Low compression on rebuilt engine (Need advice)

#1

Hey guys,

I have owned my FD for around 2 years, during which I have put very little mileage on it (less than 100 miles), and the car has been mainly sitting getting worked on. More recently, I've upgraded the fuel system (FFE primary rail and new bosch primary injectors installed) and ignition system. I've also switched to Mobil 1 from convensional oil that the previous owner ran for several years. Car has no OMP, and runs premix.

I believe the car has around 90K miles (odometer doesn't work), and when I bought the car I was told the engine was rebuilt around 20K miles ago. During the rebuild the water seals were changed, RA Apex seals were installed and the previous owner thinks the corner seals might have been replaced too.

Last week, following the ignition and fuel upgrades I took the car to get tuned, but before we put her on the dyno we did a compression test. We followed the process as per the Mazda service manual and used a rotary compression tester.

Results:

Rotor 1: All faces between 70-78 psi corrected

Rotor 2: All faced between 60-69 psi corrected

Nonetheless, the car has no problems starting even when the engine is warm, the idle also does not suggest there is anything off with the compression either.

Questions:

1) Is it possible the apex seals springs are stuck due to excessive carbon buildup and Is it worth using the ATF trick to try to free up the springs and then do another compression test?

2) Is it possible that the low compression readings are actually due to worn housings, sides seals, or other components given the overall age of the car?

3) Should I try to get some more life our of the car, or bite the bullet and go for a rebuild?

Thanks guys

I have owned my FD for around 2 years, during which I have put very little mileage on it (less than 100 miles), and the car has been mainly sitting getting worked on. More recently, I've upgraded the fuel system (FFE primary rail and new bosch primary injectors installed) and ignition system. I've also switched to Mobil 1 from convensional oil that the previous owner ran for several years. Car has no OMP, and runs premix.

I believe the car has around 90K miles (odometer doesn't work), and when I bought the car I was told the engine was rebuilt around 20K miles ago. During the rebuild the water seals were changed, RA Apex seals were installed and the previous owner thinks the corner seals might have been replaced too.

Last week, following the ignition and fuel upgrades I took the car to get tuned, but before we put her on the dyno we did a compression test. We followed the process as per the Mazda service manual and used a rotary compression tester.

Results:

Rotor 1: All faces between 70-78 psi corrected

Rotor 2: All faced between 60-69 psi corrected

Nonetheless, the car has no problems starting even when the engine is warm, the idle also does not suggest there is anything off with the compression either.

Questions:

1) Is it possible the apex seals springs are stuck due to excessive carbon buildup and Is it worth using the ATF trick to try to free up the springs and then do another compression test?

2) Is it possible that the low compression readings are actually due to worn housings, sides seals, or other components given the overall age of the car?

3) Should I try to get some more life our of the car, or bite the bullet and go for a rebuild?

Thanks guys

#2

My experience from 3 times using them is that is within normal compression readings for an engine with RA seals once they have thrashed the rotor housings with the normal gauling.

Turn the boost up and enjoy the only benefit the RA seals provide, a bit more strength under detonation!

Turn the boost up and enjoy the only benefit the RA seals provide, a bit more strength under detonation!

#5

Having an engine with RA seals is deliberately trading off protection from catastrophic failure (knock resistance) for shorter life on housings. For higher horsepower builds that get driven a few thousand miles a year they make sense. I don't know when that engine was built, but 20k sounds about right. For a lot of owners that's about 4 or 5 years of driving with low risk of breaking an apex seal. The RA seals I had on my big single turbo car held up to my many tuning mistakes back then.

Pay me now or pay me later, that's all it is.

What are your mods and what is your expected power level in future?

Pay me now or pay me later, that's all it is.

What are your mods and what is your expected power level in future?

Last edited by arghx; 09-30-19 at 10:17 AM.

#6

Thanks guys - very good info. I didn't realize the RAs were known as being so aggressive on the housings.

My goals for the car are to have a streetable 350-400whp car that I can take to a few track days each year. I'm currently running non-seq twins, but might spring for a single turbo in the future with the same power goals. The car will likely see less than 1000 miles/year for the foreseeable future.

If we go with the assumption that the engine has been running the RA seals for about 20K miles and is currently starting/driving normally:

1) Are the low compression numbers "normal" for a 13b with RA seals, as BLUE TII mentioned?

2) Given the recent history of the car (not driven much over last 2 years), is it worth trying the ATF fix to boost the compression numbers before committing to a rebuild?

3) Is it best to do the rebuild now (to save the housings) or should I just keep running the car as is, until things get worse?

Where I am in my head:

I knew I would need to rebuild the engine at some point, and I am not opposed to doing it now versus later.That said, if there is still usable life to be extracted from the current build, without significant risk of damaging the engine further, then I guess I should hold off on the rebuild for a little longer. That would allow me to enjoy the car for a little seeing as since I've bought the car, I still haven't really driven her.

Thanks again guys!

My goals for the car are to have a streetable 350-400whp car that I can take to a few track days each year. I'm currently running non-seq twins, but might spring for a single turbo in the future with the same power goals. The car will likely see less than 1000 miles/year for the foreseeable future.

If we go with the assumption that the engine has been running the RA seals for about 20K miles and is currently starting/driving normally:

1) Are the low compression numbers "normal" for a 13b with RA seals, as BLUE TII mentioned?

2) Given the recent history of the car (not driven much over last 2 years), is it worth trying the ATF fix to boost the compression numbers before committing to a rebuild?

3) Is it best to do the rebuild now (to save the housings) or should I just keep running the car as is, until things get worse?

Where I am in my head:

I knew I would need to rebuild the engine at some point, and I am not opposed to doing it now versus later.That said, if there is still usable life to be extracted from the current build, without significant risk of damaging the engine further, then I guess I should hold off on the rebuild for a little longer. That would allow me to enjoy the car for a little seeing as since I've bought the car, I still haven't really driven her.

Thanks again guys!

Trending Topics

#8

RX-7 Bad Ass

iTrader: (55)

1) I don't have first hand experience with the RA seals but that is what I've heard from a number of people. I think that's a fair estimate of the problem.

2) I doubt that would do anything. Most likely it isn't a a carbon issue which is the only thing ATF can help with, it's a mechanical issue with the fit of the seals to the housings.

3) It's not going to get better, it's really a case of when you have time/money to pull the motor and dig into it. It's possible the rotor housings are done and they probably won't get worse or better.

Dale

2) I doubt that would do anything. Most likely it isn't a a carbon issue which is the only thing ATF can help with, it's a mechanical issue with the fit of the seals to the housings.

3) It's not going to get better, it's really a case of when you have time/money to pull the motor and dig into it. It's possible the rotor housings are done and they probably won't get worse or better.

Dale

The following users liked this post:

telram (10-02-19)

#9

Racing Rotary Since 1983

iTrader: (6)

all good advice above.

what heat range plugs have been in the motor?

what boost has been run?

are you aware of any earlier compression checks?

given the numbers nothing major has broken internally but it is probable that heat and non optimum items are the culprit. heat because the numbers are lower in the rear which can run hotter.

since apex seals and rotor housings conform over time i doubt your primary comp loss is due to mismatched contours between the crown of the apex seal and the housing surface. it is more likely to be chatter which is exacerbated by seal choice.

chatter comes from heat around the plug boss, "spark plug mountain." as the apex seal rides over the lower spark plug boss it is pushed back against the springs by the fact that the area around the plug, being hotter than the rest of the rotor housing surface, has risen. the apex seal at that moment is not touching most of the housing as evidenced by the carbon. big compression loss here. the double trouble is after it passes, the compressed spring pushes the seal back out and the rotor housing damaging oscillations begin. all rotor housings acquire chatter, it is only the degree which is important. significant chatter cannot be fixed by honing and significant chatter causes compression loss to the extent of the chatter. significant chatter can literally cause an inability to start.

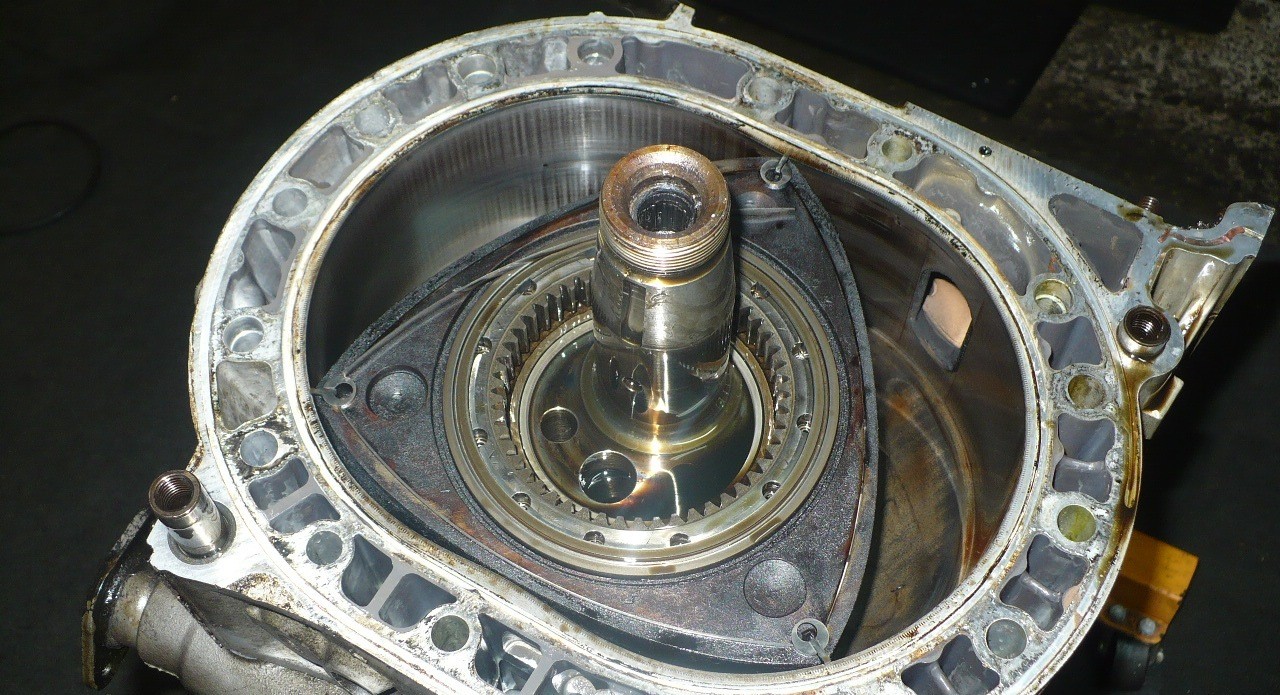

cause:

effect:

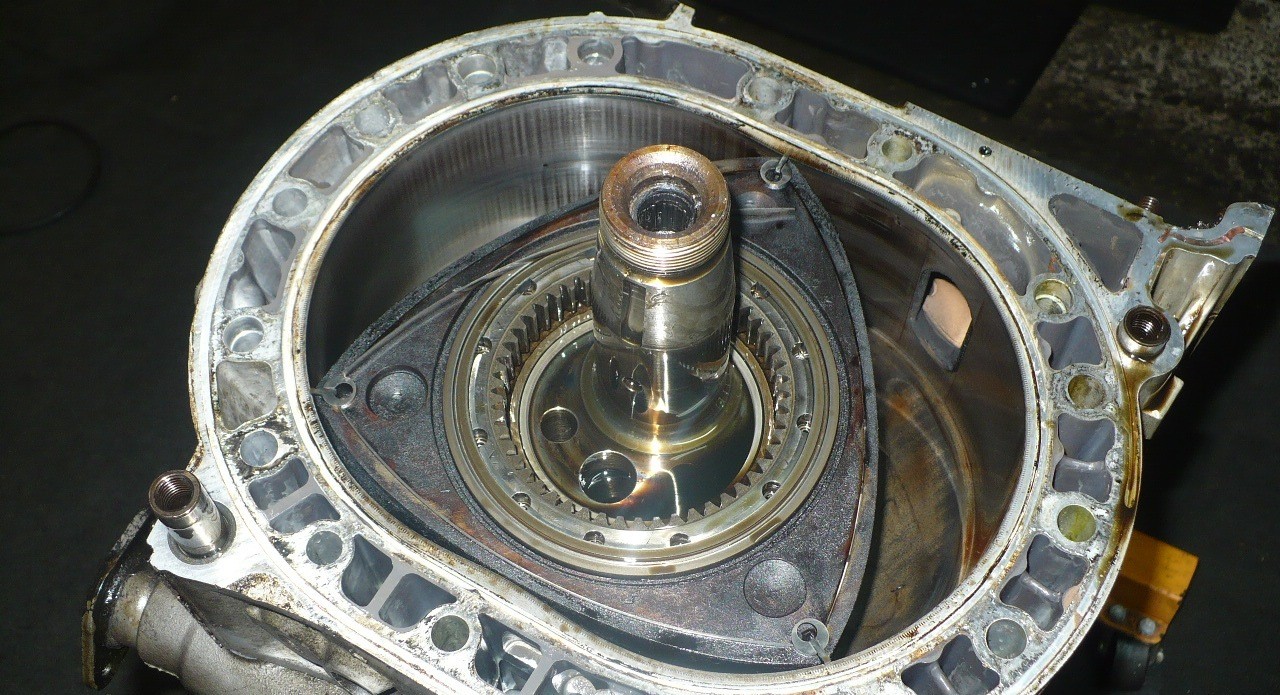

these lateral lines of carbon/oil are not just visual as every one is backed up by a lateral chrome ridge. if advanced you can feel them with your fingernail and they cause carnage.

there could be other factors such as detonation causing the corner springs to de-arch. they should be .18 free height but detonation causes internal temps to rise from around 1400 F to around 3500 F which is too much for the corner seal springs. i see corner seal springs come in at completely flat to around .13. flat corner seal springs drop comp 30%. corner seal springs generally are O K sans detonation, especially the OE FD springs which are inconel. do not buy the cheaper springs that Atkins routinely sells.

sloppy sideseal gaps could be a factor... note in picture 2 how much carbon/oil is inboard of the sideseals. there should be none with proper sideseal gap. i believe i found .1 of an inch gap on this motor.

i doubt misgapped sideseals would cause numbers in the 60s however.

probably heat and miles and chatter are your problems.

i run 67 C coolant using the Mishimoto MMTS-89 thermostat along with cold plugs, both of which provide help.

you wouldn't be making a big mistake by running your motor until it won't hot start. start putting some $s away for a new set of housings. no need to run harsh apex seals as the newer more malleable seals generally don't break and often don't warp so switch to Goopy, E&J, RXparts, Rotary Engine or I Seals when you rebuild.

good luck

what heat range plugs have been in the motor?

what boost has been run?

are you aware of any earlier compression checks?

given the numbers nothing major has broken internally but it is probable that heat and non optimum items are the culprit. heat because the numbers are lower in the rear which can run hotter.

since apex seals and rotor housings conform over time i doubt your primary comp loss is due to mismatched contours between the crown of the apex seal and the housing surface. it is more likely to be chatter which is exacerbated by seal choice.

chatter comes from heat around the plug boss, "spark plug mountain." as the apex seal rides over the lower spark plug boss it is pushed back against the springs by the fact that the area around the plug, being hotter than the rest of the rotor housing surface, has risen. the apex seal at that moment is not touching most of the housing as evidenced by the carbon. big compression loss here. the double trouble is after it passes, the compressed spring pushes the seal back out and the rotor housing damaging oscillations begin. all rotor housings acquire chatter, it is only the degree which is important. significant chatter cannot be fixed by honing and significant chatter causes compression loss to the extent of the chatter. significant chatter can literally cause an inability to start.

cause:

effect:

these lateral lines of carbon/oil are not just visual as every one is backed up by a lateral chrome ridge. if advanced you can feel them with your fingernail and they cause carnage.

there could be other factors such as detonation causing the corner springs to de-arch. they should be .18 free height but detonation causes internal temps to rise from around 1400 F to around 3500 F which is too much for the corner seal springs. i see corner seal springs come in at completely flat to around .13. flat corner seal springs drop comp 30%. corner seal springs generally are O K sans detonation, especially the OE FD springs which are inconel. do not buy the cheaper springs that Atkins routinely sells.

sloppy sideseal gaps could be a factor... note in picture 2 how much carbon/oil is inboard of the sideseals. there should be none with proper sideseal gap. i believe i found .1 of an inch gap on this motor.

i doubt misgapped sideseals would cause numbers in the 60s however.

probably heat and miles and chatter are your problems.

i run 67 C coolant using the Mishimoto MMTS-89 thermostat along with cold plugs, both of which provide help.

you wouldn't be making a big mistake by running your motor until it won't hot start. start putting some $s away for a new set of housings. no need to run harsh apex seals as the newer more malleable seals generally don't break and often don't warp so switch to Goopy, E&J, RXparts, Rotary Engine or I Seals when you rebuild.

good luck

Last edited by Howard Coleman; 10-01-19 at 10:29 AM.

The following users liked this post:

telram (10-02-19)

#10

Rotary Enthusiast

iTrader: (5)

I have used RA seals only in three or 4 engines, my rx8 was my guinea pig lol. . I am not engine builder or anything close to it, but the the engine I lost on the dyno was due to hight air intake temp, when the tuner told me that the air temp were too high it was to damn late. Had this engine for 45k miles with RA super seals, had atkins corner seal got stuck, housings were chattered up by spark plugs area.The car worked everytime until the dyno **** up.

A lot of people blame the apex seals, but also have to check everything else specially the lubrication to them. Howard is on point as usual.

A lot of people blame the apex seals, but also have to check everything else specially the lubrication to them. Howard is on point as usual.

The following 2 users liked this post by Red94fd:

Howard Coleman (10-01-19),

telram (10-02-19)

#11

Unless you have heaps of money to burn through I would just keep running that engine until it starts to have issues. If you are only putting on a few hundred miles a year it may not even happen in your lifetime of ownership.

Also are you sure the shop wasn't just trying to squeeze a rebuild out of you or maybe it was a CYA for any mishaps on the Dyno?

Also are you sure the shop wasn't just trying to squeeze a rebuild out of you or maybe it was a CYA for any mishaps on the Dyno?

The following users liked this post:

telram (10-02-19)

#12

Thanks a lot guys! I appreciate you guys taking the time to put together your responses.

Based on the above, I will hold off on the rebuild for now. Seeing as the car is running and starting fine, I will move forward on some other areas (suspension, body work, etc) and start saving up for an eventual rebuild.

Given, the car is currently not tuned for boost, is there any issue if I tune her and turn up the boost at this stage?

I am already running non-seq twin turbo setup, with support fuel and ignition mods through a PFC. Based on some of the comments above I'm assuming this is not going to cause any catastrophic failures if the tune is done properly.

Thanks again

Based on the above, I will hold off on the rebuild for now. Seeing as the car is running and starting fine, I will move forward on some other areas (suspension, body work, etc) and start saving up for an eventual rebuild.

Given, the car is currently not tuned for boost, is there any issue if I tune her and turn up the boost at this stage?

I am already running non-seq twin turbo setup, with support fuel and ignition mods through a PFC. Based on some of the comments above I'm assuming this is not going to cause any catastrophic failures if the tune is done properly.

Thanks again

#13

RX-7 Bad Ass

iTrader: (55)

How much boost are you running currently?

Dale

Dale

#15

Senior Member

which of these will a file have the hardest time cutting into the metal?? I'd go for that 1!! my experience with Goopy NOT good.

Last edited by Clubuser; 10-03-19 at 03:18 PM.

#16

Apex seals with harder wear surface are easier on the chrome housings.

That is how any moving engine parts without a hydrodynamic wedge (engine oil) bearing surface work.

The softer material gets hot from sliding friction and welds itself to the housing chrome on a molecular level and then tears back apart, leaving ruts of missing chrome and furrows of soft seal left on the housing chrome. These are the longitudinal record grooves left on the rotor housings (and different from chatter marks which are a harmonic problem and leave grooves in the axial direction or short direction of the housings).

That is how any moving engine parts without a hydrodynamic wedge (engine oil) bearing surface work.

The softer material gets hot from sliding friction and welds itself to the housing chrome on a molecular level and then tears back apart, leaving ruts of missing chrome and furrows of soft seal left on the housing chrome. These are the longitudinal record grooves left on the rotor housings (and different from chatter marks which are a harmonic problem and leave grooves in the axial direction or short direction of the housings).

Thread

Thread Starter

Forum

Replies

Last Post

importedboi

2nd Generation Specific (1986-1992)

5

09-10-06 03:44 PM

BuckyFD3

3rd Generation Specific (1993-2002)

4

08-23-06 12:32 AM

'87 turbo II

2nd Generation Specific (1986-1992)

8

02-26-06 02:46 PM