dual Walbro wiring

#1

Teddy bears have claws

Thread Starter

iTrader: (2)

Join Date: Aug 2004

Location: Eugene/Springfield, OR

Posts: 360

Likes: 0

Received 0 Likes

on

0 Posts

dual Walbro wiring

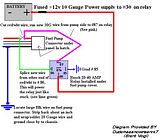

I'm in the process of intalling dual walbro's and was wondering how I need to wire them. I already rewired my fuel pump and bent the speed relay to give the constant 12v, but I was just wondering if that was enough, or if I need to run separate wiring to the second pump.

Thanks.

Thanks.

#4

Teddy bears have claws

Thread Starter

iTrader: (2)

Join Date: Aug 2004

Location: Eugene/Springfield, OR

Posts: 360

Likes: 0

Received 0 Likes

on

0 Posts

I did the rewire like the guy in post #10 in this thread: https://www.rx7club.com/showthread.p...el+pump+rewire

If I run a parallel power wire and upgrade the ground like described in post #17 in this thread: https://www.rx7club.com/showthread.p...el+pump+rewire

that should give me about the same effect of running bigger wires to each pump, correct? Would this way work well to power two walbros?

I'm not trying to argue against the ways you guys suggested, I'm just trying to find the cleanest install.

Thanks.

If I run a parallel power wire and upgrade the ground like described in post #17 in this thread: https://www.rx7club.com/showthread.p...el+pump+rewire

that should give me about the same effect of running bigger wires to each pump, correct? Would this way work well to power two walbros?

I'm not trying to argue against the ways you guys suggested, I'm just trying to find the cleanest install.

Thanks.

#5

I never payed close attention to the factory circuit for the fuel pump. But it's grossly inadequate for one fuel pump, and even worse for 2. Whether maintaining some of the factory wiring and replacing or adding more in some areas is sufficient i couldn't say. But I know that running a direct 10 gauge wire for both positive and negative will insure that both pumps are always supplied with the most voltage possible. Some black wiring loom will make any install clean. And the rest of the connections are made under the fuel pump cover. Also the wiring from the white connector on top to the fuel pump bracket to the fuel pump is rather puny, i used it with my first rewire for a single pump, but not for the duals.

#7

Teddy bears have claws

Thread Starter

iTrader: (2)

Join Date: Aug 2004

Location: Eugene/Springfield, OR

Posts: 360

Likes: 0

Received 0 Likes

on

0 Posts

How did you guys seal the new holes with the wires going to the pumps?

I tried JB Weld first, and it started leaking between the bulkhead thing and the JB Weld, then I sanded down to bare metal and tried using Seal-All and grommets, as suggested by Summit. Now its leaking from where the seal-all touches the grommet.

I tried JB Weld first, and it started leaking between the bulkhead thing and the JB Weld, then I sanded down to bare metal and tried using Seal-All and grommets, as suggested by Summit. Now its leaking from where the seal-all touches the grommet.

Trending Topics

#9

Teddy bears have claws

Thread Starter

iTrader: (2)

Join Date: Aug 2004

Location: Eugene/Springfield, OR

Posts: 360

Likes: 0

Received 0 Likes

on

0 Posts

Ok,I've been having a hell of a time getting these damn wires to seal. I finally have it mostly using Permatex gas tank repair kit epoxy and Seal-All, but now the gas is actually pushing through the inside of my wires. I just put Seal-All on the ends of the wires, where the insulation ends, but I'm starting to wonder if there isn't something else going. Does it sound like I have too much pressure in my tank?

#10

try this link for some info. not sure how helpful it is but..

http://www.reganrotaryracing.com/fddualfuelpumps.htm

http://www.reganrotaryracing.com/fddualfuelpumps.htm

#11

Teddy bears have claws

Thread Starter

iTrader: (2)

Join Date: Aug 2004

Location: Eugene/Springfield, OR

Posts: 360

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the link. I wish I'd known about those electrical things when I started. The way I have things routed, though, I don't think I can fit them in there.

#12

That sure is some stubborn gasoline, i didnt have any of these issues when i did mine. I say you hook your wires up to the fuel rail and use it as another supply line haha. Ok kidding aside, what about using crimp on ring terminals and shrink wrap the crimped section and solder the end closed. Make sure the fuel is out. Or try sealing the ends with the permatex.

Thread

Thread Starter

Forum

Replies

Last Post