Watts Link: vague feeling. OEM vs Urethane?

#1

Watts Link: vague feeling. OEM vs Urethane?

Since my last track day in December I've been noticing that the rear end of my 85' has an oddly vague feeling about it in the turns around town. It's like it is about to step out while I'm going around a turn, but it can be felt at low speeds and only happens for a quick moment.

Today I gave the rear of my car a quick 'hip check' and I went wide eyes as the rear kept shaking side to side like a fish for a few seconds. I thought this motion was from the tire sidewalls, but it is accompanied by a soft clunking sound.

Bouncing up and down on the back won't produce this motion. So the shocks seem to be doing their job.

It's raining today, but after it dries out, I'm going to jack up the car and take a look around the watts linkage bushings.

They are original, so likely gone from the the track day abuse and may have been a factor in my 3 spinouts around the downhill off-camber turn.

(That and my inexperience)

Full RB suspension. But I didn't touch the watts bushings.

Tha Mazdatrix site recommends keeping OEM rubber bushings, but that means buying the entire link components and is very $$$$.

Urethane bushings are much cheaper than getting new links with the rubber pressed in.

Ride quality is not an issue for me since this is my track car in training.

Does anyone have an opinion between OEM vs Urethane bushings for Watts Linkage?

Today I gave the rear of my car a quick 'hip check' and I went wide eyes as the rear kept shaking side to side like a fish for a few seconds. I thought this motion was from the tire sidewalls, but it is accompanied by a soft clunking sound.

Bouncing up and down on the back won't produce this motion. So the shocks seem to be doing their job.

It's raining today, but after it dries out, I'm going to jack up the car and take a look around the watts linkage bushings.

They are original, so likely gone from the the track day abuse and may have been a factor in my 3 spinouts around the downhill off-camber turn.

(That and my inexperience)

Full RB suspension. But I didn't touch the watts bushings.

Tha Mazdatrix site recommends keeping OEM rubber bushings, but that means buying the entire link components and is very $$$$.

Urethane bushings are much cheaper than getting new links with the rubber pressed in.

Ride quality is not an issue for me since this is my track car in training.

Does anyone have an opinion between OEM vs Urethane bushings for Watts Linkage?

#3

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,800

Received 2,574 Likes

on

1,830 Posts

i looked at the Watts in mine, and you need a soft bushing in there.

since the upper links are shorter than the lower links the pinion angle actually changes as the suspension moves up and down, IE the axle actually needs to pivot.

so the watts links actually need to rotate a little, or if you like its a multi axis pivot.

a firmer bushing is actually going to make it harder for things to pivot, so it'll make things worse.

back in the olden days, the Pro7 people used to buy new watts links, and then use a jamb nut so the links were as loose as possible.

since the upper links are shorter than the lower links the pinion angle actually changes as the suspension moves up and down, IE the axle actually needs to pivot.

so the watts links actually need to rotate a little, or if you like its a multi axis pivot.

a firmer bushing is actually going to make it harder for things to pivot, so it'll make things worse.

back in the olden days, the Pro7 people used to buy new watts links, and then use a jamb nut so the links were as loose as possible.

#4

its supposed to do that

Going to a tri-link and using urethane bushings in the watts makes an amazing difference. Even farther with a tri-link and panhard is also a noticeable improvement.

Isaac

Isaac

#5

Does anyone have a preferred source to get a tri-link or panhard bar?

I'm up for cutting and welding if need be.

I remember hearing talking in the past about how strange the watts link can be, even binding under track conditions. Maybe now is as good time as any to consider alternatives.

I'm up for cutting and welding if need be.

I remember hearing talking in the past about how strange the watts link can be, even binding under track conditions. Maybe now is as good time as any to consider alternatives.

#6

An adjustable panhard would be the way to go IMHO.

If set up correctly they shouldn't introduce any bind. The bar has to be parallel to the axle in both planes. Most use a Spherical or Heim joint to prevent any bind as the axle cycles through it's range of motion. You just have to make sure the joints don't hit and bind when the axle moves through it's arc of motion.

There is a slight amount of movement introduced when the axle moves up and down from the centered position, which is why a longer bar is better than a short bar (less movement).

I got my bar through G Force Engineering, unfortunately he retired and they're no longer available. Unless he still has some old stock on hand?

I haven't had any problems with mine, but I probably haven't pushed it as hard as it sounds like you have. They're not that hard to fabricate yourself if you have the patience to do lots of measuring and fitting.

The three link is strictly custom as far as I know, at least I didn't see anyone selling kits. I researched what guys are running on the track and planned mine accordingly. I'm using equal length arms to get rid of the pinion angle change, there are different schools of thought on arm lengths and angles.

3 Link Rear Suspension System

This is one of the links I was looking at when researching my mods. Also read up on 4 links, but they were a lot more complicated with very little advantage. The good part about 3 links in our cars is that we have no back seat, therefor losing rear seat room is not an issue. Just my thoughts.

If set up correctly they shouldn't introduce any bind. The bar has to be parallel to the axle in both planes. Most use a Spherical or Heim joint to prevent any bind as the axle cycles through it's range of motion. You just have to make sure the joints don't hit and bind when the axle moves through it's arc of motion.

There is a slight amount of movement introduced when the axle moves up and down from the centered position, which is why a longer bar is better than a short bar (less movement).

I got my bar through G Force Engineering, unfortunately he retired and they're no longer available. Unless he still has some old stock on hand?

I haven't had any problems with mine, but I probably haven't pushed it as hard as it sounds like you have. They're not that hard to fabricate yourself if you have the patience to do lots of measuring and fitting.

The three link is strictly custom as far as I know, at least I didn't see anyone selling kits. I researched what guys are running on the track and planned mine accordingly. I'm using equal length arms to get rid of the pinion angle change, there are different schools of thought on arm lengths and angles.

3 Link Rear Suspension System

This is one of the links I was looking at when researching my mods. Also read up on 4 links, but they were a lot more complicated with very little advantage. The good part about 3 links in our cars is that we have no back seat, therefor losing rear seat room is not an issue. Just my thoughts.

#7

I finally got the chance to put the car up into the air to check things out. Oh wow, I can actually pull bits of rubber out from the upper and lower links. It's amazing what a few track days will do to your car!

So I'm going to rebuild the entire rear suspension now.

It's about 5x's the price to go with rubber bushings vs polyurethane. So I'll give the urethane a try although it's not recommended. Urethane has been good in my other cars. I can always go back to rubber bushings in the future.

I like the idea of fabricating my own panhard bar.

I found lots of videos on youtube showing home made tricks for pressing out old bushings.

So I'm going to rebuild the entire rear suspension now.

It's about 5x's the price to go with rubber bushings vs polyurethane. So I'll give the urethane a try although it's not recommended. Urethane has been good in my other cars. I can always go back to rubber bushings in the future.

I like the idea of fabricating my own panhard bar.

I found lots of videos on youtube showing home made tricks for pressing out old bushings.

Trending Topics

#8

Does anyone have a preferred source to get a tri-link or panhard bar?

I'm up for cutting and welding if need be.

I remember hearing talking in the past about how strange the watts link can be, even binding under track conditions. Maybe now is as good time as any to consider alternatives.

I'm up for cutting and welding if need be.

I remember hearing talking in the past about how strange the watts link can be, even binding under track conditions. Maybe now is as good time as any to consider alternatives.

#9

I've looked into going with a Panhard bar and at the tri-link setups. The best discussion I've seen so far can be found here: FB Rear suspension Geometry Problems/Options/Solutions

and here: Panhard bar setup

I'm working with a company to develop a readily available Panhard bar for the first gens here - hopefully it works out

and here: Panhard bar setup

I'm working with a company to develop a readily available Panhard bar for the first gens here - hopefully it works out

#10

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,800

Received 2,574 Likes

on

1,830 Posts

the whole problem with the rear suspension is that the upper arms are not parallel to each other, so when the axle has to move in roll, it is actually trying to twist things, on the eat coast cars the upper arms come out of the body.

so in the stock configuration the rubber being soft is kind of key, using a harder bushing makes it worse.

so in the stock configuration the rubber being soft is kind of key, using a harder bushing makes it worse.

#11

the whole problem with the rear suspension is that the upper arms are not parallel to each other, so when the axle has to move in roll, it is actually trying to twist things, on the eat coast cars the upper arms come out of the body.

so in the stock configuration the rubber being soft is kind of key, using a harder bushing makes it worse.

so in the stock configuration the rubber being soft is kind of key, using a harder bushing makes it worse.

No one seems to make kits for the Tri-link mod anymore. So what few images I have found seem pretty straight forward. I like the idea of having a long top link attached to the top of the diff housing that runs straight through a hole in the cargo box area. I'll make it with adjustable rod ends so I can set the pinion angle. This would also mean getting rid of the watts since the new link will interfere with the watts. So Panhard bar it is.

I can then comfortably use the polyurethane bushings for the bottom links once the tri-link is in.

This will take a while for me to perform. But I'll document everything I do with pictures and try to post them in a new thread in a way that makes sense.

#12

its supposed to do that

That is pretty much the exact same plan that I have. Rather than a curved tri-link that bolts into the driveline tunnel, a straight shot through the cargo area to tie into the cross-brace behind the seats.

Isaac

Isaac

#13

its supposed to do that

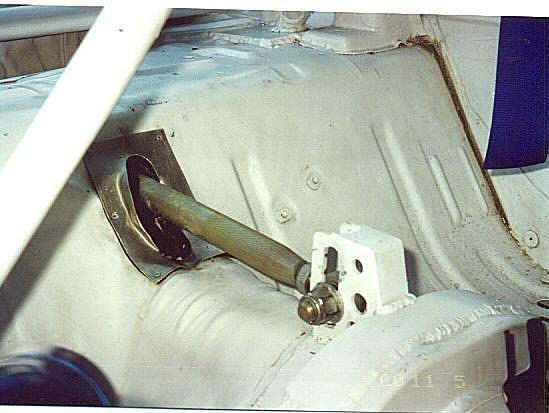

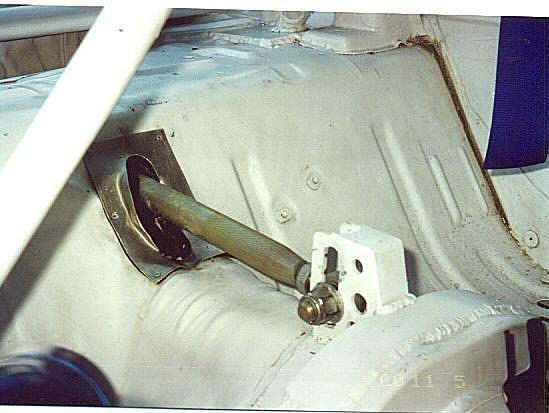

Something like so:

I would personally add quite a bit more bracing on the bracket inside the car, perhaps triangulate it out to the bottom of the B pillar area, or to the top of the framerails where they start to go up the "hump" there.

Isaac

I would personally add quite a bit more bracing on the bracket inside the car, perhaps triangulate it out to the bottom of the B pillar area, or to the top of the framerails where they start to go up the "hump" there.

Isaac

#14

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,800

Received 2,574 Likes

on

1,830 Posts

I've been going through a lot of the old threads on this, and this is the first time someone has (or I finally caught on) actually pointed out that the upper arms at not parallel to one another. Most other comments point out that the top links are too short and the watts is off-centered, but not being in the same plane to one another just horrible. That would explain the need for some give. Very sloppy, un-Mazdalike engineering. Something accountants would push through a design meeting.

No one seems to make kits for the Tri-link mod anymore. So what few images I have found seem pretty straight forward. I like the idea of having a long top link attached to the top of the diff housing that runs straight through a hole in the cargo box area. I'll make it with adjustable rod ends so I can set the pinion angle. This would also mean getting rid of the watts since the new link will interfere with the watts. So Panhard bar it is.

I can then comfortably use the polyurethane bushings for the bottom links once the tri-link is in.

This will take a while for me to perform. But I'll document everything I do with pictures and try to post them in a new thread in a way that makes sense.

No one seems to make kits for the Tri-link mod anymore. So what few images I have found seem pretty straight forward. I like the idea of having a long top link attached to the top of the diff housing that runs straight through a hole in the cargo box area. I'll make it with adjustable rod ends so I can set the pinion angle. This would also mean getting rid of the watts since the new link will interfere with the watts. So Panhard bar it is.

I can then comfortably use the polyurethane bushings for the bottom links once the tri-link is in.

This will take a while for me to perform. But I'll document everything I do with pictures and try to post them in a new thread in a way that makes sense.

yes, the top links could be longer too, the competition catalog sells you longer upper links and an axle housing with different mounting points.

so if you go out to the car, and put a measuring device on the pinion flange, and just move the axle in roll, you'll find that the pinion actually moves in an arc.

this means that the upper links have to twist, and so does the watts.

so the trick to making the rear work is to make all the pivots softer, and not harder. its also why the panhard works so well, it gets rid of some binding.

#15

Just thought I'd drop in an update.

Since I already had the polyurethane bushings ordered, I decided to go ahead and install all of them just to see how they would be. Everything in the rear is now poly including the swaybar, all 4 links and the watts linkage.

Removing the rubber from the linkages was a real bear. A drill press is a must since it helps to have both hands free. Am afraid that there is no easy method but to mutilate the rubber with a drill bit and then use a spinning wire brush (drill press again) to clean out the bores. The rubber is either glued of fused to the links. I tried burning one end, but that's just stupid, time consuming and lots of black smoke (did it at night). If I had a shop, I would not be offering this as a service.

The Energy Suspension polyurethane bushings installed without a problem.

There is a noticeable increase road noise and vibration being transmitted up through the harder bushings. But I like it! I have a much better feel for what the rear end is doing. The vagueness that I had from the rubber bushings is completely gone. That sudden snap to the left and right are gone as well.

I took my RX7 on a test run through some mountain roads and then along some nice tight up and down twisties through a nearby neighborhood of 5 million dollar homes. Many of the turns are bumpy and off camber. So I was going fairly aggressively trying to give the rear end a work out. Pedestrian free hour.

I didn't notice anything bad about the rear. No bind ups, nothing unusual to report. My car isn't very low. Perhaps my car rides high enough so binding isn't occurring. I'm using all RB springs and swaybars. My shocks are still OEM style. The car corners flat, much of the interior is stripped, but I need to get away from the stock 13" rims.

So far, for the street I think poly is great.

I'll have to see how things go out on the track.

I'll keep the idea of going 3-link + panhard in mind.

But until I spot any issues, I will keep riding on the poly.

Since I already had the polyurethane bushings ordered, I decided to go ahead and install all of them just to see how they would be. Everything in the rear is now poly including the swaybar, all 4 links and the watts linkage.

Removing the rubber from the linkages was a real bear. A drill press is a must since it helps to have both hands free. Am afraid that there is no easy method but to mutilate the rubber with a drill bit and then use a spinning wire brush (drill press again) to clean out the bores. The rubber is either glued of fused to the links. I tried burning one end, but that's just stupid, time consuming and lots of black smoke (did it at night). If I had a shop, I would not be offering this as a service.

The Energy Suspension polyurethane bushings installed without a problem.

There is a noticeable increase road noise and vibration being transmitted up through the harder bushings. But I like it! I have a much better feel for what the rear end is doing. The vagueness that I had from the rubber bushings is completely gone. That sudden snap to the left and right are gone as well.

I took my RX7 on a test run through some mountain roads and then along some nice tight up and down twisties through a nearby neighborhood of 5 million dollar homes. Many of the turns are bumpy and off camber. So I was going fairly aggressively trying to give the rear end a work out. Pedestrian free hour.

I didn't notice anything bad about the rear. No bind ups, nothing unusual to report. My car isn't very low. Perhaps my car rides high enough so binding isn't occurring. I'm using all RB springs and swaybars. My shocks are still OEM style. The car corners flat, much of the interior is stripped, but I need to get away from the stock 13" rims.

So far, for the street I think poly is great.

I'll have to see how things go out on the track.

I'll keep the idea of going 3-link + panhard in mind.

But until I spot any issues, I will keep riding on the poly.

#16

3rd time's a charm!!

Join Date: Apr 2012

Location: Montreal, Quebec

Posts: 22

Likes: 0

Received 0 Likes

on

0 Posts

Just thought I'd drop in an update.

Since I already had the polyurethane bushings ordered, I decided to go ahead and install all of them just to see how they would be. Everything in the rear is now poly including the swaybar, all 4 links and the watts linkage.

Removing the rubber from the linkages was a real bear. A drill press is a must since it helps to have both hands free. Am afraid that there is no easy method but to mutilate the rubber with a drill bit and then use a spinning wire brush (drill press again) to clean out the bores. The rubber is either glued of fused to the links. I tried burning one end, but that's just stupid, time consuming and lots of black smoke (did it at night). If I had a shop, I would not be offering this as a service.

The Energy Suspension polyurethane bushings installed without a problem.

There is a noticeable increase road noise and vibration being transmitted up through the harder bushings. But I like it! I have a much better feel for what the rear end is doing. The vagueness that I had from the rubber bushings is completely gone. That sudden snap to the left and right are gone as well.

I took my RX7 on a test run through some mountain roads and then along some nice tight up and down twisties through a nearby neighborhood of 5 million dollar homes. Many of the turns are bumpy and off camber. So I was going fairly aggressively trying to give the rear end a work out. Pedestrian free hour.

I didn't notice anything bad about the rear. No bind ups, nothing unusual to report. My car isn't very low. Perhaps my car rides high enough so binding isn't occurring. I'm using all RB springs and swaybars. My shocks are still OEM style. The car corners flat, much of the interior is stripped, but I need to get away from the stock 13" rims.

So far, for the street I think poly is great.

I'll have to see how things go out on the track.

I'll keep the idea of going 3-link + panhard in mind.

But until I spot any issues, I will keep riding on the poly.

Since I already had the polyurethane bushings ordered, I decided to go ahead and install all of them just to see how they would be. Everything in the rear is now poly including the swaybar, all 4 links and the watts linkage.

Removing the rubber from the linkages was a real bear. A drill press is a must since it helps to have both hands free. Am afraid that there is no easy method but to mutilate the rubber with a drill bit and then use a spinning wire brush (drill press again) to clean out the bores. The rubber is either glued of fused to the links. I tried burning one end, but that's just stupid, time consuming and lots of black smoke (did it at night). If I had a shop, I would not be offering this as a service.

The Energy Suspension polyurethane bushings installed without a problem.

There is a noticeable increase road noise and vibration being transmitted up through the harder bushings. But I like it! I have a much better feel for what the rear end is doing. The vagueness that I had from the rubber bushings is completely gone. That sudden snap to the left and right are gone as well.

I took my RX7 on a test run through some mountain roads and then along some nice tight up and down twisties through a nearby neighborhood of 5 million dollar homes. Many of the turns are bumpy and off camber. So I was going fairly aggressively trying to give the rear end a work out. Pedestrian free hour.

I didn't notice anything bad about the rear. No bind ups, nothing unusual to report. My car isn't very low. Perhaps my car rides high enough so binding isn't occurring. I'm using all RB springs and swaybars. My shocks are still OEM style. The car corners flat, much of the interior is stripped, but I need to get away from the stock 13" rims.

So far, for the street I think poly is great.

I'll have to see how things go out on the track.

I'll keep the idea of going 3-link + panhard in mind.

But until I spot any issues, I will keep riding on the poly.

#17

I think that the only thing I'm going to change is swapping out the OEM nut and lock washer to nylon lock nuts.

When I was test fitting the new bushings I noticed that they seemed fatter than the rubber and when the nut was torqued down the bracket would pinch the bushing so that when you rotated the link, the bushing stayed in place with the body of the car and the rotation was along the link collar and the bushing rather than the bolt and metal sleeve running through the bushing. (run on sentence)

The nylon lock nuts will allow me to NOT over tighten the bolts so that the link can rotate along the metal sleeve as intended.

It can be my imagination, but I really do like the feedback I'm getting from the firmer rear links. I'll know more after I spin out a few times, LOL.

When I was test fitting the new bushings I noticed that they seemed fatter than the rubber and when the nut was torqued down the bracket would pinch the bushing so that when you rotated the link, the bushing stayed in place with the body of the car and the rotation was along the link collar and the bushing rather than the bolt and metal sleeve running through the bushing. (run on sentence)

The nylon lock nuts will allow me to NOT over tighten the bolts so that the link can rotate along the metal sleeve as intended.

It can be my imagination, but I really do like the feedback I'm getting from the firmer rear links. I'll know more after I spin out a few times, LOL.

#18

Waffles - hmmm good

iTrader: (1)

I did the full polys up front and the polys only on the watts linkage in the rear. I still have the old

original rubber in the 4 locating links. It feels very good for me. I do get lots more road noise and

rear end noise coming through the from the rear. I'm tempted to do the links as well and use

the nylon locks nuts to make sure the movement is freer.

Anyone know the specs for the nuts I would need to get?

original rubber in the 4 locating links. It feels very good for me. I do get lots more road noise and

rear end noise coming through the from the rear. I'm tempted to do the links as well and use

the nylon locks nuts to make sure the movement is freer.

Anyone know the specs for the nuts I would need to get?

#19

All that urethane is acting like a sway bar back there. The way things bind up when the car leans the upper links have to twist and shorten. Putting urethane in them I like putting on a stiffer bar. No rubber to flex.

The stock watts link is very well designed, it moves the rear pretty straight until it reaches the upper and lower limits. Its just too high.

The stock watts link is very well designed, it moves the rear pretty straight until it reaches the upper and lower limits. Its just too high.

#20

√*(176400)

Join Date: Jun 2005

Location: Bellingham, WA

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

I second the reinforcement idea posted earlier regarding those photos of someone else's car. You're going to want much more transverse bracing on there, if it's aligned the way I think it was.

#22

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,800

Received 2,574 Likes

on

1,830 Posts

#23

Oh and with the heims it rattles like hell, would not recommend heims on the street. Use poly bushings instead.

Brad

#24

I did the full polys up front and the polys only on the watts linkage in the rear. I still have the old

original rubber in the 4 locating links. It feels very good for me. I do get lots more road noise and

rear end noise coming through the from the rear. I'm tempted to do the links as well and use

the nylon locks nuts to make sure the movement is freer.

Anyone know the specs for the nuts I would need to get?

original rubber in the 4 locating links. It feels very good for me. I do get lots more road noise and

rear end noise coming through the from the rear. I'm tempted to do the links as well and use

the nylon locks nuts to make sure the movement is freer.

Anyone know the specs for the nuts I would need to get?

I couldn't find these in the correct thread pitch any where in town. The quantities here are enough to take care of the 4-links and Watts. When I got under the car to remove to stock nuts to get a size, the center Watts nut had loosened itself, and I took it off with just my fingers. Doh!

Nylon Lock nuts:

M14x1.5 Qty 9 (one for the center Watts)

M12x1.5 Qty 4 (Watts link only)

Part# and order details:

94645A229 Zinc-Plated Steel Nylon-Insert Hex Locknut, Class 10, M12 Size, 1.5MM Pitch, 19MM Width, 12MM H, packs of 10 1 pack $6.27

90576A147 Metric Zinc-Plated Steel Nylon-Insert Locknut, Class 8, M14 Size, 1.5MM Pitch, 22MM W, 14MM H, packs of 10 1 pack $9.17

93475A300 Metric DIN 125 18-8 Stainless Steel Flat Washer, M14 Screw Size, 28MM OD, 2.3MM-2.7MM Thick, packs of 25 1 pack $7.13