Porting

#2

Senior Member

iTrader: (17)

Join Date: Jan 2005

Location: Jackson, Mo

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

Porting Upwards towards the compression stroke will require more rpms to reach maximum flow, therefore higher powerband. Only porting upwards will keep the overlap to a minimum, keeping the emissions at a minimum as well.

Porting Downwards will require fewer rpms (than porting upwards) to reach maximum flow, therefore lower powerband. Porting downwards will increase the overlap, increasing the emissions, and causing the brap brap idle.

I think that this is correct for the most part.

Porting Downwards will require fewer rpms (than porting upwards) to reach maximum flow, therefore lower powerband. Porting downwards will increase the overlap, increasing the emissions, and causing the brap brap idle.

I think that this is correct for the most part.

#3

Senior Member

Join Date: Mar 2004

Location: USA, PA, Harrisburg area.

Posts: 309

Likes: 0

Received 2 Likes

on

2 Posts

well for starters are you in a na or turbo car? advantges are more power disadvantage is mainly fuel economy and they both very with the kind and application of the port. My sugestion is to do some searching. Hmm i may have misunderstood your question...porting changes the timing for when the port opens and closes because of when the rotor passes over it. port down it opens earlier, port up and it closes later. Go to far either way and you will cause problems or get into a coolant passage. Again do some searching and research on this forum as the specifics/how to's are already there.

#4

the Appleton Don

If I am reading you right, it sounds like you guys are saying the bottom edge of the 2-dimensional view of the port (the aperture) is the opening end. If that's what you're saying, then you're incorrect. The opening edge of the port is on the side - directly opposite the edge of the oil control rings. Porting that gets the port to open earlier and it can and does increase overlap.

If I misunderstood you all, then disregard.

Going upwards does indeed close the port later.

If I misunderstood you all, then disregard.

Going upwards does indeed close the port later.

#5

It's going to vary greatly on what engine your porting. The S4-S6 center irons suck as far as stock porting goes. Stay away from the oil control ring path, and make sure you leave at least 40% of the side seal supported. If your thinking about going bridge, then stay at least 2mm from the coolant seal. Advantage? More power! Disadvantage? Suckie fuel mileage. Would a pic help?

#6

Passing life by

afterburner16 - is the correct poster listen to him down is not the closing edge and its critical to not close the port later unless you have a higher rpm motor the port timing and reversion rate are correct from Mazda and tuned exactly at 7,200rpm. Roughly 1000rpm increase is needed per mm you increase closing time. All this other port allow baloo and look how shiny I am is just to make you buy there product half the ports do more harm then good.

#7

Banned. I got OWNED!!!

Join Date: Apr 2008

Location: Australia

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

afterburner16 - is the correct poster listen to him down is not the closing edge and its critical to not close the port later unless you have a higher rpm motor the port timing and reversion rate are correct from Mazda and tuned exactly at 7,200rpm. Roughly 1000rpm increase is needed per mm you increase closing time. All this other port allow baloo and look how shiny I am is just to make you buy there product half the ports do more harm then good.

Stock is very narrow in range, and the timing is very poor for any top flight engine.

Latest generation of Rice Racing street porting.

Trending Topics

#8

Banned. I got OWNED!!!

Join Date: Apr 2008

Location: Australia

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

I thought I would post up some specifications of my Rice Racing street port timing, pics and measures both with std rotor and RR special custom rotor.

Stock Port V's RR Secondary Port

Stock Port V's RR Primary Port

Modified Exhaust Port

IO = Intake opens

IC = Intake closes

EO = Exhaust opens

EC = Exhaust closes

Primary and secondary Ports same on std Rotor

IO 15° ATDC

IC 67.5° ABDC

EO 78° BBDC

EC 60° ATDC

Primary and secondary Ports same on RR special Rotor

IO 22.5° BTDC

IC 75° ABDC

EO 78° BBDC

EC 60° ATDC

V's

Stock 13BREW

Primary

IO 45° ATDC

IC 50° ABDC

Secondary

IO 32° ATDC

IC 50° ABDC

Exhaust

EO 75° BBDC

EC 48° ATDC

**************************************

Here is a list of some port timing for other types.

Port Timing

IO = Intake opens

IC = Intake closes

EO = Exhaust opens

EC = Exhaust closes

US Model First Generation RX-7

IO 32° ATDC

IC 40° ABDC

EO 75° BBDC

EC 38° ATDC

European Model First Generation RX-7

IO 32° ATDC

IC 50° ABDC

EO 75° BBDC

EC 48° ATDC

First and Second Generation 6-Port 13B

Primary intake (Part throttle/cruise)

IO 32° ATDC

IC 40° ABDC

Secondary intake (Part to full throttle)

IO 32° ATDC

IC 30° ABDC

Auxiliary high speed ports (Full throttle above approximately 4000 rpm)

IO 45° ATDC

IC 70° ABDC

EO 71° BBDC

EC 48° ATDC

Second Gen Turbo 13B

IO 32° ATDC

IC 50° ABDC

EO 71° BBDC

EC 48° ATDC

Racing Beat "Street Port"

IO 25° ATDC

IC 60° ABDC

EO 84° BBDC

EC 48° ATDC

Racing Beat "J-Bridge Port"

IO 115° BTDC

IC 72° ABDC

EO 88° BBDC

EC 57° ATDC

Mazda Factory Peripheral Port

IO 86° BTDC

IC 75° ABDC

EO 73° BBDC

EC 65° ATDC

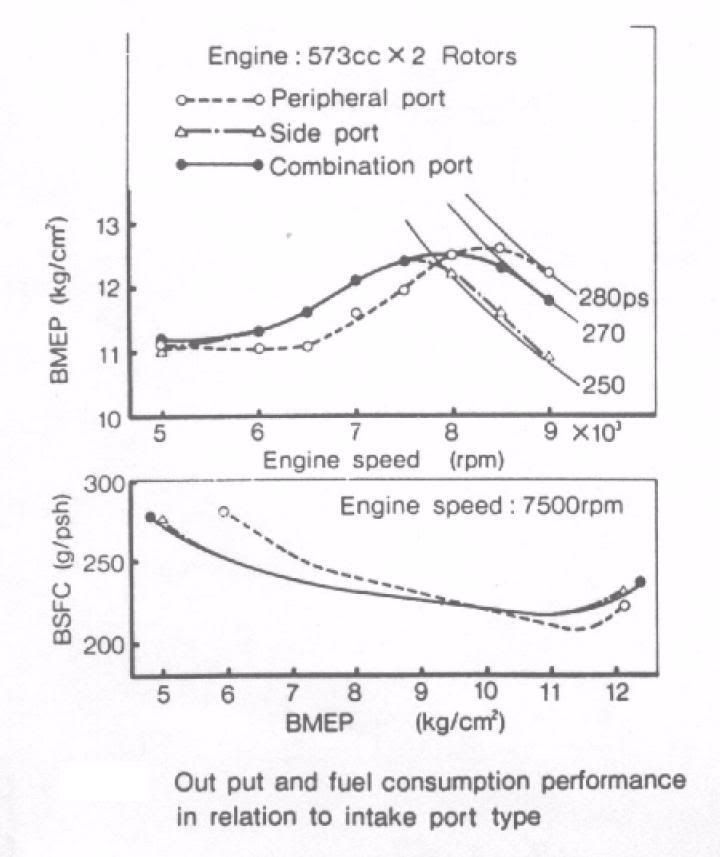

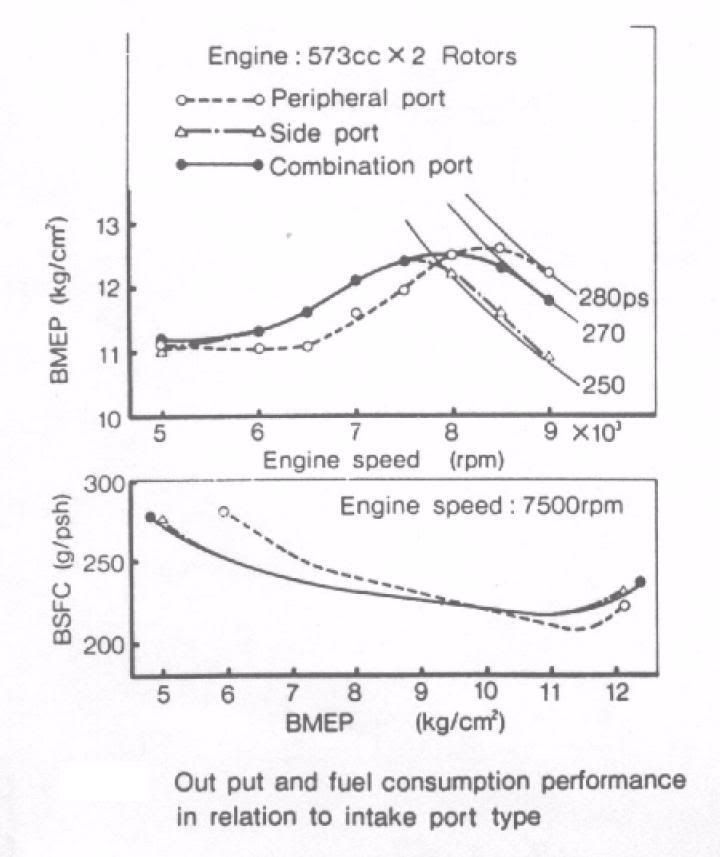

Power and BMEP curves for NA S-A bp, combination port S-C (partial pp, same as bp for comparison reasons), and peripheral port

On open racing exhaust systems

Stock Port V's RR Secondary Port

Stock Port V's RR Primary Port

Modified Exhaust Port

IO = Intake opens

IC = Intake closes

EO = Exhaust opens

EC = Exhaust closes

Primary and secondary Ports same on std Rotor

IO 15° ATDC

IC 67.5° ABDC

EO 78° BBDC

EC 60° ATDC

Primary and secondary Ports same on RR special Rotor

IO 22.5° BTDC

IC 75° ABDC

EO 78° BBDC

EC 60° ATDC

V's

Stock 13BREW

Primary

IO 45° ATDC

IC 50° ABDC

Secondary

IO 32° ATDC

IC 50° ABDC

Exhaust

EO 75° BBDC

EC 48° ATDC

**************************************

Here is a list of some port timing for other types.

Port Timing

IO = Intake opens

IC = Intake closes

EO = Exhaust opens

EC = Exhaust closes

US Model First Generation RX-7

IO 32° ATDC

IC 40° ABDC

EO 75° BBDC

EC 38° ATDC

European Model First Generation RX-7

IO 32° ATDC

IC 50° ABDC

EO 75° BBDC

EC 48° ATDC

First and Second Generation 6-Port 13B

Primary intake (Part throttle/cruise)

IO 32° ATDC

IC 40° ABDC

Secondary intake (Part to full throttle)

IO 32° ATDC

IC 30° ABDC

Auxiliary high speed ports (Full throttle above approximately 4000 rpm)

IO 45° ATDC

IC 70° ABDC

EO 71° BBDC

EC 48° ATDC

Second Gen Turbo 13B

IO 32° ATDC

IC 50° ABDC

EO 71° BBDC

EC 48° ATDC

Racing Beat "Street Port"

IO 25° ATDC

IC 60° ABDC

EO 84° BBDC

EC 48° ATDC

Racing Beat "J-Bridge Port"

IO 115° BTDC

IC 72° ABDC

EO 88° BBDC

EC 57° ATDC

Mazda Factory Peripheral Port

IO 86° BTDC

IC 75° ABDC

EO 73° BBDC

EC 65° ATDC

Power and BMEP curves for NA S-A bp, combination port S-C (partial pp, same as bp for comparison reasons), and peripheral port

On open racing exhaust systems

#9

Full Member

Join Date: Nov 2007

Location: United Kingdom

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

RXHEAVEN,

Where do your ports put the powerband? Does lower rpm suffer at all?

You can still get a smooth idle with such large streetports and benefit a stock twin/FR420 setup?

Thanks for posting the pics and timings! Very informative

Jon

Where do your ports put the powerband? Does lower rpm suffer at all?

You can still get a smooth idle with such large streetports and benefit a stock twin/FR420 setup?

Thanks for posting the pics and timings! Very informative

Jon

#10

Banned. I got OWNED!!!

Join Date: Apr 2008

Location: Australia

Posts: 114

Likes: 0

Received 0 Likes

on

0 Posts

They focus usable power range from 4000rpm to 8000+rpm *depending on the turbo charger*

TQ is totally flat! from 5000rpm to 7000rpm! and is much broader than on stock porting specification, Volumetric effeciencey is increased by over 10~15% in every engine speed range above 4000rpm.

Maximum power occurs at exactly 7400 to 7600rpm using stock inlet manifolding and turbochargers ranging from RF420's to T04Z (as a guide).

Idle speed is around 900~950rpm, and it totally smooth.

far better power capacity with higher levels of exhaust restriction or TIP to IMP pressure ratios than any bridge port.

Typical power ranges are 520 to 580bhp (20psi to 25psi boost) on medium sized turbo chargers.

#12

Racing Rotary Since 1983

iTrader: (6)

it is nice to see a decent thread on porting in this forum.

Peter, i really like you talking degrees when talking rotary ports. there are lots of rotorfiles that just pick up a die grinder. they would do well to study up on piston engine camshaft/valve timing. plan to do alot of reading, then grab the most important porting tool

a degree wheel.

for instance, i have a set of beautifully executed and i mean beautiful, ports that have the exact same timing as the factory! and i was wondering why my torque was falling off.

i will be on the dyno shortly w a set of intakes that add 22 additional degrees of duration and as well as a tricked up exhaust that should add spool.

as far as bigger not always being better... i totally agree if you are talking NA. i disagree as to the face area on the iron re the intakes. when ramming air/fuel down into the combustion chamber w a TURBO, bigger is generally better.

unfortunately when we get to the finer points on porting most of us, myself included, revert to being what we are: racers. as such there are a number of things we all keep under wraps.

howard coleman

Peter, i really like you talking degrees when talking rotary ports. there are lots of rotorfiles that just pick up a die grinder. they would do well to study up on piston engine camshaft/valve timing. plan to do alot of reading, then grab the most important porting tool

a degree wheel.

for instance, i have a set of beautifully executed and i mean beautiful, ports that have the exact same timing as the factory! and i was wondering why my torque was falling off.

i will be on the dyno shortly w a set of intakes that add 22 additional degrees of duration and as well as a tricked up exhaust that should add spool.

as far as bigger not always being better... i totally agree if you are talking NA. i disagree as to the face area on the iron re the intakes. when ramming air/fuel down into the combustion chamber w a TURBO, bigger is generally better.

unfortunately when we get to the finer points on porting most of us, myself included, revert to being what we are: racers. as such there are a number of things we all keep under wraps.

howard coleman

#13

Passing life by

port timing is the monkey porting anyone can cut the timing. Bigger is not always better ever its is not about timing it is about intake port velocity. The timing needs to be cut accordingly to the motors rpm range in corolation to intake port runner length reversion timing. After that the last 3hrs of each port is spent inside the runner and then flow testing regrinding. Like I said ok a degree wheel cool nitto still don't mater you just cut that according to the setup. Ok your TQ dropped who cares TQ is irrelevant we are after HP and keeping an avg broad HP curve. Some timing charts copied over from rotaryillistrations.com is hardly the basis of designing a good motor.

#14

Full Member

Join Date: Nov 2007

Location: United Kingdom

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

it is nice to see a decent thread on porting in this forum.

Peter, i really like you talking degrees when talking rotary ports. there are lots of rotorfiles that just pick up a die grinder. they would do well to study up on piston engine camshaft/valve timing. plan to do alot of reading, then grab the most important porting tool

a degree wheel.

for instance, i have a set of beautifully executed and i mean beautiful, ports that have the exact same timing as the factory! and i was wondering why my torque was falling off.

i will be on the dyno shortly w a set of intakes that add 22 additional degrees of duration and as well as a tricked up exhaust that should add spool.

as far as bigger not always being better... i totally agree if you are talking NA. i disagree as to the face area on the iron re the intakes. when ramming air/fuel down into the combustion chamber w a TURBO, bigger is generally better.

unfortunately when we get to the finer points on porting most of us, myself included, revert to being what we are: racers. as such there are a number of things we all keep under wraps.

howard coleman

Peter, i really like you talking degrees when talking rotary ports. there are lots of rotorfiles that just pick up a die grinder. they would do well to study up on piston engine camshaft/valve timing. plan to do alot of reading, then grab the most important porting tool

a degree wheel.

for instance, i have a set of beautifully executed and i mean beautiful, ports that have the exact same timing as the factory! and i was wondering why my torque was falling off.

i will be on the dyno shortly w a set of intakes that add 22 additional degrees of duration and as well as a tricked up exhaust that should add spool.

as far as bigger not always being better... i totally agree if you are talking NA. i disagree as to the face area on the iron re the intakes. when ramming air/fuel down into the combustion chamber w a TURBO, bigger is generally better.

unfortunately when we get to the finer points on porting most of us, myself included, revert to being what we are: racers. as such there are a number of things we all keep under wraps.

howard coleman

#15

RXHEAVEN_WA

On those ports is the leading edge of the seal supported the whole way or do they drop into the port? Also the comments from the guy saying how horrible those ports are, well if you look at those ports you can oviously tell that they are not complete. Those are just rough cuts and the inside hasn't even been touched yet. Hell the damn things still have Dychem on them. The finished product should look quite good once he is done with them. Bigger is not always better but what works for some does not work for others. It's all about your combination and what works for you. RXHEAVEN_WA what size turbo do you plan on running on that combo? My motors ports are quite similar and I have a PT74GTS. Would sure like to see the end product.

On those ports is the leading edge of the seal supported the whole way or do they drop into the port? Also the comments from the guy saying how horrible those ports are, well if you look at those ports you can oviously tell that they are not complete. Those are just rough cuts and the inside hasn't even been touched yet. Hell the damn things still have Dychem on them. The finished product should look quite good once he is done with them. Bigger is not always better but what works for some does not work for others. It's all about your combination and what works for you. RXHEAVEN_WA what size turbo do you plan on running on that combo? My motors ports are quite similar and I have a PT74GTS. Would sure like to see the end product.

#16

Racing Rotary Since 1983

iTrader: (6)

reversion:

actually a really really important item to get right. hugely effects the brake specific if it is off. i fail to understand how you are going to adjust reversion with porting. reversion is about runner length primarily. granted it is also about runner volume but the porting we are able to do in the FD runners is not enough to effect where standoff occurs. so you aren't going to change reversion materially by porting.

as far as velocity.... very important NA. not very important when you are shoving 80 lbs/minute down the throat of a rotary. you have all the velocity you need courtesy of Mr. Garrett.

howard coleman

actually a really really important item to get right. hugely effects the brake specific if it is off. i fail to understand how you are going to adjust reversion with porting. reversion is about runner length primarily. granted it is also about runner volume but the porting we are able to do in the FD runners is not enough to effect where standoff occurs. so you aren't going to change reversion materially by porting.

as far as velocity.... very important NA. not very important when you are shoving 80 lbs/minute down the throat of a rotary. you have all the velocity you need courtesy of Mr. Garrett.

howard coleman

Last edited by Howard Coleman; 03-30-09 at 07:08 AM.

#17

Racing Rotary Since 1983

iTrader: (6)

"a NA 20B, its preferable to leave the porting alone? Or just a mild intake port over a large streetport?"

it depends what you are after... just think of your motor as being a piston engine w a stock cam. you can change the camshaft by changing the porting. are you happy w the power as is? are you happy where the peak torque is rpm-wise?

you can add some total additive hp under the rpm curve w a proper port job... sort of free hp and/or you can move the power band up rpm-wise if you wish.

whatever you do, make sure that whoever does it knows what they are doing.

howard

it depends what you are after... just think of your motor as being a piston engine w a stock cam. you can change the camshaft by changing the porting. are you happy w the power as is? are you happy where the peak torque is rpm-wise?

you can add some total additive hp under the rpm curve w a proper port job... sort of free hp and/or you can move the power band up rpm-wise if you wish.

whatever you do, make sure that whoever does it knows what they are doing.

howard

#18

Full Member

Join Date: Nov 2007

Location: United Kingdom

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

"a NA 20B, its preferable to leave the porting alone? Or just a mild intake port over a large streetport?"

it depends what you are after... just think of your motor as being a piston engine w a stock cam. you can change the camshaft by changing the porting. are you happy w the power as is? are you happy where the peak torque is rpm-wise?

you can add some total additive hp under the rpm curve w a proper port job... sort of free hp and/or you can move the power band up rpm-wise if you wish.

whatever you do, make sure that whoever does it knows what they are doing.

howard

it depends what you are after... just think of your motor as being a piston engine w a stock cam. you can change the camshaft by changing the porting. are you happy w the power as is? are you happy where the peak torque is rpm-wise?

you can add some total additive hp under the rpm curve w a proper port job... sort of free hp and/or you can move the power band up rpm-wise if you wish.

whatever you do, make sure that whoever does it knows what they are doing.

howard

I understand its different for a turbo and NA application, Im just trying to find out why. I don't want to buy some templates from somewhere without understanding what kind of improvement is going on. Most template info is rather vauge with little reasoning why I should use theirs over a competitors.

off topic, your advice with 8/6 springs and stiffer ARBs on your other thread really helped with the handling of the car. Very pleased! Thankyou

Jon

#19

Passing life by

"a NA 20B, its preferable to leave the porting alone? Or just a mild intake port over a large streetport?"

it depends what you are after... just think of your motor as being a piston engine w a stock cam. you can change the camshaft by changing the porting. are you happy w the power as is? are you happy where the peak torque is rpm-wise?

you can add some total additive hp under the rpm curve w a proper port job... sort of free hp and/or you can move the power band up rpm-wise if you wish.

whatever you do, make sure that whoever does it knows what they are doing.

howard

it depends what you are after... just think of your motor as being a piston engine w a stock cam. you can change the camshaft by changing the porting. are you happy w the power as is? are you happy where the peak torque is rpm-wise?

you can add some total additive hp under the rpm curve w a proper port job... sort of free hp and/or you can move the power band up rpm-wise if you wish.

whatever you do, make sure that whoever does it knows what they are doing.

howard

Take for instance the stock FC intake plenum and port timing is design to peak at 7,200rpm in order to retain proper reversion with the OEM intake design aprox for each mm in closing time increase the RPM must be increased by 900/1000rpm or the runner length must be increased.

Port timing is designed to cause a correctly functioning motor it does not really determine how well the port design works. This will be accomplished in port shape. Flow bench really should be utilized for this process and a knowledge in fluid dynamics. Try creating your runner bowl more into the shape of a D.

I do understand that porting is basically dictating the powerband, Im just curious and would like more info on the specifics, such as how do the degrees of the port correlate to what type of improvement.

I understand its different for a turbo and NA application, Im just trying to find out why. I don't want to buy some templates from somewhere without understanding what kind of improvement is going on. Most template info is rather vauge with little reasoning why I should use theirs over a competitors.

off topic, your advice with 8/6 springs and stiffer ARBs on your other thread really helped with the handling of the car. Very pleased! Thankyou

Jon

I understand its different for a turbo and NA application, Im just trying to find out why. I don't want to buy some templates from somewhere without understanding what kind of improvement is going on. Most template info is rather vauge with little reasoning why I should use theirs over a competitors.

off topic, your advice with 8/6 springs and stiffer ARBs on your other thread really helped with the handling of the car. Very pleased! Thankyou

Jon

study the bowl shape

#21

talking head

i expect the difference would be seen in the DEI effect,,

i also expect the reversion is softer with a gradual close ,, and likely more suited to NON dynamic effect manifolds

-- ie with a carb

cons-- during late timing,, port area is not optimised as much as it could have been

the sharp close straight line top of port would obviously maximise the area of the port for the timing used

-- and likely produce a more violent compression- reversion pulse to be used in DEI

cons- if aiming deliberately for late timing close,, then there comes a point where the side seal leading edge will not be supported

my experience in the matters,,

none with a flow bench,,

-but i have physically evolved much of my own porting in my own street /strip turbo engines over a dozen year period

-------------------------

i follow much of what has been posted here,, and also some of what ice blue is trying to convey about the reversion principle

- but IMO,, that helmholtz theory is only PART of the full equation of what makes " area under the curve "

and if you think HP is all, then think again,,, HP is TQ x revs ,, simple

if the motor is flat and wide in the torque curve,,,

it will drive rings around one that is narrow in TQ delivery with a slightly higher peak HP

myself,, when i do four ports,, they end up not all that dissimilar to what rices do

though i use FC and not FD plates

( actually it surprised me when i first saw his ports posted in the similarities found on independent paths )

-- as for exhaust on the turbo cars,, the straight edge port also features the sharp exhaust open and close,, great for turbo

-- but **** for NA and the intended overlap and scavenge that is so important with them

so,, in all,, i agree,, big is not best with NA

-- and its all in how that overlap is controlled,, is how well scavenge and helmholtz is maintained

-- but in the turbo,, big ,, to a point is best

( no point being much further late timing than 6 port end plates do due flow losses against the rising compression )

-- especially in the exhaust,, so squar-ish sided and flat ended is maximised area= bestest

whats missing in this discussion????

no-body has pointed out, WIDER is EARLIER TIMING

going DOWN on an inlet port doesn't have a huge effect in timing overlap with the exhaust

but going wide,, does

-- a rotor moves IN and UP after it passes BDC

that why bridges have the constant overlap they do !!!

-- so as such,, cause i like LPG mixer which prefers a decent vac signal when not under load to get the mixes right

-- i avoid going too much wider than a standard s4/5 T primary port

however,, on EFI turbo,, and on some petrol carbs ,, this overlap can be used to increase port area and increase any extend ports initial overlap

(( so,, in effect not as much overlap as a bridge,, but more area than a bridge ))

bridges area rarely taken wider on the original port due to it making the bridge meat very narrow

PS,, my favourite combo,,,( after trying extend ports of varying descriptions )

6 port endplates ( stock ports, minor runner work )

and a MILD turbo centre plate

-- and a modded turbo LIM to suit

tried with varying exhaust overlaps,,, actually bloody good with stock ports

( so there may be something in the reversion DEI talk and mazda's math )

#22

Passing life by

Originally Posted by bumpstart

and if you think HP is all, then think again,,, HP is TQ x revs ,, simple

Horsepower equals torque times rpm divided by 5252. Horsepower = (Torque X RPM) / 5252

Torque equals horsepower times 5252 divided by rpm. Torque = (Horsepower X 5252) / RPM

RPM equals horsepower times 5252 divided by torque. RPM = (Horsepower X 5252) / Torque

TORQUE IN LBS./FT. = (WEIGHT IN LBS. X LEVER ARM LENGTH IN FEET.)

1 HP = 550 LBS./FT./SEC.

1 HP = 33,000 LBS./FT./MIN.

HP = (TORQUE X RPM) / 5252

TORQUE = (HP X 5252) / RPM

TORQUE AT THE REAR WHEELS = (ENGINE TORQUE X TRANSMISSION GEAR RATIO X RING AND PINION RATIO)

ACCELERATIVE THRUST = (TORQUE AT THE REAR WHEELS / TIRE RADIUS IN FT.)

RATE OF ACCELERATION = (ACCELERATIVE THRUST / TOTAL VEHICLE WEIGHT.)

Now lets take some examples and understand why we do not close latter

Originally Posted by Dave

only thing with those is they close after the rotor reaches bdc, so anything after that is just pushig air back out the port as it compresses

Originally Posted by BDC

You're getting better, but you need to focus on port opening and not port closing.

And, as I said Dave, focus on the opening edge; not the closing edge.

And, as I said Dave, focus on the opening edge; not the closing edge.

Originally Posted by Maxt

The boost loss with overlap is negligable, thats pretty much a falicy, back pressure also helps dam up the motor to retain boost pressure. Enough goes through to purge the chamber, if the exhaust side is sized correctly..The reduced timing is due to increased volumetric efficiency, thats a good thing, not a bad thing...Bp's and PP's arent just for na's, they work great with turbo motors, changing the pressure ratio of the engine, doesnt not change what overlap does for an engine.

On a turbo motor, the turbo is aiding volumetric efficiency, and late closing timing is going to bounce back some of the charge, its not needed in a forced induction motor, although mazda tried to incorporate it into the turbo motors to a small degree, once you screw with the port timing at all, its all down the drain, since the factory intake is tuned for a given port opening and closing value.

With the 6 port motors, alot of people think its just an intake port, when reality its a pressure wave port. Thats why from a flow perspective it looks so dreadful, its not really for flow at all, its just to introduce a pulse back to the intakes. Thats also why 6 ports get stuck with mung all the time, the flow tends to be alot more out, then in... Thats also why porting a 6 port motor, is polishing a turd, its a tuned and timed system, throw one thing out of whack, in regards to port timing and none of it works, the 6 port is probably the hardest motor to port effectively..

I hope that Iron on the first page was for practice, it looks totally fubarred...

On a turbo motor, the turbo is aiding volumetric efficiency, and late closing timing is going to bounce back some of the charge, its not needed in a forced induction motor, although mazda tried to incorporate it into the turbo motors to a small degree, once you screw with the port timing at all, its all down the drain, since the factory intake is tuned for a given port opening and closing value.

With the 6 port motors, alot of people think its just an intake port, when reality its a pressure wave port. Thats why from a flow perspective it looks so dreadful, its not really for flow at all, its just to introduce a pulse back to the intakes. Thats also why 6 ports get stuck with mung all the time, the flow tends to be alot more out, then in... Thats also why porting a 6 port motor, is polishing a turd, its a tuned and timed system, throw one thing out of whack, in regards to port timing and none of it works, the 6 port is probably the hardest motor to port effectively..

I hope that Iron on the first page was for practice, it looks totally fubarred...

Originally Posted by Dave

are you trying to convince me that a stock port is gonna make more power than that?

Originally Posted by Maxt

If you left ithe timing stock and just polished it , probably yeah....I got a pretty good lesson on porting in Japan. You'd be amazed on how easy it is to lose power porting an engine...The air and fuel really doesnt care how sexy it looks...

having a resonance effect back into the intake at the wrong time is the point...Flow isnt everything on a rotary port, since port shape is also a port timing function.. Thats where piston and rotary engines take different paths, if you were to stick to one port timing and then alter the rest of the port for flow than yeah sure, but measuring flow with diffenent size and timed intake port exits, will tell you nothing as far as actually power production.

Because rotary owners have Northern Pike DNA, they'll bite anything shiney that moves...

Its not so much porting doesnt make power, its that porting later has little effect when the intake cant or isnt tuned to take advantage of it... Mazda uses a computer the size of a gravel truck to figure out the port closing to the intake manifold length relationship, the chances of most of us bettering it with a die grinder in our garage's is slim to none... All the power from porting will come from just blending and port opening time.

having a resonance effect back into the intake at the wrong time is the point...Flow isnt everything on a rotary port, since port shape is also a port timing function.. Thats where piston and rotary engines take different paths, if you were to stick to one port timing and then alter the rest of the port for flow than yeah sure, but measuring flow with diffenent size and timed intake port exits, will tell you nothing as far as actually power production.

Because rotary owners have Northern Pike DNA, they'll bite anything shiney that moves...

Its not so much porting doesnt make power, its that porting later has little effect when the intake cant or isnt tuned to take advantage of it... Mazda uses a computer the size of a gravel truck to figure out the port closing to the intake manifold length relationship, the chances of most of us bettering it with a die grinder in our garage's is slim to none... All the power from porting will come from just blending and port opening time.

Originally Posted by Dave

i don't get it.

you're saying the port opening time will build power but the turbine is going to be the limiting factor in this one. all opening it early is going to do is create more reversion. close it later and you can get the same amount of air shoved in there, but with less exhaust entering.

cleaner is good. y'know that little motor they call the renesis?

you're saying the port opening time will build power but the turbine is going to be the limiting factor in this one. all opening it early is going to do is create more reversion. close it later and you can get the same amount of air shoved in there, but with less exhaust entering.

cleaner is good. y'know that little motor they call the renesis?

Originally Posted by Maxt

At lower engine speeds yes, but earlier timing, you get slight purging effect into the exhaust and chamber cleansing at higher rpms, and more time to charge the chamber, with chamber pressure negative. Go later and it you get the rotor pulse back, which back to what I said before, on an intake not tuned and timed for it does nothing but create intake manifold turbulence and upsets flow.

Cleaner is good, but yes , the renesis, again is tuned and timed to take advantage of the reversion pulse, its what they had to do, to make power without overlap which is not emissiosn friendly. You can put renesis closing port time into an FD motor, and wont do jack but reduce power.. Why because the pulse is not tuned and time to the intake length to creat a positive pressure wave andwont hit the intake for the other rotor at the right time..All it will do is create rough air. Overlap will always make more power, it just isnt as clean or smooth idling as resonance effect intake timing. If it were socially acceptable the rx-8 would be 350 rwhp 13b p-port..

Cleaner is good, but yes , the renesis, again is tuned and timed to take advantage of the reversion pulse, its what they had to do, to make power without overlap which is not emissiosn friendly. You can put renesis closing port time into an FD motor, and wont do jack but reduce power.. Why because the pulse is not tuned and time to the intake length to creat a positive pressure wave andwont hit the intake for the other rotor at the right time..All it will do is create rough air. Overlap will always make more power, it just isnt as clean or smooth idling as resonance effect intake timing. If it were socially acceptable the rx-8 would be 350 rwhp 13b p-port..

Originally Posted by BDC

Early Port Opening = Higher chamber VE, increase in overlap for pre-charging of the turbo, and better mid-range and high-end potential due to higher efficiency VE at higher RPM's compared to stock ...

Better all around the board minus the emissions issue as well as relative loss of low-end power at negligible RPM's (below 1000rpm depending on the kind of early opening and here I am not advocating a BP necessarily...)

Better all around the board minus the emissions issue as well as relative loss of low-end power at negligible RPM's (below 1000rpm depending on the kind of early opening and here I am not advocating a BP necessarily...)

Originally Posted by Maxt

Theory is what makes it all work..The stock based hybrids are a mistake anyway, and are unbalanced on stock ports...

If you put port timing late, the chamber is going to accept a fix amount of charge, go 6 port late, and you are gonna get a pulse back from the closing of the chamber and the reduction of chamber volume as it goes back to compression. Now if that intake is not tuned to use that intake pulse at that time to help pack the charge into the reducing volume chamber of the other rotor, it s going to just create turbulence and pressure wave against flow with no benefit in the intake manifold. The chamber isnt perfectly cleansed either, there are some re expansion gases lurking in the chamber. You are always better off to open earlier, and purge through to the exhaust so you purge the expanding gas, you will always gain power doing that, you want some overlap on even a "stock turbo" motor, just not bridgeport overlap, as engine speed increases, also with rpm, there is less time for reversion to happen, and intake velocity increases, enough that even when both port are open the intake is enough to overcome the reversion, and the added port time when the chamber is relative negative pressure, gives more chamber charging. As engine speed increases, events have to happen sooner, not later, just like ignition timing. You have to port to suit whats strapped to the *** end of the engine as well..

But back to the original, all mazda intakes are resonance tuned, once you change the timing, speed, and duration of the pressure wave, all bets are off... Port opening has little effect on that wave, port closing has all the effect on it... Screw with it, and bad things happen, all that engineering mazda did on the intake length is done and gone.

What happens though, is typically when people port, they do enough other mods at the same time , to not notice the missing 12-15 hp the tournament effect gives them...

I take into account everything when I port a motor, the turbo, or non turbo, the intake manifold, the engine speed, the ecu, the exhaust system... Using every part of the motor properly and taking into account all the "theory" is what makes one car faster than the other...There is a ton of engineering in those engine parts that people take for granted...

The later the port closes, the less bottom end torque a motor will make as well, as more charge is reversed out of the chamber, alot of people think only early opening makes a torque drop..

Closing time has no real effect on emmissions or fuel economy or idle for that matter, the closing time on the motor is tuned to its original intake, and is pretty much optimal as its every going to be for power output to the useable rpm band of the manifolds.

The turbine is a limiting factor on port opening, no one is avoiding that, as said before you dont go bridgeporting a stock turbine motor... Take it into account, you can add a bit more overlap to get a more powerband out of it, since the charge poisoning will disappear above a certain rpm anyway, most stock based turbos will not feed enough at high rpms either where late port timing comes into play. On a stock turbine car, the port work that is useful and required is almost not much more than a polish and most of the shaping is going to be on the primaries, a hint more of overlap will help spool it earlier and give more powerband, the reason it is where it is though, again is just for emissions, idle quality, and low load fuel economy..

If you make the port timing later, you are going to shift any effect you would see from it way higher in the rpm range, like 10,000 rpm +, alot of good thats going to do a stock turbo car... What you were looking for was an excuse not to port earlier with a stock turbo in the original question. Port to make the most use of all the parts motor. You know the intake is tuned to that port close time, so use it. Overlap will not affect that, but will bring on boost earlier aiding power earlier, stretching the powerband downward on a turbo car. But you have to know the limit.

The problem is one person posts a blingy secondary port, and everyone wants to then make their ports all super huge and blingy... It just doesnt work like that when you take all the parts into account..

Its like switching to Brodix heads and .780 lift roller cam , then running the stock cast iron dual plane manifold on a big block chev..

Look at like this, you charge a negative chamber with 10 psi, the rotor pushes back a bit, so you have 10 psi + reversion wave pushing back , for that matter it doesnt matter if its 10" of vac or 10 psi, its absolute pressure...Change port timing from stock, intake manifold is tuned for stock intake closing, change wave dynamics, manifold is no longer tuned to port..

**** its not that tough to understand....

You are not just changing the powerband, you are detuning the intake manifold from being effective in the tournament effect charge pattern...... My god man... Its free tuning and horsepower that is built into the motor... To many people just hog away ports convinced they are doing nothing but good.... I have seen a collection of over 500 dyno sheet with port profiles proving this...

This is reminiscent of all the people that use to write into Car craft that said, the ported their Mopar heads with the mopar head template, and lost power They ground the short side radius becuase it was bumpy, Car craft would tell them to re-read the instructions, dont touch short side radius....

The only dead horses are the people I am trying to pass on something I learned from people with more experience than all of us put together..

The added problem is you lenghthen the charge reversion effect higher as well as you port later.. Where as in the 6 port and renesis, it has a means of valving off the longer intake, to preserve low to mid speed operation.. Where as in a turbo motor, you have no mechanism to do this.. Mazda pushed port timing as late as the could with each manifold design to capitalize on the supercharging effect.. Lengthening it more, again does nothing good...

Here, maybe in someone elses words will help...Man so much effort required to a pass on a good porting tip.. Yeesh...

If you put port timing late, the chamber is going to accept a fix amount of charge, go 6 port late, and you are gonna get a pulse back from the closing of the chamber and the reduction of chamber volume as it goes back to compression. Now if that intake is not tuned to use that intake pulse at that time to help pack the charge into the reducing volume chamber of the other rotor, it s going to just create turbulence and pressure wave against flow with no benefit in the intake manifold. The chamber isnt perfectly cleansed either, there are some re expansion gases lurking in the chamber. You are always better off to open earlier, and purge through to the exhaust so you purge the expanding gas, you will always gain power doing that, you want some overlap on even a "stock turbo" motor, just not bridgeport overlap, as engine speed increases, also with rpm, there is less time for reversion to happen, and intake velocity increases, enough that even when both port are open the intake is enough to overcome the reversion, and the added port time when the chamber is relative negative pressure, gives more chamber charging. As engine speed increases, events have to happen sooner, not later, just like ignition timing. You have to port to suit whats strapped to the *** end of the engine as well..

But back to the original, all mazda intakes are resonance tuned, once you change the timing, speed, and duration of the pressure wave, all bets are off... Port opening has little effect on that wave, port closing has all the effect on it... Screw with it, and bad things happen, all that engineering mazda did on the intake length is done and gone.

What happens though, is typically when people port, they do enough other mods at the same time , to not notice the missing 12-15 hp the tournament effect gives them...

I take into account everything when I port a motor, the turbo, or non turbo, the intake manifold, the engine speed, the ecu, the exhaust system... Using every part of the motor properly and taking into account all the "theory" is what makes one car faster than the other...There is a ton of engineering in those engine parts that people take for granted...

The later the port closes, the less bottom end torque a motor will make as well, as more charge is reversed out of the chamber, alot of people think only early opening makes a torque drop..

Closing time has no real effect on emmissions or fuel economy or idle for that matter, the closing time on the motor is tuned to its original intake, and is pretty much optimal as its every going to be for power output to the useable rpm band of the manifolds.

The turbine is a limiting factor on port opening, no one is avoiding that, as said before you dont go bridgeporting a stock turbine motor... Take it into account, you can add a bit more overlap to get a more powerband out of it, since the charge poisoning will disappear above a certain rpm anyway, most stock based turbos will not feed enough at high rpms either where late port timing comes into play. On a stock turbine car, the port work that is useful and required is almost not much more than a polish and most of the shaping is going to be on the primaries, a hint more of overlap will help spool it earlier and give more powerband, the reason it is where it is though, again is just for emissions, idle quality, and low load fuel economy..

If you make the port timing later, you are going to shift any effect you would see from it way higher in the rpm range, like 10,000 rpm +, alot of good thats going to do a stock turbo car... What you were looking for was an excuse not to port earlier with a stock turbo in the original question. Port to make the most use of all the parts motor. You know the intake is tuned to that port close time, so use it. Overlap will not affect that, but will bring on boost earlier aiding power earlier, stretching the powerband downward on a turbo car. But you have to know the limit.

The problem is one person posts a blingy secondary port, and everyone wants to then make their ports all super huge and blingy... It just doesnt work like that when you take all the parts into account..

Its like switching to Brodix heads and .780 lift roller cam , then running the stock cast iron dual plane manifold on a big block chev..

Look at like this, you charge a negative chamber with 10 psi, the rotor pushes back a bit, so you have 10 psi + reversion wave pushing back , for that matter it doesnt matter if its 10" of vac or 10 psi, its absolute pressure...Change port timing from stock, intake manifold is tuned for stock intake closing, change wave dynamics, manifold is no longer tuned to port..

**** its not that tough to understand....

You are not just changing the powerband, you are detuning the intake manifold from being effective in the tournament effect charge pattern...... My god man... Its free tuning and horsepower that is built into the motor... To many people just hog away ports convinced they are doing nothing but good.... I have seen a collection of over 500 dyno sheet with port profiles proving this...

This is reminiscent of all the people that use to write into Car craft that said, the ported their Mopar heads with the mopar head template, and lost power They ground the short side radius becuase it was bumpy, Car craft would tell them to re-read the instructions, dont touch short side radius....

The only dead horses are the people I am trying to pass on something I learned from people with more experience than all of us put together..

The added problem is you lenghthen the charge reversion effect higher as well as you port later.. Where as in the 6 port and renesis, it has a means of valving off the longer intake, to preserve low to mid speed operation.. Where as in a turbo motor, you have no mechanism to do this.. Mazda pushed port timing as late as the could with each manifold design to capitalize on the supercharging effect.. Lengthening it more, again does nothing good...

Here, maybe in someone elses words will help...Man so much effort required to a pass on a good porting tip.. Yeesh...

Originally Posted by BDC

I vote for keeping porting timing the same yet focus on velocity. Do the things that help retain velocity through the port by removing the turbulent trouble-spots...

Originally Posted by Maxt

How is opening it later going to give it a cleaner charge? The pocket of unburnt gases at the leading edge of the chamber has no where to go.. Thats the point of ealier opening, and overlap, to purge to the exhaust...

The closing time is timed to give, I use a real simple term, a burp back to the intake, this helps to generate a pulse to aid the other chamber in filling... Nah forget it, I am not typing it a 10 th freaking time...

To answer your 10,000 rpm question.. When you throw the stock systems out of whack , the power band takes a drastic shift, the port timing is tuned to the intake length, mess up those equations and it goes north.. Late closing without the tuned intake moves the rpm band up drastically.. For instance, the 6 port motor when operated with a non stock intake, peaks at over 10,000 rpm. Then when its ported later than stock, every 1.5 mm made a 900 rpm or so jump on turbo motors, when people push the port timing really late, the lowering of the volumetric efficiency due to the loss of the tuned intake, pushes it northward again, until rotor speed is fast enough to overcome the VE loss of charge back into the intake ... Again it doesn't matter if its 10 psi, or 10" , the density of the gas doesn't matter, the rotor will always squich some of the charge back out with later port timing. .. Most people never see the effect of that because they dont have the turbo, the motor or even the idea they have done that to the motor to ever find that out...

So you hog the port out huge , the motor makes 425 hp at 6500 rpm, wow, we are impressed....Now you do the same exact combo, port the port in the RIGHT places instead of just hogging the thing out to the walls.. And you will see a gain in hp over and above what I call the "internet port".

Overlap will always make power, its just the degree to what its done is the maker and breaker. Thats where the experience comes in when porting. We all can easily tune to other components of the back side of the motor, to accomodate overlap to make power.. We do it , via turbine trim, boost level, exhaust design and size, header length etc etc... But when is the last time you tuned the intake to accomadate the changing of the back pulse when you pushed a port taller...Never... Thats why 99% of the Japanese tuners will draw an x over the top of the port and say "dont touch"...None of us have the equipment or the combined knowledge to rethink the wheel better than mazda.

There is merit to late port opening, but its maxed out on the oem motors, the intakes are tuned to that timing and in order for it to have a positive effect on the motor in a usable rpm range, it has to be used with the proper intake tuning, otherwise as I said before, it simply wont come into play till stratospheric rpms...The factory intake tuning, drags that down into a useable band, and thats why I said, Dont screw with it...

Can you add power with stock turbo and overlap....

I need member "roshambo" to post his dyno sheet, he has a bone stock s4 TII I built about 1.5 years ago.... I did 90% of the porting on the primaries, and the exhaust ports.. Secondaries are very sedate, I added just enough overlap, that its audible. The result was 200 rwhp on a bone stock car on stock boost and an extremely wide power curve.... Had I gone up or down on those ports anymore, I know the power wouldnt have been what it is..

Your dilemna is more stuck around your choice of turbine.... You have to tune everything together and keep what you cant tune under control, which is the point of my last 6 diatribes... You cant expect to keep porting and keep pushing one component past what physics allow...If you stepped up your turbine, then put more overlap in it, and your power would go up.....

I should also add, 90% of the exhaust systems out there will max out right around 400 rwhp... I am assuming you have enough exhaust system capacity... If you dont see any gain from a given boost pressure thats another point to watch...

I would add overlap to it beyond stock overlap, I just wouldnt add Bp overlap to it, and think I was gonna make more power. I said way back when, overlap is the maker and the breaker, to little , less, to much no... Bad turbine selection an unbalanced turbos is another thread entirely... If you are over running your turbine at 17 psi, have you ever thought about improving VE and charge cleansing to make more power at lower boost levels with more overlap? Move a little less into the motor, but make more use of what you are moving? Mazdas hands were tied by low speed and idle emmission when it came to overlap on the new cars, there is room there for performance, even mazda will tell you that.. It goes back the example I gave before with the stock TII, I knew the turbine was a limiting factory so I added enoug port overlap to make power at a lower boost level, instead of going with girgantuan port job, and then running that turbo in an area to the point its choking the motor, and pushing hot charge temps. Its the additive some of the parts instead of going hog wild one area and expecting everything else to work well with it..

Who ever is arguing there is no gain from sp to bp has never seen enough dyno sheets of true comparisons.. I studied a binder full of dyno sheets of every kind of port, and the bp always has a positive effect on power when the rest of the car is set up to support it. The reason Bp's spool a turbo faster is not actually the overlap adding air down low, its the third wave miss effect of the intake charge being fouled with exhaust gases. Its the same reason misfires blows motors. When a misfire occurs, the next combustion event on that rotor face will have a 30-40 percent peak higher normal combustion pressure than normal, because of higher VE due to the low pressure misfire event not leaving a large amount of higher pressure gases behind for re expansion which normally lowers VE. That high VE cycle has a much more powerful exhaust pulse than normal.. brap brap brap..

The other positive is the intake is blowing across the rotor tip, and above the side seals, so less intake charge is blown in between the side seal and oil seal which tends to become part of the blow by into the crankcase. On large street ports, the positive pressure in the intake track also tends to push the rotor over as it passes..Keep the main port reasonable, the bridge big, and you get less rotor wobble and less iron wear.

The closing time is timed to give, I use a real simple term, a burp back to the intake, this helps to generate a pulse to aid the other chamber in filling... Nah forget it, I am not typing it a 10 th freaking time...

To answer your 10,000 rpm question.. When you throw the stock systems out of whack , the power band takes a drastic shift, the port timing is tuned to the intake length, mess up those equations and it goes north.. Late closing without the tuned intake moves the rpm band up drastically.. For instance, the 6 port motor when operated with a non stock intake, peaks at over 10,000 rpm. Then when its ported later than stock, every 1.5 mm made a 900 rpm or so jump on turbo motors, when people push the port timing really late, the lowering of the volumetric efficiency due to the loss of the tuned intake, pushes it northward again, until rotor speed is fast enough to overcome the VE loss of charge back into the intake ... Again it doesn't matter if its 10 psi, or 10" , the density of the gas doesn't matter, the rotor will always squich some of the charge back out with later port timing. .. Most people never see the effect of that because they dont have the turbo, the motor or even the idea they have done that to the motor to ever find that out...

So you hog the port out huge , the motor makes 425 hp at 6500 rpm, wow, we are impressed....Now you do the same exact combo, port the port in the RIGHT places instead of just hogging the thing out to the walls.. And you will see a gain in hp over and above what I call the "internet port".

Overlap will always make power, its just the degree to what its done is the maker and breaker. Thats where the experience comes in when porting. We all can easily tune to other components of the back side of the motor, to accomodate overlap to make power.. We do it , via turbine trim, boost level, exhaust design and size, header length etc etc... But when is the last time you tuned the intake to accomadate the changing of the back pulse when you pushed a port taller...Never... Thats why 99% of the Japanese tuners will draw an x over the top of the port and say "dont touch"...None of us have the equipment or the combined knowledge to rethink the wheel better than mazda.

There is merit to late port opening, but its maxed out on the oem motors, the intakes are tuned to that timing and in order for it to have a positive effect on the motor in a usable rpm range, it has to be used with the proper intake tuning, otherwise as I said before, it simply wont come into play till stratospheric rpms...The factory intake tuning, drags that down into a useable band, and thats why I said, Dont screw with it...

Can you add power with stock turbo and overlap....

I need member "roshambo" to post his dyno sheet, he has a bone stock s4 TII I built about 1.5 years ago.... I did 90% of the porting on the primaries, and the exhaust ports.. Secondaries are very sedate, I added just enough overlap, that its audible. The result was 200 rwhp on a bone stock car on stock boost and an extremely wide power curve.... Had I gone up or down on those ports anymore, I know the power wouldnt have been what it is..

Your dilemna is more stuck around your choice of turbine.... You have to tune everything together and keep what you cant tune under control, which is the point of my last 6 diatribes... You cant expect to keep porting and keep pushing one component past what physics allow...If you stepped up your turbine, then put more overlap in it, and your power would go up.....

I should also add, 90% of the exhaust systems out there will max out right around 400 rwhp... I am assuming you have enough exhaust system capacity... If you dont see any gain from a given boost pressure thats another point to watch...

I would add overlap to it beyond stock overlap, I just wouldnt add Bp overlap to it, and think I was gonna make more power. I said way back when, overlap is the maker and the breaker, to little , less, to much no... Bad turbine selection an unbalanced turbos is another thread entirely... If you are over running your turbine at 17 psi, have you ever thought about improving VE and charge cleansing to make more power at lower boost levels with more overlap? Move a little less into the motor, but make more use of what you are moving? Mazdas hands were tied by low speed and idle emmission when it came to overlap on the new cars, there is room there for performance, even mazda will tell you that.. It goes back the example I gave before with the stock TII, I knew the turbine was a limiting factory so I added enoug port overlap to make power at a lower boost level, instead of going with girgantuan port job, and then running that turbo in an area to the point its choking the motor, and pushing hot charge temps. Its the additive some of the parts instead of going hog wild one area and expecting everything else to work well with it..

Who ever is arguing there is no gain from sp to bp has never seen enough dyno sheets of true comparisons.. I studied a binder full of dyno sheets of every kind of port, and the bp always has a positive effect on power when the rest of the car is set up to support it. The reason Bp's spool a turbo faster is not actually the overlap adding air down low, its the third wave miss effect of the intake charge being fouled with exhaust gases. Its the same reason misfires blows motors. When a misfire occurs, the next combustion event on that rotor face will have a 30-40 percent peak higher normal combustion pressure than normal, because of higher VE due to the low pressure misfire event not leaving a large amount of higher pressure gases behind for re expansion which normally lowers VE. That high VE cycle has a much more powerful exhaust pulse than normal.. brap brap brap..

The other positive is the intake is blowing across the rotor tip, and above the side seals, so less intake charge is blown in between the side seal and oil seal which tends to become part of the blow by into the crankcase. On large street ports, the positive pressure in the intake track also tends to push the rotor over as it passes..Keep the main port reasonable, the bridge big, and you get less rotor wobble and less iron wear.

#23

Full Member

Join Date: Nov 2007

Location: United Kingdom

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

Thats what bumpstart just said...

and like rxheaven states, increasing the rpm whilst keeping same torque will result in a hp increase...you just said this yourself with the formula...

#24

Racing Rotary Since 1983

iTrader: (6)

i have now deleted 28 posts and and edited 2 posts in this thread.

posts remaining have two similarities:

they contain content relating to.... PORTING. (title of thread)

and

they are not insulting/argumentative.

now that i have moderating power in this section the thread will stay on message.

if you want to talk porting ALL posters are welcome. if you want to insult someone take it outside.

porting is a very important aspect of rotary development and there are both many ways to skin the cat and there are differing objectives and as such differing port styles to achieve each.

so there's lots to discuss. get to it.

just don't come in here w a know it all attitude because no one knows it all.

all the crapola is now out of this thread and we will now conduct ourselves in a respectful manner.

howard coleman

posts remaining have two similarities:

they contain content relating to.... PORTING. (title of thread)

and

they are not insulting/argumentative.

now that i have moderating power in this section the thread will stay on message.

if you want to talk porting ALL posters are welcome. if you want to insult someone take it outside.

porting is a very important aspect of rotary development and there are both many ways to skin the cat and there are differing objectives and as such differing port styles to achieve each.

so there's lots to discuss. get to it.

just don't come in here w a know it all attitude because no one knows it all.

all the crapola is now out of this thread and we will now conduct ourselves in a respectful manner.

howard coleman