Rear Control Arms, OEM Rubber vs. Lower Durometer Liquid Poly DIY

#1

Rotary Enthusiast

Thread Starter

Rear Control Arms, OEM Rubber vs. Lower Durometer Liquid Poly DIY

Hi folks. For my FB I have the ~80A Shore scale Energy Suspension poly bushings. But reading here that the gold standard is fresh OEM rubber and knowing myself as willing to go to great lengths to save a couple of bucks, it got me thinking about DIY liquid poly bushings in a durometer that is closer to the OEM rubber, say 60A. The liquid urethane is ~$35 for 25 cubic inches, new arms are ~$400.

In this thread, DreamInRotary describes making some custom bushings for a tranny mount. https://www.rx7club.com/1st-generati.../#post12245643

So I'm looking for opinions if anyone has tried this or if you've considered and rejected the idea. I was thinking remove the arms, jig up the metal center tube (from the Energy Susp bushings) and pour around them in place. Edit: For clarity talking about the rear control arms only.

Liquid urethane in 20/40/60/80A here: https://www.mcmaster.com/liquid-urethane/

I welcome your thoughts. Thanks!

In this thread, DreamInRotary describes making some custom bushings for a tranny mount. https://www.rx7club.com/1st-generati.../#post12245643

So I'm looking for opinions if anyone has tried this or if you've considered and rejected the idea. I was thinking remove the arms, jig up the metal center tube (from the Energy Susp bushings) and pour around them in place. Edit: For clarity talking about the rear control arms only.

Liquid urethane in 20/40/60/80A here: https://www.mcmaster.com/liquid-urethane/

I welcome your thoughts. Thanks!

Last edited by Toruki; 07-25-20 at 01:53 PM.

#2

Slowly getting there...

iTrader: (1)

For a tinkerer, scientist, or all-around nerd this is interesting. I fall into one or two of those categories. But for the average guy just trying to get his car back on the road,.... seems like a lot of trouble for unknown results. What if those bushings / suspension joints rip apart doing 70 through a 45 mph turn? As we do.

Let us know how it turns out.

Let us know how it turns out.

#3

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,855

Received 2,617 Likes

on

1,854 Posts

you should try it on the watts, if that fails, you might not even notice!

so what happens is that the rear axle tilts forward as the suspension compresses (pinion angle changes), so the watts has to go up and down AND pivot, its the pivot part that makes a hard bushing a poor choice. Rod ends work great, plus its adjustable.

in the lower links, they are parallel, so the stock arms, or rod end/pillow ***** work fine here, urethane is probably ok too.

the upper links are short, and not parallel, so they need to twist, move up and down AND change lengths, so the stock parts are the best choice, although you might try making a bushing. the SCCA guys were doing this for a while, because they could add the 3rd link, but due to the rules, had to leave the upper links, so they used some foam non-bushings

so what happens is that the rear axle tilts forward as the suspension compresses (pinion angle changes), so the watts has to go up and down AND pivot, its the pivot part that makes a hard bushing a poor choice. Rod ends work great, plus its adjustable.

in the lower links, they are parallel, so the stock arms, or rod end/pillow ***** work fine here, urethane is probably ok too.

the upper links are short, and not parallel, so they need to twist, move up and down AND change lengths, so the stock parts are the best choice, although you might try making a bushing. the SCCA guys were doing this for a while, because they could add the 3rd link, but due to the rules, had to leave the upper links, so they used some foam non-bushings

#4

Rotary Enthusiast

Thread Starter

For a tinkerer, scientist, or all-around nerd this is interesting. I fall into one or two of those categories. But for the average guy just trying to get his car back on the road,.... seems like a lot of trouble for unknown results. What if those bushings / suspension joints rip apart doing 70 through a 45 mph turn? As we do.

Let us know how it turns out.

Let us know how it turns out.

you should try it on the watts, if that fails, you might not even notice!

so what happens is that the rear axle tilts forward as the suspension compresses (pinion angle changes), so the watts has to go up and down AND pivot, its the pivot part that makes a hard bushing a poor choice. Rod ends work great, plus its adjustable.

in the lower links, they are parallel, so the stock arms, or rod end/pillow ***** work fine here, urethane is probably ok too.

the upper links are short, and not parallel, so they need to twist, move up and down AND change lengths, so the stock parts are the best choice, although you might try making a bushing. the SCCA guys were doing this for a while, because they could add the 3rd link, but due to the rules, had to leave the upper links, so they used some foam non-bushings

so what happens is that the rear axle tilts forward as the suspension compresses (pinion angle changes), so the watts has to go up and down AND pivot, its the pivot part that makes a hard bushing a poor choice. Rod ends work great, plus its adjustable.

in the lower links, they are parallel, so the stock arms, or rod end/pillow ***** work fine here, urethane is probably ok too.

the upper links are short, and not parallel, so they need to twist, move up and down AND change lengths, so the stock parts are the best choice, although you might try making a bushing. the SCCA guys were doing this for a while, because they could add the 3rd link, but due to the rules, had to leave the upper links, so they used some foam non-bushings

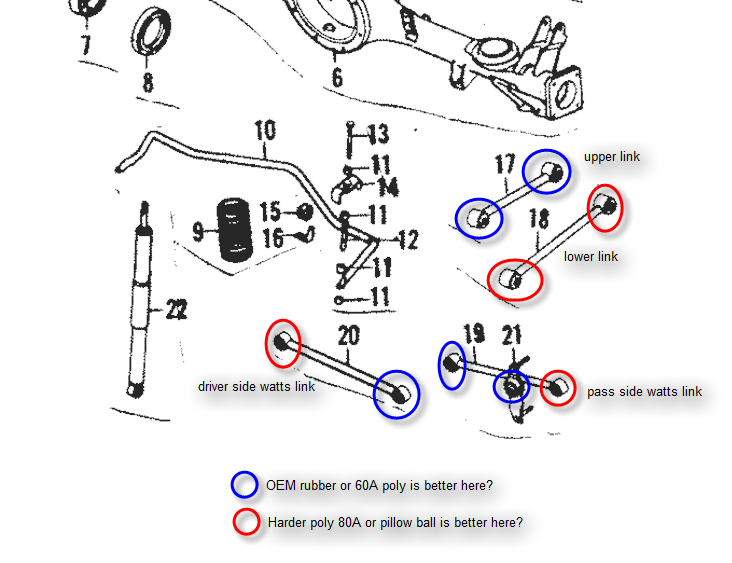

So is it correct that more compliance is better in the blue areas and that red areas benefit from harder bushings or even pillowball ends?

#5

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,855

Received 2,617 Likes

on

1,854 Posts

Mazda loves to use multi axis pivots, the joint goes up and down, but also will twist or rotate.

a rubber bushing does this well, with no friction, and a pillow ball will also do this with no friction. urethane does not do this well, and it also tends to have a lot of friction, its not my favorite choice of bushing, although it does have its place (its great for steering rack bushings)

the problem with the upper links is that since they are short, and not parallel when seen from above, they need to pivot in three axis (axes? achwell? Mr Foley?) they need to get longer and shorter, and the pillow ball can't do that at all. best option is the stock rubber, although something softer would be better

the other thing is that there are kind of two philosophies with the rear suspension, the current thinking is to make it soft, which means that everything needs to move more, and that makes the binding a problem. the old school way was to make it stiffer, so it didn't move as much. the less it moves, the less that any of the geometry and binding matter. Herb Adam's book is basically that, he just makes the suspension not move and sets the alignment, which works on cars with bad geometry.

a softer setup, is easier to drive, and its been proven faster. you could split the difference

a rubber bushing does this well, with no friction, and a pillow ball will also do this with no friction. urethane does not do this well, and it also tends to have a lot of friction, its not my favorite choice of bushing, although it does have its place (its great for steering rack bushings)

the problem with the upper links is that since they are short, and not parallel when seen from above, they need to pivot in three axis (axes? achwell? Mr Foley?) they need to get longer and shorter, and the pillow ball can't do that at all. best option is the stock rubber, although something softer would be better

the other thing is that there are kind of two philosophies with the rear suspension, the current thinking is to make it soft, which means that everything needs to move more, and that makes the binding a problem. the old school way was to make it stiffer, so it didn't move as much. the less it moves, the less that any of the geometry and binding matter. Herb Adam's book is basically that, he just makes the suspension not move and sets the alignment, which works on cars with bad geometry.

a softer setup, is easier to drive, and its been proven faster. you could split the difference

The following users liked this post:

Rx7fb spirit r (07-27-20)

#6

Slowly getting there...

iTrader: (1)

Part #17 yes (upper links). These need to be soft. Part #18 is also soft (same durometer) from the factory, and they help share the twisting/stretching loads with the upper links.

If you replace the lower links with urethane or rod ends its okay because they stabilize the axle better and swing in nice straight arcs. But over uneven bumps, where the wheel height is different side to side (picture just one rear tire up on a ramp), then all the squish twisting force must be absorbed by the short upper links. Which swing at wildly different arcs than the parallel lower links, and actually add steering input on the rear end.

This is okay on most cars. I'm just saying... the squish/flex/stretch between wildly different arcs has to happen somewhere. This is why Mazda put soft rubbers everywhere in the rear end. Because if they were all urethane or rod ends the mounting points would rip from the body's sheetmetal under hard driving. The early 7's rear end is a packaging compromise, that most people never notice under normal street driving. But if you start swapping "must-have-flex" parts with rock-solid parts, something will eventually give.

You dont need that while speeding through the mountains.

The watts links are similar but different. Looking at them from the wheels, you would think they move up and down in smooth arcs. But since the upper trailing links are much shorter than the lowers, as the axle moves up the pinion angle clocks down. This puts big twisting forces on the watts links, and by extension the watts' center pivot bushing. Replacing these with eurethane will impede that necessary twist, and either/both will make it harder for the suspension to cycle. Or, stress the mounting points. Neither is good. But, replacing the watts link ends with rod ends eliminates the twisting bind, since pillow ***** move and twist smoothly like that. There's very minimal side to side (left to right wheels) movement, even with the uneven length watts.

For street cars this is all academic bench racing talk. For someone racing in an SCCA class, or someone REALLY pushing their cars through the canyon, then this could be "firm suspension SUDDENLY snaps you into the wall, .. or off the cliff.

In academic theory.

If you replace the lower links with urethane or rod ends its okay because they stabilize the axle better and swing in nice straight arcs. But over uneven bumps, where the wheel height is different side to side (picture just one rear tire up on a ramp), then all the squish twisting force must be absorbed by the short upper links. Which swing at wildly different arcs than the parallel lower links, and actually add steering input on the rear end.

This is okay on most cars. I'm just saying... the squish/flex/stretch between wildly different arcs has to happen somewhere. This is why Mazda put soft rubbers everywhere in the rear end. Because if they were all urethane or rod ends the mounting points would rip from the body's sheetmetal under hard driving. The early 7's rear end is a packaging compromise, that most people never notice under normal street driving. But if you start swapping "must-have-flex" parts with rock-solid parts, something will eventually give.

You dont need that while speeding through the mountains.

The watts links are similar but different. Looking at them from the wheels, you would think they move up and down in smooth arcs. But since the upper trailing links are much shorter than the lowers, as the axle moves up the pinion angle clocks down. This puts big twisting forces on the watts links, and by extension the watts' center pivot bushing. Replacing these with eurethane will impede that necessary twist, and either/both will make it harder for the suspension to cycle. Or, stress the mounting points. Neither is good. But, replacing the watts link ends with rod ends eliminates the twisting bind, since pillow ***** move and twist smoothly like that. There's very minimal side to side (left to right wheels) movement, even with the uneven length watts.

For street cars this is all academic bench racing talk. For someone racing in an SCCA class, or someone REALLY pushing their cars through the canyon, then this could be "firm suspension SUDDENLY snaps you into the wall, .. or off the cliff.

In academic theory.

The following users liked this post:

gracer7-rx7 (07-27-20)

#7

Rotary Enthusiast

Thread Starter

Thanks you guys for the excellent descriptions of the dynamics in the back end. There's always more subtlety to these things.

Slight tangent: Are the parts for the upper/lower/watts links and brackets the same in 84 as for the 83? All of the online OEM parts sites only go back to 84 now.

Slight tangent: Are the parts for the upper/lower/watts links and brackets the same in 84 as for the 83? All of the online OEM parts sites only go back to 84 now.

Trending Topics

#8

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,855

Received 2,617 Likes

on

1,854 Posts

Thanks you guys for the excellent descriptions of the dynamics in the back end. There's always more subtlety to these things.

Slight tangent: Are the parts for the upper/lower/watts links and brackets the same in 84 as for the 83? All of the online OEM parts sites only go back to 84 now.

Slight tangent: Are the parts for the upper/lower/watts links and brackets the same in 84 as for the 83? All of the online OEM parts sites only go back to 84 now.

The following users liked this post:

Toruki (07-26-20)

#9

Waffles - hmmm good

iTrader: (1)

I have poly in my watts linkage and OEM rubber still in the rear links. Done a lot of mtn driving and do not experience any surprising behavior at full compression or extension of rear suspension. It will snap oversteer at some point but its no worse than it was before the poly on the watts and swaybar links. Has great road feel so I can tell as I near that edge of traction front and rear. Sometimes I feel a lot of folks over think this stuff.

The following users liked this post:

Toruki (07-27-20)

#10

I know it's probably best to leave things alone back there but would the T3 upper links that relocate the mount help any? I'd really just like to replace the 40yo rubber which will soon be 50yo rubber then 60... I guess I should just get OEM before the pool dries up.

#11

Slowly getting there...

iTrader: (1)

Yeti,

I was talking to T3 last year and they told me about the relocation "kit" before they started listing it on their site. They say that yes, by spacing the forward mount "outboard" like that, that the upper links are almost straight with the chassis and most of the suspension goofy-ness is eliminated.

But, two things to keep in mind with this mod-

1) Relocating the link with a spacer puts a little extra stress on that joint (talking about sheet metal) as well as making it single sheer-point on the bolt. MAKE SURE you don't have any hidden rust in this area first (check behind the storage bins!) so your not putting new stress on a possibly weak spot.

2) Check your tire clearance. I have 225's on the back with 15x7 38mm offset and I have the room. But somebody with 245's or 10" wide rims might not.

If I get around to having the rust repaired and that area reinforced I will definitely try it (I already have the T3 parts).

I was talking to T3 last year and they told me about the relocation "kit" before they started listing it on their site. They say that yes, by spacing the forward mount "outboard" like that, that the upper links are almost straight with the chassis and most of the suspension goofy-ness is eliminated.

But, two things to keep in mind with this mod-

1) Relocating the link with a spacer puts a little extra stress on that joint (talking about sheet metal) as well as making it single sheer-point on the bolt. MAKE SURE you don't have any hidden rust in this area first (check behind the storage bins!) so your not putting new stress on a possibly weak spot.

2) Check your tire clearance. I have 225's on the back with 15x7 38mm offset and I have the room. But somebody with 245's or 10" wide rims might not.

If I get around to having the rust repaired and that area reinforced I will definitely try it (I already have the T3 parts).

#12

Rotary Enthusiast

Thread Starter

I have poly in my watts linkage and OEM rubber still in the rear links. Done a lot of mtn driving and do not experience any surprising behavior at full compression or extension of rear suspension. It will snap oversteer at some point but its no worse than it was before the poly on the watts and swaybar links. Has great road feel so I can tell as I near that edge of traction front and rear. Sometimes I feel a lot of folks over think this stuff.

#13

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,855

Received 2,617 Likes

on

1,854 Posts

we took Fungus Mungus's car to Sevenstock, a couple of times, and its suspension is pretty basic, on super sticky tires, and it works fine. it rolls a LOT too. not saying there isn't room for improvement, just saying that it was about #3 on the list of drivers complaints.... driver wanted more brakes, more power, and the seat belt doesn't crush his man area enough, so i guess suspension would be #4

Thread

Thread Starter

Forum

Replies

Last Post

kensin

3rd Generation Specific (1993-2002)

3

01-03-18 12:19 PM

GOT-RTRY

2nd Generation Specific (1986-1992)

4

05-20-10 12:12 PM

yomamasmama

3rd Generation Specific (1993-2002)

1

12-03-01 04:19 PM