have any of you dowl pinned your motor?

#1

WTB** Very Low Miles 94-95

Thread Starter

Join Date: Jul 2001

Location: Tejas

Posts: 3,298

Likes: 0

Received 0 Likes

on

0 Posts

have any of you dowl pinned your motor?

at what HP number should I worry about having my motor dowl pinned?

my motor is out now and will be done within a short time.

Should I do this now?

what are the downsides to this modifications?

jason

my motor is out now and will be done within a short time.

Should I do this now?

what are the downsides to this modifications?

jason

#3

WTB** Very Low Miles 94-95

Thread Starter

Join Date: Jul 2001

Location: Tejas

Posts: 3,298

Likes: 0

Received 0 Likes

on

0 Posts

thank you

thank you very much. I will pass on that. I want to go no higher than 425...if I could even get there with the current setup and the intercooler etc..that I still need.

j

j

#6

i've been told that it's only necessary if u put more then 16psi through it.

then again, i've been told there is no need if it's tuned right

most experts have different opinions

then again, i've been told there is no need if it's tuned right

most experts have different opinions

#7

Eats, Sleeps, Dreams Rotary

iTrader: (1)

Can anyone show me pictures of a dowelpinned motor? So I can see where exactly its doweled. And how thick and whatnot.

And is it dowl

Or dowel like the round pieces of wood

Also anyone have any good examples of modification of the water jacket (is that what it is called?)

And is it dowl

Or dowel like the round pieces of wood

Also anyone have any good examples of modification of the water jacket (is that what it is called?)

Trending Topics

#8

Rotary Enthusiast

Join Date: Feb 2001

Location: The First State

Posts: 1,375

Likes: 0

Received 0 Likes

on

0 Posts

Originally posted by Node

Can anyone show me pictures of a dowelpinned motor? So I can see where exactly its doweled. And how thick and whatnot.

And is it dowl

Or dowel like the round pieces of wood

Also anyone have any good examples of modification of the water jacket (is that what it is called?)

Can anyone show me pictures of a dowelpinned motor? So I can see where exactly its doweled. And how thick and whatnot.

And is it dowl

Or dowel like the round pieces of wood

Also anyone have any good examples of modification of the water jacket (is that what it is called?)

#9

Banned. I got OWNED!!!

Join Date: Apr 2001

Location: Washington, PA USA

Posts: 131

Likes: 0

Received 0 Likes

on

0 Posts

Hey node! Stock rotaries actually have two (2) dowl pins from the factory. The dowel pins are fit around two of the tension bolts, and thier outer diameter is the same as the machined opening in both the rotor housings and intermediate housings. The Pins are the length of one rotor housing, plus one end housing, plus 1/2 center housing. Two pins are used in one opening that runs the length of the engine -- they are installed seperately end-to-end so that it is possible to assemble the engine! Thus, all of the housings are locked together from any lateral movement. The stock pins are in opposite corners of the housings. The theory with adding extra dowls is that the side of the housings in a high HP engine will flex under the extra stress, allowing gas to bypass the coolant o-rings and cause failure, or even rupture the housings. I destroyed an '87 rear housing from excess flex at the upper dowel pin. This was a weak point on the '87 design, and was vastly improved on the '89 + blocks. My housing flex was due to a failed boost controller that caused massive detonation. The only damage to the engine was the cracked metal around the dowel pin -- the internals (3mm) were fine! To add extra dowls, the standard openings for X # of tension bolts are enlarged to the diameter of the dowls, and they are installed just like the factory ones. To picture this better, the holes for the tension bolts are slighty larger than the bolts themselves. Nothing would keep the whole sandwhich from sliding from side to side without something rigid to lock the whole thing together. If you are going to stick your sandwich out the window of a moving car with lots of extra mayo, you are going to need a few toothpicks to keep your tomatoes in place. Get it? Pictures would help. I'll go out in the shop and take a few pictures if I get a chance.

Node -- do a search and you should find some pics of my water jacket mods. If I find the article #, I will link to it here.

Node -- do a search and you should find some pics of my water jacket mods. If I find the article #, I will link to it here.

#10

Rotary Enthusiast

Join Date: Feb 2001

Location: The First State

Posts: 1,375

Likes: 0

Received 0 Likes

on

0 Posts

Originally posted by Exit13B

Hey node! Stock rotaries actually have two (2) dowl pins from the factory. The dowel pins are fit around two of the tension bolts, and thier outer diameter is the same as the machined opening in both the rotor housings and intermediate housings. The Pins are the length of one rotor housing, plus one end housing, plus 1/2 center housing. Two pins are used in one opening that runs the length of the engine -- they are installed seperately end-to-end so that it is possible to assemble the engine! Thus, all of the housings are locked together from any lateral movement. The stock pins are in opposite corners of the housings. The theory with adding extra dowls is that the side of the housings in a high HP engine will flex under the extra stress, allowing gas to bypass the coolant o-rings and cause failure, or even rupture the housings. I destroyed an '87 rear housing from excess flex at the upper dowel pin. This was a weak point on the '87 design, and was vastly improved on the '89 + blocks. My housing flex was due to a failed boost controller that caused massive detonation. The only damage to the engine was the cracked metal around the dowel pin -- the internals (3mm) were fine! To add extra dowls, the standard openings for X # of tension bolts are enlarged to the diameter of the dowls, and they are installed just like the factory ones. To picture this better, the holes for the tension bolts are slighty larger than the bolts themselves. Nothing would keep the whole sandwhich from sliding from side to side without something rigid to lock the whole thing together. If you are going to stick your sandwich out the window of a moving car with lots of extra mayo, you are going to need a few toothpicks to keep your tomatoes in place. Get it? Pictures would help. I'll go out in the shop and take a few pictures if I get a chance.

Node -- do a search and you should find some pics of my water jacket mods. If I find the article #, I will link to it here.

Hey node! Stock rotaries actually have two (2) dowl pins from the factory. The dowel pins are fit around two of the tension bolts, and thier outer diameter is the same as the machined opening in both the rotor housings and intermediate housings. The Pins are the length of one rotor housing, plus one end housing, plus 1/2 center housing. Two pins are used in one opening that runs the length of the engine -- they are installed seperately end-to-end so that it is possible to assemble the engine! Thus, all of the housings are locked together from any lateral movement. The stock pins are in opposite corners of the housings. The theory with adding extra dowls is that the side of the housings in a high HP engine will flex under the extra stress, allowing gas to bypass the coolant o-rings and cause failure, or even rupture the housings. I destroyed an '87 rear housing from excess flex at the upper dowel pin. This was a weak point on the '87 design, and was vastly improved on the '89 + blocks. My housing flex was due to a failed boost controller that caused massive detonation. The only damage to the engine was the cracked metal around the dowel pin -- the internals (3mm) were fine! To add extra dowls, the standard openings for X # of tension bolts are enlarged to the diameter of the dowls, and they are installed just like the factory ones. To picture this better, the holes for the tension bolts are slighty larger than the bolts themselves. Nothing would keep the whole sandwhich from sliding from side to side without something rigid to lock the whole thing together. If you are going to stick your sandwich out the window of a moving car with lots of extra mayo, you are going to need a few toothpicks to keep your tomatoes in place. Get it? Pictures would help. I'll go out in the shop and take a few pictures if I get a chance.

Node -- do a search and you should find some pics of my water jacket mods. If I find the article #, I will link to it here.

Are you using the 87 block pinned now? or did you go with a 89+ block>?

#11

Old [Sch|F]ool

I found some cylinder head dowel pins that would be just right for this, and they're real cheap too. The hard part will be finding a machine shop I can trust to PRECISELY machine all the holes! I was thinking of four dowels along the combustion side of the engine per sealing surface, that's 8 dowels per rotor - 16 total - 32 holes that must be milled in exact alignment with each other. Pretty scary to think about how EASILY it can get screwed up, and turn a pile of expensive housings into scrap metal.

BTW I *was* thinking about doing sets of 5 instead of 4, but I'm doing this to 12A plates and rotor housings, and there's one part of the casting on the front plate where the metal is REALLY thin around the tension bolt threads, wouldn't trust it to support any side load, so no dowels along that tension bolt.

If I was doing a later 13BT block, I wouldn't worry about dowelling, as I'm not looking for Huge Power, but I do want a turbo on a 12A with some sort of reliability, so it gets doweled.

BTW I *was* thinking about doing sets of 5 instead of 4, but I'm doing this to 12A plates and rotor housings, and there's one part of the casting on the front plate where the metal is REALLY thin around the tension bolt threads, wouldn't trust it to support any side load, so no dowels along that tension bolt.

If I was doing a later 13BT block, I wouldn't worry about dowelling, as I'm not looking for Huge Power, but I do want a turbo on a 12A with some sort of reliability, so it gets doweled.

#13

Old [Sch|F]ool

Yeah, it was the 5 tension bolt holes down from the top dowel that I was planning on putting extra dowels in. Then I got a sample of what dowels I was going to use, and did some measuring, and it was either the 3rd or the 4th dowel that wouldn't work too well because of lack of material. I'm pretty sure it was the 4th one down.

#15

Old [Sch|F]ool

When you run on cheap fuel, blow through a carburetor, and use a dizzy for timing, hell yes you're gonna need band-aids! it's still cheaper than $2k plus for a Haltech + tuning... that would cost more than a 1st-gen is worth!

#16

inteligent extratarestril

Join Date: Mar 2001

Location: The Sunny B.O.P, New Zealand

Posts: 1,313

Likes: 0

Received 0 Likes

on

0 Posts

all comes down to how much HP you want to be able to make RELAIBLY and how truely DRIVEABLE you want it to be

its like on another forum i frequent a guy was complaing about the prices of the likes of Haltech/motec/autronic to run a 20B - if you wanna play with the big boys and make big boys numbers then be prepared to pay big boys $$$

its like on another forum i frequent a guy was complaing about the prices of the likes of Haltech/motec/autronic to run a 20B - if you wanna play with the big boys and make big boys numbers then be prepared to pay big boys $$$

#17

Old [Sch|F]ool

Just throwing money at a car isn't very sporting. The real fun comes from trying to do everything on zero budget - that's where innovation comes in.

#18

Eats, Sleeps, Dreams Rotary

iTrader: (1)

Originally posted by peejay

Just throwing money at a car isn't very sporting. The real fun comes from trying to do everything on zero budget - that's where innovation comes in.

Just throwing money at a car isn't very sporting. The real fun comes from trying to do everything on zero budget - that's where innovation comes in.

#19

Old [Sch|F]ool

Originally posted by Node

junkyard turbo, junkyard IC, custom mods, all done by yourself, custom exhaust (done by shop for cheap if not by yourself), yada yada yada.

junkyard turbo, junkyard IC, custom mods, all done by yourself, custom exhaust (done by shop for cheap if not by yourself), yada yada yada.

I know what'll happen though... it'll end up that dowelling will just be too freakin' much money for the machine shop labor so I'll end up doing another one of my port-a-junkyard-engine-and-reuse-everything jobs and run the mixtures really rich and keep timing knocked back to like 15L/0T in the powerband and use water injection as well as a big I/C and cross my fingers and pray that it doesn't detonate and kill the engine because of crappy fuel... all the while making less power and less MPG than if I'd spent the same money on a twin turbo non-I/C small block Ford that would also last lots longer.

'Cos SBFs don't sound as cool, that's why!

I was also thinking of trying out ceramic thermal coating on the rotor faces... everyone I've talked to/heard from who put the spray-on ceramic coatings on pistons/cylinder heads said that no matter what they did with timing they could not get their cars to detonate.. at all! Even to the point of misfiring and losing power, they couldn't get the engines to knock even on the cheapest swampwater, err gasoline. A downside was that the engines wouldn't warm up in the winter, so they had ****-poor heat... but as I only want to (only CAN for that matter) put ceramic coat on the rotor faces, that would only really affect oil temps... oil temps stay low because of less heat to absorb, WILL also affect coolant temps as well, keep things from getting too hot. Downside is that the rotor faces have to be sandblasted and the rotors have to be baked to cure the coating... meaning new rotor bearings are probably mandatory (unless they can handle 350deg for an hour!) Keeping the junk out of the apex seal grooves will also be fun, but I can think of a couple ways of doing it.

Last edited by peejay; 01-25-02 at 04:23 AM.

#20

Full Member

iTrader: (1)

Join Date: Mar 2001

Location: Gainesville, GA USA

Posts: 241

Likes: 0

Received 0 Likes

on

0 Posts

PeeJay,

I like your ideas. I agree with the tuning issue, but if you can make something more reliable... why not? I am building a '87 TII engine and have been told that I can't make big power w/o some pinning. I also understand that detonation will kill any motor, but if you can build it for "just in case" then why not. I have gotten bad diesel fuel before and it cost hundreds of dollars in injectors. I have also heard of fuel stations in my area putting 87 in the 93 pumps. How are you gonna tune to compensate for that? Like I said I'm a firm believer in good tuning, but since this will be a street car that will be fueled at many different places I like things to be a little more robust if possible. Other instances are things such as wastegate lines etc. In some of these instances 1 sec. is equivalent to infinite time, but if you can buy yourself .5 sec to lift off the gas and save it then it is all worth it. This kinda makes me rethink my 2mm vs. 3mm debate. I know everything is in a grand system of tradeoffs. I know a good deal about rotarys. Not nearly as much as many of you, but my car will be built by me, painted by me, modded by me, and tuned by me. I just want to do it all so I know exactly what's goin' on. Is there anything wrong with my reasoning?

I like your ideas. I agree with the tuning issue, but if you can make something more reliable... why not? I am building a '87 TII engine and have been told that I can't make big power w/o some pinning. I also understand that detonation will kill any motor, but if you can build it for "just in case" then why not. I have gotten bad diesel fuel before and it cost hundreds of dollars in injectors. I have also heard of fuel stations in my area putting 87 in the 93 pumps. How are you gonna tune to compensate for that? Like I said I'm a firm believer in good tuning, but since this will be a street car that will be fueled at many different places I like things to be a little more robust if possible. Other instances are things such as wastegate lines etc. In some of these instances 1 sec. is equivalent to infinite time, but if you can buy yourself .5 sec to lift off the gas and save it then it is all worth it. This kinda makes me rethink my 2mm vs. 3mm debate. I know everything is in a grand system of tradeoffs. I know a good deal about rotarys. Not nearly as much as many of you, but my car will be built by me, painted by me, modded by me, and tuned by me. I just want to do it all so I know exactly what's goin' on. Is there anything wrong with my reasoning?

#21

Unconfirmed

Join Date: Nov 2001

Location: Arbor Zena

Posts: 147

Likes: 0

Received 0 Likes

on

0 Posts

Look at:

http://www.xtremerotaries.com/ for pictures & comments.

No, I do not work there.

Yes, I have a pinned motor, (not by Ztreme...).

I thought it was worth it ...

ZoooooooM!

http://www.xtremerotaries.com/ for pictures & comments.

No, I do not work there.

Yes, I have a pinned motor, (not by Ztreme...).

I thought it was worth it ...

ZoooooooM!

#22

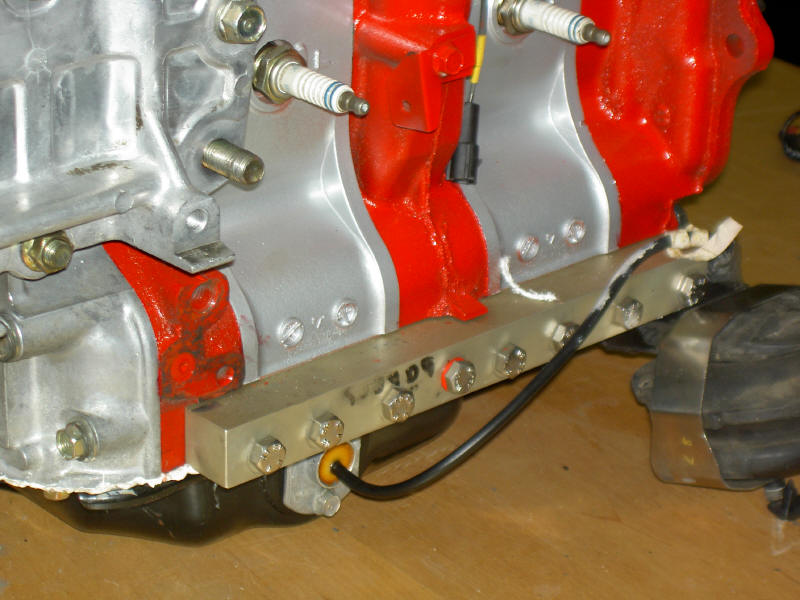

I have a piece of sturdy 7076 T6 aluminum bolted to the outside of the engine to achieve pretty much the same thing as dowelpinning.

Pic stolen from Spinola (www.rx7.nu), we have the same engine builder.

Pic stolen from Spinola (www.rx7.nu), we have the same engine builder.

Last edited by mks; 03-22-04 at 08:17 AM.

#23

Currently Winning

Join Date: May 2002

Location: Birmingham, AL

Posts: 2,438

Likes: 0

Received 0 Likes

on

0 Posts

Originally posted by peejay

When you run on cheap fuel, blow through a carburetor, and use a dizzy for timing, hell yes you're gonna need band-aids! it's still cheaper than $2k plus for a Haltech + tuning... that would cost more than a 1st-gen is worth!

When you run on cheap fuel, blow through a carburetor, and use a dizzy for timing, hell yes you're gonna need band-aids! it's still cheaper than $2k plus for a Haltech + tuning... that would cost more than a 1st-gen is worth!

and are some of you implying that down pinning isn't required if the tuning is perfect?

#24

NorCal 7's Co-founder

NO tuning is perfect. There is always a margin of error. I know some people are damned close to perfect like Steve Kan and a very few select others, but none are actually perfect. Just my .02 anyway.

Zach

Zach

#25

Missin' my FD

Join Date: Aug 2002

Location: Seminole, FL (Tampa Bay Area)

Posts: 1,755

Likes: 0

Received 0 Likes

on

0 Posts

My motor is dowel-pinned. The previous owner told me he was shooting for 600 RWHP, so I guess that's why it was done. He never even broke the motor in before selling it to me, so he never got a chance to try for 600.