6-port actuator removal question

#1

6-port actuator removal question

Hi,

on one of my project cars I have a stock '84 6-port with the stock injection and custom exhaust. I was thinking of removing the port actuators just to simplify the set up. Plus, the custom exhaust probably won't be making enough back-pressure...

Is it as simple as pulling off the intake manifold and pulling out the sleeves?

And will this effect the streetability very much?

Any top end improvement without the sleeves adding restriction?

My guess is there will be some loss of off-the-line torque, maybe idling issues?

Don't the actuators come on at 3k rpm?

Thanks, it's been over two years since I logged onto this forum.

on one of my project cars I have a stock '84 6-port with the stock injection and custom exhaust. I was thinking of removing the port actuators just to simplify the set up. Plus, the custom exhaust probably won't be making enough back-pressure...

Is it as simple as pulling off the intake manifold and pulling out the sleeves?

And will this effect the streetability very much?

Any top end improvement without the sleeves adding restriction?

My guess is there will be some loss of off-the-line torque, maybe idling issues?

Don't the actuators come on at 3k rpm?

Thanks, it's been over two years since I logged onto this forum.

#2

I remember you. This info might help. I just assemled an S4 NA recently and test fired it a couple days ago. It has no sleeves. The intake manifold is a combination mostly of a 12A manifold welded to a GSL-SE flange. Carb is an 81-82 Nikki race prepped so there's no choke.

As a fresh rebuild it was able to fire up and sort of idle within a few seconds. Again no sleeves. I haven't driven it yet as the truck now needs an exhaust system. I just tested it with an exhaust manifold and an aftermarket cat shoved on the end. Kinda loudish.

As a fresh rebuild it was able to fire up and sort of idle within a few seconds. Again no sleeves. I haven't driven it yet as the truck now needs an exhaust system. I just tested it with an exhaust manifold and an aftermarket cat shoved on the end. Kinda loudish.

#3

I bought my car without the sleeves in (PO took them out). Without them the car ran fine and idled fine. It just seemed to take a little longer than it should to get up to speed.

I have since rebuilt the engine and replaced them. I noticed its much more "torquey" but along with rebuilding the block I installed a new stage 1 clutch and have yet to fully break it in so I haven't gone above 4k with the sleeves in.

I have since rebuilt the engine and replaced them. I noticed its much more "torquey" but along with rebuilding the block I installed a new stage 1 clutch and have yet to fully break it in so I haven't gone above 4k with the sleeves in.

#4

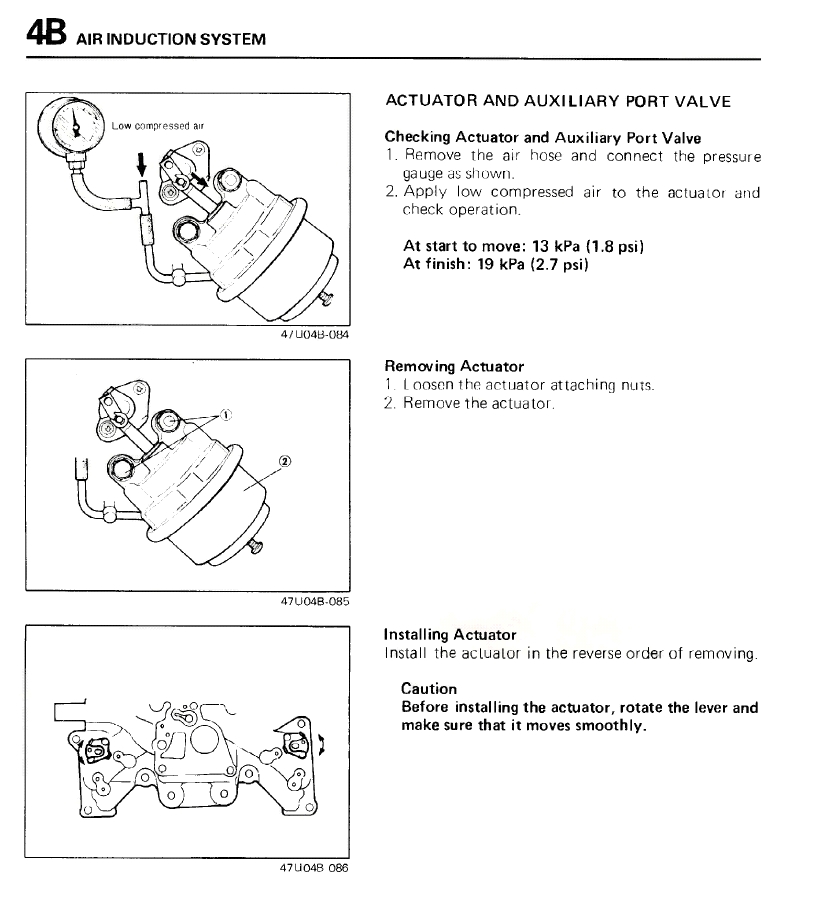

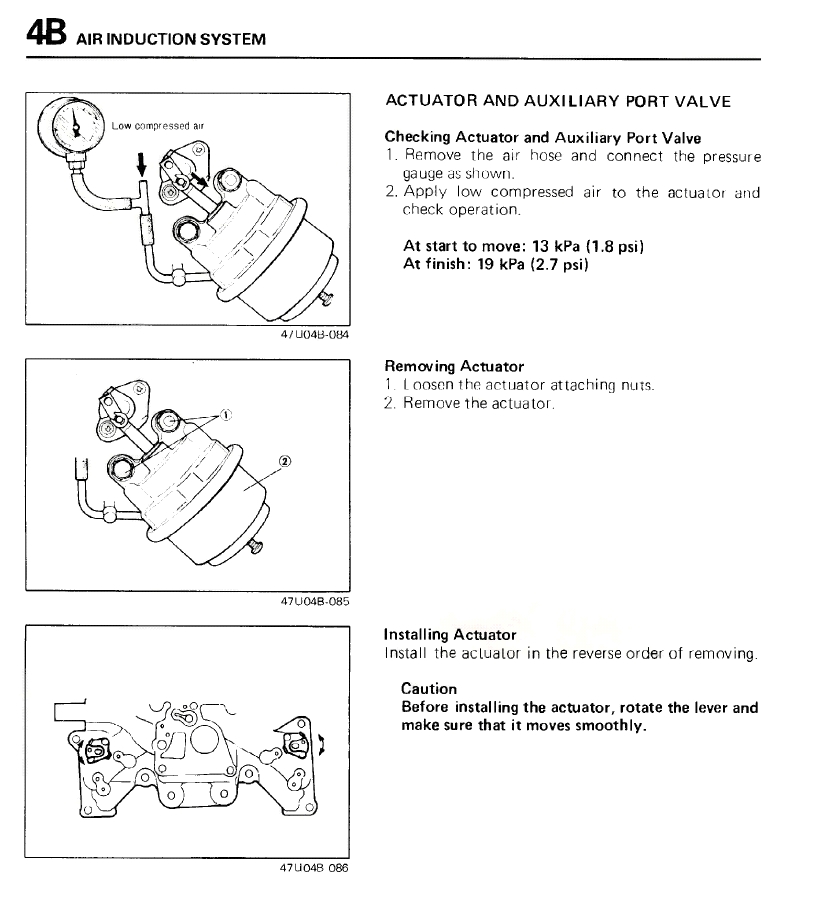

I'd be surprised if your exhaust doesn't produce enough back pressure. You only need 3 psi to open them completely. I have full RB SP exhaust on a GSLSE engine with a Dellorto carb and the actuators are hooked up per Trochoids suggestion in this thread. Works great, very easy, still have great low end torque.

https://www.rx7club.com/1st-generation-specific-1979-1985-18/6-port-actuator-question-803883/

https://www.rx7club.com/1st-generation-specific-1979-1985-18/6-port-actuator-question-803883/

#5

Hi Jeff, long time no see. I got my project cars out of moth ***** again. Built a 30x30 garage, so I should have no excuses for covering them up in junk again.

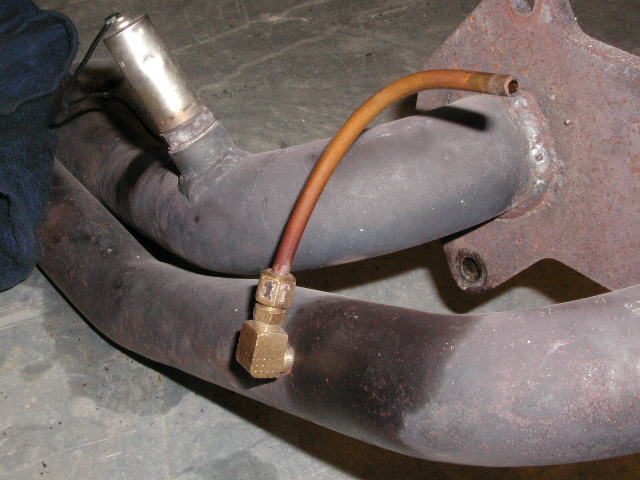

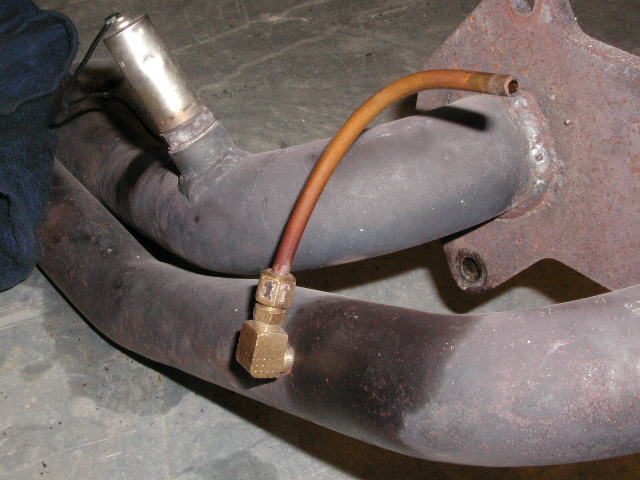

wow, those fittings and hose look just like the water feed for my refrigerator.

After reading what it will take to remove of the LIM, maybe I'll consider attaching a line like that and keep the actuators. 3lbs doesn't seem to be a lot of pressure.

Thanks for the info.

wow, those fittings and hose look just like the water feed for my refrigerator.

After reading what it will take to remove of the LIM, maybe I'll consider attaching a line like that and keep the actuators. 3lbs doesn't seem to be a lot of pressure.

Thanks for the info.

#6

If I ever get around to building a 6 port 12A, I'll start with the stock exhaust manifold, which has a tube similar to NA FC engines, which the GSL-SE manifolds lack. I think the tube is for feeding pressure into the ACV channel to open the actuators. But it it's not, I'll need to rig up a tube like the one pictured; especially when it gets a header as the manifold is kinda restrictive looking compared to our US-spec exhaust manifolds. Then again the restrictive nature probably helps feed 3psi into the actuators. I'd still prefer a header though.

Hey I've got an update for you about my MG Midget. I'm in the process of streetporting a set of Y plates so I can use an RB Holley 600. I have to use a 76 Cosmo reverse runner manifold as no other type will fit and still allow manifold install/removal with the engine in the car. Yes it's that tight in there, as you know. I did not like the thought of cutting up the car just for a manifold. Similar for the exhaust system. I've got a super shorty header that collects to 2.5" where it turns 90° under the car. Not ideal but all I can work with. I'll run some 2.5" RB and magnaflow components under the car that hopefully will allow enough ground clearance. They're be no taller than 4". As for the intake manifold, I've got a carb adaptor to fit a Holley on a stock stud pattern and stock runner spacing. Fortunately the reverse runner manifold flows the best on a flowbench compared to any SA or FB manifold. I'd say it flows almost as well as an actual RB Holley manifold, which would never fit this car.

I have to use a 76 Cosmo reverse runner manifold as no other type will fit and still allow manifold install/removal with the engine in the car. Yes it's that tight in there, as you know. I did not like the thought of cutting up the car just for a manifold. Similar for the exhaust system. I've got a super shorty header that collects to 2.5" where it turns 90° under the car. Not ideal but all I can work with. I'll run some 2.5" RB and magnaflow components under the car that hopefully will allow enough ground clearance. They're be no taller than 4". As for the intake manifold, I've got a carb adaptor to fit a Holley on a stock stud pattern and stock runner spacing. Fortunately the reverse runner manifold flows the best on a flowbench compared to any SA or FB manifold. I'd say it flows almost as well as an actual RB Holley manifold, which would never fit this car.  Another nice thing is the holley and the carb adaptor actually sits slightly lower than a stock carb by itself. This gives more hood clearance. Plus I can still trim a lot of height from the aftermarket foam air cleaner assembly for more breathing room between the hood and the top of the air cleaner. It's all figured out at this point. The only part I'm struggling with is how far to port it.

Another nice thing is the holley and the carb adaptor actually sits slightly lower than a stock carb by itself. This gives more hood clearance. Plus I can still trim a lot of height from the aftermarket foam air cleaner assembly for more breathing room between the hood and the top of the air cleaner. It's all figured out at this point. The only part I'm struggling with is how far to port it.  I don't have an RB template here so I'm making educated guesses. I don't like the thought of it loosing some of its low end driveability, but the car is so small and light that it won't be as noticeable as a rotary truck or RX-4.

I don't have an RB template here so I'm making educated guesses. I don't like the thought of it loosing some of its low end driveability, but the car is so small and light that it won't be as noticeable as a rotary truck or RX-4.

Hey I've got an update for you about my MG Midget. I'm in the process of streetporting a set of Y plates so I can use an RB Holley 600.

I have to use a 76 Cosmo reverse runner manifold as no other type will fit and still allow manifold install/removal with the engine in the car. Yes it's that tight in there, as you know. I did not like the thought of cutting up the car just for a manifold. Similar for the exhaust system. I've got a super shorty header that collects to 2.5" where it turns 90° under the car. Not ideal but all I can work with. I'll run some 2.5" RB and magnaflow components under the car that hopefully will allow enough ground clearance. They're be no taller than 4". As for the intake manifold, I've got a carb adaptor to fit a Holley on a stock stud pattern and stock runner spacing. Fortunately the reverse runner manifold flows the best on a flowbench compared to any SA or FB manifold. I'd say it flows almost as well as an actual RB Holley manifold, which would never fit this car.

I have to use a 76 Cosmo reverse runner manifold as no other type will fit and still allow manifold install/removal with the engine in the car. Yes it's that tight in there, as you know. I did not like the thought of cutting up the car just for a manifold. Similar for the exhaust system. I've got a super shorty header that collects to 2.5" where it turns 90° under the car. Not ideal but all I can work with. I'll run some 2.5" RB and magnaflow components under the car that hopefully will allow enough ground clearance. They're be no taller than 4". As for the intake manifold, I've got a carb adaptor to fit a Holley on a stock stud pattern and stock runner spacing. Fortunately the reverse runner manifold flows the best on a flowbench compared to any SA or FB manifold. I'd say it flows almost as well as an actual RB Holley manifold, which would never fit this car.  Another nice thing is the holley and the carb adaptor actually sits slightly lower than a stock carb by itself. This gives more hood clearance. Plus I can still trim a lot of height from the aftermarket foam air cleaner assembly for more breathing room between the hood and the top of the air cleaner. It's all figured out at this point. The only part I'm struggling with is how far to port it.

Another nice thing is the holley and the carb adaptor actually sits slightly lower than a stock carb by itself. This gives more hood clearance. Plus I can still trim a lot of height from the aftermarket foam air cleaner assembly for more breathing room between the hood and the top of the air cleaner. It's all figured out at this point. The only part I'm struggling with is how far to port it.  I don't have an RB template here so I'm making educated guesses. I don't like the thought of it loosing some of its low end driveability, but the car is so small and light that it won't be as noticeable as a rotary truck or RX-4.

I don't have an RB template here so I'm making educated guesses. I don't like the thought of it loosing some of its low end driveability, but the car is so small and light that it won't be as noticeable as a rotary truck or RX-4.

#7

Junior Member

Join Date: Jul 2009

Location: Nova Scotia

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

I have a stock GSL-SE and simply removed the 2 bolts holding each actuator. I then used a zip tie to hold the ports wide open at all times.

Results: Idle is perfect. No noticable loss of low end torque, and the upper end ALWAYS works. When I removed the old lines used to open the actuators, I found that they were clogged/restricted from the exhaust used for backpressure. Now they always work.

I recently returned from Deals Gap (from Nova Scotia, Canada):

Total miles = 3951 miles

US gallons used = 160 US gal

Avg MPG = 24.6 MPG (US) (includes Dragon runs!)

Best MPG for a tank = 28.4 MPG (US)

Car ran flawlessly with the ports wired wide open.

Steve

1984 GSL-SE

Results: Idle is perfect. No noticable loss of low end torque, and the upper end ALWAYS works. When I removed the old lines used to open the actuators, I found that they were clogged/restricted from the exhaust used for backpressure. Now they always work.

I recently returned from Deals Gap (from Nova Scotia, Canada):

Total miles = 3951 miles

US gallons used = 160 US gal

Avg MPG = 24.6 MPG (US) (includes Dragon runs!)

Best MPG for a tank = 28.4 MPG (US)

Car ran flawlessly with the ports wired wide open.

Steve

1984 GSL-SE

Trending Topics

Thread

Thread Starter

Forum

Replies

Last Post

Skeese

Adaptronic Engine Mgmt - AUS

65

03-28-17 03:30 PM

msilvia

3rd Generation Specific (1993-2002)

28

04-14-16 12:58 PM

CaptainKRM

2nd Generation Specific (1986-1992)

14

08-26-15 09:52 PM