Pulling 12a flywheel help please!!!

#1

Full Member

Thread Starter

Join Date: Oct 2004

Location: Tucson

Posts: 123

Likes: 0

Received 0 Likes

on

0 Posts

Pulling 12a flywheel help please!!!

So Im am in the middle of tearing down my engine to rebuild it. I got to the flywheel and came across this huge nut holding my flywheel on. What is the procedure to reomve it? I cant find any help in my chilton's repair manual. Sorry if this has been coverd before, But nothing came up in the search.

#2

Rotary Enthusiast

iTrader: (1)

Join Date: Feb 2004

Location: Waterloo & Mississauga, Ontario, Canada

Posts: 838

Likes: 0

Received 1 Like

on

1 Post

https://www.rx7club.com/1st-generation-specific-1979-1985-18/what-size-flywheel-nut-359733/

everything you need is in there ^

everything you need is in there ^

#4

Eats, Sleeps, Dreams Rotary

Join Date: Jul 2004

Location: Allentown, PA - Paterson, NJ

Posts: 3,247

Likes: 0

Received 2 Likes

on

2 Posts

Originally Posted by 81gsl12a

get a 2 1/8 socket and an impact gun.....than you will need a puller to get the flywheel off or the wrong way hit it on the bottom with a hammer and pry on the top with a

BF-screwdriver or pry bar. than hit on the other side and will shake loose

BF-screwdriver or pry bar. than hit on the other side and will shake loose

#5

Keep in mind that wailing away on the flywheel transfers that force through the e-shaft. What stops that movement on the other end of the shaft is the e-shaft nut. In between there, what absorbs the impact, is the torrington bearings. Something to concider the next time one gets the BFH out.

I modified an off the shelf puller to match the spread of the bolt holes in the flywheel. I tighten the puller down with an impact wrench, snugly, not too tight, then walk over to get a hammer. Half the time the flywheel has popped by the time I get back with the hammer. Otherwise it takes a moderate tap on the flywheel, towards the front of the engine, not the back.

Always leave the flywheel nut on the e-shaft until it has popped loose.

I modified an off the shelf puller to match the spread of the bolt holes in the flywheel. I tighten the puller down with an impact wrench, snugly, not too tight, then walk over to get a hammer. Half the time the flywheel has popped by the time I get back with the hammer. Otherwise it takes a moderate tap on the flywheel, towards the front of the engine, not the back.

Always leave the flywheel nut on the e-shaft until it has popped loose.

#6

Senior Member

iTrader: (2)

Join Date: Feb 2003

Location: Kingston Ontario

Posts: 719

Likes: 0

Received 0 Likes

on

0 Posts

Inless you like a flywheel on your head that is. Also tapeing the threads help protect them and the bearings inside. 10 cents worth of electrical tape can save 100s in bearings.

#7

Originally Posted by Marek

Also tapeing the threads help protect them and the bearings inside. 10 cents worth of electrical tape can save 100s in bearings.

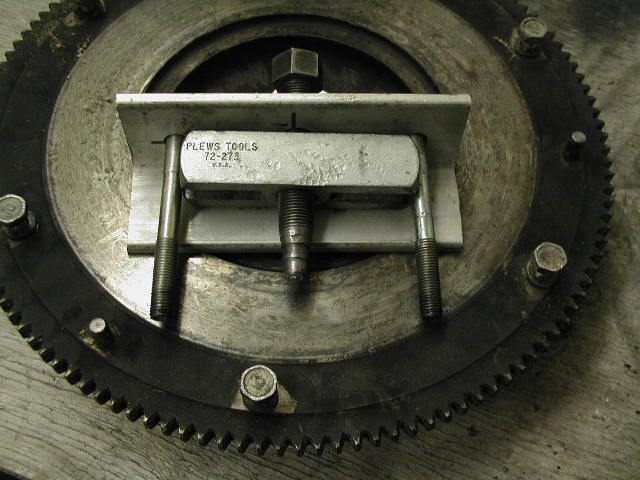

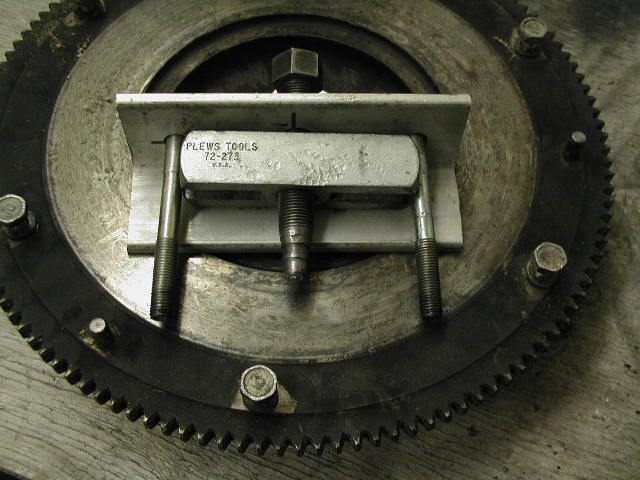

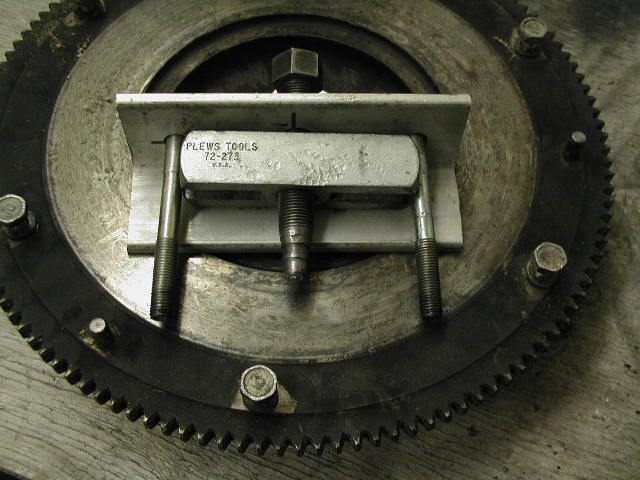

This is the setup I have found to be the easiest and most effective. The angle is 2x2x6x1/4" aluminum. 3/16" steel will work as well. Note the aluminum square under the end of the puller that is protecting the e-shaft and pilot bearing. Flywheel nut should be flush with the end of the e-shaft.

Now gentlemen, and ladies, work smarter, not harder and quit beating you car.

Trending Topics

#8

I bought this kit from harbor freight. Bearing Separator and Puller Set

in the middle of the picture, there is a bar with a hole through it. I used this instead of making my own; too much time and effort. cheaper to pick this up at harbor freight for $40.

in the middle of the picture, there is a bar with a hole through it. I used this instead of making my own; too much time and effort. cheaper to pick this up at harbor freight for $40.

#10

Junior Member

Join Date: Feb 2005

Location: Little Rock, Arkansas

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

Question

[QUOTE=trochoid;5491536]Would you care to explain this in more details. If you are refering to the torrington bearings, then I don't believe you know what, or where, they are. If you are refering to the pilot bearing, that is a $10 or less part and should not even be in harms way unless one uses a puller and sticks the end of it in the end of the e-shaft. If one does that, tape is not going to protect it.

This is the setup I have found to be the easiest and most effective. The angle is 2x2x6x1/4" aluminum. 3/16" steel will work as well. Note the aluminum square under the end of the puller that is protecting the e-shaft and pilot bearing. Flywheel nut should be flush with the end of the e-shaft.

Now gentlemen, and ladies, work smarter, not harder and quit beating you car. :pfanndina

[/QUOT

[/QUOT

Looks like an idea to try. However, my flywheel appears to have threaded holes that have a thread lead of 1.5 mm and the lead on the two bolts that you appear to thread into the flywheel are a finer thread like 1.25.

Can you let me know please if there is a difference between your flywheel and mine in the threaded holes? Also the threaded holes on the flywheel attached to my engine do not appear to go entirely through the flywheel.

This is the setup I have found to be the easiest and most effective. The angle is 2x2x6x1/4" aluminum. 3/16" steel will work as well. Note the aluminum square under the end of the puller that is protecting the e-shaft and pilot bearing. Flywheel nut should be flush with the end of the e-shaft.

Now gentlemen, and ladies, work smarter, not harder and quit beating you car. :pfanndina

[/QUOT

[/QUOTLooks like an idea to try. However, my flywheel appears to have threaded holes that have a thread lead of 1.5 mm and the lead on the two bolts that you appear to thread into the flywheel are a finer thread like 1.25.

Can you let me know please if there is a difference between your flywheel and mine in the threaded holes? Also the threaded holes on the flywheel attached to my engine do not appear to go entirely through the flywheel.

Thread

Thread Starter

Forum

Replies

Last Post