Aeromotive 340 Stealth Fuel Pump

#126

******

iTrader: (7)

Join Date: May 2009

Location: miami

Posts: 901

Likes: 0

Received 0 Likes

on

0 Posts

Was on the dyno a few days ago and had a similar problem. After my fourth run at 19lbs of boost we noticed it started leaning out slightly after 6500 rpm. We decided to up the fuel pressure because the duty cycles were getting kinda high and the problem got worse. After two more pull where I had to lift off earlier and earlier because my AFRs were rising quickly, the operator did a run with outside watching the mechanical fuel pressure. He said the pressure rose from 45 to 60 but at high rpm would take a dive and that's where I would be lifting throttle. Luckily the motor didn't get hurt but I'm a little puzzled as I thought this pump would support over 500whp. I only made 418 at 18.8lbs. I'm gonna change the fuel filter and fuel pump as I have a new Walbro 400 in my garage and see if the problem goes away. Also I will check the wiring for anything fishy. Also, I was running 1 oz per gallon Protek R and the tank was almost completely full.

#128

Rotary Freak

iTrader: (28)

Join Date: Jun 2009

Location: Ontario, Canada

Posts: 2,089

Likes: 0

Received 0 Likes

on

0 Posts

Was on the dyno a few days ago and had a similar problem. After my fourth run at 19lbs of boost we noticed it started leaning out slightly after 6500 rpm. We decided to up the fuel pressure because the duty cycles were getting kinda high and the problem got worse. After two more pull where I had to lift off earlier and earlier because my AFRs were rising quickly, the operator did a run with outside watching the mechanical fuel pressure. He said the pressure rose from 45 to 60 but at high rpm would take a dive and that's where I would be lifting throttle. Luckily the motor didn't get hurt but I'm a little puzzled as I thought this pump would support over 500whp. I only made 418 at 18.8lbs. I'm gonna change the fuel filter and fuel pump as I have a new Walbro 400 in my garage and see if the problem goes away. Also I will check the wiring for anything fishy. Also, I was running 1 oz per gallon Protek R and the tank was almost completely full.

Is your fuel pump rewired?

If so check the amperage of the relay.

When I had the same situation on the dyno my wires were getting hot. I ended up losing the motor but later found out my voltage was dropping as the wires got hot. Less voltage = less fuel pressure.

#129

A few years ago I had a similar situation.

Is your fuel pump rewired?

If so check the amperage of the relay.

When I had the same situation on the dyno my wires were getting hot. I ended up losing the motor but later found out my voltage was dropping as the wires got hot. Less voltage = less fuel pressure.

Is your fuel pump rewired?

If so check the amperage of the relay.

When I had the same situation on the dyno my wires were getting hot. I ended up losing the motor but later found out my voltage was dropping as the wires got hot. Less voltage = less fuel pressure.

#130

My fuel pump is rewired with 8 gauge straight to the battery. I changed to the Walbro 400 and haven't had a problem in over a year. I haven't been back to the dyno though but I have run over 22 PSI and haven't run lean. If you put the 400 next to the 340 it looks way beefier.

#133

Old [Sch|F]ool

Also consider running heavier gauge wire through a pass-through bulkhead connector. The 340s suck a LOT of current!

What I do is get a bulkhead pass-through from Summit (one of the plastic fuel cell companies makes them) and then I put a Weatherpak connector on it so you can still drop the tank or otherwise disconnect it from the car. Weatherpaks are easy to assemble and the tools to do it are practically generic. I run 14 gauge from the pump to the (close mounted) relay and 10-8 gauge from the battery to the relay.

What I do is get a bulkhead pass-through from Summit (one of the plastic fuel cell companies makes them) and then I put a Weatherpak connector on it so you can still drop the tank or otherwise disconnect it from the car. Weatherpaks are easy to assemble and the tools to do it are practically generic. I run 14 gauge from the pump to the (close mounted) relay and 10-8 gauge from the battery to the relay.

Last edited by peejay; 12-23-15 at 07:58 PM.

#134

RX-7 Old Timer

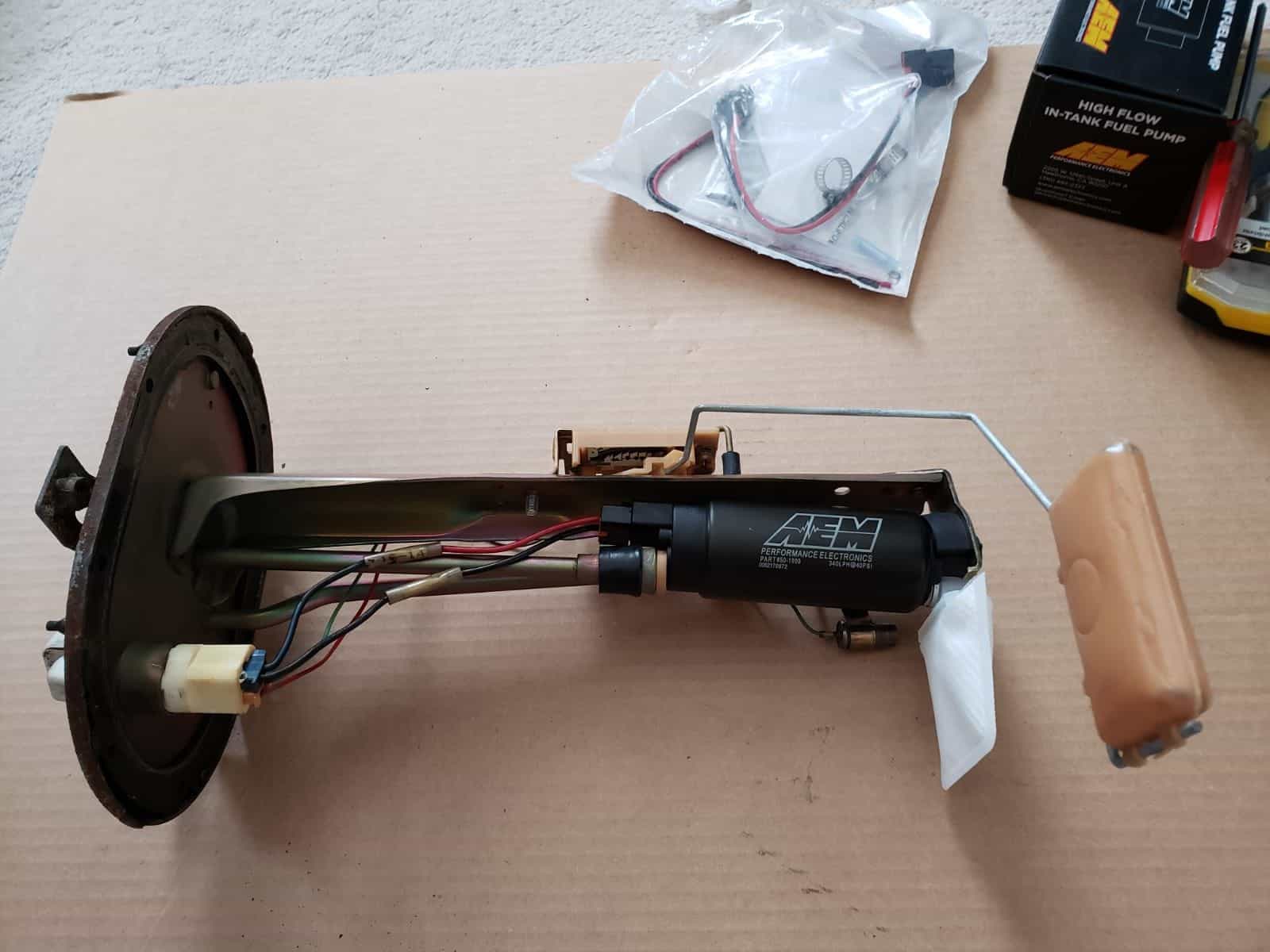

Throwing mine in, S4 Turbo.

-Wired with new 10 gauge wire to the stock positive bulkhead "post" and negative to the frame.

-Non-insulated crimp terminals on the new wiring

-Chemical/Diesel resistant wire and shrink wrap from McMaster Carr.

-Gasoline resistant fuel tubing from Amazon (walbro brand).

-Stainless zip-tied the pump to the frame (otherwise, the smaller body is a bit loose).

-Wired with new 10 gauge wire to the stock positive bulkhead "post" and negative to the frame.

-Non-insulated crimp terminals on the new wiring

-Chemical/Diesel resistant wire and shrink wrap from McMaster Carr.

-Gasoline resistant fuel tubing from Amazon (walbro brand).

-Stainless zip-tied the pump to the frame (otherwise, the smaller body is a bit loose).

Last edited by ColinShark; 12-23-15 at 09:16 PM.

#135

Work in Progress

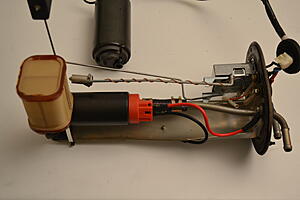

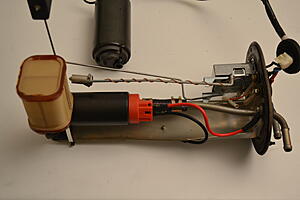

Just looking at this photo again I think I may of got the polarity switched around, anyone able to confirm this for me please.

#136

Rotary Enthusiast

Does not look ideal to me...

Generally one would cut the "bulb" bit off the stock fuel pump hanger and connect the pump to the hardline with a short section of submersible fuel hose & hose clamps.

Not sure that stock "bulb thing" will seal properly with anything but the stock fuel pump (and even then it sucks). I personally doubt that's going to hold 60psi + of pressure..but you never know.

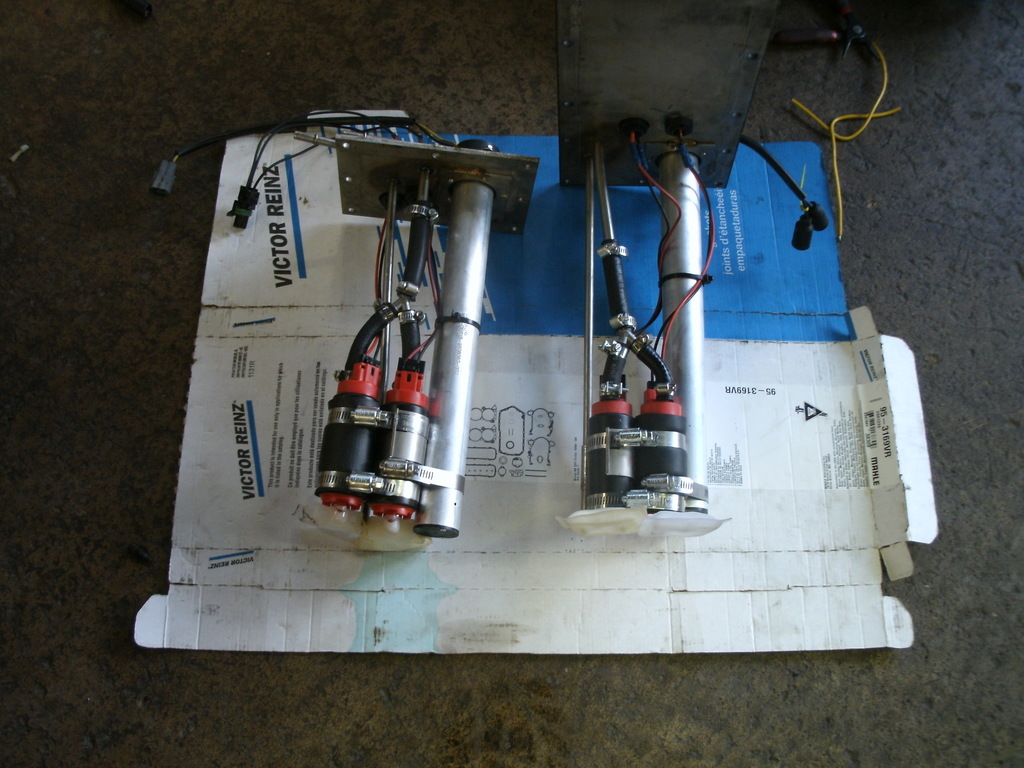

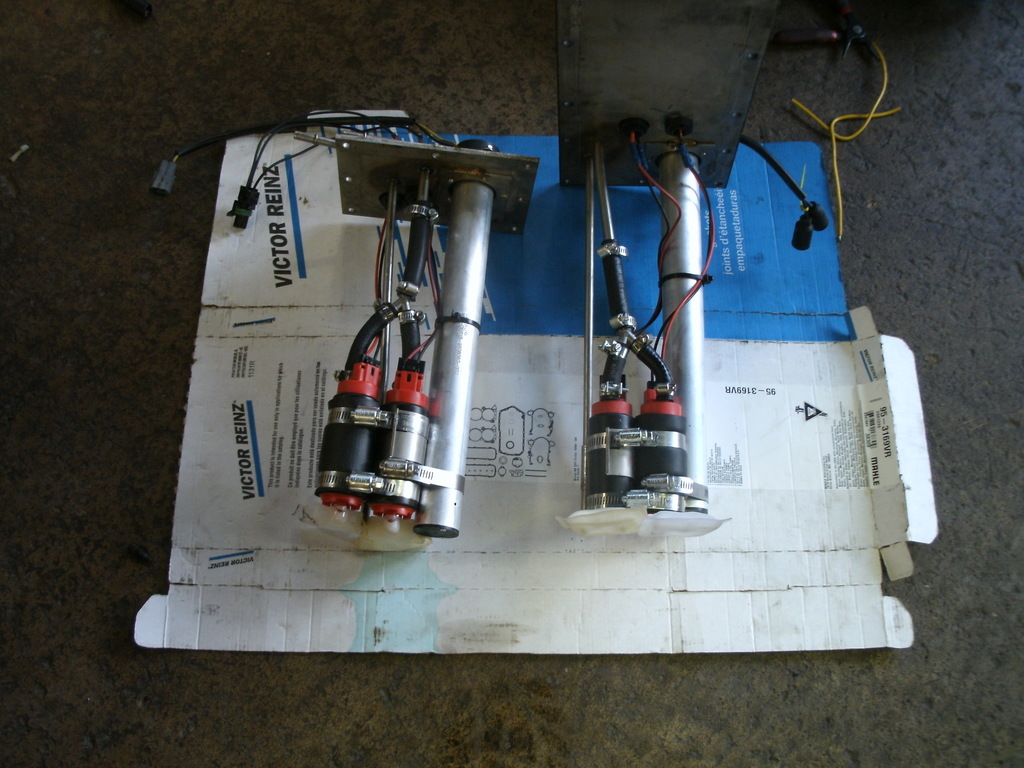

Most people would do like this (its a walbro 400, but the same applies)

I would suggest redoing the fuel pump to hardline connection like the above image.

Last edited by 96fd3s; 01-27-16 at 09:00 PM.

#138

Rotary Enthusiast

Not sure what pressure the hardlines can take, way more pressure than you would ever run though. (500+ psi?, maybe more, just guessing) You don't need to worry about them as far as pressure goes though.

#140

I think you may be at risk of losing fuel pressure with the pump attached to the hard line with the stock fitting. Should cut that off, de-bur, and join the pump to the line with SAE30R10 submersible FI hose. Also, consider bypassing the stock connector. Pretty common failure point and will also cause pressure loss.

#141

I wonder if the factory bulb on the hard line may be my issue? I have mine wired and mounted about the same and ran out of fuel on the dyno at 430whp this summer, I thought the pump would do at least 500? I have a #10 feed of the battery to a relay and an aftermarket bulkhead running parallel #14 wires to the pump. I have been debating on duel pumps or a boost a pump?

#142

Arrogant Wankeler

You need to recognize the pump flows are only rated at 3 bar, if you are running 1.5 bar boost and have the pressure drop of the filter and lines you will be a fair way down the flow curve on the pump if it is seeing more 5.X bar pressure head.

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 04:40 PM

Skeese

Adaptronic Engine Mgmt - AUS

65

03-28-17 03:30 PM