Latest Experiment…Failure!

#251

"Elusive, not deceptive!”

Thread Starter

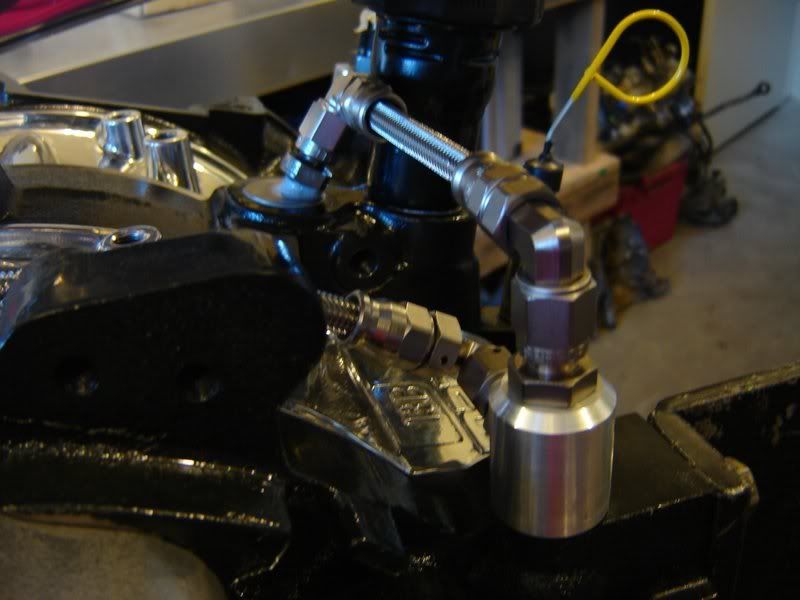

Just the oil supply for those plates. It looks like an OZ modification 4 rotor with needle bearings on std. center side plates.

Barry

Barry

#253

"Elusive, not deceptive!”

Thread Starter

Vest, sweet set-up!

Nice pictures showing the oil lines going to the center bearing.

Did you do any cooling mods to the housings? I seem to remember four end mill cuts of the 3rd gen variety around the spark plug area.

Barry

Nice pictures showing the oil lines going to the center bearing.

Did you do any cooling mods to the housings? I seem to remember four end mill cuts of the 3rd gen variety around the spark plug area.

Barry

#254

It`s only the standar mods that are on the 3rd gen.

#255

"Elusive, not deceptive!”

Thread Starter

More excellent workmanship,

I wonder if it would weaken the housing surface too much to connect those cuts to the other side. It seems like such a restriction to water pump flow in that area next to the plugs.

Thanks Vest Racing,

Barry

I wonder if it would weaken the housing surface too much to connect those cuts to the other side. It seems like such a restriction to water pump flow in that area next to the plugs.

Thanks Vest Racing,

Barry

#256

Because the water will be at a stand still in the corner..

So it would be much better if u hade rounded it of.

If u understand what I meen?

#257

Starting bumping up the boost to 18 psi. Need to find a video/camera intergrated bore scope to see the rotor housing face at the spark plugs.

#258

Interesting, they just drilled and tapped into the front iron for the water supply. Really good idea, but wouldn't have worked for me since the air pump is in the way.

Starting bumping up the boost to 18 psi. Need to find a video/camera intergrated bore scope to see the rotor housing face at the spark plugs.

Starting bumping up the boost to 18 psi. Need to find a video/camera intergrated bore scope to see the rotor housing face at the spark plugs.

-J

#262

"Elusive, not deceptive!”

Thread Starter

Adam,

My 1050şC EGT's have gotten to the turbine housing. The turbine wheel looks great but cast iron 1.00 AR housing is cracking and the internal channels are collapsing. I installed an unused TO4Z that Kenny had .

If, I should say, when this engine fails I want to try to even-up the flow around the plugs with porting connecting the end-mill areas of both sides (particularly #5 area in the earlier photos).

I sent in the In-Chamber testing sensor for an update to its internal heat shielding. I should start testing again soon but Jack and Jonathan don’t want me to hurt anything and not go to Deals Gap (DGRRXI).

The TO4Z seems to smoke at idle with a .030" jet. Jonathan thinks a .025" is recommended.

Barry

My 1050şC EGT's have gotten to the turbine housing. The turbine wheel looks great but cast iron 1.00 AR housing is cracking and the internal channels are collapsing. I installed an unused TO4Z that Kenny had .

If, I should say, when this engine fails I want to try to even-up the flow around the plugs with porting connecting the end-mill areas of both sides (particularly #5 area in the earlier photos).

I sent in the In-Chamber testing sensor for an update to its internal heat shielding. I should start testing again soon but Jack and Jonathan don’t want me to hurt anything and not go to Deals Gap (DGRRXI).

The TO4Z seems to smoke at idle with a .030" jet. Jonathan thinks a .025" is recommended.

Barry

#263

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,835

Received 2,604 Likes

on

1,847 Posts

the newer turbo piston engines like the bmw 330 and the new VW dual charged 1.4 are both designed to run EGT's over 1000C.

the relevant part is that to do 1000c+ they change the turbo...

http://www.volkspage.net/technik/ssp/ssp/SSP_359.pdf

page 19, please.

"Up to now in petrol engines, the mixture was enriched

early due to the high exhaust gas temperatures.

The exhaust manifold on the 1.4l TSI engine is

designed for exhaust gas temperatures up to

1,050 °C. As a result, the engine can be run with a

high boost pressure and with Lambda 1 in almost all

map ranges"

the relevant part is that to do 1000c+ they change the turbo...

http://www.volkspage.net/technik/ssp/ssp/SSP_359.pdf

page 19, please.

"Up to now in petrol engines, the mixture was enriched

early due to the high exhaust gas temperatures.

The exhaust manifold on the 1.4l TSI engine is

designed for exhaust gas temperatures up to

1,050 °C. As a result, the engine can be run with a

high boost pressure and with Lambda 1 in almost all

map ranges"

#265

Adam,

My 1050şC EGT's have gotten to the turbine housing. The turbine wheel looks great but cast iron 1.00 AR housing is cracking and the internal channels are collapsing. I installed an unused TO4Z that Kenny had .

If, I should say, when this engine fails I want to try to even-up the flow around the plugs with porting connecting the end-mill areas of both sides (particularly #5 area in the earlier photos).

I sent in the In-Chamber testing sensor for an update to its internal heat shielding. I should start testing again soon but Jack and Jonathan don’t want me to hurt anything and not go to Deals Gap (DGRRXI).

The TO4Z seems to smoke at idle with a .030" jet. Jonathan thinks a .025" is recommended.

Barry

My 1050şC EGT's have gotten to the turbine housing. The turbine wheel looks great but cast iron 1.00 AR housing is cracking and the internal channels are collapsing. I installed an unused TO4Z that Kenny had .

If, I should say, when this engine fails I want to try to even-up the flow around the plugs with porting connecting the end-mill areas of both sides (particularly #5 area in the earlier photos).

I sent in the In-Chamber testing sensor for an update to its internal heat shielding. I should start testing again soon but Jack and Jonathan don’t want me to hurt anything and not go to Deals Gap (DGRRXI).

The TO4Z seems to smoke at idle with a .030" jet. Jonathan thinks a .025" is recommended.

Barry

#266

"Elusive, not deceptive!”

Thread Starter

the newer turbo piston engines like the bmw 330 and the new VW dual charged 1.4 are both designed to run EGT's over 1000C.

the relevant part is that to do 1000c+ they change the turbo...

http://www.volkspage.net/technik/ssp/ssp/SSP_359.pdf

page 19, please.

"Up to now in petrol engines, the mixture was enriched

early due to the high exhaust gas temperatures.

The exhaust manifold on the 1.4l TSI engine is

designed for exhaust gas temperatures up to

1,050 °C. As a result, the engine can be run with a

high boost pressure and with Lambda 1 in almost all

map ranges"

the relevant part is that to do 1000c+ they change the turbo...

http://www.volkspage.net/technik/ssp/ssp/SSP_359.pdf

page 19, please.

"Up to now in petrol engines, the mixture was enriched

early due to the high exhaust gas temperatures.

The exhaust manifold on the 1.4l TSI engine is

designed for exhaust gas temperatures up to

1,050 °C. As a result, the engine can be run with a

high boost pressure and with Lambda 1 in almost all

map ranges"

Good article!

The other novel idea was a variable displacement oil pump that regulates itself to 50 psi for better mileage.

Barry

#269

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,835

Received 2,604 Likes

on

1,847 Posts

interesting that one is doing that "fish scale" thing with the chrome, seems to be kind of normal on a PP housing.

notice please that those DO NOT have the sheetmetal insert like the production housings.

how hard would it be for you to compare spark plug position on those housings VS like an FD?

notice please that those DO NOT have the sheetmetal insert like the production housings.

how hard would it be for you to compare spark plug position on those housings VS like an FD?

#270

Rotary Enthusiast

I had a lot of problems with cooling back 10-11yrs, 3 engines down, very unhappy

so used Evans coolant(no water), custom made a pump impellor in water pump. much tighter clearences, solid bronze impeller, pumps more volume,faster and at higher pressures.

no more probs with cooling.

HEY, works for me, and couple other guys i did the mods for.

so used Evans coolant(no water), custom made a pump impellor in water pump. much tighter clearences, solid bronze impeller, pumps more volume,faster and at higher pressures.

no more probs with cooling.

HEY, works for me, and couple other guys i did the mods for.

#271

this is why you have to be extremely careful when doing the water jacket modifications. those bosses around the spark plugs are very thin on all series of motors which i realized very early on. with my first motor build as electrolysis had eaten its way through into the plug hole such as your plugs had a similar issue with so i have since been very weary of messing with that area much, same as around the exhaust ports.

1k miles on the one that i used for that thread a few months ago, water temps are slightly cooler and no issues with water leaking yet. i just wish i had a way to measure the tempertaure differences in the chamber faces before and after the modification.

the engine i used in my water jacket porting example i ran studs through the engine to reinforce it also and treated the raw aluminum after porting prior to assembly to help prevent corrosion. with that said i also do not like the idea of cutting away the bridges between the walls, which is what will cause more rotor housing distortions in the hottest areas along combustion chamber wall, which will wear the skirts+irons causing gaps inside the motor for the coolant seals to be compromised. that modification is more of a strictly racing application modification, not for any engine you may expect to last a good long while on.

1k miles on the one that i used for that thread a few months ago, water temps are slightly cooler and no issues with water leaking yet. i just wish i had a way to measure the tempertaure differences in the chamber faces before and after the modification.

the engine i used in my water jacket porting example i ran studs through the engine to reinforce it also and treated the raw aluminum after porting prior to assembly to help prevent corrosion. with that said i also do not like the idea of cutting away the bridges between the walls, which is what will cause more rotor housing distortions in the hottest areas along combustion chamber wall, which will wear the skirts+irons causing gaps inside the motor for the coolant seals to be compromised. that modification is more of a strictly racing application modification, not for any engine you may expect to last a good long while on.

Last edited by RotaryEvolution; 04-11-11 at 07:13 PM.

#272

"Elusive, not deceptive!”

Thread Starter

I had a lot of problems with cooling back 10-11yrs, 3 engines down, very unhappy

so used Evans coolant(no water), custom made a pump impellor in water pump. much tighter clearences, solid bronze impeller, pumps more volume,faster and at higher pressures.

no more probs with cooling.

HEY, works for me, and couple other guys i did the mods for.

so used Evans coolant(no water), custom made a pump impellor in water pump. much tighter clearences, solid bronze impeller, pumps more volume,faster and at higher pressures.

no more probs with cooling.

HEY, works for me, and couple other guys i did the mods for.

It seems like there ought to be one out there that is close to size and turns the proper way.

Barry

#274

"Elusive, not deceptive!”

Thread Starter

As an update the "failure".... it is still running 3 years later. I do have to re-Loctite the spark plug at each replacement.

The latest experiment is with the in-chamber sensor where we just broke 1000 psi chamber pressure for the first time (10 lb wastegate spring goes to 12psi).

The latest experiment is with the in-chamber sensor where we just broke 1000 psi chamber pressure for the first time (10 lb wastegate spring goes to 12psi).