Something completely different - a very long term tube chassis project

#26

spoon!

Thread Starter

#28

spoon!

Thread Starter

Realistically, even if I wanted to, not really. Computer simulation is pretty good at modelling materials when they're still behaving elastically, but kinda **** at modelling stuff as it's failing.

Besides, the cage meets the rules. Good enough.

This week's project - either a bellhousing (I'm looking at doing a setup to mount a small diameter Tilton flywheel intended for an LSx and a 5.5" clutch to an Elite sequential... look, I know how that sounds but it actually makes sense) or I start doing the centerlock axles and upright for the front suspension.

Besides, the cage meets the rules. Good enough.

This week's project - either a bellhousing (I'm looking at doing a setup to mount a small diameter Tilton flywheel intended for an LSx and a 5.5" clutch to an Elite sequential... look, I know how that sounds but it actually makes sense) or I start doing the centerlock axles and upright for the front suspension.

#30

spoon!

Thread Starter

In other news, I just realized that despite somebody's willingness to help, in the end I'll trust measurements I'm doing myself a lot more than ones that someone else is making. So in other words, I just bought a used centerlock spindle that I won't actually be using other than to pull dimensions from to make sure I design something that will fit conventional Trans Am / GT-1 style centerlock wheels.

Ever have one of those times when you realize your project may be crazy?

#31

spoon!

Thread Starter

New (to me) parts time! I want to thank the guys at Roadraceparts.com for working with me and selling me these used bits so I can measure them up; it's an incredible help. So that said, on to pics!

So that's a BBS E55 series wheel center setup for centerlock, and a used centerlock spindle from I'm not sure what honestly.

Beefy sucker; the bearing races on the left are something like 2" but the whole thing is hollowed out pretty extensively. It's not even just a straight bore either, the part that bulges out to locate the wheel is a larger ID than the part that the bearing races are on. I need to put some thought into how they did that.

Side view of the wheel center... one of the older style where the rim halves bolt on to the outside of the wheel center. The newer ones are setup for bunch more caliper clearance but this lets me confirm all of the machining surfaces necessary to bolt it to the spindle.

Rear (or inside, whatever) view of the wheel center; note 12 holes for the drive pins. Same wheel center works with spindles with either 4 or 6 drive pins.

Next up, I start pulling dimensions and doing modeling!

So that's a BBS E55 series wheel center setup for centerlock, and a used centerlock spindle from I'm not sure what honestly.

Beefy sucker; the bearing races on the left are something like 2" but the whole thing is hollowed out pretty extensively. It's not even just a straight bore either, the part that bulges out to locate the wheel is a larger ID than the part that the bearing races are on. I need to put some thought into how they did that.

Side view of the wheel center... one of the older style where the rim halves bolt on to the outside of the wheel center. The newer ones are setup for bunch more caliper clearance but this lets me confirm all of the machining surfaces necessary to bolt it to the spindle.

Rear (or inside, whatever) view of the wheel center; note 12 holes for the drive pins. Same wheel center works with spindles with either 4 or 6 drive pins.

Next up, I start pulling dimensions and doing modeling!

#33

spoon!

Thread Starter

Oh yeah, mentioned this other places... these are lifed out Trans Am parts that as far as I can tell were being used for setup stuff. My idea is that Trans Am is mandated to run the same wheel diameters I am, thus the same wheel centers, and basically it just seems like it would be nice to not be stuck with orphan wheels that don't fit any other car. Although I'm more than a it tempted to design some wheel centers (to accept BBS motorsport rim halves) and get some quotes to have them CNC'd, just to see how much that'd run.

I'm doing my own bearing package so it won't be a straight clone, and uprights are to be fabricated chromoly in the style of champ car, 90s vintage F-1 or Daytona Prototype stuff.

I'm doing my own bearing package so it won't be a straight clone, and uprights are to be fabricated chromoly in the style of champ car, 90s vintage F-1 or Daytona Prototype stuff.

#34

Senior Member

This is gonna be my favorite build ever. I wish I had the time to do something like this. as cool as custom wheel centers are, I am sure it is way cheaper to use existing ones. I believe they used a boring bar and probably machined that hub from both directions.

#35

spoon!

Thread Starter

I'm not sure either way at this point. Used BBS wheel centers sure go for a lot whenever I've seen them advertised... I'm half thinking of just banging out a design quick and sending it out for a quote to see how much it would be to do my own. I need to do so for mockup purposes anyway, you know? I'm kinda looking at the centerlock Panasports that Mandeville and the Nissan GTU team were running in the early 90s.

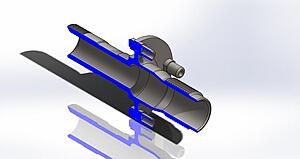

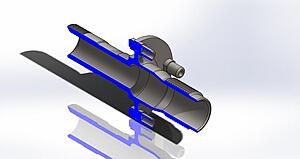

Oh yeah, reverse engineered the spindle already.

CAD weight was within an ounce of measured weight so good for another sanity check on getting the geometry right. I already have a modified version using angular contact bearings and oil instead of tapered rollers and grease.

Oh yeah, reverse engineered the spindle already.

CAD weight was within an ounce of measured weight so good for another sanity check on getting the geometry right. I already have a modified version using angular contact bearings and oil instead of tapered rollers and grease.

#36

roadraceparts.com.......thanks for adding to my list of routinely visited sites!

Seriously, hand-me-down parts from professional racing can fuel allot of dreams on the cheap. When NASCAR switched over to the Car Of Tomorrow a glut of left side shifted Jericos and Tex Racing gear boxes hit the market. Same thing happened when NASCAR eliminated qualifying specific parts. A friend of mine ended up with a Jerico Y2K qualifying box for his EP car. All of the gears were narrowed and all of the shafts were gun drilled.

Seriously, hand-me-down parts from professional racing can fuel allot of dreams on the cheap. When NASCAR switched over to the Car Of Tomorrow a glut of left side shifted Jericos and Tex Racing gear boxes hit the market. Same thing happened when NASCAR eliminated qualifying specific parts. A friend of mine ended up with a Jerico Y2K qualifying box for his EP car. All of the gears were narrowed and all of the shafts were gun drilled.

#37

spoon!

Thread Starter

These specific parts... well, the axle has "for setup only" written on it in paint pen, and I think it was repaired after crash damage or something. But for what I'm doing, pulling dimensions, it's perfect.

This whole project is kind of an exercise of having one set of parts designed around the "well, what's the coolest way I could solve this problem?" idea. I still might do a version just using more available 5x5 hubs to prove stuff out depending on what quotes for some of this stuff will cost to make.

This whole project is kind of an exercise of having one set of parts designed around the "well, what's the coolest way I could solve this problem?" idea. I still might do a version just using more available 5x5 hubs to prove stuff out depending on what quotes for some of this stuff will cost to make.

#38

spoon!

Thread Starter

This isn't just for this car, but enables things for this car... the Skip Barber bankruptcy auction was running last week, and I won the bidding for an engine dyno water brake and pump, and a guy I know just picked it up.

So yeah, this is one of those enabling tools that should let me do a lot of interesting things.

So yeah, this is one of those enabling tools that should let me do a lot of interesting things.

#40

spoon!

Thread Starter

It showed up at work! Good bearings on the dyno to frame, not-great bearings on the dyno itself but it turns over. Probably hasn't been greased lately. I figure given everything I'm going to open it up and check/replace bearings and seals.

And ready for the final transport stage... I'm excited as hell.

#41

spoon!

Thread Starter

OK, so what the heck... got back to work on this thing.

First off, wheels. So, centerlock is too expensive (cool but good lord, the cost of whittling a piece of steel to shape) and isn't necessary especially for sprint races where I'm not really doing tire changes. So decided to set up a 5x5 setup with a BBS styled 3-piece wheel.

Old design front wheel assumption was Wide 5 - these are cheap and cheerful.

The problem is they're not intended for low scrub applications - with the biggest backspacing wheels available the rotor is inboard of centerline.

I don't like that at all - it forces more scrub, more kingpin angle, and mostly, both. See, where the lower ball joint (or rod end, whatever) goes is determined by the inner face of the brake rotor. So I went and mocked up... well, I started with the idea of a BBS E50 style center but more concave, like so:

Which not only looks the business but helps move things outboard a lot.

Brake rotor is moved out a full 1.6" plus it looks snazzy! And I think I could even just *gasp* buy some E50 centers and use them as is. Also, new setup is with bigger rotors and bigger calipers which is also good.

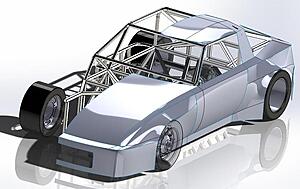

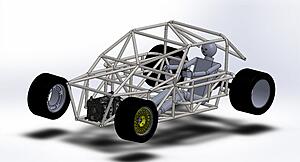

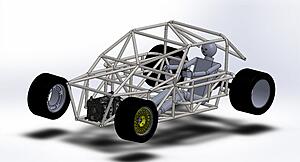

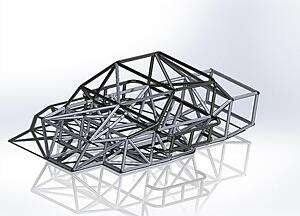

Then did some work; major rejiggering of the chassis. Converted everything to round tube, threw a dummy in to make sure of positioning... well.

Left the rear chassis tubes off the redesign for the moment since I need to actually put steel in the right places. Chassis lost 130 pounds compared to the last version and should be a lot stiffer.

First off, wheels. So, centerlock is too expensive (cool but good lord, the cost of whittling a piece of steel to shape) and isn't necessary especially for sprint races where I'm not really doing tire changes. So decided to set up a 5x5 setup with a BBS styled 3-piece wheel.

Old design front wheel assumption was Wide 5 - these are cheap and cheerful.

The problem is they're not intended for low scrub applications - with the biggest backspacing wheels available the rotor is inboard of centerline.

I don't like that at all - it forces more scrub, more kingpin angle, and mostly, both. See, where the lower ball joint (or rod end, whatever) goes is determined by the inner face of the brake rotor. So I went and mocked up... well, I started with the idea of a BBS E50 style center but more concave, like so:

Which not only looks the business but helps move things outboard a lot.

Brake rotor is moved out a full 1.6" plus it looks snazzy! And I think I could even just *gasp* buy some E50 centers and use them as is. Also, new setup is with bigger rotors and bigger calipers which is also good.

Then did some work; major rejiggering of the chassis. Converted everything to round tube, threw a dummy in to make sure of positioning... well.

Left the rear chassis tubes off the redesign for the moment since I need to actually put steel in the right places. Chassis lost 130 pounds compared to the last version and should be a lot stiffer.

#43

spoon!

Thread Starter

Yeah, was at Road America for the Trans Am weekend... was poking around a lot of cars and got some ideas. Plus, with the way Solidworks does weldments, I can have it spit out mitering patterns to make round tube a lot easier to work with than it would be otherwise. But I'm also looking at some homebrew CNC plasma cutters that people have done to do automated tube notching...

#44

Senior Member

Yeah, was at Road America for the Trans Am weekend... was poking around a lot of cars and got some ideas. Plus, with the way Solidworks does weldments, I can have it spit out mitering patterns to make round tube a lot easier to work with than it would be otherwise. But I'm also looking at some homebrew CNC plasma cutters that people have done to do automated tube notching...

#45

spoon!

Thread Starter

Depends on how many of these chassis I end up building - I'm thinking in terms of keeping spares of everything but if I don't have to build them too often, paper templates might be fine.

#46

spoon!

Thread Starter

Got a lifed-out 5x5 hub in to reverse engineer...

Quick whipped that up. It's hilarious how big the bearings are compared to production car stuff... the taper bearings are 2" OD, 3.5" OD. It positively dwarfs any of the stock Mazda stuff.

Means that my interim BBS style wheel center is obsoleted now but that's no big deal, I expected that anyway.

Quick whipped that up. It's hilarious how big the bearings are compared to production car stuff... the taper bearings are 2" OD, 3.5" OD. It positively dwarfs any of the stock Mazda stuff.

Means that my interim BBS style wheel center is obsoleted now but that's no big deal, I expected that anyway.

#47

spoon!

Thread Starter

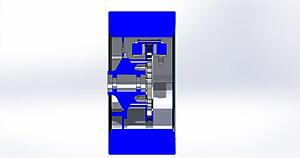

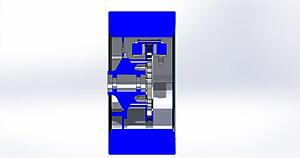

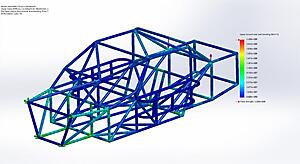

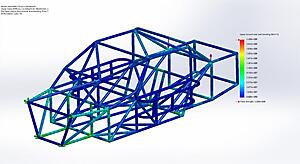

Let's do some FEA!

So, what's going on here? The four joints at the front bulkhead were set to immovable and a 2,000 pound load is applied to the rear coilover mounts, one upwards and one downwards. Some math gives a result of just shy of 20,000 ft-lb per degree of chassis twist, which is a bit more than the Viper GTS-R (the caged race ones) and in the same ballpark as a Zonda, Ford GT, or a modern F-1 car. For a non-aero car it's doing pretty OK.

So, what's going on here? The four joints at the front bulkhead were set to immovable and a 2,000 pound load is applied to the rear coilover mounts, one upwards and one downwards. Some math gives a result of just shy of 20,000 ft-lb per degree of chassis twist, which is a bit more than the Viper GTS-R (the caged race ones) and in the same ballpark as a Zonda, Ford GT, or a modern F-1 car. For a non-aero car it's doing pretty OK.

#48

Senior Member

Nice work!! What is the purpose of the structure behind the coilover mounts? Could you do a removable subframe on that instead so crash damage is easier to repair

#49

spoon!

Thread Starter

Assuming you're looking at the boring box in the back, it's to hold the fuel cell and some bodywork. It might get revised a bit but there's no suspension loads fed in back there.

#50

spoon!

Thread Starter

What's that, another revision? Why yes. Refinement of another version I didn't post where I started moving to different tube wall thicknesses depending on what's doing what. Going to add some more details and do FEA but I expect it to be stiffer than the last version for 40-50 pounds less and some other less obvious details. I figure that once I do some FEA to sanity check things, it's close enough to start buying, cutting and welding tube.

Also talking to Hartman Fiberglass about bodywork - it seems like a lot less work to mold fenders and stuff to a spare shell then pull molds from that rather than make a bodywork plug myself.