fd not starting after rebuilt engine

#1

Full Member

Thread Starter

iTrader: (3)

Join Date: Sep 2008

Location: Colorado Springs, Co

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

fd not starting after rebuilt engine

first of all, i know there are a lot of posts on this, i just wanted to get some insight on my unique problem.

i have recently rebuilt my engine. it was my first one and i know i should check the compression numbers to make sure i did it right, but i would like some other things to check as i am confident the numbers will be good. i am non seq with a downpipe and a power fc w/ commander. i have put my car completely back together and it wont start. i have misplaced a pipe off the intercooler, so i dont have the turbos in the loop yet. i have also had some issues with the wiring harness. i dont have to oil pressure sensor hooked up. would this cause the car to not start? i have fuel, air, and spark. what else should i look for. im going to break down the top side of the engine and take a long hard look at the wiring harness. other than that and the compression test im at a dead end. if anyone has any other ideas i would like to hear them. also, when i press down the pedal while trying to start, the car sounds like it really wants to start. please help any input would be grateful.

i have recently rebuilt my engine. it was my first one and i know i should check the compression numbers to make sure i did it right, but i would like some other things to check as i am confident the numbers will be good. i am non seq with a downpipe and a power fc w/ commander. i have put my car completely back together and it wont start. i have misplaced a pipe off the intercooler, so i dont have the turbos in the loop yet. i have also had some issues with the wiring harness. i dont have to oil pressure sensor hooked up. would this cause the car to not start? i have fuel, air, and spark. what else should i look for. im going to break down the top side of the engine and take a long hard look at the wiring harness. other than that and the compression test im at a dead end. if anyone has any other ideas i would like to hear them. also, when i press down the pedal while trying to start, the car sounds like it really wants to start. please help any input would be grateful.

#3

It sounds like it's flooded. What was your side seal to corner seal clearance? Did you replace all the springs? Did the rotor housings have any chrome flake? Did you lubricate the housings with engine oil while you were putting it together? Lubricate them well and then turn the engine over at least 15 to 20 full rotations by hand. You did turn the engine over by hand to verify strong "puff" sounds right? I guess it's late for that now though.

I'd start by pulling the plugs and turning the starter to get any fuel out of there. Then feed a small amount of oil or ATF (be careful with ATF, don't let it sit in there for a while) into the plug holes or through a vacuum line.

As for the compression test, just make sure the numbers are even on each face even if they are low. And you are positive that the fuel lines aren't reversed and the crank angle sensors are good (rpm reading on Power FC during cranking)?

I'd start by pulling the plugs and turning the starter to get any fuel out of there. Then feed a small amount of oil or ATF (be careful with ATF, don't let it sit in there for a while) into the plug holes or through a vacuum line.

As for the compression test, just make sure the numbers are even on each face even if they are low. And you are positive that the fuel lines aren't reversed and the crank angle sensors are good (rpm reading on Power FC during cranking)?

#4

Full Member

Thread Starter

iTrader: (3)

Join Date: Sep 2008

Location: Colorado Springs, Co

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

i believe i went with a .05 mm gap for the side seal clearance. i replaced all the springs. rotor housings had a small amount of flake on them, but nothing too serious. the housings were lubricated with marvel mystery oil. i turned the motor over and i get strong puffs out of the spark plug holes. the puff actually sounds louder when i cranked it w/o the spark plugs in then when i took it out. the front rotor housing plugs were kinda dry and the rear had a little fuel residue on the plugs when i pulled them. im going to go ahead and replace all the plugs and try it again. im also going to pull the UIM and double check all the plugs on the wiring harness. there are a fair amount of plugs not used due to the non seq mod. i do get rpm readings on the PFC. its around 300 when cranking, so i know that the sensors there are good.

just a question though, will the car still crank with the oil pressure sensor un plugged? i also dont have the turbos plugged in. just straight from the elbow. i am assuming this will mess with the vaccum to the lines plugged in before the throttle body. usually this means rough idle, but can it cause the motor to not start?

just a question though, will the car still crank with the oil pressure sensor un plugged? i also dont have the turbos plugged in. just straight from the elbow. i am assuming this will mess with the vaccum to the lines plugged in before the throttle body. usually this means rough idle, but can it cause the motor to not start?

Trending Topics

#8

Full Member

Thread Starter

iTrader: (3)

Join Date: Sep 2008

Location: Colorado Springs, Co

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

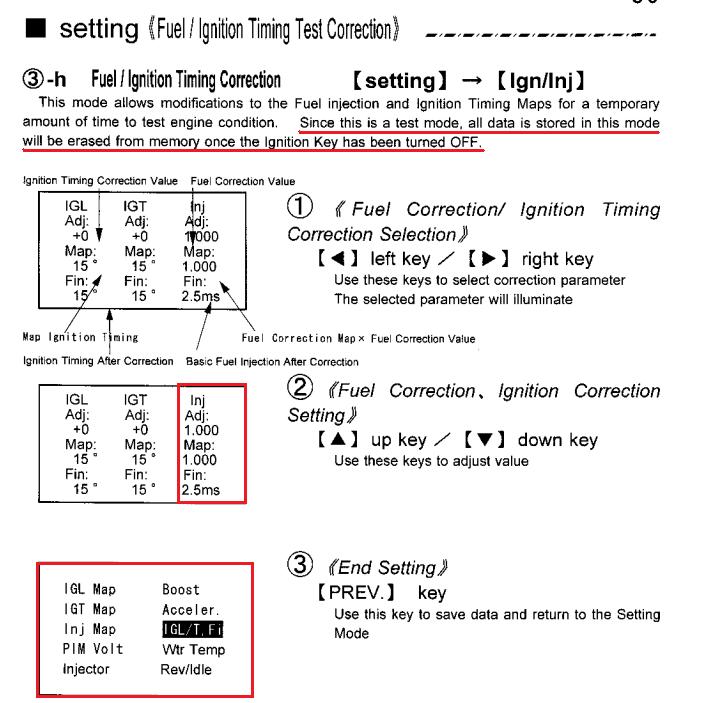

ok, so good news first. the car started after a little coaxing and pulling it while riding the clutch. but it has a non existant idle and likes to pulse when holding the accelerator steady. also when you press it to the floor, it wont rev past 2400 rpm then drop off to about 2k then back up to 2400 and so on until it dies after about 5 minutes. we have narrowed it down to a fule problem, and more than likely in the injectors since we are getting fuel out of the hose when you turn the key on, and the PFC injector duty is retardedly low for both starting and trying to keep it running. im going to go ahead and check the plugs going to the injectors and also the vacuum lines to the regulator even though i just went over the diagram again.

on a separate note, i am leaking coolant out of the big black nipple on the rear iron. the clips are broken and i need a new one. anyone know where i can get one fast, and what it is called?

on a separate note, i am leaking coolant out of the big black nipple on the rear iron. the clips are broken and i need a new one. anyone know where i can get one fast, and what it is called?

#12

Full Member

Thread Starter

iTrader: (3)

Join Date: Sep 2008

Location: Colorado Springs, Co

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

i am reading water temp properly. i did remove the thermowax, but i never had the problem of the reving before the rebuild. it would just not want to idle when it was cold. not to mention the water temp hasnt been below 20 degrees C and has been up to 60 C.

#14

Full Member

Thread Starter

iTrader: (3)

Join Date: Sep 2008

Location: Colorado Springs, Co

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

ok, so i found the problem. one of the injector plugs doesnt have a clip on it to hold it in place which allowed it to work its way off the plug just enough to not get good contact. so i plugged it in and was getting a good injector percentage when reved and runs fine.

on the way home though, i guess the coolant hasnt filtered through the engine completely, so i am getting a constant coolant light and buzzer. not to mention it is really liking to overheat. any have any tricks to completely fill the engine before it gets too hot to pull the cap?

on the way home though, i guess the coolant hasnt filtered through the engine completely, so i am getting a constant coolant light and buzzer. not to mention it is really liking to overheat. any have any tricks to completely fill the engine before it gets too hot to pull the cap?

#16

DO NOT let that motor overheat. You'll have to rebuild it again if you let it get too hot. Go get an extended Funnel from autozone. and bleed out all the air bubbles from your coolant system. Undo the water line to your throttle body and bleed out the air. It might take a while....but it needs to be done. Or you could let the car idle and turn on your heater. rev it up to about 3k for about 2 min and then idle again for another couple. turn it off and bleed the air from your AST or fill it with coolant. The second method takes a bunch of times to get all the air out... so i'd suggest the first. Good luck...and again.. don't let the motor get hot.

#18

#19

Full Member

Thread Starter

iTrader: (3)

Join Date: Sep 2008

Location: Colorado Springs, Co

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

i have successfully bleed the coolant system. it doesnt overheat at all, but i am still getting the coolant buzzer. a plug did break off the wiring harness during the rebuild i am assuming that is it. how do you bypass the buzzer? at least as a temp fix until i can fix the plug.

also i dont have any runnin lights or dash lights. i have checked all the fuses, no dice. any ideas?

also i dont have any runnin lights or dash lights. i have checked all the fuses, no dice. any ideas?

#21

Full Member

Thread Starter

iTrader: (3)

Join Date: Sep 2008

Location: Colorado Springs, Co

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

oh man dont say that. after all the money and time i just put into this thing, last thing i want to do is that lol. ill see what i can do to repair this possibly, and start looking for a new harness.

Thread

Thread Starter

Forum

Replies

Last Post

smikels

2nd Generation Specific (1986-1992)

3

08-18-15 01:26 PM

ncds_fc

New Member RX-7 Technical

1

08-15-15 10:06 AM