Porting

#26

Passing life by

There is someone in Hawaii there running one of my HB motors with HKS T71. You could talk to him if you like. ReTed is also over there hes tuned some of mine as well.

#27

Senior Member

iTrader: (1)

Join Date: Sep 2001

Location: San Francisco

Posts: 321

Likes: 0

Received 0 Likes

on

0 Posts

Question about the side seal support

Man, your ports are very similar to mine:

https://www.rx7club.com/rotary-car-performance-77/porting-questions-849832/

I'm just wondering that what happens when the end of the side seals are not supported and fall into the port (it looks like both of our ports will likely do that)? Do you think this will cause the side seals to wear out pre-maturely?

https://www.rx7club.com/rotary-car-performance-77/porting-questions-849832/

I'm just wondering that what happens when the end of the side seals are not supported and fall into the port (it looks like both of our ports will likely do that)? Do you think this will cause the side seals to wear out pre-maturely?

I thought I would post up some specifications of my Rice Racing street port timing, pics and measures both with std rotor and RR special custom rotor.

Stock Port V's RR Secondary Port

Stock Port V's RR Primary Port

Modified Exhaust Port

IO = Intake opens

IC = Intake closes

EO = Exhaust opens

EC = Exhaust closes

Primary and secondary Ports same on std Rotor

IO 15° ATDC

IC 67.5° ABDC

EO 78° BBDC

EC 60° ATDC

Primary and secondary Ports same on RR special Rotor

IO 22.5° BTDC

IC 75° ABDC

EO 78° BBDC

EC 60° ATDC

V's

Stock 13BREW

Primary

IO 45° ATDC

IC 50° ABDC

Secondary

IO 32° ATDC

IC 50° ABDC

Exhaust

EO 75° BBDC

EC 48° ATDC

**************************************

Here is a list of some port timing for other types.

Port Timing

IO = Intake opens

IC = Intake closes

EO = Exhaust opens

EC = Exhaust closes

US Model First Generation RX-7

IO 32° ATDC

IC 40° ABDC

EO 75° BBDC

EC 38° ATDC

European Model First Generation RX-7

IO 32° ATDC

IC 50° ABDC

EO 75° BBDC

EC 48° ATDC

First and Second Generation 6-Port 13B

Primary intake (Part throttle/cruise)

IO 32° ATDC

IC 40° ABDC

Secondary intake (Part to full throttle)

IO 32° ATDC

IC 30° ABDC

Auxiliary high speed ports (Full throttle above approximately 4000 rpm)

IO 45° ATDC

IC 70° ABDC

EO 71° BBDC

EC 48° ATDC

Second Gen Turbo 13B

IO 32° ATDC

IC 50° ABDC

EO 71° BBDC

EC 48° ATDC

Racing Beat "Street Port"

IO 25° ATDC

IC 60° ABDC

EO 84° BBDC

EC 48° ATDC

Racing Beat "J-Bridge Port"

IO 115° BTDC

IC 72° ABDC

EO 88° BBDC

EC 57° ATDC

Mazda Factory Peripheral Port

IO 86° BTDC

IC 75° ABDC

EO 73° BBDC

EC 65° ATDC

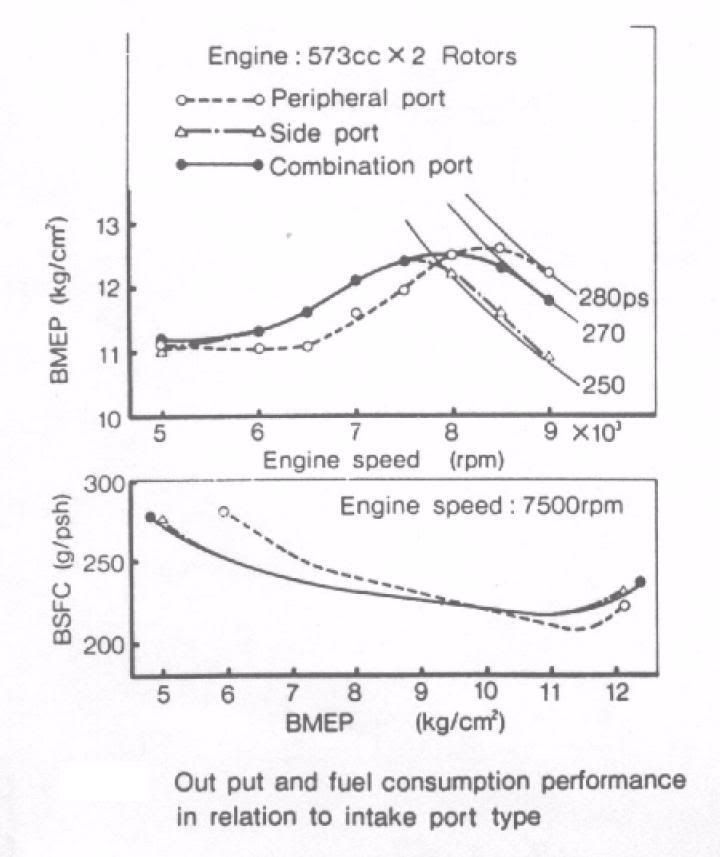

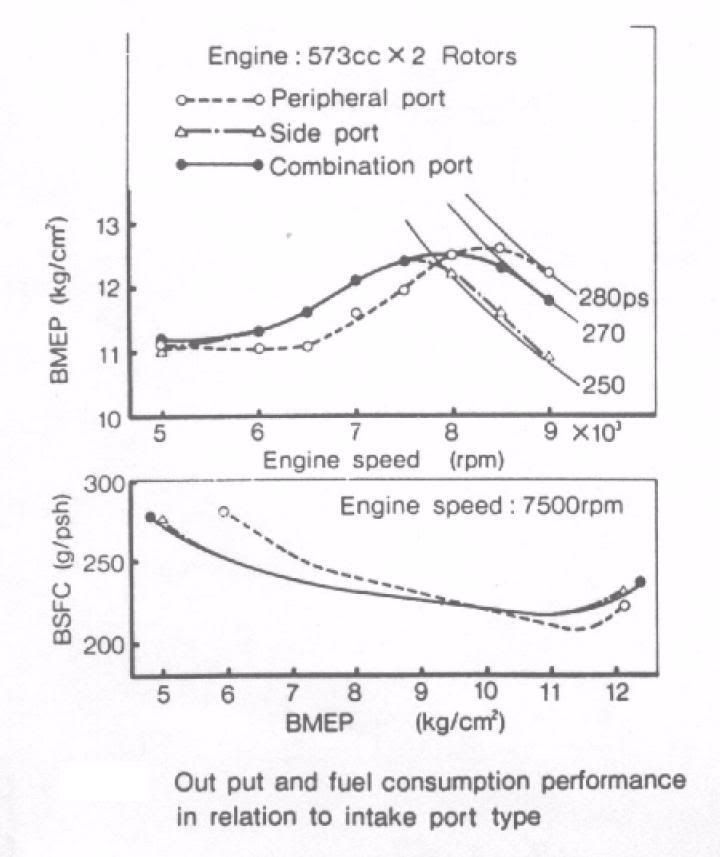

Power and BMEP curves for NA S-A bp, combination port S-C (partial pp, same as bp for comparison reasons), and peripheral port

On open racing exhaust systems

Stock Port V's RR Secondary Port

Stock Port V's RR Primary Port

Modified Exhaust Port

IO = Intake opens

IC = Intake closes

EO = Exhaust opens

EC = Exhaust closes

Primary and secondary Ports same on std Rotor

IO 15° ATDC

IC 67.5° ABDC

EO 78° BBDC

EC 60° ATDC

Primary and secondary Ports same on RR special Rotor

IO 22.5° BTDC

IC 75° ABDC

EO 78° BBDC

EC 60° ATDC

V's

Stock 13BREW

Primary

IO 45° ATDC

IC 50° ABDC

Secondary

IO 32° ATDC

IC 50° ABDC

Exhaust

EO 75° BBDC

EC 48° ATDC

**************************************

Here is a list of some port timing for other types.

Port Timing

IO = Intake opens

IC = Intake closes

EO = Exhaust opens

EC = Exhaust closes

US Model First Generation RX-7

IO 32° ATDC

IC 40° ABDC

EO 75° BBDC

EC 38° ATDC

European Model First Generation RX-7

IO 32° ATDC

IC 50° ABDC

EO 75° BBDC

EC 48° ATDC

First and Second Generation 6-Port 13B

Primary intake (Part throttle/cruise)

IO 32° ATDC

IC 40° ABDC

Secondary intake (Part to full throttle)

IO 32° ATDC

IC 30° ABDC

Auxiliary high speed ports (Full throttle above approximately 4000 rpm)

IO 45° ATDC

IC 70° ABDC

EO 71° BBDC

EC 48° ATDC

Second Gen Turbo 13B

IO 32° ATDC

IC 50° ABDC

EO 71° BBDC

EC 48° ATDC

Racing Beat "Street Port"

IO 25° ATDC

IC 60° ABDC

EO 84° BBDC

EC 48° ATDC

Racing Beat "J-Bridge Port"

IO 115° BTDC

IC 72° ABDC

EO 88° BBDC

EC 57° ATDC

Mazda Factory Peripheral Port

IO 86° BTDC

IC 75° ABDC

EO 73° BBDC

EC 65° ATDC

Power and BMEP curves for NA S-A bp, combination port S-C (partial pp, same as bp for comparison reasons), and peripheral port

On open racing exhaust systems

#28

Building my car...

iTrader: (1)

Join Date: Apr 2004

Location: Arizona

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

i have now deleted 28 posts and and edited 2 posts in this thread.

posts remaining have two similarities:

they contain content relating to.... PORTING. (title of thread)

and

they are not insulting/argumentative.

now that i have moderating power in this section the thread will stay on message.

if you want to talk porting ALL posters are welcome. if you want to insult someone take it outside.

porting is a very important aspect of rotary development and there are both many ways to skin the cat and there are differing objectives and as such differing port styles to achieve each.

so there's lots to discuss. get to it.

just don't come in here w a know it all attitude because no one knows it all.

all the crapola is now out of this thread and we will now conduct ourselves in a respectful manner.

howard coleman

posts remaining have two similarities:

they contain content relating to.... PORTING. (title of thread)

and

they are not insulting/argumentative.

now that i have moderating power in this section the thread will stay on message.

if you want to talk porting ALL posters are welcome. if you want to insult someone take it outside.

porting is a very important aspect of rotary development and there are both many ways to skin the cat and there are differing objectives and as such differing port styles to achieve each.

so there's lots to discuss. get to it.

just don't come in here w a know it all attitude because no one knows it all.

all the crapola is now out of this thread and we will now conduct ourselves in a respectful manner.

howard coleman

#29

mmm doritos

iTrader: (4)

Join Date: Apr 2006

Location: lancaster PA

Posts: 2,107

Likes: 0

Received 0 Likes

on

0 Posts

lets keep this thread alive...im in the process of gathering info for my first rebuild/port job on a S4 13b im trying to decide what porting to go with for this motor, ill be putting all my current externals on this new motor when the current one blows..i just made 450whp on stock ports on the current engine with T04Z. I was told by my tuner/rotary builder that i should do a race port on the secondaries and a street port on the primaries, he suggested the pineapple racing templates..he then said not to port the exhaust ports because the factory ports are made in the specific narrow oval pattern to help the velocity of exhaust gases flowing out of the ports, he stated that porting huge exhaust ports or making the port more rounded slows the velocity down which makes the turbo very laggy, is this true? He did however say that i should take a slight bit off the edges of the port, the black area you see from the inside, which isnt much. And also what kind of intake ports would you pros recommend? id like to hear multiple opinions with detailed explanations. The car is a street driven car but not a daily driver and i drag race the car often, id like to keep a good mid range power band

#30

mmm doritos

iTrader: (4)

Join Date: Apr 2006

Location: lancaster PA

Posts: 2,107

Likes: 0

Received 0 Likes

on

0 Posts

what exactly is the difference between a half bridge and full bridge? do both require the rotor housing to be notched/beveled at the bridge area? i love the sound of the bridge port but i dont want to lose all my low and mid end power.. from my understanding thats what happens, the bridge is only good for top end, but im not sure what RPM range that would be?

#31

i prefer to be a rotorfile. i pick up my grinder and port, test and see the results, the rest is just random bullshit and hypothesis.

how come i don't see any discussions about enlarging/shortening the port runners? they are the bottleneck in the system, not the port size.

how come i don't see any discussions about enlarging/shortening the port runners? they are the bottleneck in the system, not the port size.

#33

Porting looks great BUT why do the center iron always smaller? I have seen many engine builders with small center iron ports? You can still port more if you what your doing.

pic below is a series 4 turbo 2 center iron, I will a take picture of a rew center iron I have ported later.[/SIZE]

pic below is a series 4 turbo 2 center iron, I will a take picture of a rew center iron I have ported later.[/SIZE]

#35

Sideways is the only way

iTrader: (2)

Join Date: Nov 2007

Location: Vermont

Posts: 958

Likes: 0

Received 0 Likes

on

0 Posts

wow, what a read! this is great information and I'm glad its cleaned up now. This should be stickied somewhere, probably the "new member" section to keep people from ruining their ports.lol.

I "inherited" a torn apart S4 T2 motor from my brother (missing the intercooler, turbo and turbo manifold mind you, will be switching to the S5 turbo and manifold). I am rebuilding and was considering porting it mildly as its my summer daily driver. so I am wondering what kind of porting to do. I am planning on upgrading the turbo system in the future but my HP goal is only going to be 300-350rwhp.

This is my first rebuild and first port job so what do you guys recommend? and can I do a port based on my 300-350rwhp goal to run on my stock T2 for now or would I have to wait and port it with the final setup? more importantly, is it worth porting at all for the HP goal?

thanks, I heard the pineapple racing tamplates were good and they seem to know a lot but what are your opinions/suggestions for porting tamplates?

(EDIT: Mods, if I need to make a new thread for this instead of posting it here, feel free to delete this post. just thought I'd ask the guys that know what they're doing. )

)

I "inherited" a torn apart S4 T2 motor from my brother (missing the intercooler, turbo and turbo manifold mind you, will be switching to the S5 turbo and manifold). I am rebuilding and was considering porting it mildly as its my summer daily driver. so I am wondering what kind of porting to do. I am planning on upgrading the turbo system in the future but my HP goal is only going to be 300-350rwhp.

This is my first rebuild and first port job so what do you guys recommend? and can I do a port based on my 300-350rwhp goal to run on my stock T2 for now or would I have to wait and port it with the final setup? more importantly, is it worth porting at all for the HP goal?

thanks, I heard the pineapple racing tamplates were good and they seem to know a lot but what are your opinions/suggestions for porting tamplates?

(EDIT: Mods, if I need to make a new thread for this instead of posting it here, feel free to delete this post. just thought I'd ask the guys that know what they're doing.

)

)

#41

Full Member

Join Date: Jul 2009

Location: Markham, ON, Canada

Posts: 181

Likes: 0

Received 0 Likes

on

0 Posts

I have a question of my own...

Is the factory tuned rotary the more fuel efficient and healthy way for the rotary engine, in terms of longevity?? Is it possible to tune/port the engine so that it can breathe better, become more fuel efficient and healthier...making it last longer? I'm not asking about increasing horsepower, just simply the goal of creating a healthier rotary engine with a longer lifespan?

Just out of curiosity.

Thanks!

Is the factory tuned rotary the more fuel efficient and healthy way for the rotary engine, in terms of longevity?? Is it possible to tune/port the engine so that it can breathe better, become more fuel efficient and healthier...making it last longer? I'm not asking about increasing horsepower, just simply the goal of creating a healthier rotary engine with a longer lifespan?

Just out of curiosity.

Thanks!

#43

I asked this once to someone with a infinite amount of high boost knowledge. His low boost would be 100psi. His exact words were, "When I run a 100psi or 220psi I learned that the same principles applied." You still want the air in and out as fast as possible. You know, as I do, boost pressure is not a measure of flow, and more a measure of resistance. Our discussion came about because we were talking about plenum and end tank shape and how large a effect it actually has.

#44

OK, one thing i been wanting to do is make my own ports. i have always used templates. But how do i measure where i can and cannot port to?

I was told to lay either the front or rear plate down with the stat gear in place. and rotate the rotor around the gear. measure where the side seal and corner seal are and make sure at least half of the corner seal is still supported. but how do i measure and mark that if the corner seal and side seal are flat against the plate!?

any other way to do this?

can anyone enlighten me on this? using templates is getting old. im ready to step up to the next level and make my own ports...

I was told to lay either the front or rear plate down with the stat gear in place. and rotate the rotor around the gear. measure where the side seal and corner seal are and make sure at least half of the corner seal is still supported. but how do i measure and mark that if the corner seal and side seal are flat against the plate!?

any other way to do this?

can anyone enlighten me on this? using templates is getting old. im ready to step up to the next level and make my own ports...

#45

"Elusive, not deceptive!”

OK, one thing i been wanting to do is make my own ports. i have always used templates. But how do i measure where i can and cannot port to?

I was told to lay either the front or rear plate down with the stat gear in place. and rotate the rotor around the gear. measure where the side seal and corner seal are and make sure at least half of the corner seal is still supported. but how do i measure and mark that if the corner seal and side seal are flat against the plate!?

any other way to do this?

can anyone enlighten me on this? using templates is getting old. im ready to step up to the next level and make my own ports...

I was told to lay either the front or rear plate down with the stat gear in place. and rotate the rotor around the gear. measure where the side seal and corner seal are and make sure at least half of the corner seal is still supported. but how do i measure and mark that if the corner seal and side seal are flat against the plate!?

any other way to do this?

can anyone enlighten me on this? using templates is getting old. im ready to step up to the next level and make my own ports...

The thumbnail below is from nopistons' Lynn Hanover.

Note: only one end is scribed in this example.

Barry

#47

I asked this once to someone with a infinite amount of high boost knowledge. His low boost would be 100psi. His exact words were, "When I run a 100psi or 220psi I learned that the same principles applied." You still want the air in and out as fast as possible. You know, as I do, boost pressure is not a measure of flow, and more a measure of resistance. Our discussion came about because we were talking about plenum and end tank shape and how large a effect it actually has.

How does porting affect egt's and the same power level?? does a stock ported motor create more heat because it requires more pressure to make to same amount of power??

#48

"Elusive, not deceptive!”

#50

Senior Member

Join Date: Mar 2002

Location: Logan Utah

Posts: 409

Likes: 0

Received 0 Likes

on

0 Posts

I have a question about Port filling.

I have heard often that the bowl volume in the stock ports is too large to begin with. Has anyone tried filling the bowl and provide a less angled entry to the combustion chamber by having material there to shape for a better skateboard ramp for the air? (so to speak)

I apologize about the grammar, but this idea has bothered me for some time. I've wanted to try it but haven't had my motor apart yet to figure out what I'd do as far as a plan of attack. Still figuring out what I'd use as a filler that I wouldn't be afraid would chip and cause damage.

Ideas?

I have heard often that the bowl volume in the stock ports is too large to begin with. Has anyone tried filling the bowl and provide a less angled entry to the combustion chamber by having material there to shape for a better skateboard ramp for the air? (so to speak)

I apologize about the grammar, but this idea has bothered me for some time. I've wanted to try it but haven't had my motor apart yet to figure out what I'd do as far as a plan of attack. Still figuring out what I'd use as a filler that I wouldn't be afraid would chip and cause damage.

Ideas?