NA 13b Warping Apex Seals! Need assistance..

#1

Junior Member

Thread Starter

NA 13b Warping Apex Seals! Need assistance..

First of all, thanks for giving this a read and offering your advice, I apologize for the length, I figure too much information is better than too little.

So here is the situation in a nutshell: I have a N/A 6 port 13b powered Miata that consistently warps apex seals and loses compression. I can say “consistently,” because I’ve pulled and refreshed the motor more than a few times now chasing this problem.. it only takes one session or race weekend and she’s toast. This is a dedicated road race car.

Background: I have been road racing second gen RX7’s for almost 20 years now. I consider myself a decent car builder / fabricator and competent engine builder though I am no tuner. I have never run into anything like this. A few years back I swapped a n/a 13b into a street miata, this car gave me years of reliable service (stock ecu). At some point I decided to build it into a race car and that’s where my problems started. I had always run Microtec in my RX7’s but my goal for this car necessitated something with more features, so I went Haltech Elite 1000. Haltech seemed like a popular choice and my team was running an Elite 2500 in an e36 race car with good results.

This particular 13b had been built by a very reputable shop and I had the same shop install the Elite and tune the car. – This tuner had been tuning my team’s cars for years with excellent results. First race weekend out and compression was down 30 psi and she wouldn’t start hot. While investigating, I found that my timing was properly zeroed however the timing would drift 5-6 degrees at high RPM. I thought this was my problem so we used the compensation table to keep everything zeroed. When I tore the motor down I found all apex seals had the warped banana shape where you can see light between them when stacked. There was no other damage. I rebuilt the engine, all new hard and soft seals and resurfaced parts and she did the same thing the next time out.

Suffice it to say, this process has repeated itself multiple times.. I put my head together with the tuner and others, we find the smoking gun, and it never is. Since the beginning I have tried two of practically everything – different engines built by different people (me now), different tuners, car has been fully stripped and rewired from scratch, I have even swapped to an Elite 1500. The common denominator appears to be the Haltech, but I have been foolishly stubborn in keeping it as I know people have good experiences with this box.. I can only imagine that a critical setting or something in the tune is off that my tuner is missing and that I don’t even know to look for. The thing is - the car dynos and runs beautifully – at least briefly. She puts down 190+ whp and gives no indication that anything is amiss.. until you check the compression after the session.

Lets go over the engine, I will also mention parts that I tried on previous iterations of the engine:

S5 6 port with S4 front cover

OMP disabled, 1 ounce per gal premix, always TCW-3 or Idemitsu

S5 Intake

Lightened and clearanced rotors, balanced rotating assembly

OEM apex seals (I have tried many brands now with the same result)

3rd gen oil pressure reg

Elite 1500, car fully wired using Haltech harness

Bosch wideband

IGN1A coils (stock coils previously)

BR10IEX Plugs (ran BUR9 previously)

Full Function hall effect trigger kit (ran FF VR kit and stock previously)

DW 300 fuel pump

Aeromotive Fuel Regulator

Siemans 60lb injectors (ran stock previously)

Racing Beat “custom” header kit to custom 3” exhaust

Racing Beat front pulley w/ timing marks

Engine bolts up to nearly stock miata drivetrain

Additional Notes:

· I have verified with a good timing light that there is no ignition drift at high RPM now. Car is only revved to about 8000 rpm.

· There is a knock sensor installed – I believe the tuner set it up with a decibel threshold approach – he knows not to knock a rotary on a dyno.

So there it is, I have attached my tune – We are running Haltech NSP software. I took the car out a few days ago for a track day – spent one session puttering around in traffic, and you guessed it, she lost compression.. I have attached a datalog from that session. Data was gathered from an Aim Solo 2 and I have attached the data in several file formats. There are a number of useful channels on there as the car has a lot of sensors. I believe we were running max advance of 24 degrees and a target AFR of 12.8.

Thanks for reading and for your input!

So here is the situation in a nutshell: I have a N/A 6 port 13b powered Miata that consistently warps apex seals and loses compression. I can say “consistently,” because I’ve pulled and refreshed the motor more than a few times now chasing this problem.. it only takes one session or race weekend and she’s toast. This is a dedicated road race car.

Background: I have been road racing second gen RX7’s for almost 20 years now. I consider myself a decent car builder / fabricator and competent engine builder though I am no tuner. I have never run into anything like this. A few years back I swapped a n/a 13b into a street miata, this car gave me years of reliable service (stock ecu). At some point I decided to build it into a race car and that’s where my problems started. I had always run Microtec in my RX7’s but my goal for this car necessitated something with more features, so I went Haltech Elite 1000. Haltech seemed like a popular choice and my team was running an Elite 2500 in an e36 race car with good results.

This particular 13b had been built by a very reputable shop and I had the same shop install the Elite and tune the car. – This tuner had been tuning my team’s cars for years with excellent results. First race weekend out and compression was down 30 psi and she wouldn’t start hot. While investigating, I found that my timing was properly zeroed however the timing would drift 5-6 degrees at high RPM. I thought this was my problem so we used the compensation table to keep everything zeroed. When I tore the motor down I found all apex seals had the warped banana shape where you can see light between them when stacked. There was no other damage. I rebuilt the engine, all new hard and soft seals and resurfaced parts and she did the same thing the next time out.

Suffice it to say, this process has repeated itself multiple times.. I put my head together with the tuner and others, we find the smoking gun, and it never is. Since the beginning I have tried two of practically everything – different engines built by different people (me now), different tuners, car has been fully stripped and rewired from scratch, I have even swapped to an Elite 1500. The common denominator appears to be the Haltech, but I have been foolishly stubborn in keeping it as I know people have good experiences with this box.. I can only imagine that a critical setting or something in the tune is off that my tuner is missing and that I don’t even know to look for. The thing is - the car dynos and runs beautifully – at least briefly. She puts down 190+ whp and gives no indication that anything is amiss.. until you check the compression after the session.

Lets go over the engine, I will also mention parts that I tried on previous iterations of the engine:

S5 6 port with S4 front cover

OMP disabled, 1 ounce per gal premix, always TCW-3 or Idemitsu

S5 Intake

Lightened and clearanced rotors, balanced rotating assembly

OEM apex seals (I have tried many brands now with the same result)

3rd gen oil pressure reg

Elite 1500, car fully wired using Haltech harness

Bosch wideband

IGN1A coils (stock coils previously)

BR10IEX Plugs (ran BUR9 previously)

Full Function hall effect trigger kit (ran FF VR kit and stock previously)

DW 300 fuel pump

Aeromotive Fuel Regulator

Siemans 60lb injectors (ran stock previously)

Racing Beat “custom” header kit to custom 3” exhaust

Racing Beat front pulley w/ timing marks

Engine bolts up to nearly stock miata drivetrain

Additional Notes:

· I have verified with a good timing light that there is no ignition drift at high RPM now. Car is only revved to about 8000 rpm.

· There is a knock sensor installed – I believe the tuner set it up with a decibel threshold approach – he knows not to knock a rotary on a dyno.

So there it is, I have attached my tune – We are running Haltech NSP software. I took the car out a few days ago for a track day – spent one session puttering around in traffic, and you guessed it, she lost compression.. I have attached a datalog from that session. Data was gathered from an Aim Solo 2 and I have attached the data in several file formats. There are a number of useful channels on there as the car has a lot of sensors. I believe we were running max advance of 24 degrees and a target AFR of 12.8.

Thanks for reading and for your input!

The following users liked this post:

Relisys190 (03-27-23)

The following 2 users liked this post by BLUE TII:

diabolical1 (03-21-23),

need-a-t2 (03-23-23)

#3

Old [Sch|F]ool

You are not running enough oil IMO.

The stock MOP drools the oil directly onto the rotor housing surface. Premixing puts the oil into the airstream with the fuel and most of it goes right out the exhaust without ever touching the inside of the engine.

In a racing environment, with premix only, I like to see a minimum of 2oz/gallon. I usually run closer to 2.5-3oz/gallon and would like to run more but the exhaust starts to get visible.

The stock MOP drools the oil directly onto the rotor housing surface. Premixing puts the oil into the airstream with the fuel and most of it goes right out the exhaust without ever touching the inside of the engine.

In a racing environment, with premix only, I like to see a minimum of 2oz/gallon. I usually run closer to 2.5-3oz/gallon and would like to run more but the exhaust starts to get visible.

Last edited by peejay; 03-21-23 at 07:11 PM.

The following 3 users liked this post by peejay:

The following users liked this post:

diabolical1 (03-21-23)

#5

Junior Member

Thread Starter

Thanks for the replies so far guys

In regard to premix: I have reached out to other teams and all the ITS / STL / EP racers in my area run 4-5 oz premix per 5 gal fuel jug, no OMP. We are strictly talking n/a 13b powered cars. I have run 1oz per gallon in all of our ITS / STL RX7's for years. These cars get punished season after season with the occasional 12 hour enduro thrown in and we have not seen any abnormal wear or compression loss. Not saying your wrong of course - I'm sure there are many rotaries built and raced in such a way that requires more premix, and I'm not against running more - I just dont believe it to be the root cause of the problem in this case. We have had success with TCW-3 2-stroke premix, though we stick with Idemitsu for the most part these days because it passes the post race fuel test at SCCA Majors / Super Tour events.

Agreed on the plugs - I love the colder NGK race plugs and we use 11's exclusively on the 13b powered EP car. I have experimented with everything from 9 to 11 heat range on ITS / STL motors. The 10s in the car now are reading beautifully and show no evidence of being a source of pre-ignition.

Interesting stuff there about the ESP vs NSP. We have only been running NSP this last rebuild - all the previous failures were on ESP of various firmwares.

In regard to premix: I have reached out to other teams and all the ITS / STL / EP racers in my area run 4-5 oz premix per 5 gal fuel jug, no OMP. We are strictly talking n/a 13b powered cars. I have run 1oz per gallon in all of our ITS / STL RX7's for years. These cars get punished season after season with the occasional 12 hour enduro thrown in and we have not seen any abnormal wear or compression loss. Not saying your wrong of course - I'm sure there are many rotaries built and raced in such a way that requires more premix, and I'm not against running more - I just dont believe it to be the root cause of the problem in this case. We have had success with TCW-3 2-stroke premix, though we stick with Idemitsu for the most part these days because it passes the post race fuel test at SCCA Majors / Super Tour events.

Agreed on the plugs - I love the colder NGK race plugs and we use 11's exclusively on the 13b powered EP car. I have experimented with everything from 9 to 11 heat range on ITS / STL motors. The 10s in the car now are reading beautifully and show no evidence of being a source of pre-ignition.

Interesting stuff there about the ESP vs NSP. We have only been running NSP this last rebuild - all the previous failures were on ESP of various firmwares.

#7

Junior Member

Thread Starter

Using a DTC500 compression tester I saw about 110 on all 6 faces with no more than maybe 4 psi variation across faces. Car was not beat up on the dyno - tuner did maybe 2 full power pulls. In previous failures I have noted the front housing loosing compression a little faster than the rear though ultimately both are losing compression.

Trending Topics

#8

OEM apex seals (I have tried many brands now with the same result)

but can appreciate not wanting to pay to play with them

the Haltech angle is an interesting point

is your ecu setup to cut fuel off-throttle? No fuel when using premix means no oil either. This came up in recent similar threads.

.

Last edited by TeamRX8; 03-22-23 at 08:14 PM.

The following 2 users liked this post by TeamRX8:

diabolical1 (03-23-23),

peejay (03-22-23)

#9

Old [Sch|F]ool

Oh MY yes.... never DFCO when relying on premix!

The road racers used to turn the idle up on their bridgeys to about 2200-2500 not because the engines needed to idle that high, but to ensure airflow through the engine off throttle so the seals would not oil starve. (And now, pieces fitting into a puzzle, I wonder if this is part of why Mazda's Le Mans efforts had MOPs, because to win Le Mans you need maximum fuel economy, and if you have a MOP you can DFCO)

SAAB did an end run around the problem on their 2 stroke models by putting a one way clutch into the transmission, so the transmission couldn't drive the engine.

The road racers used to turn the idle up on their bridgeys to about 2200-2500 not because the engines needed to idle that high, but to ensure airflow through the engine off throttle so the seals would not oil starve. (And now, pieces fitting into a puzzle, I wonder if this is part of why Mazda's Le Mans efforts had MOPs, because to win Le Mans you need maximum fuel economy, and if you have a MOP you can DFCO)

SAAB did an end run around the problem on their 2 stroke models by putting a one way clutch into the transmission, so the transmission couldn't drive the engine.

#11

Mazda ran OMP on all their endurance race cars since they made the mistake of eliminating OMP on their 1967 Cosmo Sport endurance race car.

They had to remove oil from the sump several times in the pits as the oil level rose due to the usual fuel dilution.

Source- Yamaguchi RX7 book.

They had to remove oil from the sump several times in the pits as the oil level rose due to the usual fuel dilution.

Source- Yamaguchi RX7 book.

#13

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,844

Received 2,606 Likes

on

1,849 Posts

Mazda ran OMP on all their endurance race cars since they made the mistake of eliminating OMP on their 1967 Cosmo Sport endurance race car.

They had to remove oil from the sump several times in the pits as the oil level rose due to the usual fuel dilution.

Source- Yamaguchi RX7 book.

They had to remove oil from the sump several times in the pits as the oil level rose due to the usual fuel dilution.

Source- Yamaguchi RX7 book.

The following users liked this post:

diabolical1 (03-31-23)

#14

Junior Member

Thread Starter

doubting that’d be the case with Iannetti ceramic seals.

but can appreciate not wanting to pay to play with them

the Haltech angle is an interesting point

is your ecu setup to cut fuel off-throttle? No fuel when using premix means no oil either. This came up in recent similar threads.

.

but can appreciate not wanting to pay to play with them

the Haltech angle is an interesting point

is your ecu setup to cut fuel off-throttle? No fuel when using premix means no oil either. This came up in recent similar threads.

.

#15

Junior Member

Thread Starter

doubting that’d be the case with Iannetti ceramic seals.

but can appreciate not wanting to pay to play with them

the Haltech angle is an interesting point

is your ecu setup to cut fuel off-throttle? No fuel when using premix means no oil either. This came up in recent similar threads.

.

but can appreciate not wanting to pay to play with them

the Haltech angle is an interesting point

is your ecu setup to cut fuel off-throttle? No fuel when using premix means no oil either. This came up in recent similar threads.

.

#18

Old [Sch|F]ool

There is also a hysteresis involved, here. If you have sufficient premix oiling for light load work, the engine will handle short bursts with no issue. So on the street, 1:128 is fine because you spend 99.9% of the time putting around where Mazda was drooling about 1/3rd as much into the engine.

On the TRACK, however, you're under heavy load for 20 minutes straight, maybe more. You need more oil because you've shifted from putting around with an occasional burst, to the other extreme. You have to alter your premix percentage accordingly.

I have also noted through experimentation that horsepower increases measurably the more oil is in the fuel. After I started going crazy with the oil, I noted that my rotor housings would look a lot less "smeared" and they stopped getting that weird wavy wear you see on high power engines. Still no carbon deposits despite running as much as 1:50 on a regular basis.

Racing Beat recommended as much as 6oz/gallon (1:20) in endurance racing engines.

Last edited by peejay; 03-27-23 at 08:47 PM.

The following 4 users liked this post by peejay:

Black Knight RX7 FC3S (04-15-23),

diabolical1 (03-31-23),

neit_jnf (03-27-23),

Relisys190 (03-27-23)

#20

On the street, 1oz/gallon (1:128) is fine, because under low load conditions Mazda was injecting about 1:400, directly to the rotor housing. Under high load conditions the oil volume injected went up, of course.

There is also a hysteresis involved, here. If you have sufficient premix oiling for light load work, the engine will handle short bursts with no issue. So on the street, 1:128 is fine because you spend 99.9% of the time putting around where Mazda was drooling about 1/3rd as much into the engine.

On the TRACK, however, you're under heavy load for 20 minutes straight, maybe more. You need more oil because you've shifted from putting around with an occasional burst, to the other extreme. You have to alter your premix percentage accordingly.

I have also noted through experimentation that horsepower increases measurably the more oil is in the fuel. After I started going crazy with the oil, I noted that my rotor housings would look a lot less "smeared" and they stopped getting that weird wavy wear you see on high power engines. Still no carbon deposits despite running as much as 1:50 on a regular basis.

Racing Beat recommended as much as 6oz/gallon (1:20) in endurance racing engines.

There is also a hysteresis involved, here. If you have sufficient premix oiling for light load work, the engine will handle short bursts with no issue. So on the street, 1:128 is fine because you spend 99.9% of the time putting around where Mazda was drooling about 1/3rd as much into the engine.

On the TRACK, however, you're under heavy load for 20 minutes straight, maybe more. You need more oil because you've shifted from putting around with an occasional burst, to the other extreme. You have to alter your premix percentage accordingly.

I have also noted through experimentation that horsepower increases measurably the more oil is in the fuel. After I started going crazy with the oil, I noted that my rotor housings would look a lot less "smeared" and they stopped getting that weird wavy wear you see on high power engines. Still no carbon deposits despite running as much as 1:50 on a regular basis.

Racing Beat recommended as much as 6oz/gallon (1:20) in endurance racing engines.

I'm speaking about the track. I build engines with ceramics, steels, and carbons (when they've been available/found/customer has wanted), I dyno them on both my engine dyno and hubs and I'm still of the opinion that 3 oz to the gallon (1:40) is far from a 'need' and is probably just as over the top as the idea that people say that a ported rotary *needs* to have an annoying 1700 rpm 'brap' to function (we live in the age of technology, we don't have to have locked timing at idle in the 25* + range). I also never suggested running 128:1 - nor have I mentioned the ratio I run on my engines or suggestion to my customers (not that it's a magic number, just pointing out fact).

With regards to Jim Mederer's research in the past and RacingBeats published numbers there're a host of things that I've found to not add up doing my own testing on both personal and customers engines. This isn't to say that if you follow their advice your flirting with disaster just that there are more than a couple conclusions and suggestions that - to me - haven't particularly been landed on in an empirical fashion however they tend to be passed on as if they were cooked up in a well controlled lab. They weren't, they had facilities such as mine - and I haven't noticed horsepower deviations based upon 'over' oiling in the dyno tank (over meaning I accidently doubled up) nor markedly reduced wear when going to pretty batty with 1:20.

Anywhosit, If people feel safer running 1:40 that's fine, I'm not going to walk up to them and say 'you're doing it wrong', however when I see the words 'need' etc with no testing or real info to back it up, I can't help but disagree. The same can be said for those who spread the rumor that the second you stop using Idemitsu as your premix you're going to destroy your engine.

Last edited by dguy; 03-28-23 at 11:50 AM.

The following 2 users liked this post by dguy:

gracer7-rx7 (04-07-23),

Speed of light (03-28-23)

#21

Old [Sch|F]ool

I can only report my findings. I do use steel seals, not iron Mazda seals. The steel seem to need more oil to keep the rotor housings happy. The main thing that wears in my engines are the side seals and the underside of the apex seals, where the springs contact.

I have met racers who said the oil hurts power so they remove the MOP and run straight gasoline and the engines last fine. "Lasts fine" to me means 50k miles of street and competition driving, "lasts fine" to them means it makes it through five or six drag meets.

I have met racers who said the oil hurts power so they remove the MOP and run straight gasoline and the engines last fine. "Lasts fine" to me means 50k miles of street and competition driving, "lasts fine" to them means it makes it through five or six drag meets.

Last edited by peejay; 03-28-23 at 12:08 PM.

#22

Junior Member

Thread Starter

That is correct, I have run Haltech Elite on stock CAS, then FFE reluctor, then FFE hall effect, each on a fresh engine build. All three exhibited significant ignition drift (as haltech is known for). I expected the final move to hall effect to be free of this drift but it had the same drift as the others. As you can see in the tune, we used the TDC offset angle table to compensate. The ignition drifts increasingly at a linear rate - by 8000 rpm we are correcting 5 degrees (again typical from what I gather from other Elite users). Early on we were using run of the mill timing lights to verify our ignition. They would stay true and then begin to scatter by high rpms - this however was a shortcoming of the light, not the ignition. By the end we were using the es-125 timing light as recommended by Mazdatrix. This superb light stayed true all the way to 9k and showed our ignition was hitting dead on throughout the full rev range.

#23

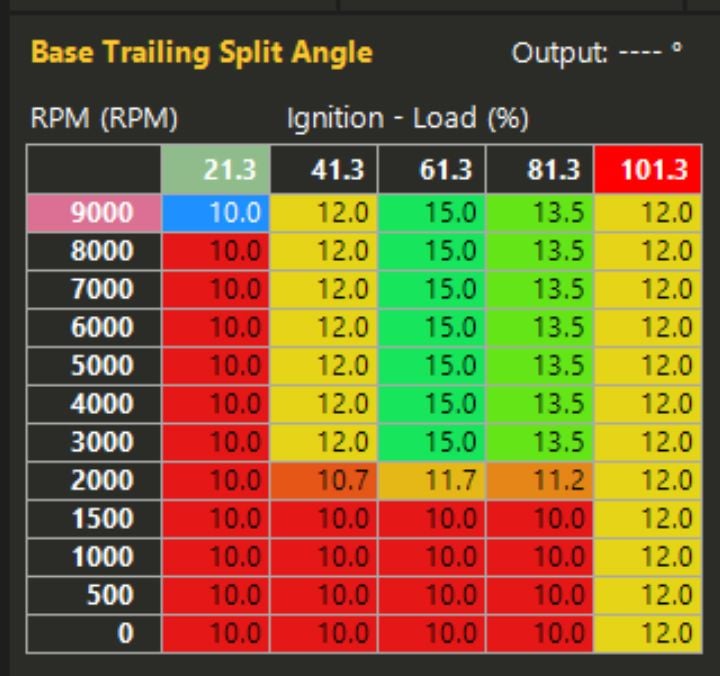

For the benefit of everyone here can you post screenshots of your timing maps? I don't have the Haltech software up and running right now. I did take a quick glance at your log, and I'm seeing things like 6000rpm with 24 degrees timing and .95 lambda / over 14:1 AFR , 5000 rpm and 12.8 AFR as you're saying.

I'm really concerned about how lean you are. It's like... internet forum rule of thumb AFR, not actual known proven reliable AFR. Known proven reliable AFR is - SURPRISE! , stock tune... in the 11's and 10's. Also you have high compression rotors, so you've got a lot less margin for error.

If it were my car, the first thing I'd do beyond mechanical checks is I'd set it to run 11.0:1 in all area at WOT, and all areas from 4000rpm to max revs. Are you going to lose power? Of course. What's faster than a car that runs 12.8:1 though? A car that runs 11.0:1 and doesn't blow up. You could lean it out a bit later if you want to.

I'm really concerned about how lean you are. It's like... internet forum rule of thumb AFR, not actual known proven reliable AFR. Known proven reliable AFR is - SURPRISE! , stock tune... in the 11's and 10's. Also you have high compression rotors, so you've got a lot less margin for error.

If it were my car, the first thing I'd do beyond mechanical checks is I'd set it to run 11.0:1 in all area at WOT, and all areas from 4000rpm to max revs. Are you going to lose power? Of course. What's faster than a car that runs 12.8:1 though? A car that runs 11.0:1 and doesn't blow up. You could lean it out a bit later if you want to.

Last edited by arghx; 03-31-23 at 06:44 AM.

The following 3 users liked this post by arghx:

#24

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,844

Received 2,606 Likes

on

1,849 Posts

it seems like this base got covered but its possible to assemble the FFE setup incorrectly. https://www.rx7club.com/single-turbo.../#post12554644

i haven't had one in my hand, but the FC pullies vary, and the FFE setup doesn't fix that part, so it needs to be checked

on the AFR front, 12.8 should be ok, but 13.9 probably isn't. its the kind of thing where if you had 1 dyno run at 13.9, it would be ok, but a 20 minute session probably not. i agree with Arghx, i'd start at some known good value, and make it consistent everywhere, the stock tune is about 12.5 at 4000rpm, and then gradually gets richer as it revs higher (it caps EGT at 700c). in my experience if you hit 12.5 @4000 and just have it stay at 12.5 the whole way up that is a lot happier, EGT's will go up, but should stay within reason (you want to keep it ~900c or less). we used to run the race car in the low 13's but the power difference between 13.2 and 12.5 is really small. we got to the point where even the piston engines were high 12's, mid 13's and lots of timing will blow a honda up too....

if you're on the dyno you might also try timing at like 18, 20, 22 and 24 and lay the charts on top of each other, engine will tell you what it wants.

i haven't had one in my hand, but the FC pullies vary, and the FFE setup doesn't fix that part, so it needs to be checked

on the AFR front, 12.8 should be ok, but 13.9 probably isn't. its the kind of thing where if you had 1 dyno run at 13.9, it would be ok, but a 20 minute session probably not. i agree with Arghx, i'd start at some known good value, and make it consistent everywhere, the stock tune is about 12.5 at 4000rpm, and then gradually gets richer as it revs higher (it caps EGT at 700c). in my experience if you hit 12.5 @4000 and just have it stay at 12.5 the whole way up that is a lot happier, EGT's will go up, but should stay within reason (you want to keep it ~900c or less). we used to run the race car in the low 13's but the power difference between 13.2 and 12.5 is really small. we got to the point where even the piston engines were high 12's, mid 13's and lots of timing will blow a honda up too....

if you're on the dyno you might also try timing at like 18, 20, 22 and 24 and lay the charts on top of each other, engine will tell you what it wants.

The following users liked this post:

diabolical1 (04-05-23)

#25

Junior Member

Thread Starter

For the benefit of everyone here can you post screenshots of your timing maps? I don't have the Haltech software up and running right now. I did take a quick glance at your log, and I'm seeing things like 6000rpm with 24 degrees timing and .95 lambda / over 14:1 AFR , 5000 rpm and 12.8 AFR as you're saying.

I'm really concerned about how lean you are. It's like... internet forum rule of thumb AFR, not actual known proven reliable AFR. Known proven reliable AFR is - SURPRISE! , stock tune... in the 11's and 10's. Also you have high compression rotors, so you've got a lot less margin for error.

If it were my car, the first thing I'd do beyond mechanical checks is I'd set it to run 11.0:1 in all area at WOT, and all areas from 4000rpm to max revs. Are you going to lose power? Of course. What's faster than a car that runs 12.8:1 though? A car that runs 11.0:1 and doesn't blow up. You could lean it out a bit later if you want to.

I'm really concerned about how lean you are. It's like... internet forum rule of thumb AFR, not actual known proven reliable AFR. Known proven reliable AFR is - SURPRISE! , stock tune... in the 11's and 10's. Also you have high compression rotors, so you've got a lot less margin for error.

If it were my car, the first thing I'd do beyond mechanical checks is I'd set it to run 11.0:1 in all area at WOT, and all areas from 4000rpm to max revs. Are you going to lose power? Of course. What's faster than a car that runs 12.8:1 though? A car that runs 11.0:1 and doesn't blow up. You could lean it out a bit later if you want to.