Changing hotside from .82 to 1.05

#1

Senior Member

Thread Starter

Changing hotside from .82 to 1.05

Hi everyone, Been a long time since I posted.

The turbo is a PT6266 Vband in and out .82AR. Thinking of changing to the THV5S turbine housing which is 1.05AR.

What would be the effects on performance?

How about the tune?

The turbo is a PT6266 Vband in and out .82AR. Thinking of changing to the THV5S turbine housing which is 1.05AR.

What would be the effects on performance?

How about the tune?

#2

Senior Member

Thread Starter

Reading my own post, I think I may not have given enough info for someone to be able to formulate a reply.

The car is a 94 FD, The Turbo kit from A-Spec was installed going on 5 years ago. At that time it had a mild street port, and we were expecting close to 500whp. The tuner was only able to get about 400whp, and said it "seemed restricted". About 2 years ago it needed some body work and we took it to Speed 1. While there, we had Dave touch up the tune to try to improve the injector staging event (still sucks). While on the dyno the engine laid down, broken apex seal and dented rotor. So they went through the engine, put in lightened TII rotors, and and much more aggressive port job. So now it gets to 425whp. Dave says it "seems restricted".

The owner of the car and I have had discussions about what could be changed, And I feel the .82 AR turbine housing seems to be the likely culprit. I was looking at T4 housings to see if maybe I could make it fit with the shorty manifold. Then I saw that Precision now offers a 1.05 ar v-band housing.

So, can anyone give me some advice on what kind of improvement (or not) switching to a 1.05 AR housing would give?

And how much of a difference it would make with the tune? Would it likely need more or less fuel? Ignition timing?

The car is a 94 FD, The Turbo kit from A-Spec was installed going on 5 years ago. At that time it had a mild street port, and we were expecting close to 500whp. The tuner was only able to get about 400whp, and said it "seemed restricted". About 2 years ago it needed some body work and we took it to Speed 1. While there, we had Dave touch up the tune to try to improve the injector staging event (still sucks). While on the dyno the engine laid down, broken apex seal and dented rotor. So they went through the engine, put in lightened TII rotors, and and much more aggressive port job. So now it gets to 425whp. Dave says it "seems restricted".

The owner of the car and I have had discussions about what could be changed, And I feel the .82 AR turbine housing seems to be the likely culprit. I was looking at T4 housings to see if maybe I could make it fit with the shorty manifold. Then I saw that Precision now offers a 1.05 ar v-band housing.

So, can anyone give me some advice on what kind of improvement (or not) switching to a 1.05 AR housing would give?

And how much of a difference it would make with the tune? Would it likely need more or less fuel? Ignition timing?

#4

Senior Member

Thread Starter

Pump gas(93 octane) 50/50 water/methanol injection. 18psi.

Scouring through many build posts it seems that people with .82ish turbine housings get 400-420whp or so, and with 1.05 it's closer to 500. Everything was done to support 500+, except the .82 A/R

Scouring through many build posts it seems that people with .82ish turbine housings get 400-420whp or so, and with 1.05 it's closer to 500. Everything was done to support 500+, except the .82 A/R

#6

Is that 0.82 a T3?

Either way it should help out. Precision usually sizes their turbines on the small size compared to BW. So you have a turbo with a relatively small sized turbine with a small a/r on an engine that needs to breathe..

PTE 6266

Either way it should help out. Precision usually sizes their turbines on the small size compared to BW. So you have a turbo with a relatively small sized turbine with a small a/r on an engine that needs to breathe..

PTE 6266

- Turbine Wheel Exducer: 66mm

- Turbine Wheel Inducer: 74.17mm

- Turbine Wheel Exducer: 68mm

- Turbine Wheel Inducer: 76

#7

Old [Sch|F]ool

.82 on a rotary??

You will like the larger exhaust housing, in the same way that Captain Hiller liked the alien ship from Area 51 in Independence Day.

You will like the larger exhaust housing, in the same way that Captain Hiller liked the alien ship from Area 51 in Independence Day.

The following users liked this post:

b3delta (03-26-20)

Trending Topics

#8

Racing Rotary Since 1983

iTrader: (6)

you have a flow restricted system that will be an engine killer if run long enough.

Strokercharged asks the right question... is it a T3?

according to the catalog Precision only makes the .82 in a T3

a T3 should never never be anywhere near a 13B-REW as it has only 4.14 sq inches of inlet V a T4 at 5.5.

your motor is breathing thru a straw. i bet your back pressure at 18 is way more than 40 psi and your egts are probably 2000 F.

"Dave" is spot on... the system is restricted

please review the "System Design Sections" of my site

http://www.colemanprecisionrotaries....em-design.html

you need to do whatever you can to remove the T3 flange and replace it w a T4.

Precision T4 hotside options are .84, 1.0, 1.15 and 1.32. pick the 1.0 for your purposes. you will think you have a different engine in the car.

what size wastegate/s?

what is the I D of the runners on your manifold?

with a proper setup and tune the 6266 will make 550 rotary rwhp.

Strokercharged asks the right question... is it a T3?

according to the catalog Precision only makes the .82 in a T3

a T3 should never never be anywhere near a 13B-REW as it has only 4.14 sq inches of inlet V a T4 at 5.5.

your motor is breathing thru a straw. i bet your back pressure at 18 is way more than 40 psi and your egts are probably 2000 F.

"Dave" is spot on... the system is restricted

please review the "System Design Sections" of my site

http://www.colemanprecisionrotaries....em-design.html

you need to do whatever you can to remove the T3 flange and replace it w a T4.

Precision T4 hotside options are .84, 1.0, 1.15 and 1.32. pick the 1.0 for your purposes. you will think you have a different engine in the car.

what size wastegate/s?

what is the I D of the runners on your manifold?

with a proper setup and tune the 6266 will make 550 rotary rwhp.

Last edited by Howard Coleman; 07-28-19 at 07:05 PM.

The following users liked this post:

crash x 4 (04-14-20)

#9

Senior Member

Thread Starter

you have a flow restricted system that will be an engine killer if run long enough.

Strokercharged asks the right question... is it a T3?

according to the catalog Precision only makes the .82 in a T3

a T3 should never never be anywhere near a 13B-REW as it has only 4.14 sq inches of inlet V a T4 at 5.87.

your motor is breathing thru a straw. i bet your back pressure at 18 is way more than 40 psi and your egts are probably 2000 F.

"Dave" is spot on... the system is restricted

please review the "System Design Sections" of my site

SYSTEM DESIGN

you need to do whatever you can to remove the T3 flange and replace it w a T4.

Precision T4 hotside options are .84, 1.0, 1.15 and 1.32. pick the 1.0 for your purposes. you will think you have a different engine in the car.

what size wastegate/s?

what is the I D of the runners on your manifold?

with a proper setup and tune the 6266 will make 550 rotary rwhp.

Strokercharged asks the right question... is it a T3?

according to the catalog Precision only makes the .82 in a T3

a T3 should never never be anywhere near a 13B-REW as it has only 4.14 sq inches of inlet V a T4 at 5.87.

your motor is breathing thru a straw. i bet your back pressure at 18 is way more than 40 psi and your egts are probably 2000 F.

"Dave" is spot on... the system is restricted

please review the "System Design Sections" of my site

SYSTEM DESIGN

you need to do whatever you can to remove the T3 flange and replace it w a T4.

Precision T4 hotside options are .84, 1.0, 1.15 and 1.32. pick the 1.0 for your purposes. you will think you have a different engine in the car.

what size wastegate/s?

what is the I D of the runners on your manifold?

with a proper setup and tune the 6266 will make 550 rotary rwhp.

The 1.05 A/R housing (THV5S) that we are looking at is supposed to be a bolt on replacement.

The manifold/kit was built by Sean at A-Spec. The primary tubes are very short, and about 2"dia.

Wastegate is a single PT 46mm unit. I expect as the exhaust housing flow capacity is increased, the size of the wastegate will need to go up at some point.

Switching to a T4 would require major rework/replacement of the manifold, and just going to this 1.05 housing could be done in an afternoon. How much of an improvement do you think that would be? And by freeing up the hot side, what changes would I expect to have to do to the tune on the Haltech PS1000?

Last edited by Vicoor; 07-28-19 at 11:44 AM. Reason: left something out

#11

Racing Rotary Since 1983

iTrader: (6)

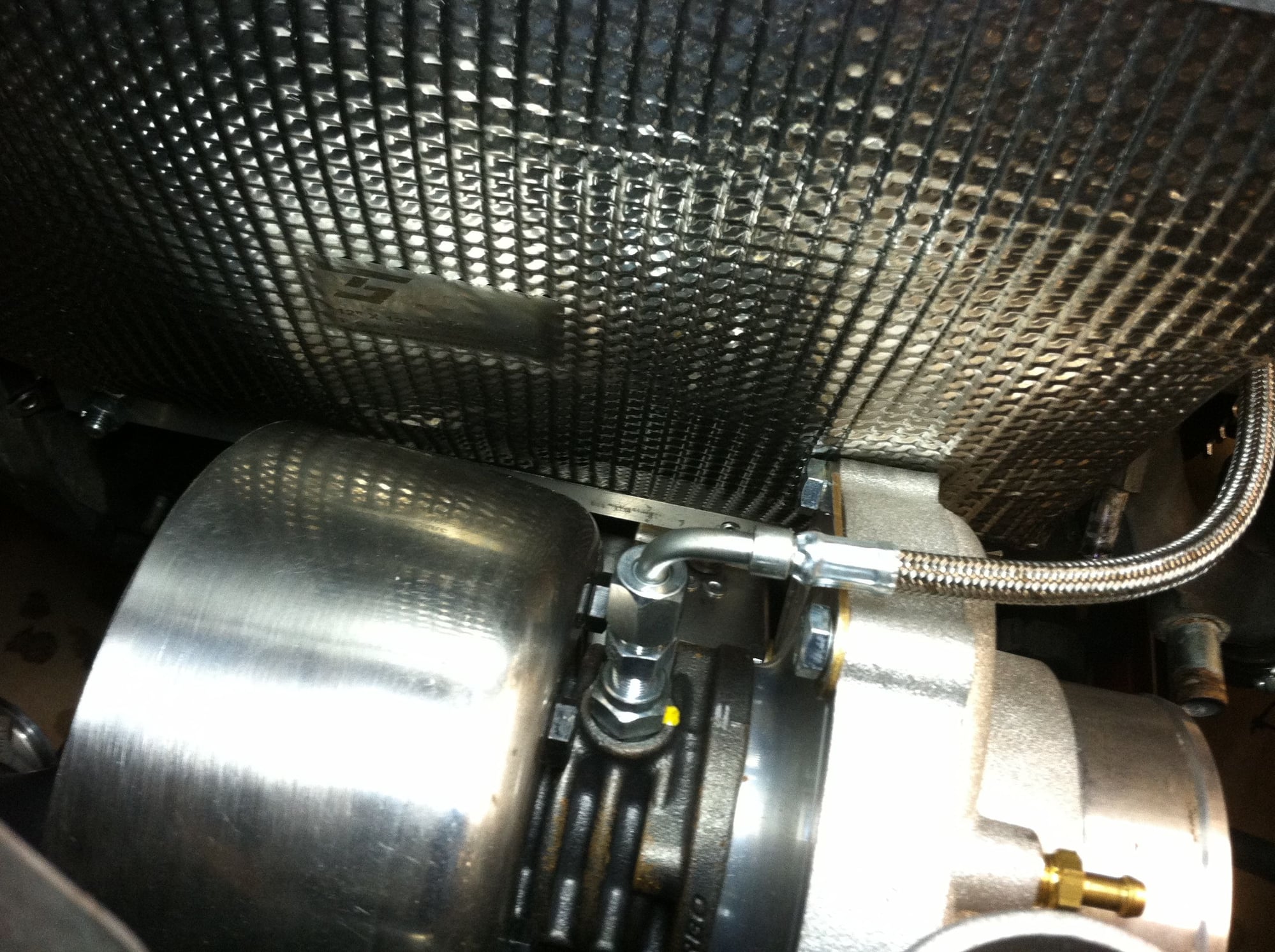

looks like a 3 inch I D on the V band in the picture. Precision lists a four bolt T3 discharge flange and a 5 bolt (for a Ford internal WG) as well as a T3 V band. they do not disclose the I D of the T 3 V band hotside. if it is 3 inches, which would mate with your manifold, that would give you plenty of area... 7.07 sq inches. this does not change the fact that the hotside is a T3. i am sure you know that a 1.0 T3 and a 1.0 T4 are vastly different as to flow. the number relates the radius to the diameter. you are probably O K with giving the larger T3 a go as it is your most simple and inexpensive possible fix.

i built a twin turbo (Garrett TO4E 44) manifold and ran it for four years, 10,000 miles. i had T3 hotsides. i started w .83 and ended up with 1.05s... but there were two... one for each rotor. i found a fair amount of backpressure with two .83s and less w the 1.05s. each had it's own 3 inch downpipe.

if you feel up to it i would be interested in the actual I D of your runners and the I D of the inlet on your hotside. if either of these is small it does change the situation as to max flow. i also suggest that you add a 1/4 Mica shield between your hotside housing and the motor as a turbo blanket won't get it done since your hotside is close to the runners. turbo blankets lower underhood temps but do not significantly impact the massive heat (1800 F) from the housing. Mica eliminates heat radiation.

i built a twin turbo (Garrett TO4E 44) manifold and ran it for four years, 10,000 miles. i had T3 hotsides. i started w .83 and ended up with 1.05s... but there were two... one for each rotor. i found a fair amount of backpressure with two .83s and less w the 1.05s. each had it's own 3 inch downpipe.

if you feel up to it i would be interested in the actual I D of your runners and the I D of the inlet on your hotside. if either of these is small it does change the situation as to max flow. i also suggest that you add a 1/4 Mica shield between your hotside housing and the motor as a turbo blanket won't get it done since your hotside is close to the runners. turbo blankets lower underhood temps but do not significantly impact the massive heat (1800 F) from the housing. Mica eliminates heat radiation.

The following users liked this post:

crash x 4 (04-14-20)

#12

Senior Member

Thread Starter

looks like a 3 inch I D on the V band in the picture. Precision lists a four bolt T3 discharge flange and a 5 bolt (for a Ford internal WG) as well as a T3 V band. they do not disclose the I D of the T 3 V band hotside. if it is 3 inches, which would mate with your manifold, that would give you plenty of area... 7.07 sq inches. this does not change the fact that the hotside is a T3. i am sure you know that a 1.0 T3 and a 1.0 T4 are vastly different as to flow. the number relates the radius to the diameter. you are probably O K with giving the larger T3 a go as it is your most simple and inexpensive possible fix.

i built a twin turbo (Garrett TO4E 44) manifold and ran it for four years, 10,000 miles. i had T3 hotsides. i started w .83 and ended up with 1.05s... but there were two... one for each rotor. i found a fair amount of backpressure with two .83s and less w the 1.05s. each had it's own 3 inch downpipe.

if you feel up to it i would be interested in the actual I D of your runners and the I D of the inlet on your hotside. if either of these is small it does change the situation as to max flow. i also suggest that you add a 1/4 Mica shield between your hotside housing and the motor as a turbo blanket won't get it done since your hotside is close to the runners. turbo blankets lower underhood temps but do not significantly impact the massive heat (1800 F) from the housing. Mica eliminates heat radiation.

i built a twin turbo (Garrett TO4E 44) manifold and ran it for four years, 10,000 miles. i had T3 hotsides. i started w .83 and ended up with 1.05s... but there were two... one for each rotor. i found a fair amount of backpressure with two .83s and less w the 1.05s. each had it's own 3 inch downpipe.

if you feel up to it i would be interested in the actual I D of your runners and the I D of the inlet on your hotside. if either of these is small it does change the situation as to max flow. i also suggest that you add a 1/4 Mica shield between your hotside housing and the motor as a turbo blanket won't get it done since your hotside is close to the runners. turbo blankets lower underhood temps but do not significantly impact the massive heat (1800 F) from the housing. Mica eliminates heat radiation.

Right now I'm just gathering info. And it sounds like the best course of action would be a full T4 setup. But we may in fact go the 1.05 housing route. I'm thinking I'm going to put a pressure tap in the manifold first, so I can check the back pressure (map/emap pressure ratio).

As far as heat management I already installed a stainless heatshield on the turbine, and an inconel heatshield on the LIM.

here's a picture

Last edited by Vicoor; 07-28-19 at 08:40 PM. Reason: incorrect text

#13

Racing Rotary Since 1983

iTrader: (6)

good catch on the site...

the (total) intake area into your hotside housing is 3.33 square inches.

each (single) 13B-REW exhaust port is 3.04.

as mentioned, the entirely inadequate rectangular T3 has 4.14 and a divided T4 is the rotary friendly fit at 5.5.

given the intake area and the need for lots more flow (around 30%) to make the same power as a piston engine as well as approx 200+F (higher than piston) exhaust gas temp i would be inclined to roll up my sleeves. your engine will thank you.

before getting into manifold modding i would make sure the I D of the runners is at least 2.0 inches. numerous manifolds were made of 1 1/2 pipe which is 1.90 O D but 1.61 I D. the 2.04 inch area puts the brakes on flow at 400 rw rotary hp causing higher EGTs, significant backpressure and a clamp on power.. sort of O K, back in the day, for the 370 rwhp GT35s but not a fit for modern turbos.

you mentioned tune w a proper hotside versus what you have. of course tune is very important to get right and i applaud you for using AI... what will happen is you will find your motor will be visiting areas of your map previously not logged. earlier spool and higher rpm. you will be decreasing backpressure and also losing exhaust being swept into the next intake stroke. look at a current log and make sure adjoining areas to what has been logged contain injector ontimes similar to what has been logged.

you are going to be shocked going to a T4.

BTW, i did a comparison between a .91 and 1.0 Borg Warner hotside last year. (SX-E 62). i was surprised how little difference although the 1.0 came out on top for me. the .91 made very good power at 8850, not a lot of power drop off from peak torque at 6450. EGTs were lower by 60 F w the 1.0 and backpressure dropped 15%. spool seemed the same.

the (total) intake area into your hotside housing is 3.33 square inches.

each (single) 13B-REW exhaust port is 3.04.

as mentioned, the entirely inadequate rectangular T3 has 4.14 and a divided T4 is the rotary friendly fit at 5.5.

given the intake area and the need for lots more flow (around 30%) to make the same power as a piston engine as well as approx 200+F (higher than piston) exhaust gas temp i would be inclined to roll up my sleeves. your engine will thank you.

before getting into manifold modding i would make sure the I D of the runners is at least 2.0 inches. numerous manifolds were made of 1 1/2 pipe which is 1.90 O D but 1.61 I D. the 2.04 inch area puts the brakes on flow at 400 rw rotary hp causing higher EGTs, significant backpressure and a clamp on power.. sort of O K, back in the day, for the 370 rwhp GT35s but not a fit for modern turbos.

you mentioned tune w a proper hotside versus what you have. of course tune is very important to get right and i applaud you for using AI... what will happen is you will find your motor will be visiting areas of your map previously not logged. earlier spool and higher rpm. you will be decreasing backpressure and also losing exhaust being swept into the next intake stroke. look at a current log and make sure adjoining areas to what has been logged contain injector ontimes similar to what has been logged.

you are going to be shocked going to a T4.

BTW, i did a comparison between a .91 and 1.0 Borg Warner hotside last year. (SX-E 62). i was surprised how little difference although the 1.0 came out on top for me. the .91 made very good power at 8850, not a lot of power drop off from peak torque at 6450. EGTs were lower by 60 F w the 1.0 and backpressure dropped 15%. spool seemed the same.

#15

Senior Member

Thread Starter

Once you get that housing changed, let me know what differences it makes to the tune.

#16

Banned. I got OWNED!!!

V-Band is always the way to go.

The following users liked this post:

Vicoor (08-05-19)

#19

Senior Member

Thread Starter

#21

Old [Sch|F]ool

What is funny is, RICE RACING used to say that larger ARs would actually decrease spool time because the engine could breathe better.

He was a big fan of 1.32s on street ports.

He was a big fan of 1.32s on street ports.

#22

Senior Member

Thread Starter

#23

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,818

Received 2,589 Likes

on

1,839 Posts

in general, if a part, like a turbine housing is way too big or way too small, taking a step closer to the ideal size will probably help everywhere. once you get closer to the optimal size though, then you will start to see it act like you would expect.

for example, lets just say that the optimal turbine housing is a 1.32, and the .82 is way too small. putting the 1.0 on there is still small, but it is a better fit than the .82, so it is possible that it will spool better. another example is like a stock FC turbo, its so undersized that you can switch to a full T4 and not really loose any spool...

for example, lets just say that the optimal turbine housing is a 1.32, and the .82 is way too small. putting the 1.0 on there is still small, but it is a better fit than the .82, so it is possible that it will spool better. another example is like a stock FC turbo, its so undersized that you can switch to a full T4 and not really loose any spool...

#24

Senior Member

Thread Starter

in general, if a part, like a turbine housing is way too big or way too small, taking a step closer to the ideal size will probably help everywhere. once you get closer to the optimal size though, then you will start to see it act like you would expect.

for example, lets just say that the optimal turbine housing is a 1.32, and the .82 is way too small. putting the 1.0 on there is still small, but it is a better fit than the .82, so it is possible that it will spool better. another example is like a stock FC turbo, its so undersized that you can switch to a full T4 and not really loose any spool...

for example, lets just say that the optimal turbine housing is a 1.32, and the .82 is way too small. putting the 1.0 on there is still small, but it is a better fit than the .82, so it is possible that it will spool better. another example is like a stock FC turbo, its so undersized that you can switch to a full T4 and not really loose any spool...

I'm waiting for an opportunity to actually measure backpressure with this .82 housing. The discussion with the owner is leaning more towards a T4 divided upgrade. but we're not there yet.

Still need input on how this change will affect the tune.

#25

On the other hand, the original exhaust manifold looks like it would be great for someone who wants 350rwp on a small turbo. For instace, one could re-flanged it for used Inycar efr 7163 v-band and reflanged the wastegate for a 60mm one.

Problem is, not many FD owners want 350rwhp single turbo since it is so easy to make that with the stock twins.

But, it could be run on stock fuel system and rom tuned ecu up to ~14psi which would be cool.

You should check if that manifold will fit a small turbo in an rew swapped rx8, because it looks like it would.

Problem is, not many FD owners want 350rwhp single turbo since it is so easy to make that with the stock twins.

But, it could be run on stock fuel system and rom tuned ecu up to ~14psi which would be cool.

You should check if that manifold will fit a small turbo in an rew swapped rx8, because it looks like it would.