How pulsewidth/duty control works.

#1

How pulsewidth/duty control works.

Bored at work. Time for another article guys.

In the automotive applications that enthusiasts typically care about most, pulsewidth-based duty cycle control is the key method of electronically controlling fluid flow with precision and fast response. The three main applications I want to discuss are:

fuel flow (fuel injectors)

boost control (boost control solenoid valve)

idle speed control (idle air control solenoid valve)

Theory

Here's how it works. When we are trying to control delivery of a fluid, the fluid is placed under some kind of vacuum or pressure by whatever is pumping that fluid. The pump could be a fuel pump (supplies the fuel injector), a turbo compressor (supplies the boost control solenoid), or the engine itself (draws a vacuum to pull air through the ISC valve). Some kind of valve is used to turn the flow on or off. In the simplified model I am presenting here, we can control the flow by:

1) changing the size of the orifice

This is like rejetting a carburetor or changing the nozzle in a methanol injection system as the only means of controlling flow. It may be necessary for a particular application, but it's not the most precise way of continuously metering flow for different conditions.

2) changing the position of on open valve

Precisely controlling how far open or closed a valve is can be complicated. Think of what's involved in controlling a throttle plate: at the very least we need a cable or a motor, and some way of measuring its position.

3) adjusting the vacuum/pressure on the fluid

One of the problems with adjusting the vacuum/pressure of the fluid to control flow is that you may have to speed up or slow down whatever pump you are using. This can be complicated, relatively unresponsive, or expensive. Some methanol injection systems may speed up or slow down the pump to provide crude control over methanol flow.

4) Completely opening or shutting the valve

Aha! This is cheap and simple, like flipping a light switch! We don't need to know exactly how the valve is positioned, we don't need to change the amount of pressure on the fluid, and we can keep the orifice the same! But how do we precisely meter flow if the valve effectively has only two positions, fully open or fully closed?

To understand the concept of duty cycle control, find an [empty, so people don't think you're nuts] room with a light switch. Flip the switch off and on rapidly. As the light fixture cycles on and off, it kind of looks like the room is lit up. There are a few ways you can increase how "lit" the room appears. In a given interval of time, you can

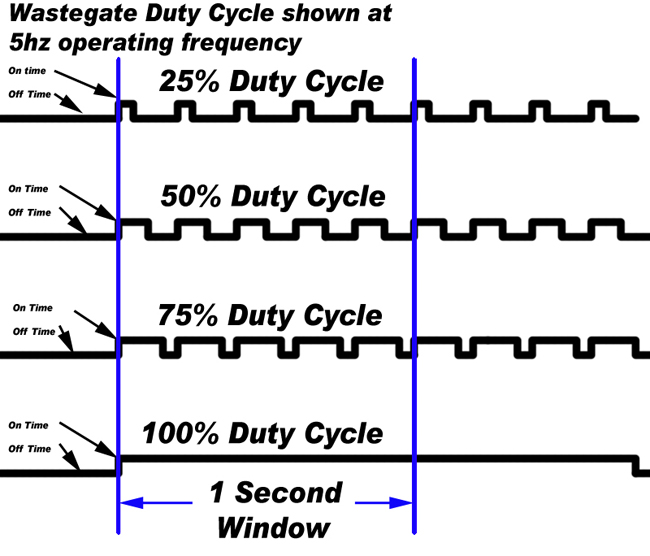

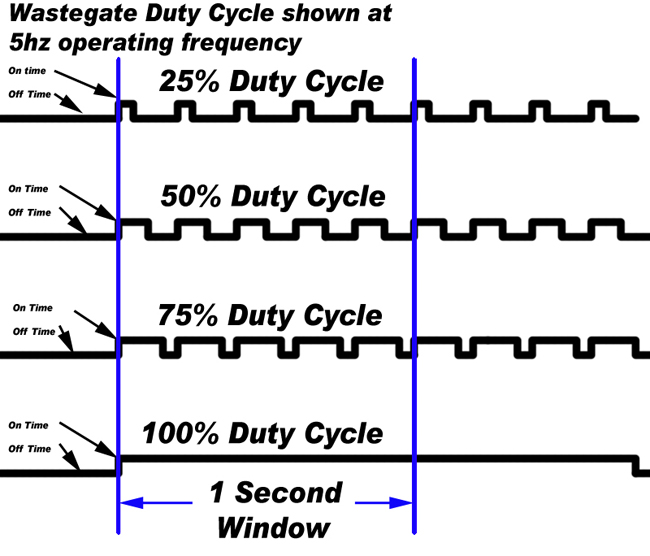

1) flick the light switch more rapidly (increase the frequency). As the frequency increases, the light is turned on more times in a given interval. But the switch is actually "on" for a shorter time period (pulsewidth) each time the switch is cycled from on to off.

2) flick the light switch the same number times in a given interval (keep the frequency constant), but leave the switch on longer (longer pulsewidth) each time.

Here's an example. I decide I am going to flip a light switch on and off 60 times in one minute. The frequency is fixed, I'm not going to change the number of times I cycle the switch. But what if I still want to make the room appear "brighter" ? Well, every time I cycle the light switch on, I keep it on longer before I turn it off (increase the pulsewidth). But I'm still cycling the light switch on and off 60 times in one minute. Again, the frequency is fixed.

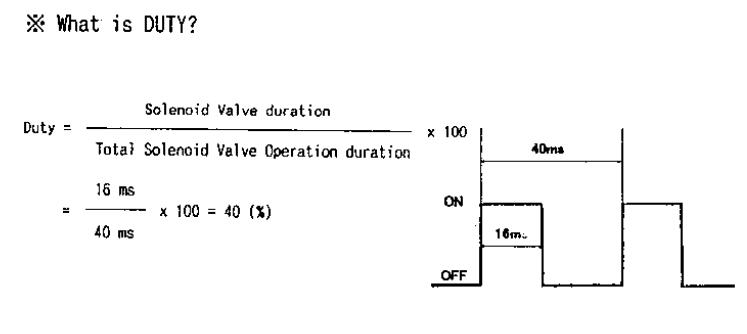

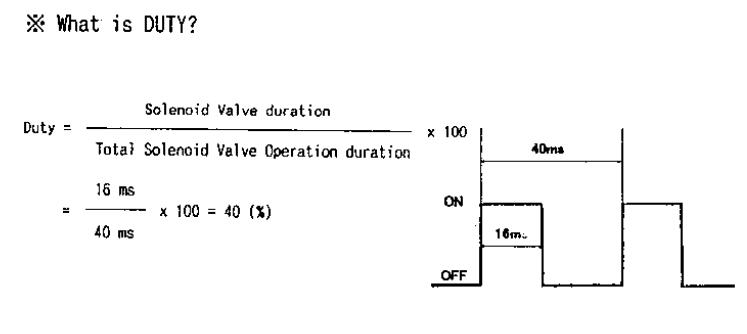

So how do I predict how "bright" the room will be? I know I'm going to flip the switch 60 times. So I measure how long the light switch was ON vs how long the light switch was OFF. That's my duty cycle.

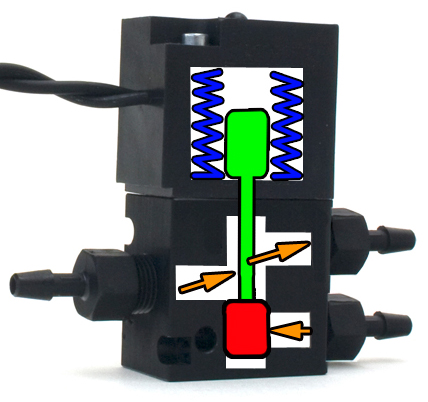

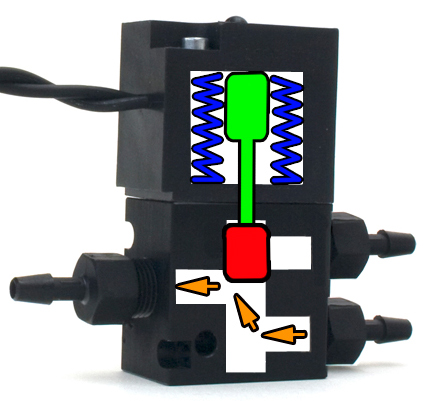

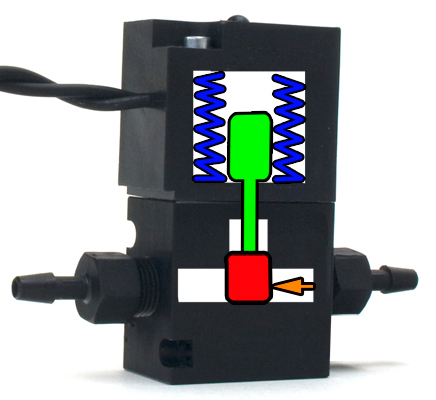

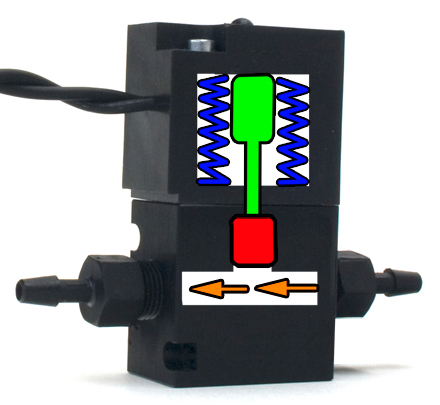

This is exactly how fuel flow, idle TB bypass air flow, and wastegate actuator air flow are metered. Instead of a human flipping a switch attached to a light fixture, we have a computer engaging a magnet which pulls open a valve.

To review, on the mechanical side we have:

-- Fixed fluid pressure (fixed relative to something). That's the same as "base" fuel pressure"

-- Fixed orifice size (TB size, nozzle size ,etc)

-- Only two possible valve positions: full open or full closed

On the electrical side we have:

-- Fixed frequency (number of times the magnetic coil is cycled in a given interval)

-- variable pulsewidth (number of milliseconds the coil is ON per cycle). Increasing pulsewidth yields increasing duty.

-- increasing duty for increased flow rates. Duty is the ratio of ON time to OFF time

Applications

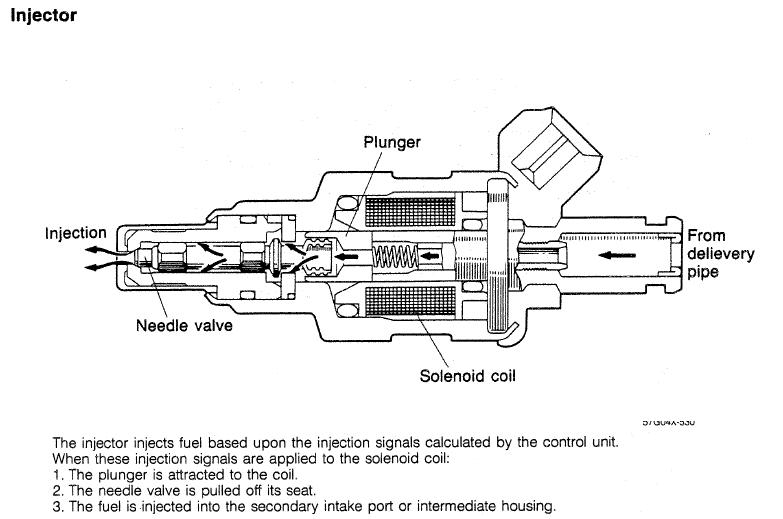

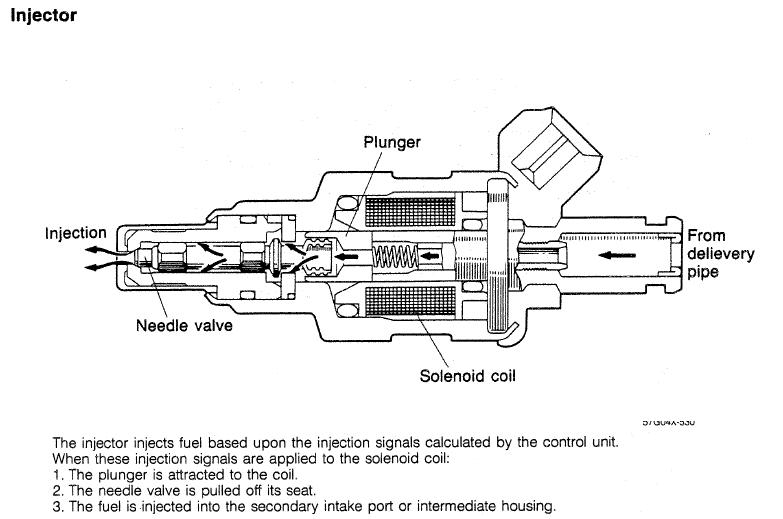

Top feed fuel injector

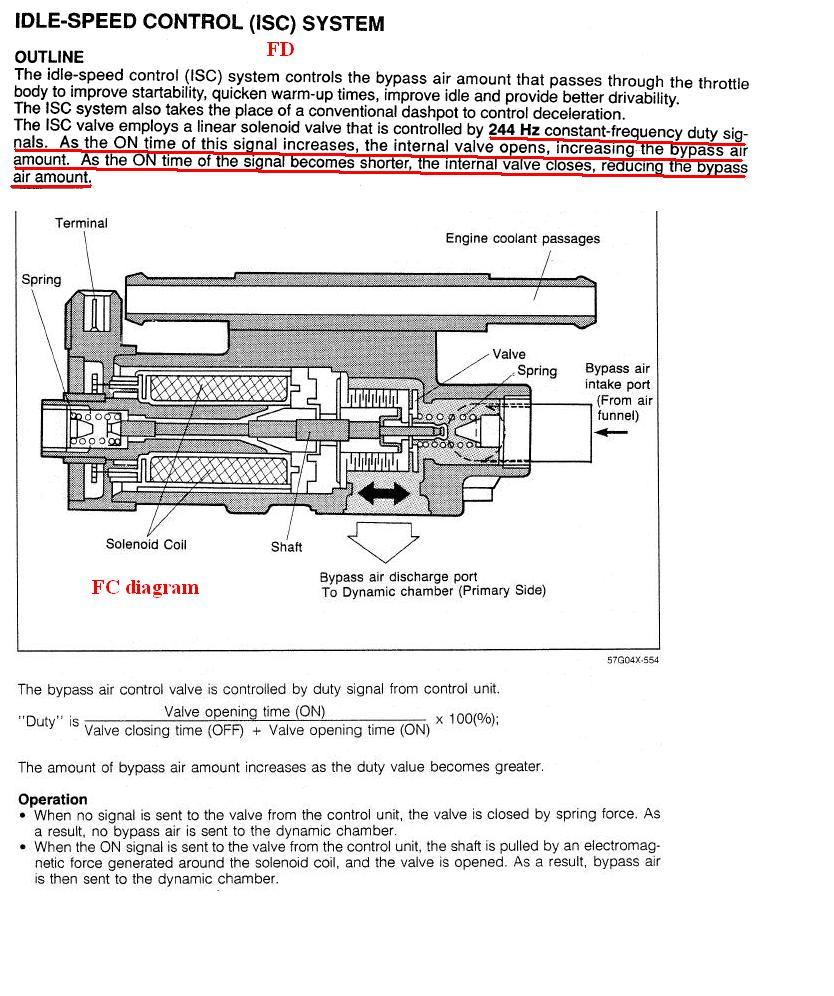

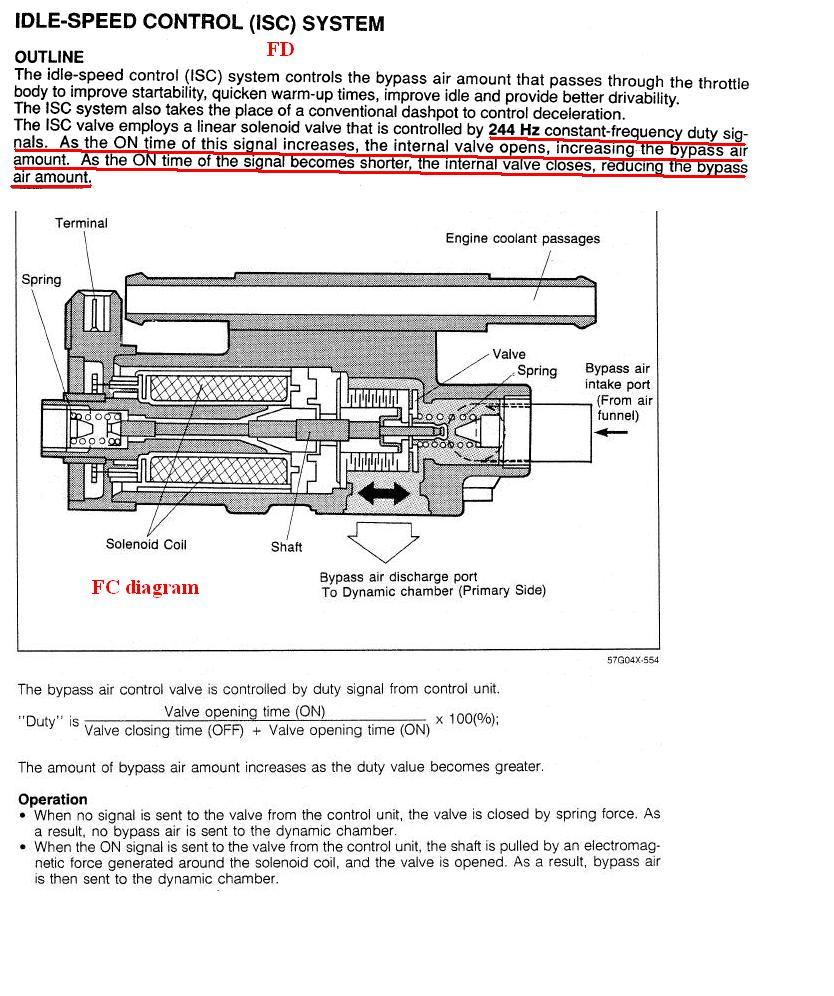

ISC valve

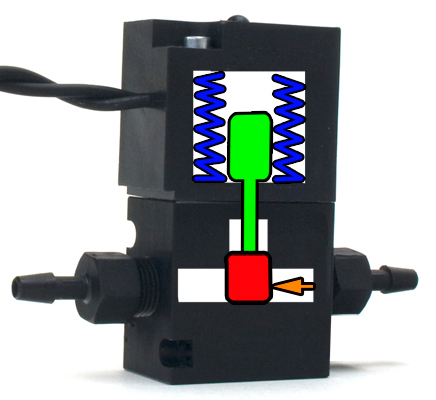

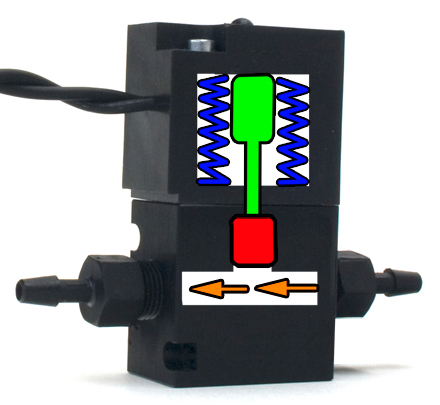

OEM style 2 port boost control solenoid

In the automotive applications that enthusiasts typically care about most, pulsewidth-based duty cycle control is the key method of electronically controlling fluid flow with precision and fast response. The three main applications I want to discuss are:

fuel flow (fuel injectors)

boost control (boost control solenoid valve)

idle speed control (idle air control solenoid valve)

Theory

Here's how it works. When we are trying to control delivery of a fluid, the fluid is placed under some kind of vacuum or pressure by whatever is pumping that fluid. The pump could be a fuel pump (supplies the fuel injector), a turbo compressor (supplies the boost control solenoid), or the engine itself (draws a vacuum to pull air through the ISC valve). Some kind of valve is used to turn the flow on or off. In the simplified model I am presenting here, we can control the flow by:

1) changing the size of the orifice

This is like rejetting a carburetor or changing the nozzle in a methanol injection system as the only means of controlling flow. It may be necessary for a particular application, but it's not the most precise way of continuously metering flow for different conditions.

2) changing the position of on open valve

Precisely controlling how far open or closed a valve is can be complicated. Think of what's involved in controlling a throttle plate: at the very least we need a cable or a motor, and some way of measuring its position.

3) adjusting the vacuum/pressure on the fluid

One of the problems with adjusting the vacuum/pressure of the fluid to control flow is that you may have to speed up or slow down whatever pump you are using. This can be complicated, relatively unresponsive, or expensive. Some methanol injection systems may speed up or slow down the pump to provide crude control over methanol flow.

4) Completely opening or shutting the valve

Aha! This is cheap and simple, like flipping a light switch! We don't need to know exactly how the valve is positioned, we don't need to change the amount of pressure on the fluid, and we can keep the orifice the same! But how do we precisely meter flow if the valve effectively has only two positions, fully open or fully closed?

To understand the concept of duty cycle control, find an [empty, so people don't think you're nuts] room with a light switch. Flip the switch off and on rapidly. As the light fixture cycles on and off, it kind of looks like the room is lit up. There are a few ways you can increase how "lit" the room appears. In a given interval of time, you can

1) flick the light switch more rapidly (increase the frequency). As the frequency increases, the light is turned on more times in a given interval. But the switch is actually "on" for a shorter time period (pulsewidth) each time the switch is cycled from on to off.

2) flick the light switch the same number times in a given interval (keep the frequency constant), but leave the switch on longer (longer pulsewidth) each time.

Here's an example. I decide I am going to flip a light switch on and off 60 times in one minute. The frequency is fixed, I'm not going to change the number of times I cycle the switch. But what if I still want to make the room appear "brighter" ? Well, every time I cycle the light switch on, I keep it on longer before I turn it off (increase the pulsewidth). But I'm still cycling the light switch on and off 60 times in one minute. Again, the frequency is fixed.

So how do I predict how "bright" the room will be? I know I'm going to flip the switch 60 times. So I measure how long the light switch was ON vs how long the light switch was OFF. That's my duty cycle.

This is exactly how fuel flow, idle TB bypass air flow, and wastegate actuator air flow are metered. Instead of a human flipping a switch attached to a light fixture, we have a computer engaging a magnet which pulls open a valve.

To review, on the mechanical side we have:

-- Fixed fluid pressure (fixed relative to something). That's the same as "base" fuel pressure"

-- Fixed orifice size (TB size, nozzle size ,etc)

-- Only two possible valve positions: full open or full closed

On the electrical side we have:

-- Fixed frequency (number of times the magnetic coil is cycled in a given interval)

-- variable pulsewidth (number of milliseconds the coil is ON per cycle). Increasing pulsewidth yields increasing duty.

-- increasing duty for increased flow rates. Duty is the ratio of ON time to OFF time

Applications

Top feed fuel injector

ISC valve

OEM style 2 port boost control solenoid

Thread

Thread Starter

Forum

Replies

Last Post

Jeff20B

1st Generation Specific (1979-1985)

73

09-16-18 07:16 PM

alexdimen

3rd Generation Specific (1993-2002)

20

10-23-15 01:50 PM

The1Sun

1st Generation Specific (1979-1985)

0

09-07-15 10:21 PM