thread has been up for a year or there abouts right?

just wondering. Id love to see the results.

jason

#56

Rotary Enthusiast

Join Date: Feb 2001

Location: In the Sky

Posts: 1,190

Likes: 0

Received 0 Likes

on

0 Posts

no problem.

Originally posted by SPOautos

Poweraxle, I'm sorry if I got under your skin. I dont really want to **** anyone off, I'm just trying to tell everyone what these turbos are all about. I guess your first post just rubbed me the wrong way, to ME is sounded like you were trashing them in a round about way. Maybe you didnt intend it that way.

STEPHEN

Poweraxle, I'm sorry if I got under your skin. I dont really want to **** anyone off, I'm just trying to tell everyone what these turbos are all about. I guess your first post just rubbed me the wrong way, to ME is sounded like you were trashing them in a round about way. Maybe you didnt intend it that way.

STEPHEN

#57

Originally posted by mjw

Here, I even did the research for you.. not that I follow these laws anyway.

http://www.arb.ca.gov/msprog/aftermkt/aftermkt.htm

Legal add-on or modified parts (Executive Order parts)

List of parts granted Executive Orders (EO's) Exempted parts are add-on or modified parts that have undergone an ARB engineering evaluation. If the part or modification is shown to not increase vehicle emissions, it is granted an exemption to emission control system anti-tampering laws. This exemption is called an Executive Order (EO) and allows the modification to be installed on specific emission controlled vehicles. Every Executive Order part or modification has an assigned number that can be verified by Smog Check stations, BAR Referee stations, or by the ARB.

Competition or racing use only parts

Information about uncontrolled vehicles Competition or racing parts are those that have not been proven by their manufacturer to not increase vehicle emissions. These parts are not legal for use on any pollution controlled vehicle. These parts may only be used on closed course racing or competition vehicles or on off-road vehicles manufactured prior to the introduction of emissions control standards (uncontrolled vehicles).

Here, I even did the research for you.. not that I follow these laws anyway.

http://www.arb.ca.gov/msprog/aftermkt/aftermkt.htm

Legal add-on or modified parts (Executive Order parts)

List of parts granted Executive Orders (EO's) Exempted parts are add-on or modified parts that have undergone an ARB engineering evaluation. If the part or modification is shown to not increase vehicle emissions, it is granted an exemption to emission control system anti-tampering laws. This exemption is called an Executive Order (EO) and allows the modification to be installed on specific emission controlled vehicles. Every Executive Order part or modification has an assigned number that can be verified by Smog Check stations, BAR Referee stations, or by the ARB.

Competition or racing use only parts

Information about uncontrolled vehicles Competition or racing parts are those that have not been proven by their manufacturer to not increase vehicle emissions. These parts are not legal for use on any pollution controlled vehicle. These parts may only be used on closed course racing or competition vehicles or on off-road vehicles manufactured prior to the introduction of emissions control standards (uncontrolled vehicles).

If you read my post again I stated if someone wanted to go through the process I bet you could get your car to pass.

If you read my post again I stated if someone wanted to go through the process I bet you could get your car to pass."Exempted parts are add-on or modified parts that have undergone an ARB engineering evaluation. If the part or modification is shown to not increase vehicle emissions, it is granted an exemption to emission control system anti-tampering laws."

So someone would have to be willing to get EO's on there parts. Having the parts on your on your car is not illegal, having parts that haven't gone through the process is.

If one person would be willing to take there car in with this IC and that turbo kit, or take the parts in it would open it up for everyone at that point.

#58

Hey, where did my $$$ go?

Join Date: Feb 2001

Location: Bimingham, AL

Posts: 4,413

Likes: 0

Received 0 Likes

on

0 Posts

I'm pretty sure thats the process a company does when they get something "CARB approved"

I dont think its a very easy or quick process. If it was most aftermarket parts would try to get carb approved.

STEPHEN

I dont think its a very easy or quick process. If it was most aftermarket parts would try to get carb approved.

STEPHEN

#61

Originally posted by SPOautos

I'm pretty sure thats the process a company does when they get something "CARB approved"

I dont think its a very easy or quick process. If it was most aftermarket parts would try to get carb approved.

STEPHEN

I'm pretty sure thats the process a company does when they get something "CARB approved"

I dont think its a very easy or quick process. If it was most aftermarket parts would try to get carb approved.

STEPHEN

The point I am trying to make to ZeroR is that you can't just slap on whatever you want and roll up to the emissions station like..'hey, slap it on the dyno.. it'll pass the sniffer.' That just isn't the case, they will fail you on the spot if they see anything out of place.

So someone would have to be willing to get EO's on there parts. Having the parts on your on your car is not illegal, having parts that haven't gone through the process is.

If one person would be willing to take there car in with this IC and that turbo kit, or take the parts in it would open it up for everyone at that point.

No, having the parts on your car IS illegal..

You are oversimplifing the CARB certification process, I can't just take my car in and tell them, 'hey, my car passes.. so x part and y part should be legal now give me my CARB sticker.' Emissions in CA is very tough, I wish it were that easy.

Matt

#62

I never said you could, I never said it was a simple process, I said again if you would read the posts it is possible if you wanted to do it, nowhere does it say you can't. As far as oversimplifing everything hardly. But this is the same kind of simple ignorance that gets blabbed around about motorex and importing vehicles and how much it costs and how hard it is,IT'S NOT . They lead you to believe it is harder than it is, or not possible,or only they can. I can get you a skyline for dirt cheap, and I can get it complied for a third what Motorex does. I have done it for people in the past.Same thing goes with this, it was said you can't do it the law says so, all I'm saying is it doesn't say you can't, just that you need to go through the process required, and most don't value the car enough to go through whats involved.

#63

Eats, Sleeps, Dreams Rotary

iTrader: (2)

I don't know what BNR uses for thier compressor wheels and I am pretty sure BNR is not going to tell us. I used to offer stock turbo turbo upgrades when I still owned RX-7 Fashion. The wheels used are the T3 super 60 which flows about 32 lb/min at 1 bar.

Right now there are the new GT turbo compressor wheels that you can use and I am pretty sure they are more efficient than the T3 super 60. Maybe BNR is using the new GT turbo compressor wheels.

BNR does not have to tell us which exact wheel he uses but I am very interested in what kind of flow rate it has at 1 bar in comparision with the T3 super 60 ones.

I dyno tuned one of my friend's car with the stock sequential twins. The car has straight pipe, stock mount IC, ported motor (racing beat street port template), intake,HKS twin power, R33 fuel pump, and a restrictive HKS old style cat-back exhaust

It was dynoed at 385 at the wheel running at 1.15 kg/cm2 of boost according power fc. From that number, I am guessing the BNR compressor probably flows about the same as the T3 Super 60 but since it has a more efficient compressor wheel, it made more power.

If I am guessing correctly, BNR is probably using the same GT wheel that's on the M2 ball bearing turbo. There are only certain compressor wheels that has the size that will fit into the stock compressor housing.

Chuck Huang

Right now there are the new GT turbo compressor wheels that you can use and I am pretty sure they are more efficient than the T3 super 60. Maybe BNR is using the new GT turbo compressor wheels.

BNR does not have to tell us which exact wheel he uses but I am very interested in what kind of flow rate it has at 1 bar in comparision with the T3 super 60 ones.

I dyno tuned one of my friend's car with the stock sequential twins. The car has straight pipe, stock mount IC, ported motor (racing beat street port template), intake,HKS twin power, R33 fuel pump, and a restrictive HKS old style cat-back exhaust

It was dynoed at 385 at the wheel running at 1.15 kg/cm2 of boost according power fc. From that number, I am guessing the BNR compressor probably flows about the same as the T3 Super 60 but since it has a more efficient compressor wheel, it made more power.

If I am guessing correctly, BNR is probably using the same GT wheel that's on the M2 ball bearing turbo. There are only certain compressor wheels that has the size that will fit into the stock compressor housing.

Chuck Huang

Originally posted by SPOautos

Yea, I know they both play a part. I've figured since they cool so much better than other upgraded twins I've seen I concluded it was probably due to the dynamic seal. Maybe its just that the other upgraded twins had a poorly choosen compressor wheel. I'm no turbo engineer, I was just going off my assumptions.

Either way, they are much cooler and spool faster than stockers....no matter if its from the seal, compressor wheel, or a combination of the two.

STEPHEN

Yea, I know they both play a part. I've figured since they cool so much better than other upgraded twins I've seen I concluded it was probably due to the dynamic seal. Maybe its just that the other upgraded twins had a poorly choosen compressor wheel. I'm no turbo engineer, I was just going off my assumptions.

Either way, they are much cooler and spool faster than stockers....no matter if its from the seal, compressor wheel, or a combination of the two.

STEPHEN

#64

Rotary Enthusiast

Join Date: Mar 2001

Location: Mechanicsburg, PA USA

Posts: 1,392

Likes: 0

Received 0 Likes

on

0 Posts

If I had a choice and money wasn't an option, I'd do a single turbo. Simple, proven, and certain turbos really are streetable. I know everyone has a different idea for "streetable" as far as lag goes but these BNRs really are impressive. They have more response down low than a RX6 and make over 400+ rwhp non-seq. It would be interesting to see how they run sequential.

I chose the BNRs because my wife wouldn't let me spend the money on a single - I wanted a TO4S or a custom TO4e but the kits are around $3K plus fuel rail. The only downfall I see to the BNR is if something does go wrong, it's such a PITA pulling those turbos. A single is a cinch to work on. Other than that - you can have very impressive hp for $1K-2K less than a single turbo. The BNRs need to be proven though like others here have stated. Single turbos have definitely proven they can make reliable power.

- I wanted a TO4S or a custom TO4e but the kits are around $3K plus fuel rail. The only downfall I see to the BNR is if something does go wrong, it's such a PITA pulling those turbos. A single is a cinch to work on. Other than that - you can have very impressive hp for $1K-2K less than a single turbo. The BNRs need to be proven though like others here have stated. Single turbos have definitely proven they can make reliable power.

I chose the BNRs because my wife wouldn't let me spend the money on a single

- I wanted a TO4S or a custom TO4e but the kits are around $3K plus fuel rail. The only downfall I see to the BNR is if something does go wrong, it's such a PITA pulling those turbos. A single is a cinch to work on. Other than that - you can have very impressive hp for $1K-2K less than a single turbo. The BNRs need to be proven though like others here have stated. Single turbos have definitely proven they can make reliable power.

- I wanted a TO4S or a custom TO4e but the kits are around $3K plus fuel rail. The only downfall I see to the BNR is if something does go wrong, it's such a PITA pulling those turbos. A single is a cinch to work on. Other than that - you can have very impressive hp for $1K-2K less than a single turbo. The BNRs need to be proven though like others here have stated. Single turbos have definitely proven they can make reliable power.

#65

Eats, Sleeps, Dreams Rotary

iTrader: (2)

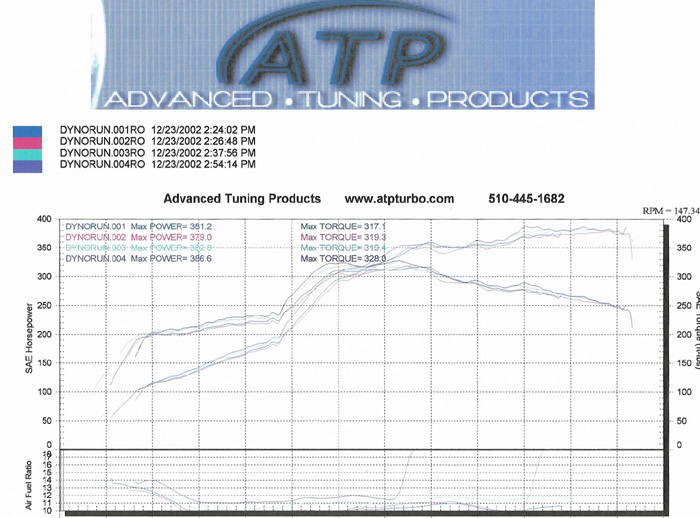

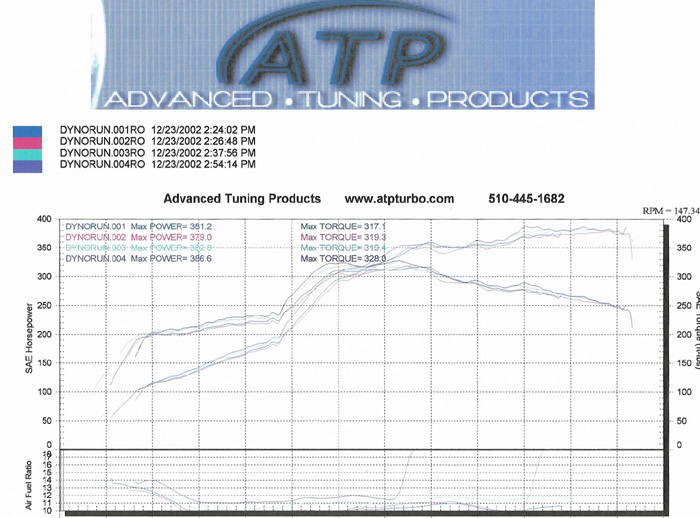

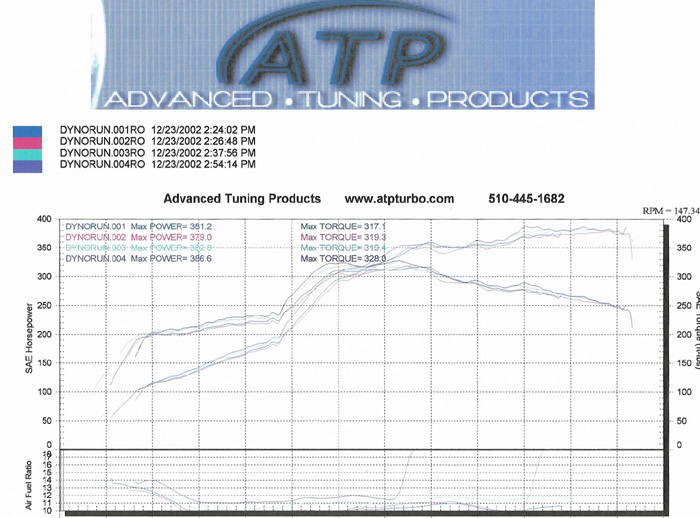

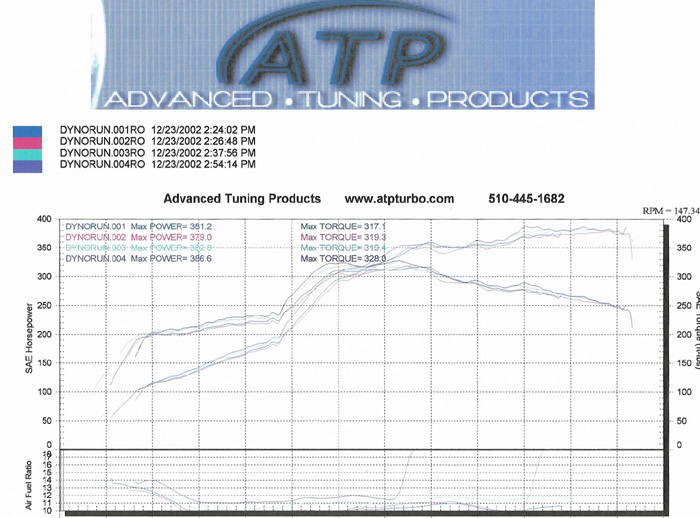

386.6 at the wheel with stock twins

Here is the Dynosheet I was talking about.

The car has the following mods:

R33 fuel pump

cold air intake

large stock mount IC

550cc/min primary and 1300cc/min secondary

HKS twin power

downpipe, midpipe and the restrictive old school HKS cat-back

power fc

The dynosheet shows the a/f. At some of the runs, the o2 sensor blows out of the tail pipe during the run so it looks like it's running lean like crazy but it's not. The intake temp measured by the power fc is at 45C.

Chuck Huang

The car has the following mods:

R33 fuel pump

cold air intake

large stock mount IC

550cc/min primary and 1300cc/min secondary

HKS twin power

downpipe, midpipe and the restrictive old school HKS cat-back

power fc

The dynosheet shows the a/f. At some of the runs, the o2 sensor blows out of the tail pipe during the run so it looks like it's running lean like crazy but it's not. The intake temp measured by the power fc is at 45C.

Chuck Huang

#66

Eats, Sleeps, Dreams Rotary

iTrader: (2)

386.6 at the wheel with stock twins

Here is the Dynosheet I was talking about.

The car has the following mods:

R33 fuel pump

cold air intake

large stock mount IC

550cc/min primary and 1300cc/min secondary

HKS twin power

downpipe, midpipe and the restrictive old school HKS cat-back

power fc

The dynosheet shows the a/f. At some of the runs, the o2 sensor blows out of the tail pipe during the run so it looks like it's running lean like crazy at high rpm but it's not. The intake temp measured by the power fc is at 45C. The boost is at 1.15 measured by power fc.

Chuck Huang

The car has the following mods:

R33 fuel pump

cold air intake

large stock mount IC

550cc/min primary and 1300cc/min secondary

HKS twin power

downpipe, midpipe and the restrictive old school HKS cat-back

power fc

The dynosheet shows the a/f. At some of the runs, the o2 sensor blows out of the tail pipe during the run so it looks like it's running lean like crazy at high rpm but it's not. The intake temp measured by the power fc is at 45C. The boost is at 1.15 measured by power fc.

Chuck Huang

#67

Senior Member

Join Date: Jul 2001

Location: Birmingham, AL

Posts: 322

Likes: 0

Received 0 Likes

on

0 Posts

Power Excel

I was reading up on your previous posts. I can see that you understand the internals and how turbochargers work.

You want the least amount of friction on a rotating assemblies as possible. This hints to increased spool up time and also reliability, b/c less friction is less heat, and the less heat the less stress you have on a tiny 5mm shaft like the HT12's.

As for compressor trims, I will not release what type of compressor wheel I use and I will NOT ever use a 60 trim or any compressor wheel that resembles the G series compressor wheels. I have my reasons not to use them.

As for people using the stage 3's, Stephen (SPOautos) is the very first one with a set. And he was the only one that got a set. Since they are working out great and miles are being put on them, the more confidence I have in the product. Stephen is running more than 18 psi daily on these turbos every day and they haven't missed a beat. I am not impressed by much these days, but after we dynoed so much power and had room to go, I bought myself a 3rd gen to put these babies on!

I love single turbo conversions. I also love 100% bolt up hybrid turbos. There are advantages and disadvantages to both, but they both put out some numbers so it is all in what you choose! Single turbo or twins .

.

Bryan

www.bnrsupercars.com

205-663 4797

You want the least amount of friction on a rotating assemblies as possible. This hints to increased spool up time and also reliability, b/c less friction is less heat, and the less heat the less stress you have on a tiny 5mm shaft like the HT12's.

As for compressor trims, I will not release what type of compressor wheel I use and I will NOT ever use a 60 trim or any compressor wheel that resembles the G series compressor wheels. I have my reasons not to use them.

As for people using the stage 3's, Stephen (SPOautos) is the very first one with a set. And he was the only one that got a set. Since they are working out great and miles are being put on them, the more confidence I have in the product. Stephen is running more than 18 psi daily on these turbos every day and they haven't missed a beat. I am not impressed by much these days, but after we dynoed so much power and had room to go, I bought myself a 3rd gen to put these babies on!

I love single turbo conversions. I also love 100% bolt up hybrid turbos. There are advantages and disadvantages to both, but they both put out some numbers so it is all in what you choose! Single turbo or twins

.

.Bryan

www.bnrsupercars.com

205-663 4797

#68

Eats, Sleeps, Dreams Rotary

iTrader: (2)

Re: Power Excel

Hellow Bryan, I think you are directing the post to me, not poweraxel. Of course I am not going to ask you to disclose what kind of wheel you are using otherwise everyone else can duplicate your setup. What I am asking is the following:

1. What's the flow rate on that compressor wheel at 1 bar?

2. Does the turbo come with a better turbine wheel with thicker shaft?

3. Can it be run sequential?

I think your turbo is worth getting if it's stronger than the stock one and flows more. If you saw the dyno chart, I was able to push out 386.6 rwhp at 16.5 psi using the stock turbo running sequential. If your stage 3 comes with new turbine wheel with thicker shaft and has higher flow rate than the stock turbo, I will tell my friend about yours and when the time comes, we will get a set from you. Thank you.

Chuck Huang

1. What's the flow rate on that compressor wheel at 1 bar?

2. Does the turbo come with a better turbine wheel with thicker shaft?

3. Can it be run sequential?

I think your turbo is worth getting if it's stronger than the stock one and flows more. If you saw the dyno chart, I was able to push out 386.6 rwhp at 16.5 psi using the stock turbo running sequential. If your stage 3 comes with new turbine wheel with thicker shaft and has higher flow rate than the stock turbo, I will tell my friend about yours and when the time comes, we will get a set from you. Thank you.

Chuck Huang

Originally posted by FEARED7

I was reading up on your previous posts. I can see that you understand the internals and how turbochargers work.

You want the least amount of friction on a rotating assemblies as possible. This hints to increased spool up time and also reliability, b/c less friction is less heat, and the less heat the less stress you have on a tiny 5mm shaft like the HT12's.

As for compressor trims, I will not release what type of compressor wheel I use and I will NOT ever use a 60 trim or any compressor wheel that resembles the G series compressor wheels. I have my reasons not to use them.

As for people using the stage 3's, Stephen (SPOautos) is the very first one with a set. And he was the only one that got a set. Since they are working out great and miles are being put on them, the more confidence I have in the product. Stephen is running more than 18 psi daily on these turbos every day and they haven't missed a beat. I am not impressed by much these days, but after we dynoed so much power and had room to go, I bought myself a 3rd gen to put these babies on!

I love single turbo conversions. I also love 100% bolt up hybrid turbos. There are advantages and disadvantages to both, but they both put out some numbers so it is all in what you choose! Single turbo or twins .

.

Bryan

www.bnrsupercars.com

205-663 4797

I was reading up on your previous posts. I can see that you understand the internals and how turbochargers work.

You want the least amount of friction on a rotating assemblies as possible. This hints to increased spool up time and also reliability, b/c less friction is less heat, and the less heat the less stress you have on a tiny 5mm shaft like the HT12's.

As for compressor trims, I will not release what type of compressor wheel I use and I will NOT ever use a 60 trim or any compressor wheel that resembles the G series compressor wheels. I have my reasons not to use them.

As for people using the stage 3's, Stephen (SPOautos) is the very first one with a set. And he was the only one that got a set. Since they are working out great and miles are being put on them, the more confidence I have in the product. Stephen is running more than 18 psi daily on these turbos every day and they haven't missed a beat. I am not impressed by much these days, but after we dynoed so much power and had room to go, I bought myself a 3rd gen to put these babies on!

I love single turbo conversions. I also love 100% bolt up hybrid turbos. There are advantages and disadvantages to both, but they both put out some numbers so it is all in what you choose! Single turbo or twins

.

.Bryan

www.bnrsupercars.com

205-663 4797

#69

Senior Member

Join Date: Jul 2001

Location: Birmingham, AL

Posts: 322

Likes: 0

Received 0 Likes

on

0 Posts

Hey Chuck.

I don't have the compressor map in front of me on the wheel I am using. I can tell you an estimate of CFM per wheel from power made on the dyno. The compressor wheels flow an estimated 460 CFM per wheel at 18 psi. This is how I calculated 460. A rotary take an estimated 1.92 CFM to make a HP. On the dyno it made 412 RWHP with conservative tuning. So I multiplied 412 by 1.15 and got approx crank HP which is around 460. then I multiplied that by 1.92 and got 460 or so CFM. That is just a figure w/o a calculator .

.

As for the shaft being small, it doesn't matter how small it is. If there are minimal vibrations in the rotating assemblies, they will live. When I build each turbocharger, I balance each component about 5 times better than the factory, then I put the assembly together and balance the whole assembly. This ensures minimal vibrations and the least amount of stress on the shafts. They are factory shafts, and I will not use other shafts until I run out of factory shafts. It is about like the rotary engine. If you don't detonate, the engine will make a lot of power if it is tuned properly. If the turbochargers are balanced beyond spec, and there are minimal vibrations, the turbos will live a prosperous life.

Bryan

www.bnrsupercars.com

205 663 4797

I don't have the compressor map in front of me on the wheel I am using. I can tell you an estimate of CFM per wheel from power made on the dyno. The compressor wheels flow an estimated 460 CFM per wheel at 18 psi. This is how I calculated 460. A rotary take an estimated 1.92 CFM to make a HP. On the dyno it made 412 RWHP with conservative tuning. So I multiplied 412 by 1.15 and got approx crank HP which is around 460. then I multiplied that by 1.92 and got 460 or so CFM. That is just a figure w/o a calculator

.

. As for the shaft being small, it doesn't matter how small it is. If there are minimal vibrations in the rotating assemblies, they will live. When I build each turbocharger, I balance each component about 5 times better than the factory, then I put the assembly together and balance the whole assembly. This ensures minimal vibrations and the least amount of stress on the shafts. They are factory shafts, and I will not use other shafts until I run out of factory shafts. It is about like the rotary engine. If you don't detonate, the engine will make a lot of power if it is tuned properly. If the turbochargers are balanced beyond spec, and there are minimal vibrations, the turbos will live a prosperous life.

Bryan

www.bnrsupercars.com

205 663 4797

#70

Eats, Sleeps, Dreams Rotary

iTrader: (2)

Hello Bryan:

Please keep us updated on the flow rate. Thank you.

I agree with you on the friction and balance of the turbo assembly. But there is one more thing that you forgot. Larger wheel has larger rotational inertia. It does create more stress on the shaft during the spool up.

Let's say that if your turbo assmbly is perfectly balanced, you can spin it at a particular rpm the same as stock or even at a higher rpm than stock, but if you are going to accelerate from rpm x to rpm y, larger wheel with more rotational inertia will create more stress on the shaft.

From my own experience, upgraded stock turbos tend to have bend shaft when it's running sequential due to the stress created by the larger wheel during that sudden switch over. It's the 2ndary turbo that always goes bad.

That's why I ask you if the turbo comes with stronger shaft or thicker shaft. If you can keep the rotational inertia of the wheel the same as stock, you shouldn't have a problem though.

I am sorry if I bother you all these technical questions but I have a chemistry degree from UC Berkeley so I tend to evaluate performance products the scientific way.

Thank you for your help in advance.

Chuck Huang

Please keep us updated on the flow rate. Thank you.

I agree with you on the friction and balance of the turbo assembly. But there is one more thing that you forgot. Larger wheel has larger rotational inertia. It does create more stress on the shaft during the spool up.

Let's say that if your turbo assmbly is perfectly balanced, you can spin it at a particular rpm the same as stock or even at a higher rpm than stock, but if you are going to accelerate from rpm x to rpm y, larger wheel with more rotational inertia will create more stress on the shaft.

From my own experience, upgraded stock turbos tend to have bend shaft when it's running sequential due to the stress created by the larger wheel during that sudden switch over. It's the 2ndary turbo that always goes bad.

That's why I ask you if the turbo comes with stronger shaft or thicker shaft. If you can keep the rotational inertia of the wheel the same as stock, you shouldn't have a problem though.

I am sorry if I bother you all these technical questions but I have a chemistry degree from UC Berkeley so I tend to evaluate performance products the scientific way.

Thank you for your help in advance.

Chuck Huang

Originally posted by FEARED7

Hey Chuck.

I don't have the compressor map in front of me on the wheel I am using. I can tell you an estimate of CFM per wheel from power made on the dyno. The compressor wheels flow an estimated 460 CFM per wheel at 18 psi. This is how I calculated 460. A rotary take an estimated 1.92 CFM to make a HP. On the dyno it made 412 RWHP with conservative tuning. So I multiplied 412 by 1.15 and got approx crank HP which is around 460. then I multiplied that by 1.92 and got 460 or so CFM. That is just a figure w/o a calculator .

.

As for the shaft being small, it doesn't matter how small it is. If there are minimal vibrations in the rotating assemblies, they will live. When I build each turbocharger, I balance each component about 5 times better than the factory, then I put the assembly together and balance the whole assembly. This ensures minimal vibrations and the least amount of stress on the shafts. They are factory shafts, and I will not use other shafts until I run out of factory shafts. It is about like the rotary engine. If you don't detonate, the engine will make a lot of power if it is tuned properly. If the turbochargers are balanced beyond spec, and there are minimal vibrations, the turbos will live a prosperous life.

Bryan

www.bnrsupercars.com

205 663 4797

Hey Chuck.

I don't have the compressor map in front of me on the wheel I am using. I can tell you an estimate of CFM per wheel from power made on the dyno. The compressor wheels flow an estimated 460 CFM per wheel at 18 psi. This is how I calculated 460. A rotary take an estimated 1.92 CFM to make a HP. On the dyno it made 412 RWHP with conservative tuning. So I multiplied 412 by 1.15 and got approx crank HP which is around 460. then I multiplied that by 1.92 and got 460 or so CFM. That is just a figure w/o a calculator

.

. As for the shaft being small, it doesn't matter how small it is. If there are minimal vibrations in the rotating assemblies, they will live. When I build each turbocharger, I balance each component about 5 times better than the factory, then I put the assembly together and balance the whole assembly. This ensures minimal vibrations and the least amount of stress on the shafts. They are factory shafts, and I will not use other shafts until I run out of factory shafts. It is about like the rotary engine. If you don't detonate, the engine will make a lot of power if it is tuned properly. If the turbochargers are balanced beyond spec, and there are minimal vibrations, the turbos will live a prosperous life.

Bryan

www.bnrsupercars.com

205 663 4797

#71

Ghost Ride the Whip

no matter what kind of numbers people claim to have with these turbos, I would like to see what type of air intake temperatures and water temperatures that this set of turbos would run in comparison with a single turbo set up. I went to thunderhill yesterday along with a bunch of other friends who had FD's (they all had twin turbo set ups) and their air intake temperatures ranged from high 60's to mid 70's while mine stayed at a conservative 44 degrees celsius. The measuring was done using the apex'i power FC as the basis for comparison. Also my water temperatures never passed 90 degrees celsius, while my other friends hit over a 100 degrees.

It's not always pure power that makes a single turbo superior to stock twins. It's the durability, simplicity, the linear power band, it's easier to work on the car after the single is in, and the fact that the car can withstand a day's worth of thrashing on a road course with a single better than any twin set up can. Also other parts of the car(including the motor) will last longer since there is less heat cycling from all those vacuum hoses and such.

It's not always pure power that makes a single turbo superior to stock twins. It's the durability, simplicity, the linear power band, it's easier to work on the car after the single is in, and the fact that the car can withstand a day's worth of thrashing on a road course with a single better than any twin set up can. Also other parts of the car(including the motor) will last longer since there is less heat cycling from all those vacuum hoses and such.

#72

Hey, where did my $$$ go?

Join Date: Feb 2001

Location: Bimingham, AL

Posts: 4,413

Likes: 0

Received 0 Likes

on

0 Posts

Originally posted by rotaryextreme

Hello Bryan:

Please keep us updated on the flow rate. Thank you.

I agree with you on the friction and balance of the turbo assembly. But there is one more thing that you forgot. Larger wheel has larger rotational inertia. It does create more stress on the shaft during the spool up.

Let's say that if your turbo assmbly is perfectly balanced, you can spin it at a particular rpm the same as stock or even at a higher rpm than stock, but if you are going to accelerate from rpm x to rpm y, larger wheel with more rotational inertia will create more stress on the shaft.

From my own experience, upgraded stock turbos tend to have bend shaft when it's running sequential due to the stress created by the larger wheel during that sudden switch over. It's the 2ndary turbo that always goes bad.

That's why I ask you if the turbo comes with stronger shaft or thicker shaft. If you can keep the rotational inertia of the wheel the same as stock, you shouldn't have a problem though.

I am sorry if I bother you all these technical questions but I have a chemistry degree from UC Berkeley so I tend to evaluate performance products the scientific way.

Thank you for your help in advance.

Chuck Huang

Hello Bryan:

Please keep us updated on the flow rate. Thank you.

I agree with you on the friction and balance of the turbo assembly. But there is one more thing that you forgot. Larger wheel has larger rotational inertia. It does create more stress on the shaft during the spool up.

Let's say that if your turbo assmbly is perfectly balanced, you can spin it at a particular rpm the same as stock or even at a higher rpm than stock, but if you are going to accelerate from rpm x to rpm y, larger wheel with more rotational inertia will create more stress on the shaft.

From my own experience, upgraded stock turbos tend to have bend shaft when it's running sequential due to the stress created by the larger wheel during that sudden switch over. It's the 2ndary turbo that always goes bad.

That's why I ask you if the turbo comes with stronger shaft or thicker shaft. If you can keep the rotational inertia of the wheel the same as stock, you shouldn't have a problem though.

I am sorry if I bother you all these technical questions but I have a chemistry degree from UC Berkeley so I tend to evaluate performance products the scientific way.

Thank you for your help in advance.

Chuck Huang

I think a lot of the problem with the stockers is all the friction working against the shaft, if you elim the friction so they spin up much easier then that should relieve the pressure on the shaft....or at least a lot of it.

I think the twisting on the shaft in stock form is a combination of the inertia you were talking about and the friction working against it which creates a twisting stress on the shaft. If you eliminate the friction so that the shaft can spin freely (or more so) then it should be ok.

I'm by far not a turbo builder, this is just me thinking out loud.

Oh yea, about the seq versus non seq, Brian recommends to run them non seq but there are some guys that are going to try it out seq. They have never been set up seq

STEPHEN

Last edited by SPOautos; 01-27-03 at 04:19 PM.

#73

Senior Member

Join Date: Jul 2001

Location: Birmingham, AL

Posts: 322

Likes: 0

Received 0 Likes

on

0 Posts

Hey Chuck.

Haven't been on the forum in a while. Been damn busy! lol getting back to the compressor wheel, it actually weighs less than the stock comrpessor wheel. The compressor wheel inducer is lager on the upgrade, but the exducer is right at the same size. Although some people think that bigger is better, that isn't the case. When I look at compressor wheels, I don't look at the size. I look at efficiencies, air flow and what RPM's they like to turn, the RPM of the compressor wheel is matched up with the turbine wheel efficiency which is a different ball game.... Although a turbo seems simple in concept, there is a lot more there than what you see . When I see a turbine wheel or a compressor wheel, I can tell you by looking at it that it will work or if it will not work, what RPM it likes to turn, and what engine it will work well on and so on.... I guess it is a gift from being around them and pondering about them for as long as I have!!!

. When I see a turbine wheel or a compressor wheel, I can tell you by looking at it that it will work or if it will not work, what RPM it likes to turn, and what engine it will work well on and so on.... I guess it is a gift from being around them and pondering about them for as long as I have!!!

Take care,

Bryan

www.bnrsupercars.com

Haven't been on the forum in a while. Been damn busy! lol getting back to the compressor wheel, it actually weighs less than the stock comrpessor wheel. The compressor wheel inducer is lager on the upgrade, but the exducer is right at the same size. Although some people think that bigger is better, that isn't the case. When I look at compressor wheels, I don't look at the size. I look at efficiencies, air flow and what RPM's they like to turn, the RPM of the compressor wheel is matched up with the turbine wheel efficiency which is a different ball game.... Although a turbo seems simple in concept, there is a lot more there than what you see

. When I see a turbine wheel or a compressor wheel, I can tell you by looking at it that it will work or if it will not work, what RPM it likes to turn, and what engine it will work well on and so on.... I guess it is a gift from being around them and pondering about them for as long as I have!!!

. When I see a turbine wheel or a compressor wheel, I can tell you by looking at it that it will work or if it will not work, what RPM it likes to turn, and what engine it will work well on and so on.... I guess it is a gift from being around them and pondering about them for as long as I have!!!Take care,

Bryan

www.bnrsupercars.com

#74

Eats, Sleeps, Dreams Rotary

iTrader: (2)

Thank you for the info. Keep up the good work.

Chuck Huang

Chuck Huang

Originally posted by FEARED7

Hey Chuck.

Haven't been on the forum in a while. Been damn busy! lol getting back to the compressor wheel, it actually weighs less than the stock comrpessor wheel. The compressor wheel inducer is lager on the upgrade, but the exducer is right at the same size. Although some people think that bigger is better, that isn't the case. When I look at compressor wheels, I don't look at the size. I look at efficiencies, air flow and what RPM's they like to turn, the RPM of the compressor wheel is matched up with the turbine wheel efficiency which is a different ball game.... Although a turbo seems simple in concept, there is a lot more there than what you see . When I see a turbine wheel or a compressor wheel, I can tell you by looking at it that it will work or if it will not work, what RPM it likes to turn, and what engine it will work well on and so on.... I guess it is a gift from being around them and pondering about them for as long as I have!!!

. When I see a turbine wheel or a compressor wheel, I can tell you by looking at it that it will work or if it will not work, what RPM it likes to turn, and what engine it will work well on and so on.... I guess it is a gift from being around them and pondering about them for as long as I have!!!

Take care,

Bryan

www.bnrsupercars.com

Hey Chuck.

Haven't been on the forum in a while. Been damn busy! lol getting back to the compressor wheel, it actually weighs less than the stock comrpessor wheel. The compressor wheel inducer is lager on the upgrade, but the exducer is right at the same size. Although some people think that bigger is better, that isn't the case. When I look at compressor wheels, I don't look at the size. I look at efficiencies, air flow and what RPM's they like to turn, the RPM of the compressor wheel is matched up with the turbine wheel efficiency which is a different ball game.... Although a turbo seems simple in concept, there is a lot more there than what you see

. When I see a turbine wheel or a compressor wheel, I can tell you by looking at it that it will work or if it will not work, what RPM it likes to turn, and what engine it will work well on and so on.... I guess it is a gift from being around them and pondering about them for as long as I have!!!

. When I see a turbine wheel or a compressor wheel, I can tell you by looking at it that it will work or if it will not work, what RPM it likes to turn, and what engine it will work well on and so on.... I guess it is a gift from being around them and pondering about them for as long as I have!!!Take care,

Bryan

www.bnrsupercars.com

Thread

Thread Starter

Forum

Replies

Last Post