Stock port renesis dyno'd

#1

Exhaust Manifold Leak

Thread Starter

Stock port renesis dyno'd

Hello,

We're running a 6port renesis in a miata for circuit racing, a while ago I did some testing on the dyno.

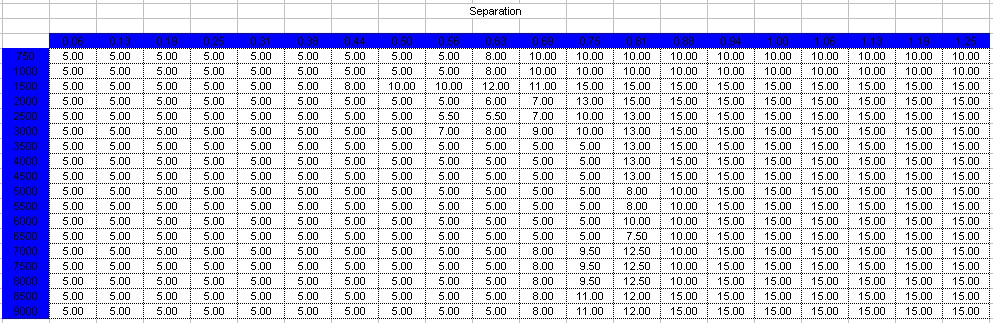

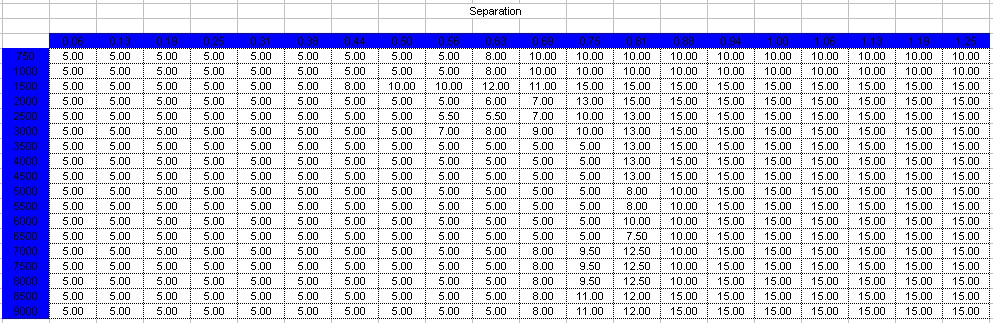

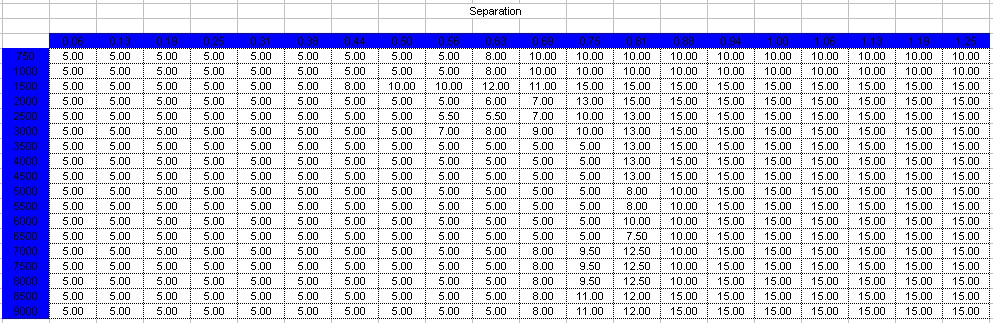

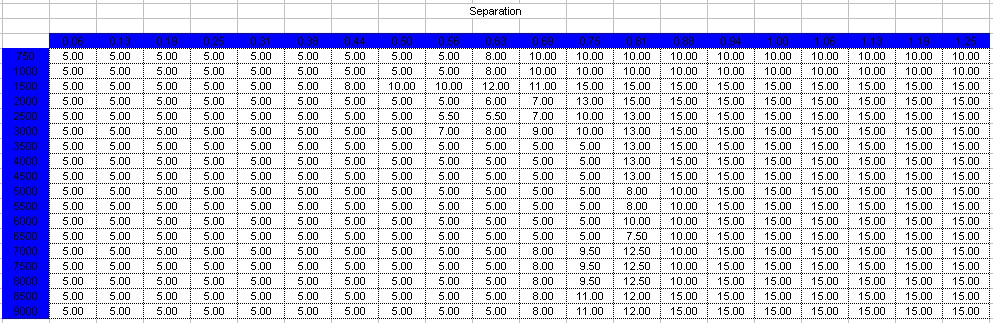

First graph is with the APV and VDI at stock opening points (6000 and 7250rpm), SSV is always open

Second graph is with the enhanced rpm points 6250 and 7750rpm, and with the airfiler removed. I wanted to roll in the run as the injector staging was doing weird things at 3800rpm

the last graph is with the enhanced points and with the airfilter back on..

it's running on a kdfi/MS2, LS2 coils, stock plugs, no split and a DIY exh header

afr's are in the high 12's for those interested, I have logs from the runs.

We're running a 6port renesis in a miata for circuit racing, a while ago I did some testing on the dyno.

First graph is with the APV and VDI at stock opening points (6000 and 7250rpm), SSV is always open

Second graph is with the enhanced rpm points 6250 and 7750rpm, and with the airfiler removed. I wanted to roll in the run as the injector staging was doing weird things at 3800rpm

the last graph is with the enhanced points and with the airfilter back on..

it's running on a kdfi/MS2, LS2 coils, stock plugs, no split and a DIY exh header

afr's are in the high 12's for those interested, I have logs from the runs.

#3

Exhaust Manifold Leak

Thread Starter

Ah ok,

The firstpower is corrected power, which is the power at the wheels+rolling resistanc x correction factor calculated per DIN 70020 with the measured data at the right hand side

the second power is the power at the wheels + rolling resistance

third is power at the wheels

fourth is peak rolling resistance

below you find peak troque

so vermogen : power

koppel : torque

anyting else

The firstpower is corrected power, which is the power at the wheels+rolling resistanc x correction factor calculated per DIN 70020 with the measured data at the right hand side

the second power is the power at the wheels + rolling resistance

third is power at the wheels

fourth is peak rolling resistance

below you find peak troque

so vermogen : power

koppel : torque

anyting else

#5

Exhaust Manifold Leak

Thread Starter

yep, by then it wasstill the idea to run a carb, but I learned about carbs with the small 250cc kart engine and E85, and since then I hate carbs so we went efi, and until now the renesis is going strong, too bad there's snow now here, otherwise we would have raced it at zolder this weekend

#7

Exhaust Manifold Leak

Thread Starter

Thats correct yes.. the inertia of the dyno is known, so after the run you press the clutch and put the car in neutral and let is roll out, tis way it calculates the drivetrain loss, wich is the green line, around 45hp seems normal at 200kph, it's a dyno with 2 small rolls and a 14" miata wheel..

Trending Topics

#9

Exhaust Manifold Leak

Thread Starter

I'm still awaiting pics and video of the dyno.. seems to take forever.. in the meantime, here's a photo from the the exh manifold tacked up..

#11

Exhaust Manifold Leak

Thread Starter

Small update, engine is in the car and running very well. Tuned it around 13.2:1 in the midrange, top end is still slightly on the rich side at 12.5:1

EGT's half a meter after the end of the 3x1 collector peaks around 915°C during track use. I am wondering if I could be runnign too uch advance? I was running around 27° midrange and 25° top WOT, 98oct fuel.

But overall the car is performing very nice, and as we speak I am uploading a onboard video from a trackday last week.

One problem remains and that is the oil temperature, it stabilizes in the 140-145°C on track, this is with 2 turbo II coolers with thermostat blocked put parallel and in the airflow. Oil pressure is regulated to 5.5-6bar

Attached a pic of the ghetto style pressure regulator, picture of the ghetto style car and a link to a datalog; youtube video will follow!

Grtz

Ruben

EGT's half a meter after the end of the 3x1 collector peaks around 915°C during track use. I am wondering if I could be runnign too uch advance? I was running around 27° midrange and 25° top WOT, 98oct fuel.

But overall the car is performing very nice, and as we speak I am uploading a onboard video from a trackday last week.

One problem remains and that is the oil temperature, it stabilizes in the 140-145°C on track, this is with 2 turbo II coolers with thermostat blocked put parallel and in the airflow. Oil pressure is regulated to 5.5-6bar

Attached a pic of the ghetto style pressure regulator, picture of the ghetto style car and a link to a datalog; youtube video will follow!

Grtz

Ruben

#12

That sounds ok timing wise, but I suspect you may want more than that. RENESIS rotors require more ignition timing than earlier rotors due to the poor combustion chamber shape. If the ignition timing is infact less than optimum for the engine it can result in higher coolant and oil temps, oil being the harder of the two to control. Even an earlier engine with stock or street porting wants 30 degrees or more ignition timing. However this is not taking into account VE, which I suspect is better in the RENESIS engine.

The best way to set the timing is too keep advancing it on the dyno 2 degrees at a time until power starts to drop, then move it back to where peak power occurred and fine tune the AFR if need be. This is where the engine is happiest and most efficient, which generally results in the least heat transfer to cooling systems.

One more thing to note - because of the higher compression ratio and the thinner wall thickness of RENESIS rotors, they do require increased oil cooling capacity. This is confirmed when RENESIS rotors are used in earlier engines. There is a significant increase in oil temps.

I think at 140-145C it will not be long before you run a bearing. Use a good quality FULL synthetic oil, if you are not already, and be sure to change it after every meeting until you can bring oil temp under control.

I'm curious as the theory behind your header design, can you elaborate?

The best way to set the timing is too keep advancing it on the dyno 2 degrees at a time until power starts to drop, then move it back to where peak power occurred and fine tune the AFR if need be. This is where the engine is happiest and most efficient, which generally results in the least heat transfer to cooling systems.

One more thing to note - because of the higher compression ratio and the thinner wall thickness of RENESIS rotors, they do require increased oil cooling capacity. This is confirmed when RENESIS rotors are used in earlier engines. There is a significant increase in oil temps.

I think at 140-145C it will not be long before you run a bearing. Use a good quality FULL synthetic oil, if you are not already, and be sure to change it after every meeting until you can bring oil temp under control.

I'm curious as the theory behind your header design, can you elaborate?

The following users liked this post:

sharingan 19 (06-05-21)

#13

A few months ago I had a PM conversation on rx8club.com with a guy who was racing Grand AM in the USA. He mentioned that when his exhaust temps exceeded about 900C/1650F (due to lean fuel-saving tune) he would get premature side seal failure (happened on multiple engines). I'm not entirely sure where that temperature was measured. After a lot of testing he was settling on a lambda of around .82 which is richer where you are at. This gave a good power and kept EGT under control. I'm not sure what timing he settled on eventually but I know his max leading advance at one point was about 36 degrees by redline.

This was a 100% stock Renesis. I believe his fuel was US 93 octane (until he later switched to race fuel) which is like European 98 RON.

If it's any help, at WOT stock Renesis will ramp up to 30 degrees leading at redline with 15 split.

y axis is a load calculation related to the MAF sensor grams/sec airflow reading as opposed to a manifold pressure reading.

This was a 100% stock Renesis. I believe his fuel was US 93 octane (until he later switched to race fuel) which is like European 98 RON.

If it's any help, at WOT stock Renesis will ramp up to 30 degrees leading at redline with 15 split.

y axis is a load calculation related to the MAF sensor grams/sec airflow reading as opposed to a manifold pressure reading.

The following users liked this post:

sharingan 19 (06-05-21)

#14

Exhaust Manifold Leak

Thread Starter

That sounds ok timing wise, but I suspect you may want more than that. RENESIS rotors require more ignition timing than earlier rotors due to the poor combustion chamber shape. If the ignition timing is infact less than optimum for the engine it can result in higher coolant and oil temps, oil being the harder of the two to control. Even an earlier engine with stock or street porting wants 30 degrees or more ignition timing. However this is not taking into account VE, which I suspect is better in the RENESIS engine.

The best way to set the timing is too keep advancing it on the dyno 2 degrees at a time until power starts to drop, then move it back to where peak power occurred and fine tune the AFR if need be. This is where the engine is happiest and most efficient, which generally results in the least heat transfer to cooling systems.

One more thing to note - because of the higher compression ratio and the thinner wall thickness of RENESIS rotors, they do require increased oil cooling capacity. This is confirmed when RENESIS rotors are used in earlier engines. There is a significant increase in oil temps.

I think at 140-145C it will not be long before you run a bearing. Use a good quality FULL synthetic oil, if you are not already, and be sure to change it after every meeting until you can bring oil temp under control.

I'm curious as the theory behind your header design, can you elaborate?

The best way to set the timing is too keep advancing it on the dyno 2 degrees at a time until power starts to drop, then move it back to where peak power occurred and fine tune the AFR if need be. This is where the engine is happiest and most efficient, which generally results in the least heat transfer to cooling systems.

One more thing to note - because of the higher compression ratio and the thinner wall thickness of RENESIS rotors, they do require increased oil cooling capacity. This is confirmed when RENESIS rotors are used in earlier engines. There is a significant increase in oil temps.

I think at 140-145C it will not be long before you run a bearing. Use a good quality FULL synthetic oil, if you are not already, and be sure to change it after every meeting until you can bring oil temp under control.

I'm curious as the theory behind your header design, can you elaborate?

So it seems I will be trying more advance and sligtly more fuel in the midrange.

About the oiltemps, it understandable that these rotors put more heat in the oil, but I am using 2 turbo II oilcoolers and still facing this temps..:/ oil is total/elf quartz racing 10w50. In the datalogs the oil pressure doesnt drop below 5bar at normal rpms.. I'm quite satisfied by the sucky rx8 oilpan design/pick, even after 3-4 seconds of more than 1.1 lateral G there isnt the slightest drop in pressure. This is with the stock small rx8 oilpump.

What is quite strange is that even with warm engine I still measure up to 5 bar pressure drop over the coolers which are in parallel), so before coolers it can make around 10-11bar before the pressure relief in the front cover opens.. when visually looking into the coolers they look new on the inside

For the headers.. There is no real theory behind it, the main objective was flow and I had to deal with packaging constraints, as the engine is completely behind the steering rack and also as low as possible in the car, there was extremely little space to make a equal length manifold.. I was thinking as this engine has no overlap as to speak of, a tuned manifold would not give gains like one would expect on a PP-engine. We also using the stock rx-8 muffles as we have 95 dB limit on track.

here is the first part of the incar move

http://www.youtube.com/watch?v=EFxu4JkSdlA

#15

Exhaust Manifold Leak

Thread Starter

A few months ago I had a PM conversation on rx8club.com with a guy who was racing Grand AM in the USA. He mentioned that when his exhaust temps exceeded about 900C/1650F (due to lean fuel-saving tune) he would get premature side seal failure (happened on multiple engines). I'm not entirely sure where that temperature was measured. After a lot of testing he was settling on a lambda of around .82 which is richer where you are at. This gave a good power and kept EGT under control. I'm not sure what timing he settled on eventually but I know his max leading advance at one point was about 36 degrees by redline.

This was a 100% stock Renesis. I believe his fuel was US 93 octane (until he later switched to race fuel) which is like European 98 RON.

If it's any help, at WOT stock Renesis will ramp up to 30 degrees leading at redline with 15 split.

y axis is a load calculation related to the MAF sensor grams/sec airflow reading as opposed to a manifold pressure reading.

This was a 100% stock Renesis. I believe his fuel was US 93 octane (until he later switched to race fuel) which is like European 98 RON.

If it's any help, at WOT stock Renesis will ramp up to 30 degrees leading at redline with 15 split.

y axis is a load calculation related to the MAF sensor grams/sec airflow reading as opposed to a manifold pressure reading.

Do you think it would be knock sensitive to run this timing map witout split?

Here's part @ of the run

http://www.youtube.com/watch?v=rsEMTn7X5xg

#16

Save the rotary engine

Rub20b, can you share some info or a link on how the Renesis installation into the Miata was done? I am trying to do kind of the same install on my nb Miata all motor project car.

If anybody know a thread showing the install on a nb Miata please post back. Thanks

If anybody know a thread showing the install on a nb Miata please post back. Thanks

#17

Exhaust Manifold Leak

Thread Starter

Will try to post some good fotos after the weekend. I instlled the engine as low and far back as possible, because it is mounted the same way in a rx8 this was a good case for shifter position and offcourse weight distribution of the car (should be as I havent had it on the scales yet)

Here's a quick snap of the 2 TII oilcoolers, the bottom one has a small duct, the top on touches the bottomside of the radiator and the topside of the bottom oilcoolerm so if is actually a closed box, and all the air that enters has to pass trough one of the oilcoolers or the water radiator

Here's a quick snap of the 2 TII oilcoolers, the bottom one has a small duct, the top on touches the bottomside of the radiator and the topside of the bottom oilcoolerm so if is actually a closed box, and all the air that enters has to pass trough one of the oilcoolers or the water radiator

#18

Will try to post some good fotos after the weekend. I instlled the engine as low and far back as possible, because it is mounted the same way in a rx8 this was a good case for shifter position and offcourse weight distribution of the car (should be as I havent had it on the scales yet)

Here's a quick snap of the 2 TII oilcoolers, the bottom one has a small duct, the top on touches the bottomside of the radiator and the topside of the bottom oilcoolerm so if is actually a closed box, and all the air that enters has to pass trough one of the oilcoolers or the water radiator

Here's a quick snap of the 2 TII oilcoolers, the bottom one has a small duct, the top on touches the bottomside of the radiator and the topside of the bottom oilcoolerm so if is actually a closed box, and all the air that enters has to pass trough one of the oilcoolers or the water radiator

Interesting way to mount that 2nd gen cooler! I originally had my radiator staked on top of my 2nd gen oil cooler as a cheaper way to get things running. Now I'm gonna go with twin 25 row units instead.

#19

Exhaust Manifold Leak

Thread Starter

I was optiong for the earl's 60 row, medium width, and do like a V-mount with the radiator.

I am a bit concerned to go for dual sidemounts in case of a light crash or hit on track

I am a bit concerned to go for dual sidemounts in case of a light crash or hit on track

#20

Exhaust Manifold Leak

Thread Starter

Small update.

Oilcooler is installed, its the ealrs 60 row in a Vmount setup, seems the 2 TII oilcoolers in parallel where really restrictive as now I see a nice 6 bar of pressure from cold idle till warm, warm idle is still only about 1.5 bar, but thats fine for me

Quite some time ago I got in on the dyno once more.. made less power now, altough we had to change the muffler system a bit more (due too noise constraints) which I think apart from being another dyno is the main reason for this.. I found out the engine seems to make the best numbers at around 13.2:1 afr, and ign timing doesnt have a huge impact..

We are now quite a bit earlier with timing than before

Dont have plots on this atm, altough when I dont forget I'll post them

Oilcooler is installed, its the ealrs 60 row in a Vmount setup, seems the 2 TII oilcoolers in parallel where really restrictive as now I see a nice 6 bar of pressure from cold idle till warm, warm idle is still only about 1.5 bar, but thats fine for me

Quite some time ago I got in on the dyno once more.. made less power now, altough we had to change the muffler system a bit more (due too noise constraints) which I think apart from being another dyno is the main reason for this.. I found out the engine seems to make the best numbers at around 13.2:1 afr, and ign timing doesnt have a huge impact..

We are now quite a bit earlier with timing than before

Dont have plots on this atm, altough when I dont forget I'll post them

#21

....when his exhaust temps exceeded about 900C/1650F (due to lean fuel-saving tune) he would get premature side seal failure (happened on multiple engines). I'm not entirely sure where that temperature was measured. After a lot of testing he was settling on a lambda of around .82 which is richer where you are at. This gave a good power and kept EGT under contro

#23

EGTs>1650 F=failed seals. i know someone will laugh at this but, what about water injection on an N/a? even a 100cc dribble would bring the temps down eh?

#25

There was a thread on the 8forum, where Eric Meyer, likely the source of this info, has tried that, and a few other countermeasures with no avail.

EGTs>1650 F=failed seals. i know someone will laugh at this but, what about water injection on an N/a? even a 100cc dribble would bring the temps down eh?

EGTs>1650 F=failed seals. i know someone will laugh at this but, what about water injection on an N/a? even a 100cc dribble would bring the temps down eh?

atkins also makes cryo treated side seals which may help somewhat.

the PP exhaust side seals take a bit of abuse in the renesis. keep in mind they are taking all the heat from the exhaust gases and then cooling rapidly during the intake stroke, well attempting to anyways.