Something completely different - a very long term tube chassis project

#1

spoon!

Thread Starter

Something completely different - a very long term tube chassis project

Well, why not post this.

Hi everybody, I'm a rotorholic. It started about 15 years ago crewing for my dad doing club racing stuff in 1st gens - starting off in Improved Touring, ending up in Production. Not just crewing I suppose - we did all of the engine and chassis building in house. Well, now I got my competition license and am starting off on a T4 MX-5... a nice simple car to learn what I'm doing.

This isn't about that car.

Given as how I always wanted to do it, I have a 1st gen Miata that I picked up for a song with no drivetrain - it's going to get a carbed, street ported 13B swapped in for SCCA STU.

This isn't about that car either.

What I've wanted for a while now is something that is 1st gen shaped, but without any of its weaknesses. And with more power, but still rotary - see, I'm of the view that rotaries are great for roadrace use given the ability to have a nice long TBO as long as coolant and oil are kept in the right temperatures and obviously supplied.

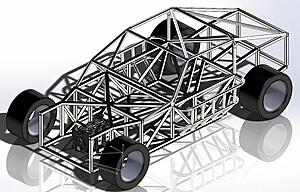

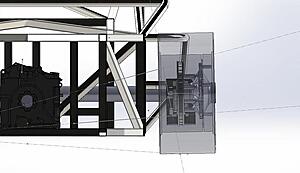

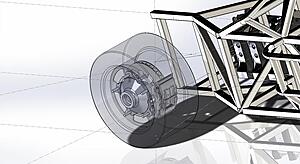

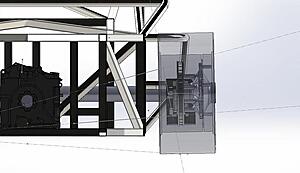

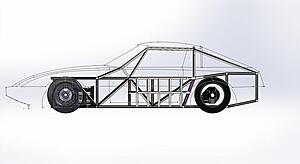

So I came up with this.

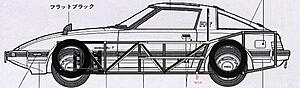

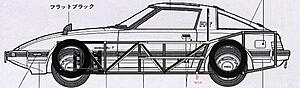

That was a few iterations ago but it's already nice and uploaded. There's also a couple (very) crude overlays to show how everything fits - yes, they're even a bit further back in the process than that last one but they just give an idea.

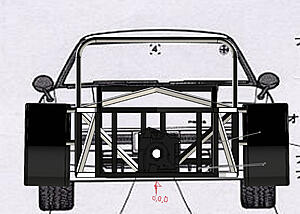

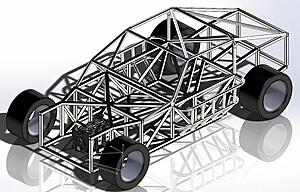

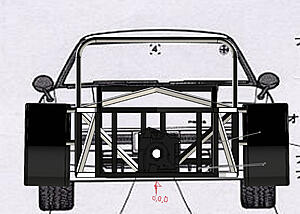

So yeah, the basic idea is an SCCA GT-2 car running a 3-rotor, chassis design similar to current Trans Am practice. But similar to some other cars that people have seen (hi Scratcher!) I was thinking in terms of keeping consumables affordable - Ford 9" rear, Late Model brakes, Jerico (or something) trans, etc. And now the crux of the matter...

See, nice affordable Wide 5 hubs. Real Racing Wheels has 16" aluminum wheels in the right sizes for far more affordable than BBS centerlock stuff, everything is golden.

Except.

10 degree KPI to get the scrub anywhere near right and it's still not great. Ugh.

Not sure whether to just put up with it, or start designing my own centerlock uprights.

... so anyway, yeah, this is all somewhat of an ambitious project. I have no illusions about being good enough to use all of what the car could do if I had it right now, but I like building stuff, and my hope is by the time I'm done building it I'll be ready. Time will tell.

Updates will likely be infrequent but what the heck.

Oh, and criticism is welcome, but I'm not even done with the design stage, and my very vague timeline has wheels rolling in 10 years.

Hi everybody, I'm a rotorholic. It started about 15 years ago crewing for my dad doing club racing stuff in 1st gens - starting off in Improved Touring, ending up in Production. Not just crewing I suppose - we did all of the engine and chassis building in house. Well, now I got my competition license and am starting off on a T4 MX-5... a nice simple car to learn what I'm doing.

This isn't about that car.

Given as how I always wanted to do it, I have a 1st gen Miata that I picked up for a song with no drivetrain - it's going to get a carbed, street ported 13B swapped in for SCCA STU.

This isn't about that car either.

What I've wanted for a while now is something that is 1st gen shaped, but without any of its weaknesses. And with more power, but still rotary - see, I'm of the view that rotaries are great for roadrace use given the ability to have a nice long TBO as long as coolant and oil are kept in the right temperatures and obviously supplied.

So I came up with this.

That was a few iterations ago but it's already nice and uploaded. There's also a couple (very) crude overlays to show how everything fits - yes, they're even a bit further back in the process than that last one but they just give an idea.

So yeah, the basic idea is an SCCA GT-2 car running a 3-rotor, chassis design similar to current Trans Am practice. But similar to some other cars that people have seen (hi Scratcher!) I was thinking in terms of keeping consumables affordable - Ford 9" rear, Late Model brakes, Jerico (or something) trans, etc. And now the crux of the matter...

See, nice affordable Wide 5 hubs. Real Racing Wheels has 16" aluminum wheels in the right sizes for far more affordable than BBS centerlock stuff, everything is golden.

Except.

10 degree KPI to get the scrub anywhere near right and it's still not great. Ugh.

Not sure whether to just put up with it, or start designing my own centerlock uprights.

... so anyway, yeah, this is all somewhat of an ambitious project. I have no illusions about being good enough to use all of what the car could do if I had it right now, but I like building stuff, and my hope is by the time I'm done building it I'll be ready. Time will tell.

Updates will likely be infrequent but what the heck.

Oh, and criticism is welcome, but I'm not even done with the design stage, and my very vague timeline has wheels rolling in 10 years.

#2

Senior Member

this is pretty awesome. As I work on my 7 more and more this thought has definitely crossed my mind. Are you planning on getting molds made for the body? What are you reservations about 10 deg KPI? Are you getting bad scrub or camber change? Also what is the roll center looking like with the current design?

#3

spoon!

Thread Starter

this is pretty awesome. As I work on my 7 more and more this thought has definitely crossed my mind. Are you planning on getting molds made for the body? What are you reservations about 10 deg KPI? Are you getting bad scrub or camber change? Also what is the roll center looking like with the current design?

The KPI just starts to lay the tire over the more you turn the steering - I don't really want the camber effects that go with it. Even with 10 degree KPI, scrub is something like an inch, which is OK-but-not-great. Roll center is (off the top of my head) about 1.5-2 inches above the ground plane at static ride height and is stationary relative to the CG under bump. None of that's completely optimized btw - this whole thing is at the "basic layout" stages still.

#4

Damn, it did start!

Amazing. Looking forward to the build.

#5

spoon!

Thread Starter

Comments on another forum have led me to a thought - the chassis side pivot points are almost identical between the centerlock and wide 5 versions of the suspension I mocked up, and it's enourmously cheaper *not* going centerlock. So I'm going to go with the preliminary plan of just running wide 5 and only convert over when/if I need to. Because after all, it's a tube chassis - even if I needed to move suspension mount points, I put them there in the first place.

Trending Topics

#8

Senior Member

My thinking is to apply what Mariah calls the GTO-1 bodywork (really the later GTU bodywork but whatever) to one of the shells I have in my field, make modifications like the later IMSA cars (front fender cutouts, etc) and pull molds from it - I don't want to have any original unibody parts. My basic thought is that in the aftermath of even something that writes off the whole chassis, I'd be able to make a new one from jigs and molds I have without needing to do any searching for any original Mazda parts other than the engine.

The KPI just starts to lay the tire over the more you turn the steering - I don't really want the camber effects that go with it. Even with 10 degree KPI, scrub is something like an inch, which is OK-but-not-great. Roll center is (off the top of my head) about 1.5-2 inches above the ground plane at static ride height and is stationary relative to the CG under bump. None of that's completely optimized btw - this whole thing is at the "basic layout" stages still.

The KPI just starts to lay the tire over the more you turn the steering - I don't really want the camber effects that go with it. Even with 10 degree KPI, scrub is something like an inch, which is OK-but-not-great. Roll center is (off the top of my head) about 1.5-2 inches above the ground plane at static ride height and is stationary relative to the CG under bump. None of that's completely optimized btw - this whole thing is at the "basic layout" stages still.

I also agree with your thoughts on KPI, I assume you cannot tune any more scrub out of the suspension either.

I want to make something similar one day, not sure what body work I would put on it though.

#9

spoon!

Thread Starter

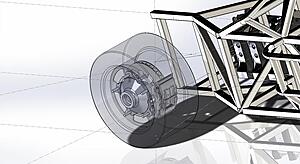

No pictures yet because I was just doing some back of the envelope math... someone on another forum suggested I start running the numbers with 5x5 hubs. I think that's the (affordable) answer. Using available Real Racing Wheels, going from a Wide 5 hub with 8" backspacing on a 10" wheel gives me about 1.5" of scrub with a 10 degree KPI. Using Real's numbers on caliper clearance and pushing everything close to the allowable limit, their 7" backspacing wheels let me push everything out enough that it gets down to a bit less than 0.5" scrub, albeit still with a 10 degree KPI. Custom Kodiak, Jongbloed or BBS wheels could probably get that down even further, to where I can start dialing out KPI.

Looks to me like a good solution is something like the Howe GT hubs up front, with a brake hat instead of using the integrated rotor mounts a lot of the stock car hubs have - gives me a lot more freedom in positioning the rotor. Rear I'm still looking at Winters for ball drive axles and whatever brake hat mount, since there's not really any clearance issues back there.

Kind of interesting to me how much the front suspension geometry depends on wheels.

Looks to me like a good solution is something like the Howe GT hubs up front, with a brake hat instead of using the integrated rotor mounts a lot of the stock car hubs have - gives me a lot more freedom in positioning the rotor. Rear I'm still looking at Winters for ball drive axles and whatever brake hat mount, since there's not really any clearance issues back there.

Kind of interesting to me how much the front suspension geometry depends on wheels.

#10

Senior Member

Front Suspension geometry is all about packaging!! I definitely agree on using a rotor hat, you can get custom offsets made if needed pretty easily. Are you going to do a solid axle or independent suspension in the rear? The model looks like its set up for IRS

#11

spoon!

Thread Starter

Nope, plain jane Ford 9"... with cambered snouts and the Winters ball drive axles that are basically outboard CV joints. There's a weight penalty for IRS, you can't run it unless the original car was IRS, and with the freedom you have with a tube chassis a live axle works *really* well. That's actually why the main chassis (ignoring the door bars) is as narrow as it is, it's to package the lower links for the rear axle. I'll actually try to knock something out to show what I mean in the next week or two (hey, I'm doing this during lunch breaks and sometimes when I take my work laptop home)

#12

Senior Member

Nope, plain jane Ford 9"... with cambered snouts and the Winters ball drive axles that are basically outboard CV joints. There's a weight penalty for IRS, you can't run it unless the original car was IRS, and with the freedom you have with a tube chassis a live axle works *really* well. That's actually why the main chassis (ignoring the door bars) is as narrow as it is, it's to package the lower links for the rear axle. I'll actually try to knock something out to show what I mean in the next week or two (hey, I'm doing this during lunch breaks and sometimes when I take my work laptop home)

#14

spoon!

Thread Starter

It's actually pretty damn different. Rob's car is ... actually I'm not quite sure how much is unibody. But he seems to be building it like a cost-no-object show car; billet this and that, cantilever shocks for no particular functional reason, AWD turbo 4-rotor, etc. Possibly a full interior? Not quite clear on that. I'm not going to dwell on it too hard but looking at pictures and some of the in-progress CAD stuff I am ... not clear on some of the design decisions, but unless you're directly competing with other people, a lot of it doesn't matter too much and it certainly does look cool.

I'm going for something for a strictly defined roadrace class with existing competition, and trying to build in as few compromises as possible while maintaining the idea of affordable(ish) maintainability. The chassis will be custom (but I'll have the jigs to be able to make new parts to repair it) but most of the suspension consumables are designed around available circle track stuff. I'm hoping to have the basic rolling chassis (trans, engine and shocks will always be pricey but what can you do?) together and, er, rolling for less than the price of Rob's transmission, and have everything else such that if the car goes into a tire barrier or wall, every single part is replaceable. "Here, make new copies out of the molds for this bodywork, cut off the damaged parts and jig weld up replacements from that jig, and here's the circle track suppliers to order the rest from." Or possibly to an extent of "well, throw the expensive bits in the spare chassis and rebuild this one when there's time."

Don't get me wrong, I'm glad that people are doing really crazy builds like that, but the purpose, design, and execution isn't very similar.

I'm going for something for a strictly defined roadrace class with existing competition, and trying to build in as few compromises as possible while maintaining the idea of affordable(ish) maintainability. The chassis will be custom (but I'll have the jigs to be able to make new parts to repair it) but most of the suspension consumables are designed around available circle track stuff. I'm hoping to have the basic rolling chassis (trans, engine and shocks will always be pricey but what can you do?) together and, er, rolling for less than the price of Rob's transmission, and have everything else such that if the car goes into a tire barrier or wall, every single part is replaceable. "Here, make new copies out of the molds for this bodywork, cut off the damaged parts and jig weld up replacements from that jig, and here's the circle track suppliers to order the rest from." Or possibly to an extent of "well, throw the expensive bits in the spare chassis and rebuild this one when there's time."

Don't get me wrong, I'm glad that people are doing really crazy builds like that, but the purpose, design, and execution isn't very similar.

#15

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,778

Received 2,563 Likes

on

1,823 Posts

cool project.

the solid axle has another reason it is a good idea: it works! really its off the shelf, geometry is relatively simple, and you basically spend your design energy where its perhaps more useful, a whole car is a huge project, and anything you can do to make it simpler is probably good.

the solid axle has another reason it is a good idea: it works! really its off the shelf, geometry is relatively simple, and you basically spend your design energy where its perhaps more useful, a whole car is a huge project, and anything you can do to make it simpler is probably good.

#16

spoon!

Thread Starter

It works, Ford 9" parts are ubiquitous and strong, you can set it up for camber, real tracks are actually quite smooth, it puts down power well, and a bunch of other reasons. Actually, a little hint before I get the links done in Solidworks for illustration... see the side view where it's overlayed on the Tamiya scan? The lower link forward pivot is on the vertical bar about in the middle of the door. So nice long links, heh heh.

#17

Banned. I got OWNED!!!

It works, Ford 9" parts are ubiquitous and strong, you can set it up for camber, real tracks are actually quite smooth, it puts down power well, and a bunch of other reasons. Actually, a little hint before I get the links done in Solidworks for illustration... see the side view where it's overlayed on the Tamiya scan? The lower link forward pivot is on the vertical bar about in the middle of the door. So nice long links, heh heh.

What figures did you end up landing on for:

- Pinion Angle Degree Per Inch of Travel

- Roll Center Height

- Anti-Squat %

- Panhard? Watt's? Triangulated 4-Link?

#18

spoon!

Thread Starter

Good. We wouldn't want to see all this hard work with a shitty dynamic pinion angle change on that custom rear end of yours.

What figures did you end up landing on for:

What figures did you end up landing on for:

- Pinion Angle Degree Per Inch of Travel

- Roll Center Height

- Anti-Squat %

- Panhard? Watt's? Triangulated 4-Link?

Even if I built it as it sits, everything is adjustable - at the front, the pivot points should all be movable vertically by an inch or two using slugs, and the outer pivot points by maybe half inch to an inch using spacers, obviously with all the links being adjustable length. The rear lower trailing arms are plus or minus an inch (3 holes for each) and the upper arm will probably have a screw adjuster with maybe 4" of travel - which should be enough to go from parallel to the lower arms to 100% anti-squat if not more. The plan is an underslung watts link at whatever roll center height in a fabricated truss structure, but I'm kinda waffling between that and the adjustability of a panhard. Triangulated 4 link is done a lot on GT-3 cars but the way everything has to be packaged for those I don't think it's possible to do the long links I'm looking at anyway, and I'm not sure I see the advantage of the triangulated 4 link vs a 3 link plus underslung watts. Certainly the current build Trans Am stuff I've seen is watts.

One way or another I want to do some simulation to tweak suspension geometry and find some starting points for wheel rates and shock valving, and I especially 100% do not want to build myself into a box that I can't adjust my way out of.

#19

Banned. I got OWNED!!!

Right now all the geometry is in the rough draft phase - like, good enough to real to figure out if the packaging will work, but very much not optimized. See the mention about going from Wide 5 to 5x5 and its effects on front geometry above? Well, I'll have to change the geometry again depending on what backspacing Jongbloed can do. So that said, right now, the front roll center is around 2 inches above ground level at static ride height and varies almost zero relative to the CG under bump or droop. Don't take that as gospel, it's just where things are at. The rear suspension is even less firmed up - for mockup sake it's set at roll center 5 inches above ground level and 50% anti-squat.

Even if I built it as it sits, everything is adjustable - at the front, the pivot points should all be movable vertically by an inch or two using slugs, and the outer pivot points by maybe half inch to an inch using spacers, obviously with all the links being adjustable length. The rear lower trailing arms are plus or minus an inch (3 holes for each) and the upper arm will probably have a screw adjuster with maybe 4" of travel - which should be enough to go from parallel to the lower arms to 100% anti-squat if not more. The plan is an underslung watts link at whatever roll center height in a fabricated truss structure, but I'm kinda waffling between that and the adjustability of a panhard. Triangulated 4 link is done a lot on GT-3 cars but the way everything has to be packaged for those I don't think it's possible to do the long links I'm looking at anyway, and I'm not sure I see the advantage of the triangulated 4 link vs a 3 link plus underslung watts. Certainly the current build Trans Am stuff I've seen is watts.

One way or another I want to do some simulation to tweak suspension geometry and find some starting points for wheel rates and shock valving, and I especially 100% do not want to build myself into a box that I can't adjust my way out of.

Even if I built it as it sits, everything is adjustable - at the front, the pivot points should all be movable vertically by an inch or two using slugs, and the outer pivot points by maybe half inch to an inch using spacers, obviously with all the links being adjustable length. The rear lower trailing arms are plus or minus an inch (3 holes for each) and the upper arm will probably have a screw adjuster with maybe 4" of travel - which should be enough to go from parallel to the lower arms to 100% anti-squat if not more. The plan is an underslung watts link at whatever roll center height in a fabricated truss structure, but I'm kinda waffling between that and the adjustability of a panhard. Triangulated 4 link is done a lot on GT-3 cars but the way everything has to be packaged for those I don't think it's possible to do the long links I'm looking at anyway, and I'm not sure I see the advantage of the triangulated 4 link vs a 3 link plus underslung watts. Certainly the current build Trans Am stuff I've seen is watts.

One way or another I want to do some simulation to tweak suspension geometry and find some starting points for wheel rates and shock valving, and I especially 100% do not want to build myself into a box that I can't adjust my way out of.

Not sure if I entirely agree with the front setup as far as a starting roll center, but the rear sounds like it'll be excellent. I'd slightly reconsider your target anti-squat figures and don't be afraid to trash all the naysayers.

A great example of an Underslug Watt's link was done very well by Elwood aka Winfield Coachman, where he did a Toyota 8" Solid Axle (that's what I decided on too), with a 3-link.

https://sites.google.com/site/elwood...ension-upgrade

The problem you're going to have on here is there are very few people who understand this. Fewer still who have tried and tested it with real world results. You're definitely looking in the right place though, and this build should inspire many to innovate for themselves, as I hope mine has done.

Ohh, by the way, my links are VERY long. You might want to read over my build log to see some pictures of the design implementation on a factory chassis for a Gran Touring street build. Completely different approach, but we're coming to very similar conclusions as to what optimizes these solid axle vehicles.

Another note for Jongbloed - If I remember correctly, Ryan will come out to us local guys, measure the maximum available space, and build ANY custom wheel set for $2500. Built to the application usage (ultra-lightweight race wheels that have a tendency to flex, street wheels which have safety standards, etc). Something like that. They're a great local business.

#21

spoon!

Thread Starter

Roll center height at the front is fairly well firmed up... it doesn't hurt that I have Trans Am front geometry to crib from.

The vertical position is a tuning variable though, but I don't want to go higher than 2 inches or so at static... the higher it is, the more roll is resisted by nearly-infinitely-stiff suspension links instead of springs, sways and shocks... so it gets twitchy as the weight transfer happens faster and faster. It's different compared to struts, where you get the link at positions where the roll center changes very suddenly and dramatically relative to CG.. with roll center more or less constant relative to CG, cornering stiffness won't vary no matter where the chassis moves around to, so more predicable.

The vertical position is a tuning variable though, but I don't want to go higher than 2 inches or so at static... the higher it is, the more roll is resisted by nearly-infinitely-stiff suspension links instead of springs, sways and shocks... so it gets twitchy as the weight transfer happens faster and faster. It's different compared to struts, where you get the link at positions where the roll center changes very suddenly and dramatically relative to CG.. with roll center more or less constant relative to CG, cornering stiffness won't vary no matter where the chassis moves around to, so more predicable.Anti-squat... well. Two aspects of things that define my basic philosophy. 1: design with lots of adjustment but a reasonable baseline in the middle of the adjustment range. 2: pay attention to what the DAQ system says and optimize that way - I'm a test engineer for my day job, I'm really really comfortable with simulation and making DAQ systems do my bidding.

I guess, I know that I'm unlikely to find people to tell me what directions to go beforehand, especially on here (no offense guys and gals) but I'm not even really looking at that as a problem. I actually have a fair idea what I'm looking for, and have spent a few years cribbing notes for stuff that's proven to work - it's funny what you can see walking around paddocks or browsing for-sale sites - so I have a nice catalog of stuff to sanity check things. I'm more... well, who actually *does* this sort of thing (other than a few professional shops) and who actually shows some of the analysis work?

#22

spoon!

Thread Starter

Perusing the rulebook made me realize that other than requiring butterfly throttles (no slide throttles, oh well) the induction system is open. No pictures on it yet, but now I'm trying to figure out how I'd actuate a variable length trumpet setup. The gains in powerband would probably make for a slightly easier to drive car.

#23

So what is the target road racing class? SCCA GT1? Google Glen Jung, he campaigned a GT1 tube frame FD. I believe he was running a 13B turbo when I saw him at one of the Runoffs in Topeka.

Tube frame cars are a favorite of mine and like you I studied every one I could. All of the T/A cars I saw naked in the paddock were running 4 links with a watts. The trailing arms were long - like up to the middle of the door long.

The other thing I noticed is that they ran a relative narrow rear end housing (most were 9" style rear ends) with deep dish rear wheels. As in they had maybe 3-4" back spacing on a 12-13" wide wheel. Keeping the rear end narrow saves weight.

Solid rear axles are pretty common in GT1 and T/A. Even for car that came originally with IRS. So not uncommon to see a Vette or a Jag with a 9" or a Quick Change rear end.

Tube frame cars are a favorite of mine and like you I studied every one I could. All of the T/A cars I saw naked in the paddock were running 4 links with a watts. The trailing arms were long - like up to the middle of the door long.

The other thing I noticed is that they ran a relative narrow rear end housing (most were 9" style rear ends) with deep dish rear wheels. As in they had maybe 3-4" back spacing on a 12-13" wide wheel. Keeping the rear end narrow saves weight.

Solid rear axles are pretty common in GT1 and T/A. Even for car that came originally with IRS. So not uncommon to see a Vette or a Jag with a 9" or a Quick Change rear end.

#24

spoon!

Thread Starter

The target is GT2 actually - I think it's less a case of bringing a knife to a gunfight than GT1 would be and SCCA has given the traditional tube cars enough of a boost in recent years that I feel like it's a reasonable target. As of a couple months ago, 3-rotor with unrestricted induction is 2280lbs. It also gives me a little more room to not have to go crazy with lightweighting stuff to meet GT1's minimum weight.

I've seen Glen Jung's car actually... about 10 years ago when he was running a 13B with a slide throttle and about 5 years ago when he'd moved to a 3-rotor. The chassis is packaged differently though because of IRS - actually the long links for the live axle drive a lot of design considerations, like the chassis section, if you ignore the door bars, is pretty similar in width to a Lotus 7. I've actually been taking pictures of everyone who will let me, taking mental notes of those who won't, plus looking at for-sale sites. Most of the more recently updated cars have moved to 3-links, ala 1998 Chevy Corvette Trans Am Series Champion Spec Sheet

I've seen Glen Jung's car actually... about 10 years ago when he was running a 13B with a slide throttle and about 5 years ago when he'd moved to a 3-rotor. The chassis is packaged differently though because of IRS - actually the long links for the live axle drive a lot of design considerations, like the chassis section, if you ignore the door bars, is pretty similar in width to a Lotus 7. I've actually been taking pictures of everyone who will let me, taking mental notes of those who won't, plus looking at for-sale sites. Most of the more recently updated cars have moved to 3-links, ala 1998 Chevy Corvette Trans Am Series Champion Spec Sheet

#25

spoon!

Thread Starter

Just a quick post... tinkering with making a semi-accurate-ish body in Solidworks so I can figure out if the chassis is poking through anywhere and start figuring out cooler placement, stuff like that. Cooler stuff is I'm working on centerlock hubs/uprights because I'm crazy. May just stick with 5x5.

... and then I figured out what I was doing wrong with surfacing. Yeah the main hoop is poking through a little, so may either tweak that or measure an actual car.

Last edited by Kenku; 08-16-17 at 12:52 PM.