high flow metal cats vs traditional ceramic cats explained

#1

high flow metal cats vs traditional ceramic cats explained

This was originally from an ongoing series of articles I've been writing about Rotary engine emissions control systems (specifically FD, but most of the same stuff applies to earlier cars):

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/why-engine-so-damn-complicated-part-2-emissions-controls-841963/

article on how the Rx-7 FD, Cosmo 13B-RE, and Cosmo 20B sequential turbo control system works: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/why-engine-so-damn-complicated-part-1-sequential-turbos-demystified-841821/

guide to making basic adjustments (make tune safer) in an Apex'i Power FC standalone without a laptop (Datalogit) interface: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/how-make-your-untuned-pfc-basemap-safer-idle-better-no-datalogit-needed-841706/

How idle speed control (ISC)/bypass air control (BAC)/Idle air control (IAC) valves, boost control solenoids, and fuel injectors work, including an explanation of what the terms "pulsewidth" and "duty cycle" really mean: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/how-pulsewidth-duty-control-works-872055/

Ceramic vs Metallic Substrate Catalytic Converters

Metallic high flow cats have been becoming more popular recently. The two questions people usually ask are

1) which flows more?

2) On OBD 1 cars, will metallic substrate cats pass emissions tests?

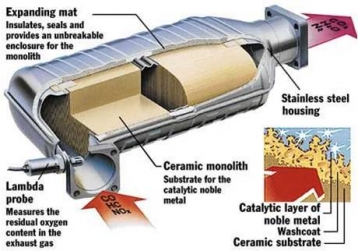

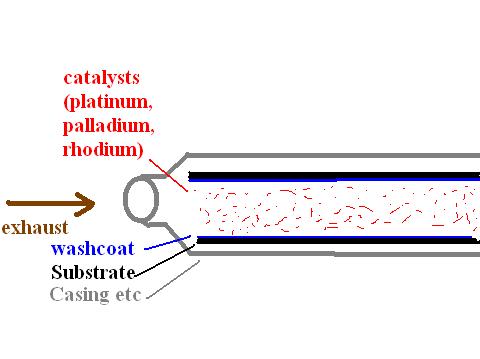

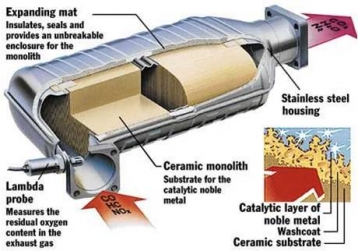

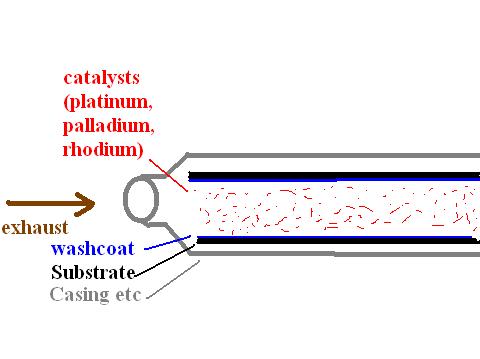

First, remember that what is changing is the substrate (ceramic vs metal), not the catalysts themselves. The substrate is almost like the work bench for the catalyzing process; the process takes place on top of the substrate. The catalysts are still platinum, palladium, and Rhodium with cerium for oxygen storage during the lean portion of the closed loop cycle.

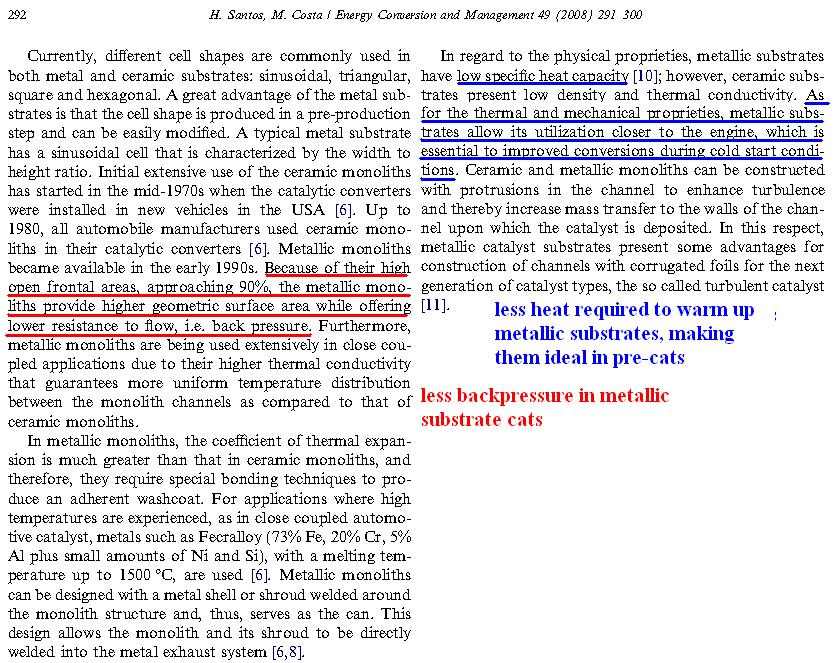

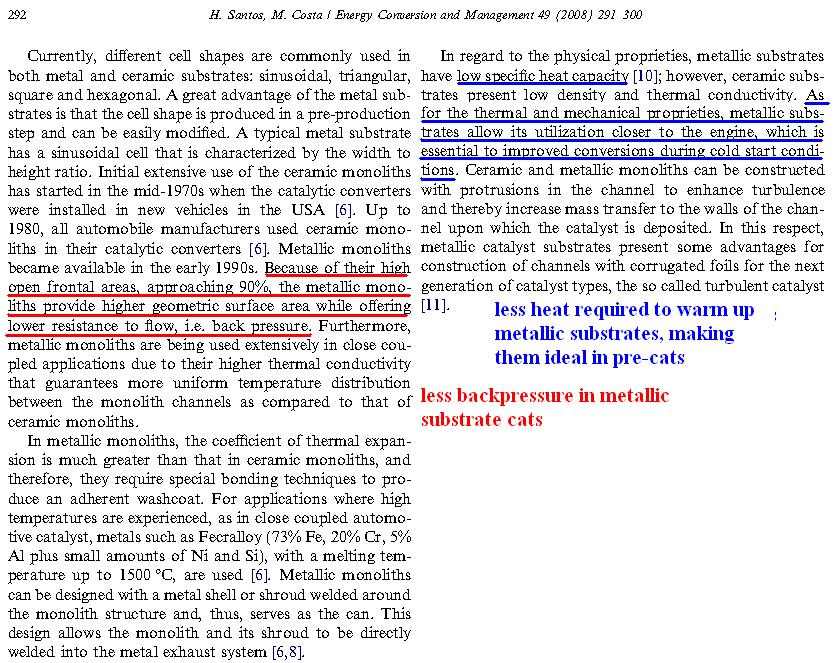

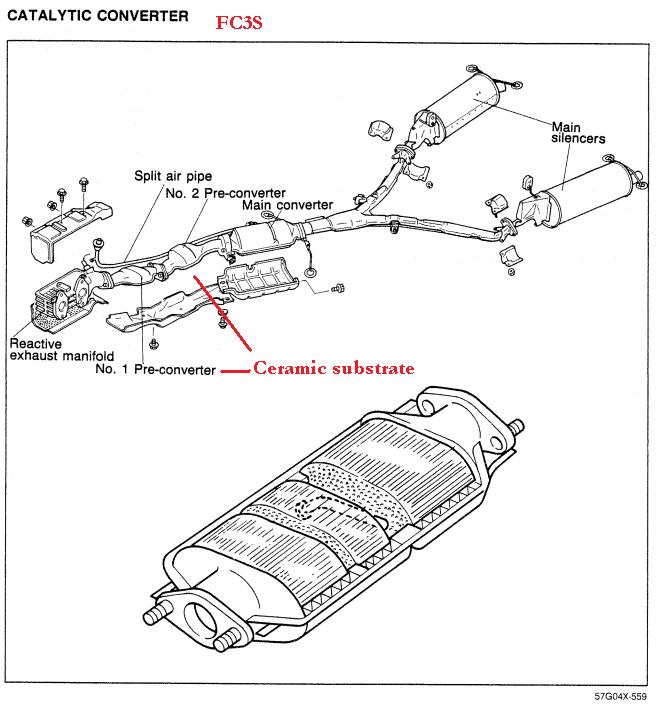

If you take two cats of the same basic dimensions but one of them has a metallic substrate, the one with the metallic substrate will typically flow more and will heat up faster. Note that the factory FD precat has a metallic substrate.

There are a lot of factors that go into the efficiency of the converter, but I'll make it simple. We'll discuss this hypothetically first, to isolate the results from changing only the substrate. If you compare two converters of very similar dimensions and physical shapes on the same engine,

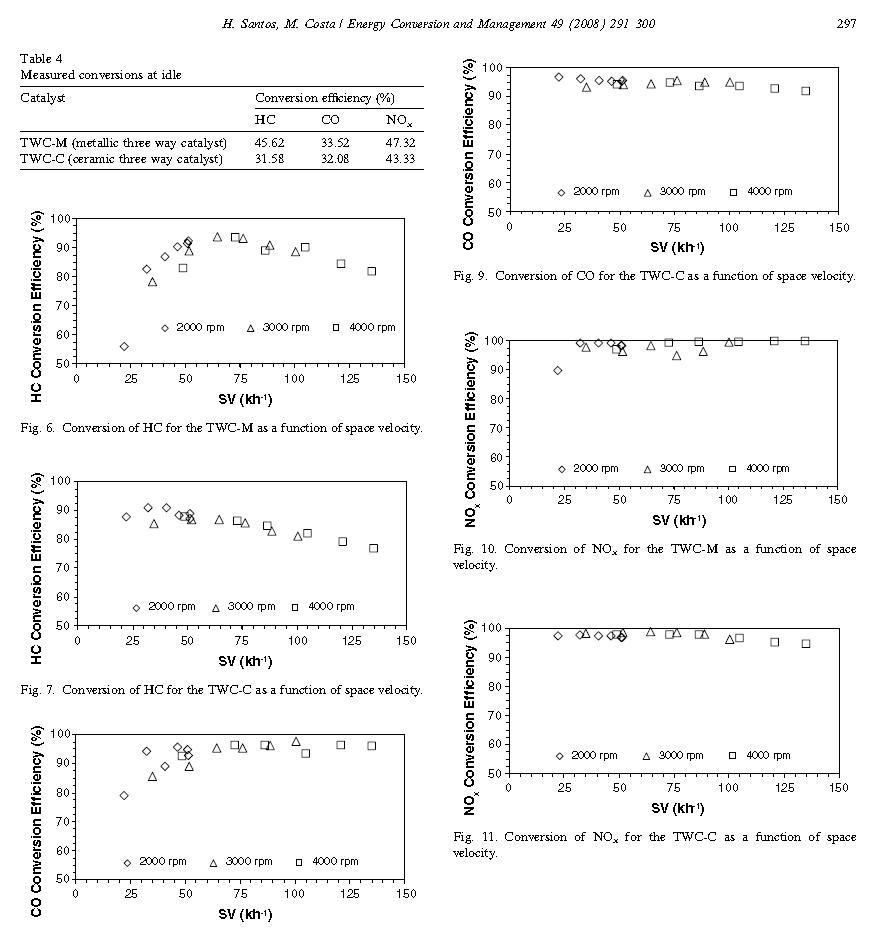

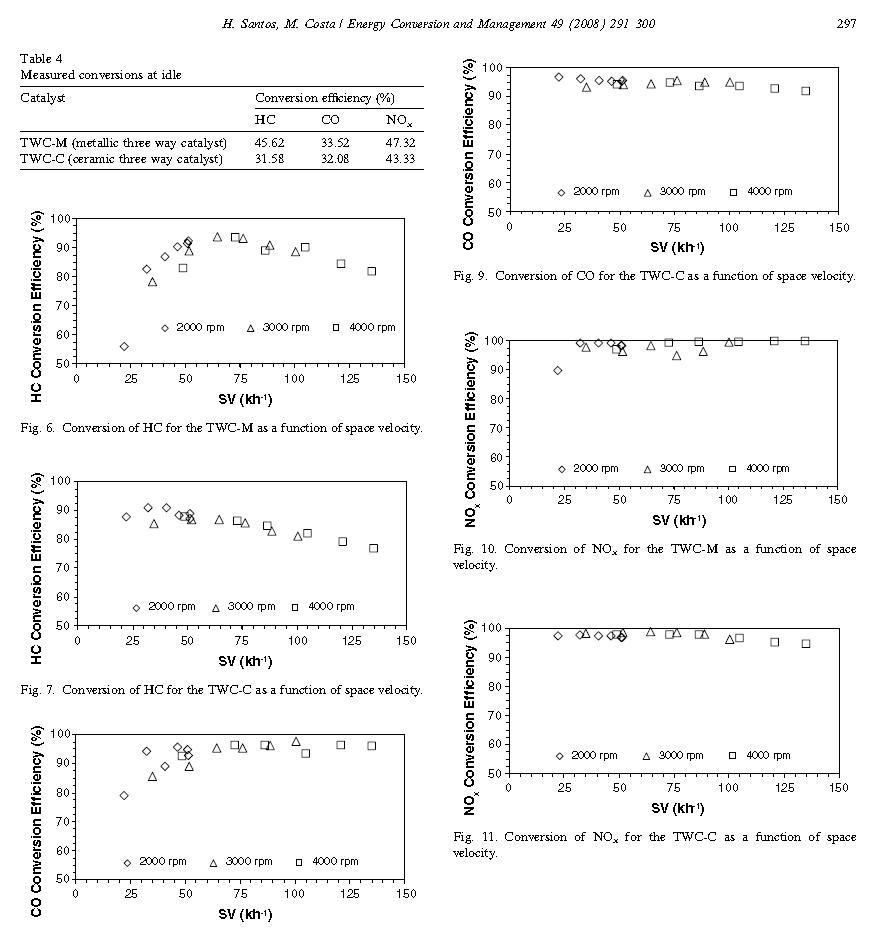

1. the metallic substrate cat may be marginally more efficient at idle for HC, CO, and NOx, at least on paper. But exhaust temperatures, idle AFR, and a lot of different factors really come into play here.

2. the ceramic substrate cat will be more efficient at HC and CO conversion for lower to medium loads and rpm ranges. These are the kind of conditions you may have on an emissions dyno test.

3. the metallic substrate will convert HC and CO better under higher loads and rpms, but these are not likely to be tested at an emissions station.

4. NOx numbers probably won't change much between either type of converter, except perhaps at idle.

Now that's examining the substrate material only. The fact of the matter is, physically smaller converters with less volume will not burn as clean. Conversion efficiency is measured by comparing how much gas is converted vs the amount of exhaust gas per a unit of volume in the cat. This is what's called space velocity:

Space velocity = a constant * [exhaust gas flow / (exhaust molecular weight * catalytic converter volume)]

That's the formula, roughly. And here are some comparison charts:

So in conclusion, for aftermarket performance applications a metallic substrate converter will yield at least some improvement in performance compared to a ceramic substrate cat of similar dimensions. This improvement can't be easily quantified because it depends on a number of factors. On OBD 1 cars that need sniffer tests, it may be more difficult to pass with a metallic cat. Rotary engines have enough problems with HC and CO emissions, and metallic cats exacerbate the problem under most driving conditions. This is especially true with performance cats because they are physically a lot smaller (less volume) than OEM units and thus don't work as well to clean up the exhaust. On OBD 2 cars where no actual sniffer tests are involved, there really isn't a downside to using a high quality metallic substrate cat if you are a performance enthusiast.

some images taken from: Santos, "Evaluation of the conversion efficiency of ceramic and metallic three way catalytic converters," Energy Conversion and Management Vol 49 Issue 2, 2008.

https://www.rx7club.com/3rd-generation-specific-1993-2002-16/why-engine-so-damn-complicated-part-2-emissions-controls-841963/

article on how the Rx-7 FD, Cosmo 13B-RE, and Cosmo 20B sequential turbo control system works: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/why-engine-so-damn-complicated-part-1-sequential-turbos-demystified-841821/

guide to making basic adjustments (make tune safer) in an Apex'i Power FC standalone without a laptop (Datalogit) interface: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/how-make-your-untuned-pfc-basemap-safer-idle-better-no-datalogit-needed-841706/

How idle speed control (ISC)/bypass air control (BAC)/Idle air control (IAC) valves, boost control solenoids, and fuel injectors work, including an explanation of what the terms "pulsewidth" and "duty cycle" really mean: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/how-pulsewidth-duty-control-works-872055/

Ceramic vs Metallic Substrate Catalytic Converters

Metallic high flow cats have been becoming more popular recently. The two questions people usually ask are

1) which flows more?

2) On OBD 1 cars, will metallic substrate cats pass emissions tests?

First, remember that what is changing is the substrate (ceramic vs metal), not the catalysts themselves. The substrate is almost like the work bench for the catalyzing process; the process takes place on top of the substrate. The catalysts are still platinum, palladium, and Rhodium with cerium for oxygen storage during the lean portion of the closed loop cycle.

If you take two cats of the same basic dimensions but one of them has a metallic substrate, the one with the metallic substrate will typically flow more and will heat up faster. Note that the factory FD precat has a metallic substrate.

There are a lot of factors that go into the efficiency of the converter, but I'll make it simple. We'll discuss this hypothetically first, to isolate the results from changing only the substrate. If you compare two converters of very similar dimensions and physical shapes on the same engine,

1. the metallic substrate cat may be marginally more efficient at idle for HC, CO, and NOx, at least on paper. But exhaust temperatures, idle AFR, and a lot of different factors really come into play here.

2. the ceramic substrate cat will be more efficient at HC and CO conversion for lower to medium loads and rpm ranges. These are the kind of conditions you may have on an emissions dyno test.

3. the metallic substrate will convert HC and CO better under higher loads and rpms, but these are not likely to be tested at an emissions station.

4. NOx numbers probably won't change much between either type of converter, except perhaps at idle.

Now that's examining the substrate material only. The fact of the matter is, physically smaller converters with less volume will not burn as clean. Conversion efficiency is measured by comparing how much gas is converted vs the amount of exhaust gas per a unit of volume in the cat. This is what's called space velocity:

Space velocity = a constant * [exhaust gas flow / (exhaust molecular weight * catalytic converter volume)]

That's the formula, roughly. And here are some comparison charts:

So in conclusion, for aftermarket performance applications a metallic substrate converter will yield at least some improvement in performance compared to a ceramic substrate cat of similar dimensions. This improvement can't be easily quantified because it depends on a number of factors. On OBD 1 cars that need sniffer tests, it may be more difficult to pass with a metallic cat. Rotary engines have enough problems with HC and CO emissions, and metallic cats exacerbate the problem under most driving conditions. This is especially true with performance cats because they are physically a lot smaller (less volume) than OEM units and thus don't work as well to clean up the exhaust. On OBD 2 cars where no actual sniffer tests are involved, there really isn't a downside to using a high quality metallic substrate cat if you are a performance enthusiast.

some images taken from: Santos, "Evaluation of the conversion efficiency of ceramic and metallic three way catalytic converters," Energy Conversion and Management Vol 49 Issue 2, 2008.

#2

Interesting. I saw a post where some one had taken a stock cat apart and removed half the monolith or substrate and re-installed. Great flow and he was passing emissions. Seems like a better idea is remove all the stock stuff and replace with 1/2 non metallic to get the better removal at medium loads and still have good flow.

I wonder why Mazda went metallic back then? flow characteristics? Cost?

I wonder why Mazda went metallic back then? flow characteristics? Cost?

#3

Interesting. I saw a post where some one had taken a stock cat apart and removed half the monolith or substrate and re-installed. Great flow and he was passing emissions. Seems like a better idea is remove all the stock stuff and replace with 1/2 non metallic to get the better removal at medium loads and still have good flow.

I wonder why Mazda went metallic back then? flow characteristics? Cost?

I wonder why Mazda went metallic back then? flow characteristics? Cost?

FD:

The FD went to a single metal precat. For whatever reason, these clogged very quickly compared to the older dual ceramic precat design.

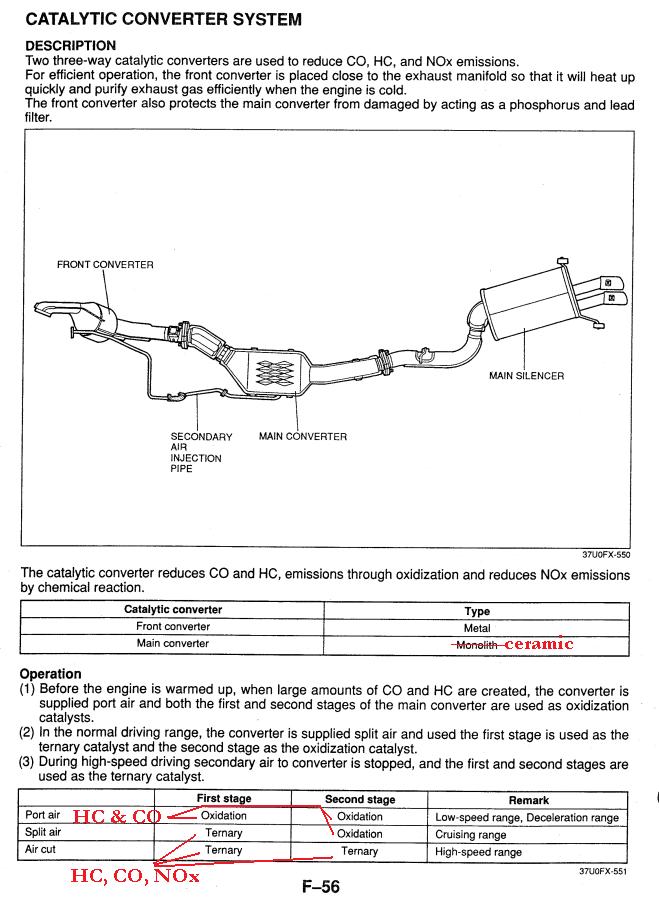

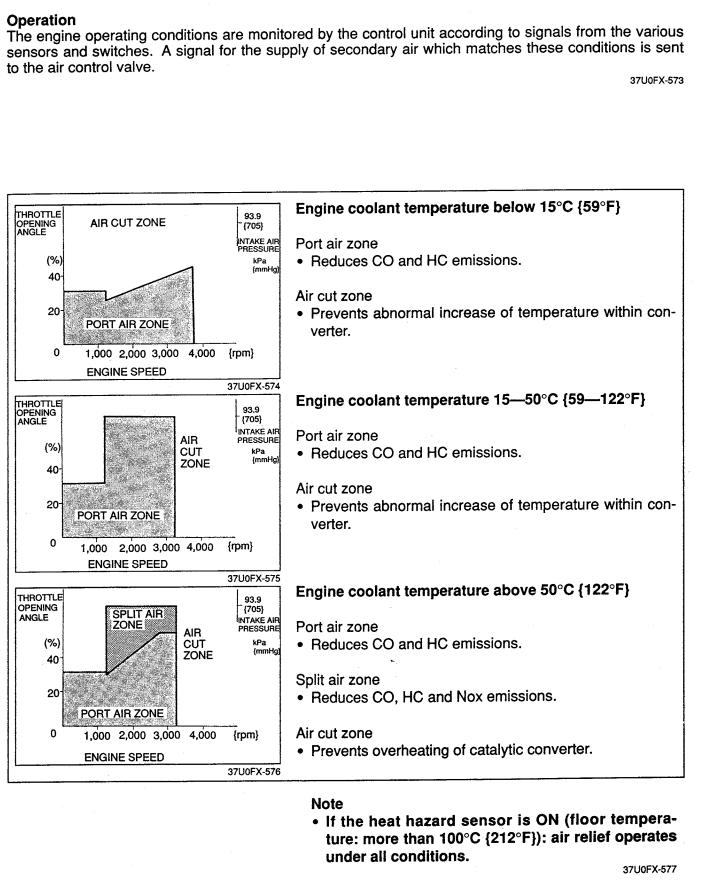

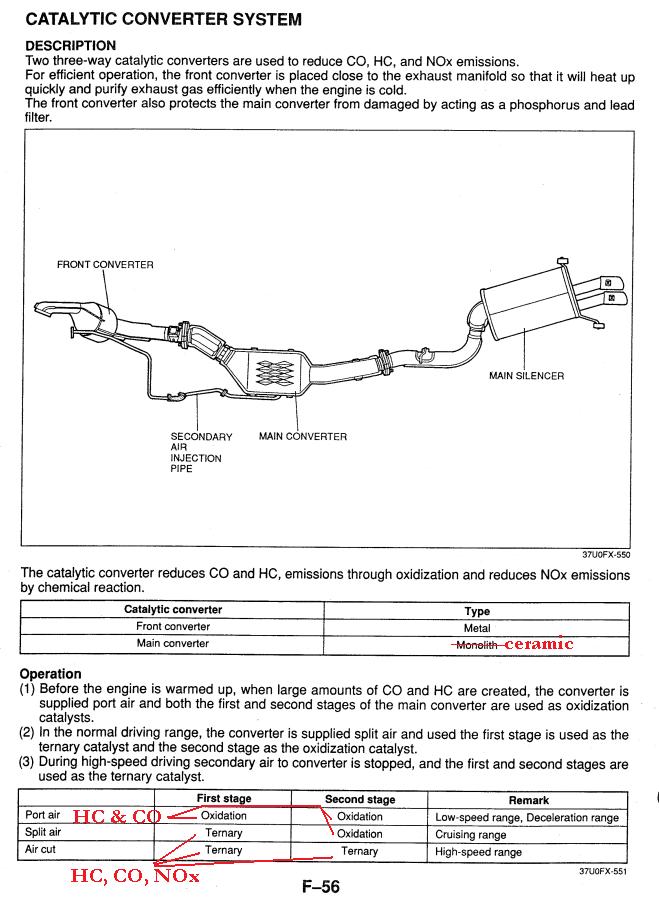

During conditions that produce high levels of HC and CO (idle and warmup), the ACV directs airpump air to the exhaust ports (before the O2 sensor) by using the port air solenoid and actuator. During port air conditions the main converter is used exclusively for oxidation (HC and CO conversion).

#4

Right, I am thinking I only care about the performance when it is fully warmed up at the emissions station. Sounds like the ceramic is better under those conditions. So take the ceramic out of one of the pre cats on the FC and install in the FD housing...probably a pain.

Maybe just to swap in.

Are you saying that the air injection only works when the substrate is cold? So when you are at the emissions station for the sniff test it should not be operating?

Interesting, maybe that simplifies getting a single turbo through some what....

Maybe just to swap in.

Are you saying that the air injection only works when the substrate is cold? So when you are at the emissions station for the sniff test it should not be operating?

Interesting, maybe that simplifies getting a single turbo through some what....

#5

Are you saying that the air injection only works when the substrate is cold? So when you are at the emissions station for the sniff test it should not be operating?

The air injection is always working unless the the exhaust overheat warning comes on or the rpms get high enough that the airpump is declutched. I suspect that the precat doesn't do much once the exhaust gets up to temperature, but I'm not sure. And nobody runs that precat anyway unless their car has 20k on it.

When port air is active (cold engine, idle, or lower load driving), air is injected before the O2 sensor. The main cat is used to convert HC and CO exclusively (oxidation). When split air is active, air is injected directly into the cat and the cat is used for both oxidation and reduction (NOx. the term "ternary" refers to 3 types of emissions being converted). Higher rpm cruising and medium loads tend to produce high levels of NOx. That is when EGR systems tend to be active on cars or intake cams are advanced (and exhaust cams retarded) to create an EGR effect.

If you want to simplify it you should be able to just hook the airpump and ACV up. Leave all the vacuum lines and plugs off the ACV and it should send air straight to the cat (if I am reading my diagrams correctly). You can pass with air going straight to the cat, 2nd gen guys do it all the time.

If you plan on installing a cat just to pass a test and then take it back off, I would go with ceramic. You might as well make the emissions test easier. I think metal substrate cats are best on cars that don't have to deal with a tailpipe sniffer. I have a friend running a metal cat on his Subaru because he wanted high flow without the smell. He can eliminate check engine lights be reflashing his stock ECU so it's not a big deal.

Thread

Thread Starter

Forum

Replies

Last Post

rgordon1979

3rd Generation Specific (1993-2002)

40

03-15-22 12:04 PM

[For Sale] Scratch & Dent, Used, and Open-Box Sale!

SakeBomb Garage

Vendor Classifieds

5

08-09-18 05:54 PM