HP limit on E85

#127

Racing Rotary Since 1983

iTrader: (6)

"Next project will be mixing methanol with E85. Maybe four gallons of e85 to one gallon of methanol. No intercooler and NO water/meth injection"

you seem to be traveling down the road that ends for most at 100% meth as base fuel. cooling on the typical 1000 rwhp 2 rotor 100% meth drag car is such that it wouldn't be a good idea to put your hand on the upper intake manifold as you might not be able to remove it until the ice melts. no intercoolers in sight.

E85 figured at 83% eth, 2% poison and 15% gas has 82,300 BTUs per gallon

Meth has 57,250 so you'll need about 44% more deliverability V E85 and, just as an aside for others, 102% V gasoline... (any gasoline).

meth cooling per gallon V gas is 3.7 X and E85 (really E83) is 1.5X.

auto ignition of gasoline (any gasoline) is 495 F

auto ignition of methanol is 867 F

autoignition of E85 (E83) is 732 F

14 1600 injectors gets it done around 1100 SAE rw rotary hp on meth.

congrats on what you have accomplished and thanks for sharing.

howard

you seem to be traveling down the road that ends for most at 100% meth as base fuel. cooling on the typical 1000 rwhp 2 rotor 100% meth drag car is such that it wouldn't be a good idea to put your hand on the upper intake manifold as you might not be able to remove it until the ice melts. no intercoolers in sight.

E85 figured at 83% eth, 2% poison and 15% gas has 82,300 BTUs per gallon

Meth has 57,250 so you'll need about 44% more deliverability V E85 and, just as an aside for others, 102% V gasoline... (any gasoline).

meth cooling per gallon V gas is 3.7 X and E85 (really E83) is 1.5X.

auto ignition of gasoline (any gasoline) is 495 F

auto ignition of methanol is 867 F

autoignition of E85 (E83) is 732 F

14 1600 injectors gets it done around 1100 SAE rw rotary hp on meth.

congrats on what you have accomplished and thanks for sharing.

howard

Last edited by Howard Coleman; 02-28-14 at 12:07 PM.

#128

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

Still on e85 no intercooler with water/meth injection.

Hurt the motor last night. Think it warped a seal.

Think the problem is how fast the motor runs through the gears, on a full pass, that the water system does not have the time needed to inject the proper amount of water/meth. When on the dyno or test passes at the track everything has time to work and the air temps stay in the 130s. Last night the max air temp was 200f in third gear. Car is in 4th gear before the 1/8 mile. The water system is my own DYI system.

It did go 9.42 letting off. MPH was down at 138. Have run over 150.

Should have had the air temp engine protection feature on.

Did have it take timing and add fuel when air temps were over 150f just not enough I guess. Added 10% fuel and removed timing were it ran 5 deg total advance last night. Never thought the air temps would go that high. SUCKS!

side note. No intercooler is awesome. Just have to figure out a way to run no intercooler with out switching fuel from e85 to methanol.

Hurt the motor last night. Think it warped a seal.

Think the problem is how fast the motor runs through the gears, on a full pass, that the water system does not have the time needed to inject the proper amount of water/meth. When on the dyno or test passes at the track everything has time to work and the air temps stay in the 130s. Last night the max air temp was 200f in third gear. Car is in 4th gear before the 1/8 mile. The water system is my own DYI system.

It did go 9.42 letting off. MPH was down at 138. Have run over 150.

Should have had the air temp engine protection feature on.

Did have it take timing and add fuel when air temps were over 150f just not enough I guess. Added 10% fuel and removed timing were it ran 5 deg total advance last night. Never thought the air temps would go that high. SUCKS!

side note. No intercooler is awesome. Just have to figure out a way to run no intercooler with out switching fuel from e85 to methanol.

#129

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

air temps reached 200f in 2nd gear not 3rd. By the end of 3rd gear air temp was 158f and carried that through 4th gear. Reason for thinking the water system was not up to the task for a full out pass.

#130

Racing Rotary Since 1983

iTrader: (6)

what was your air temp before you removed the IC?

i had close to 400 out of the turbo, and 200 into the motor. the IC removed 130 and the W/M removed 70. i am using a type K thermocouple so the data is accurate to a few mS and to the degree F.

i had close to 400 out of the turbo, and 200 into the motor. the IC removed 130 and the W/M removed 70. i am using a type K thermocouple so the data is accurate to a few mS and to the degree F.

Last edited by Howard Coleman; 03-08-14 at 01:10 PM.

#131

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

Air temps with intercooler was in the 130s. Comparing your set up and mine is a bit different I would think.

1st through 3rd gear take around 4.7 seconds. according to the datalog

1st through 3rd gear take around 4.7 seconds. according to the datalog

#132

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

I totally over looked something before hitting the track Friday night. Last week the gears in the trans were changed. Higher numerical number causing the rpms and boost to climb faster through the gears compared to the dyno and previous test passes at the track. And did not adjust the water injection to compensate for this. Explains a few things.

live and learn

live and learn

#133

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

Had it back on the rollers yesterday. With the added water meth nozzles, the air temp were 15deg f lower then the last time it was on the rollers. Max air temp was 120f. 7400rpms. Think the ignition system will take a bit more water meth injection so adding one more m10 nozzle to the charge pipe. Ran better then it ever has yesterday. Even the dyno guy noticed a difference.

650rwhp at 7400 rpms on the v-power 2$ spark plugs. Still cant get over how well the stock turboII coils and these cheap plugs perform. Since there are some really smart guys on the forum whom said it WILL NOT work and cause engine damage. So funny!

Still cant get over how well the stock turboII coils and these cheap plugs perform. Since there are some really smart guys on the forum whom said it WILL NOT work and cause engine damage. So funny!

Second the third gear start at 7500prms. Shift at 9400.

4th gear starts at 6500rpms.

650rwhp at 7400 rpms on the v-power 2$ spark plugs.

Still cant get over how well the stock turboII coils and these cheap plugs perform. Since there are some really smart guys on the forum whom said it WILL NOT work and cause engine damage. So funny!

Still cant get over how well the stock turboII coils and these cheap plugs perform. Since there are some really smart guys on the forum whom said it WILL NOT work and cause engine damage. So funny!

Second the third gear start at 7500prms. Shift at 9400.

4th gear starts at 6500rpms.

#134

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

My system, no intercooler so air temps are high. High air temps cause 100% evaporation of water meth resulting in 200f air temps. No water meth reaches the combustion chamber.

Your system, since the intercooler is reducing the air temps 130, is it possible your system is not evaporating all the water meth liquid? so you may be getting 30% of your water in the combustion chamber. Resulting in better cooling effects then me.

Even though we're both seeing 200f air temps, your system is actually cooling the combustion chamber more efficiently. My no intercooler system may just need a ton more water meth to be efficient.

Thanks for you input.

#135

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

This testing without a intercooler is rough. Did some testing last night. One test pass with a bog in first gear, it went 10.0 at 141 and air temps never got over 130.

Then next pass we upped the boost in first gear ( no bog ) and the air temp went to 160. Beginning to think my water injection system is not up to the task of injecting enough water soon enough.

more testing next week.

Then next pass we upped the boost in first gear ( no bog ) and the air temp went to 160. Beginning to think my water injection system is not up to the task of injecting enough water soon enough.

more testing next week.

#137

Racing Rotary Since 1983

iTrader: (6)

i am switching my AI to 100% meth from a mix of WM. i figure it will reduce my IAT and while i might lose a touch of in-chamber cooling from the water i don't think i will need it since i am on E85 and at a max power target of 600. maybe you might consider the same move.

the only reason i ran the combo at the Texas Mile is i didn't have enough time to convert my 4.5 gallon AI tank to get thru tech.

hc

the only reason i ran the combo at the Texas Mile is i didn't have enough time to convert my 4.5 gallon AI tank to get thru tech.

hc

#138

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

Have thought about running strait meth instead of 50/50 water meth. May end up going that rout.

Howard. in the screen shot you provided on the previous page, two things got me thinking about your numbers. EGT and AFR. If I am reading it correctly the afr was 10.6 and your target afr was 11.5. The richer afr kept the egt down were the seals will not be hurt. So this is what kept your seals together, even though the air temp seems high, i'm thinking. I use to tune 10.7 10.9 and listen to a few and started tuning to 11.8. And also got lazy monitoring egt. Now that the egt gauges have been installed again, there down in the 1400f range and afr is in the 10.5 10.9 range. Car pulls harder then ever! again. our timing numbers look to be in the same ballpark but i am running a bit more boost.

Know what hurt the seals, heat. Was thinking the high air temps is was caused the seals to go bananas but Obviously the egt were to high with afr in the high 11s. Now that we're monitoring egt and keeping the afr in the mid 10s, crossing my fingers the seals hold up.

but Obviously the egt were to high with afr in the high 11s. Now that we're monitoring egt and keeping the afr in the mid 10s, crossing my fingers the seals hold up.

Howard. in the screen shot you provided on the previous page, two things got me thinking about your numbers. EGT and AFR. If I am reading it correctly the afr was 10.6 and your target afr was 11.5. The richer afr kept the egt down were the seals will not be hurt. So this is what kept your seals together, even though the air temp seems high, i'm thinking. I use to tune 10.7 10.9 and listen to a few and started tuning to 11.8. And also got lazy monitoring egt. Now that the egt gauges have been installed again, there down in the 1400f range and afr is in the 10.5 10.9 range. Car pulls harder then ever! again. our timing numbers look to be in the same ballpark but i am running a bit more boost.

Know what hurt the seals, heat. Was thinking the high air temps is was caused the seals to go bananas

but Obviously the egt were to high with afr in the high 11s. Now that we're monitoring egt and keeping the afr in the mid 10s, crossing my fingers the seals hold up.

but Obviously the egt were to high with afr in the high 11s. Now that we're monitoring egt and keeping the afr in the mid 10s, crossing my fingers the seals hold up.

#139

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

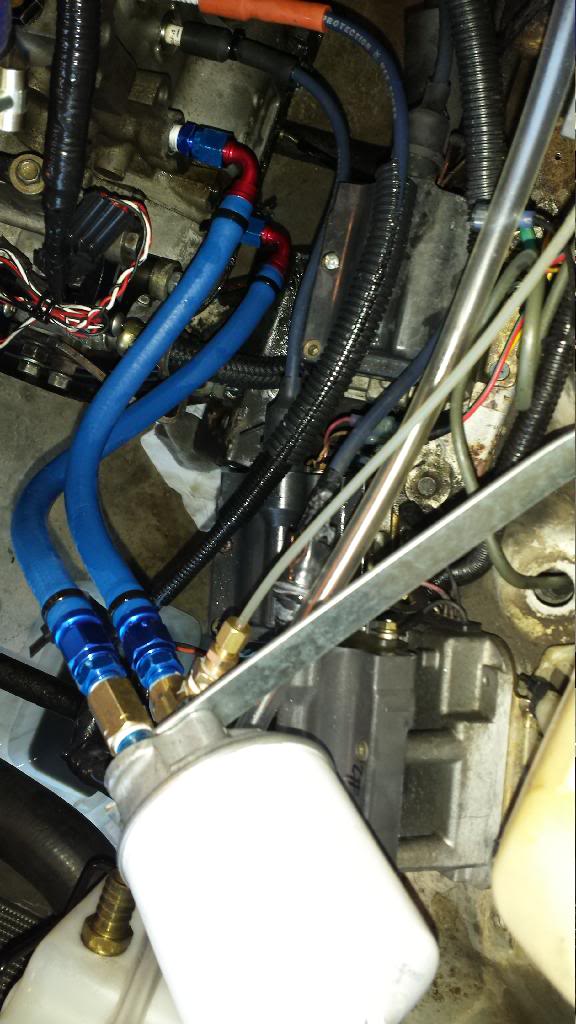

This is my water meth injection

Old 100 psi pump

2 psi hobbs switch that ground a solenoid that feed two nozzles, one pre turbo M15 and one post turbo nozzle M10

Then there is a solenoid that is run on PWM from the ecu. Starts at 10psi and full max at 40psi One post turbo nozzle M15 and two pre turbo nozzles both M15.

Thinking about adding one more M10 post turbo run off the PWM selonoid.

On a test pass that ran in the 12s et it uses what seems like more water meth then the main fuel. Maybe it's not allot, half a quart. On a 10 second pass it uses less but still close to a half quart. We monitor the water meth usage after each run so we know it's working. sound like a lot to you guys???? On a 10.0 pass it kept the air temps in the low 130s. Not bad but I may have to start the PWM solenoid to come on sooner.

Old 100 psi pump

2 psi hobbs switch that ground a solenoid that feed two nozzles, one pre turbo M15 and one post turbo nozzle M10

Then there is a solenoid that is run on PWM from the ecu. Starts at 10psi and full max at 40psi One post turbo nozzle M15 and two pre turbo nozzles both M15.

Thinking about adding one more M10 post turbo run off the PWM selonoid.

On a test pass that ran in the 12s et it uses what seems like more water meth then the main fuel. Maybe it's not allot, half a quart. On a 10 second pass it uses less but still close to a half quart. We monitor the water meth usage after each run so we know it's working. sound like a lot to you guys???? On a 10.0 pass it kept the air temps in the low 130s. Not bad but I may have to start the PWM solenoid to come on sooner.

#140

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

And my air temp sensor is just before the t-body in the charge pipe. And there are two secondary 1600cc injectors in the charge pipe 14 inches before the t-body.

Last night we did some more testing. Turned down and reset some of the setting for the boost control. Trying to get a more steady boost. Last night the boost was fluctuating a 8 psi difference between desired boost and a lower boost. So last night it was down roughly 10 psi

Air temps last night was outstanding. Two passes. one was max 135 and the other one was just a bit higher. Both max temps were in 3rd gear. 4th gear the air temp was in the low 120s. One pass was 10.5 at 130 bogged in 1st gear.

The other pass was exciting. raced a 9.3 bike. He got me off the line by .1 our 60 ft times were in the low 1.4 then he got me my .2 at the 330. He ran a 5.9 1/8 to my 6.6 BUT I had to let off at 5.2. 1.4 seconds before my 1/8 mile time. The DIY 7 was going pretty good. Think it would have been a high 9 pass on a play around boost level.

Side note. AFR gauge quit working so we ran off egt numbers with confidence like we use to.

Thinking about adding one more M10 nozzle in the charge pipe. Off a hobbs switch at a higher boost level.

Last night we did some more testing. Turned down and reset some of the setting for the boost control. Trying to get a more steady boost. Last night the boost was fluctuating a 8 psi difference between desired boost and a lower boost. So last night it was down roughly 10 psi

Air temps last night was outstanding. Two passes. one was max 135 and the other one was just a bit higher. Both max temps were in 3rd gear. 4th gear the air temp was in the low 120s. One pass was 10.5 at 130 bogged in 1st gear.

The other pass was exciting. raced a 9.3 bike. He got me off the line by .1 our 60 ft times were in the low 1.4 then he got me my .2 at the 330. He ran a 5.9 1/8 to my 6.6 BUT I had to let off at 5.2. 1.4 seconds before my 1/8 mile time. The DIY 7 was going pretty good. Think it would have been a high 9 pass on a play around boost level.

Side note. AFR gauge quit working so we ran off egt numbers with confidence like we use to.

Thinking about adding one more M10 nozzle in the charge pipe. Off a hobbs switch at a higher boost level.

#141

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

More testing last night.

One good pass. Boost was just over 30psi. short shifting at 8400rpms. Spun first gear bad. Since it bogged the other night, added one psi air pressure to the tires and did a small burn out. BAD!. Ran 10.3 at 141. Think it would have been a 9.8 if the launch was good.

Air temps reached 145 in third gear. 3rd gear seems to be where the air temps are the highest. 4th gear was 130s AFR was low 10s egt under 1500f. Next time out going to start adding timing to see if egt drop.

Going to add one more nozzle and have it activate at a air temp higher then 135, 25psi and 7000rpms. Think this will help 3rd gear and not effect the other gears.

It does use a lot of water meth liquid. Air temps out of the turbo has to be way hotter then anticipated. Thought since it was a 80mm with race cover at a low boost the air temps would be reasonable, not scorching hot based on how much water meth liquid it is using. And remember the DIY car is still on stock turboII leading coils without a box.

Air temps out of the turbo has to be way hotter then anticipated. Thought since it was a 80mm with race cover at a low boost the air temps would be reasonable, not scorching hot based on how much water meth liquid it is using. And remember the DIY car is still on stock turboII leading coils without a box.

After 3 years of use on E85 the Weldon finally went out! Estimate the car went down the track roughly 600 times in three years. Plus roller time. Great pump, would buy another A1000 but need something bigger. Going to send it out for rebuild and keep for future use.

One good pass. Boost was just over 30psi. short shifting at 8400rpms. Spun first gear bad. Since it bogged the other night, added one psi air pressure to the tires and did a small burn out. BAD!. Ran 10.3 at 141. Think it would have been a 9.8 if the launch was good.

Air temps reached 145 in third gear. 3rd gear seems to be where the air temps are the highest. 4th gear was 130s AFR was low 10s egt under 1500f. Next time out going to start adding timing to see if egt drop.

Going to add one more nozzle and have it activate at a air temp higher then 135, 25psi and 7000rpms. Think this will help 3rd gear and not effect the other gears.

It does use a lot of water meth liquid.

Air temps out of the turbo has to be way hotter then anticipated. Thought since it was a 80mm with race cover at a low boost the air temps would be reasonable, not scorching hot based on how much water meth liquid it is using. And remember the DIY car is still on stock turboII leading coils without a box.

Air temps out of the turbo has to be way hotter then anticipated. Thought since it was a 80mm with race cover at a low boost the air temps would be reasonable, not scorching hot based on how much water meth liquid it is using. And remember the DIY car is still on stock turboII leading coils without a box.

After 3 years of use on E85 the Weldon finally went out! Estimate the car went down the track roughly 600 times in three years. Plus roller time. Great pump, would buy another A1000 but need something bigger. Going to send it out for rebuild and keep for future use.

#143

Racing Rotary Since 1983

iTrader: (6)

i am really wondering about IATs...

as everyone knows the stock IAT sensor is useless. datalog a run and you get the same number from the start to the end of the pull.

i am aware there are other "faster" sensors.

my question is how fast are they?

the reason i think the question is interesting is because if the sensor isn't instantaneous the reading will not reflect the actual temperature and be too low.

i use Type k thermocouples for IAT and am pretty surprised to see how high my temps are out of the turbo and also at the stock (FD) location.

my GT4094r at 25 psi reads almost 400 F!

Type K max error is 5 degrees F at 400.

response is instantaneous.

it would be interesting if someone using the "fast" IAT sensor switched to a thermocouple.

i have a suspicion that most IAT readings could be low V the real number.

howard

as everyone knows the stock IAT sensor is useless. datalog a run and you get the same number from the start to the end of the pull.

i am aware there are other "faster" sensors.

my question is how fast are they?

the reason i think the question is interesting is because if the sensor isn't instantaneous the reading will not reflect the actual temperature and be too low.

i use Type k thermocouples for IAT and am pretty surprised to see how high my temps are out of the turbo and also at the stock (FD) location.

my GT4094r at 25 psi reads almost 400 F!

Type K max error is 5 degrees F at 400.

response is instantaneous.

it would be interesting if someone using the "fast" IAT sensor switched to a thermocouple.

i have a suspicion that most IAT readings could be low V the real number.

howard

#144

Full Member

iTrader: (1)

Join Date: Aug 2013

Location: jamaica

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

And my air temp sensor is just before the t-body in the charge pipe. And there are two secondary 1600cc injectors in the charge pipe 14 inches before the t-body. Last night we did some more testing. Turned down and reset some of the setting for the boost control. Trying to get a more steady boost. Last night the boost was fluctuating a 8 psi difference between desired boost and a lower boost. So last night it was down roughly 10 psi Air temps last night was outstanding. Two passes. one was max 135 and the other one was just a bit higher. Both max temps were in 3rd gear. 4th gear the air temp was in the low 120s. One pass was 10.5 at 130 bogged in 1st gear. The other pass was exciting. raced a 9.3 bike. He got me off the line by .1 our 60 ft times were in the low 1.4 then he got me my .2 at the 330. He ran a 5.9 1/8 to my 6.6 BUT I had to let off at 5.2. 1.4 seconds before my 1/8 mile time. The DIY 7 was going pretty good. Think it would have been a high 9 pass on a play around boost level. Side note. AFR gauge quit working so we ran off egt numbers with confidence like we use to.  Thinking about adding one more M10 nozzle in the charge pipe. Off a hobbs switch at a higher boost level.

Thinking about adding one more M10 nozzle in the charge pipe. Off a hobbs switch at a higher boost level.

Thinking about adding one more M10 nozzle in the charge pipe. Off a hobbs switch at a higher boost level.

Thinking about adding one more M10 nozzle in the charge pipe. Off a hobbs switch at a higher boost level.

#145

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

Haltech Sport 1000 ecu

Actually bought a faster/better air temp sensor but stayed with the GM sensor since most of the guys who have a aftermarket ecu use the GM sensor. Mine is in the charge pipe right before the t-body.

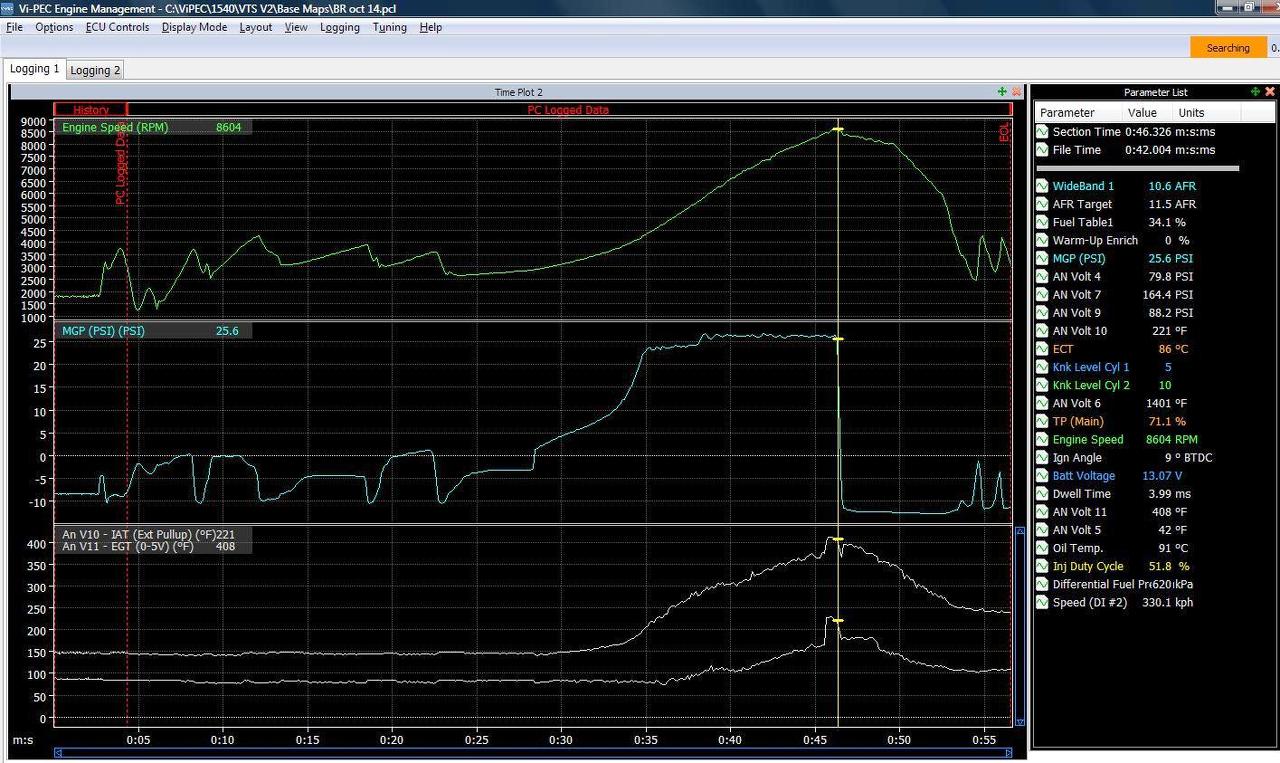

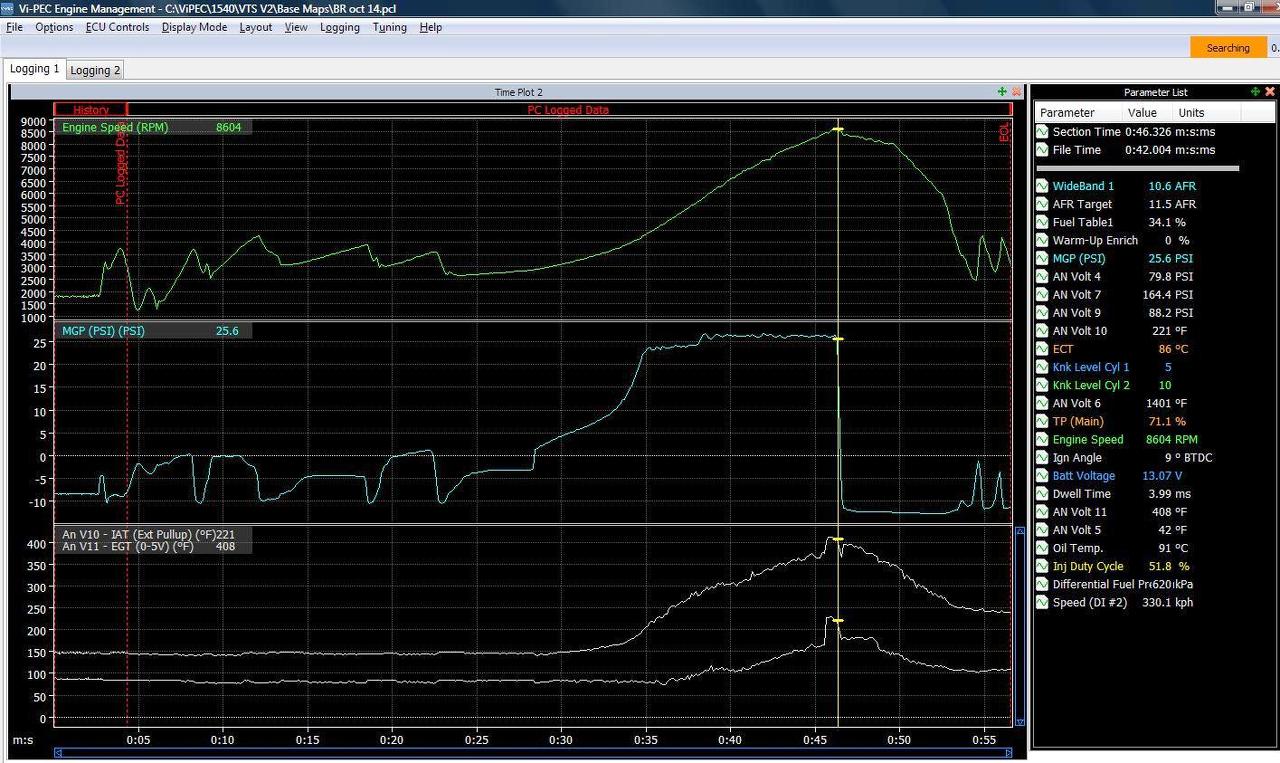

screen shot of air temp. 2nd gear through 4th gear.

Actually bought a faster/better air temp sensor but stayed with the GM sensor since most of the guys who have a aftermarket ecu use the GM sensor. Mine is in the charge pipe right before the t-body.

screen shot of air temp. 2nd gear through 4th gear.

#146

Racing Rotary Since 1983

iTrader: (6)

here's my IAT plot in fifth gear at 205 mph on the dyno. it shows about 400 out of the turbo and 175/180 at the stock location. other than the blip which i currently cannot explain. Luke probably can be of help in the matter. while the engine showed zero knock i don't like the IAT and as previously mentioned will switch to 100% meth to lower IAT a bit.

the question still remains... are my temps higher than most OR are others not getting the full measure due to the fact their setups have more lag? my type K thermocouple reading is instantaneous.

V11 is at the turbo output and V10 is stock location. disregard the EGT label...

the question still remains... are my temps higher than most OR are others not getting the full measure due to the fact their setups have more lag? my type K thermocouple reading is instantaneous.

V11 is at the turbo output and V10 is stock location. disregard the EGT label...

Last edited by Howard Coleman; 04-19-14 at 08:38 AM.

#147

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

I would think yours air temps are more accurate them mine since the sensor reacts faster then the GM one. Only question I have is the location your sensor is. Heat soak. Where if the sensor was in the charge pipe would it be lower?

So if your sensor is more accurate and faster and I am using a GM sensor and thinking your numbers are ok, I would be way out of the ball park. That's why I stayed with the gm sensor. More guys are using them so am thinking there would be more consistency between my reading and other who are using a gm sensor in the charge pipe. Also if I change sensors now I'll have nothing to compare with. Know what it ran with air to air intercooler and water to air intercooler. W/W intercooler was under 129f and the A/A intercooler was 150s at full power.

So if your sensor is more accurate and faster and I am using a GM sensor and thinking your numbers are ok, I would be way out of the ball park. That's why I stayed with the gm sensor. More guys are using them so am thinking there would be more consistency between my reading and other who are using a gm sensor in the charge pipe. Also if I change sensors now I'll have nothing to compare with. Know what it ran with air to air intercooler and water to air intercooler. W/W intercooler was under 129f and the A/A intercooler was 150s at full power.

#148

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

The other thing that has me wondering when comparing our car is your numbers are from a dyno run and mine are track numbers. When my car is on the dyno the air temps are alot lower then the track. Guessing the water meth injection has more time to cool the charge vs only seconds per gear on the track.

#149

Rotary Enthusiast

Thread Starter

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

redid the water injection.

One M15 at 3psi pre turbo

Two M10 nozzles post turbo controlled by PWM/3 port mac valve.

Then one M15 preturbo and one M15 post turbo activated at 29psi and 135deg F

Made a few passes with the air temp sensor before the T-body. Air temp was average 145f when boosting. High of 150f. Car still feels sluggish.

Then moved the air temp sensor to the intake manifold. Just below two more fuel injectors that come on at 7 psi. (secondary injectors) Also have two fuel injectors in the charge pipe before the t-body. also secondary injectors.

Car took off. No sluggish feel so let off after 3rd gear. check log and find air temps never reached 130f. Ran in the 125f range. So two nozzles never come on.

With the air temp sensor in the manifold the air temps were 150f at idle then went down to 125f under boost. Completely opposite from when the sensor was in the charge pipe. Idle was 110f and climbed from there, 150f.

EGT was 1350 with all water nozzles working. And increased to 1400 with the lower air temps with only three water nozzles working.

So it appears I was using way to much water/meth. And again never had a misfire issue. Still on four stock turboII leading ignitors and four turboII trailing coils. Gota just laugh at the guy who says that stock ignition is junk!

One M15 at 3psi pre turbo

Two M10 nozzles post turbo controlled by PWM/3 port mac valve.

Then one M15 preturbo and one M15 post turbo activated at 29psi and 135deg F

Made a few passes with the air temp sensor before the T-body. Air temp was average 145f when boosting. High of 150f. Car still feels sluggish.

Then moved the air temp sensor to the intake manifold. Just below two more fuel injectors that come on at 7 psi. (secondary injectors) Also have two fuel injectors in the charge pipe before the t-body. also secondary injectors.

Car took off. No sluggish feel so let off after 3rd gear. check log and find air temps never reached 130f. Ran in the 125f range. So two nozzles never come on.

With the air temp sensor in the manifold the air temps were 150f at idle then went down to 125f under boost. Completely opposite from when the sensor was in the charge pipe. Idle was 110f and climbed from there, 150f.

EGT was 1350 with all water nozzles working. And increased to 1400 with the lower air temps with only three water nozzles working.

So it appears I was using way to much water/meth. And again never had a misfire issue. Still on four stock turboII leading ignitors and four turboII trailing coils. Gota just laugh at the guy who says that stock ignition is junk!

#150

Racing Rotary Since 1983

iTrader: (6)

good info, thanks for sharing.

WOW so you had two M15s (1890 CC) pre turbo at 29 psi?

two M10s post T (1260 CC)

and another M15 post T (945) at 29 and 135...

of course 2 of your M15s didn't trigger after you relocated your IAT sensor because you were below 135 but wow, you had

an M15 pre, 2 M10s post. total 2205 CC.

your EGT looks great and i still wonder what your actual IAT is. i realise that if it works, which it does, it probably doesn't matter.

why don't you switch an EGT to your IAT location for a couple of runs?

howard

WOW so you had two M15s (1890 CC) pre turbo at 29 psi?

two M10s post T (1260 CC)

and another M15 post T (945) at 29 and 135...

of course 2 of your M15s didn't trigger after you relocated your IAT sensor because you were below 135 but wow, you had

an M15 pre, 2 M10s post. total 2205 CC.

your EGT looks great and i still wonder what your actual IAT is. i realise that if it works, which it does, it probably doesn't matter.

why don't you switch an EGT to your IAT location for a couple of runs?

howard