Scratching my head over what apex seals to pick

#127

Racing Rotary Since 1983

iTrader: (6)

an apex seal thread

first off, everything here is anecdotal.

we all started out w OE seals. after the tips broke, gouging the rotor, rotor housings and damaging the turbine wheel we switched to Atkins or various other seals from the prior century. Atkins users found the same result as OE. broken seal, gouged rotor, rotor housing, and dinged turbine wheel.

followed by better alternatives... Goopy, E&J, Rotary Engine, RXParts and Iannetti.

i have never broken any of these seals and have found warpage to be minimal but it can easily happen. one of my motors with Rotary Engine seals was being broken in on the dyno (big mistake by the shop) and after way too little breakin time warped the seals. no question it happened because the decel fuel cut was ON. 4 thou on each of 6 seals. motor was perfect but had to come apart. i have had wonderful results w Rotary Engine seals both in customer motors and my own. likewise i have used lots of Goopy seals, including years and years in my motor, and have zero problems.

as someone said, apex seals are mostly the same basic material and it Warps w too much heat. the easiest way to toast seals is to have no lube on decel.

i generally run I Seals or Rotary Engine these days. i recently took apart my motor which had over 130 500+ pulls on it and had a look at my I-Seals. they are perfect and are now back in my motor along w Pineapple solid one piece dowels... but that is a story for another thread.

knowing Dr Iannetti's production to sale quality hurdles i am personally dubious as to a "bad batch." the reason I-Seals are challenging to buy is that only a modest amount pass all the tests and are offered for sale. that said, we are all human and XXXX happens so it is possible, but, IMO, not probable.

apex seals have made great progress since the introduction of the FD. most of the aforementioned seals generally won't break w detonation. All of them will warp if exposed to too much heat. generally the heat comes from lack of lube. i did a calculation a few years ago to factor the centrifugal weight/force of one apex seal against the rotor housing at 9000 rpm. as i recall, it was 29 pounds. all riding on a very small contact surface.

the odds are very good that if you have an apex seal problem in 2022 you or your setup were the cause.

first off, everything here is anecdotal.

we all started out w OE seals. after the tips broke, gouging the rotor, rotor housings and damaging the turbine wheel we switched to Atkins or various other seals from the prior century. Atkins users found the same result as OE. broken seal, gouged rotor, rotor housing, and dinged turbine wheel.

followed by better alternatives... Goopy, E&J, Rotary Engine, RXParts and Iannetti.

i have never broken any of these seals and have found warpage to be minimal but it can easily happen. one of my motors with Rotary Engine seals was being broken in on the dyno (big mistake by the shop) and after way too little breakin time warped the seals. no question it happened because the decel fuel cut was ON. 4 thou on each of 6 seals. motor was perfect but had to come apart. i have had wonderful results w Rotary Engine seals both in customer motors and my own. likewise i have used lots of Goopy seals, including years and years in my motor, and have zero problems.

as someone said, apex seals are mostly the same basic material and it Warps w too much heat. the easiest way to toast seals is to have no lube on decel.

i generally run I Seals or Rotary Engine these days. i recently took apart my motor which had over 130 500+ pulls on it and had a look at my I-Seals. they are perfect and are now back in my motor along w Pineapple solid one piece dowels... but that is a story for another thread.

knowing Dr Iannetti's production to sale quality hurdles i am personally dubious as to a "bad batch." the reason I-Seals are challenging to buy is that only a modest amount pass all the tests and are offered for sale. that said, we are all human and XXXX happens so it is possible, but, IMO, not probable.

apex seals have made great progress since the introduction of the FD. most of the aforementioned seals generally won't break w detonation. All of them will warp if exposed to too much heat. generally the heat comes from lack of lube. i did a calculation a few years ago to factor the centrifugal weight/force of one apex seal against the rotor housing at 9000 rpm. as i recall, it was 29 pounds. all riding on a very small contact surface.

the odds are very good that if you have an apex seal problem in 2022 you or your setup were the cause.

The following users liked this post:

Neutron (05-19-22)

#128

@Howard Coleman - can you give a little more detail on this? Just curious. My tuner, who is a well respected tuner but not a rotary only tuner, goes through a tuning process on every car he tunes. From what I can tell it involves locking the dyno at fixed RPM points in 250 RPM increments and going through different amounts of load at each one of these fixed points.

#129

Racing Rotary Since 1983

iTrader: (6)

sorry but don't have much info other than the motor was a new build and was not driven on the street. i doubt if significant time was spent on the dyno (other than tuning) before doing power runs. i don't think break in was the cause of the warped seals.. my opinion is a fuel cut on decel did them in. the tuner is excellant but fuel cuts don't work on a rotary.

#131

It seemed to me that 1.5 oz/gal premix + OMP was likely on the light side since the stated minimum by i-R is 2.5 oz/gal

if anything it might suggest that the i-R seals might not be the optimal street car choice since most people might be reluctant to use that much premix for street use.

.

if anything it might suggest that the i-R seals might not be the optimal street car choice since most people might be reluctant to use that much premix for street use.

.

#134

Racing Rotary Since 1983

iTrader: (6)

from the enclosed I-Seals instructions...

"High Perforrmance Engines Using Methanol (Pure alcohol) Fuel

2 -2.5 oz/gal

High Perf Engines using E85 Fuel or Gasoline Fuel

1.5-2 oz/gal

Engines w Functioning Oil Metering Pump using Gasoline or E85 Fuels

1-1.25 oz/gal "

"High Perforrmance Engines Using Methanol (Pure alcohol) Fuel

2 -2.5 oz/gal

High Perf Engines using E85 Fuel or Gasoline Fuel

1.5-2 oz/gal

Engines w Functioning Oil Metering Pump using Gasoline or E85 Fuels

1-1.25 oz/gal "

#135

I should know better than to trust my memory, but I keep forgetting that too

guess I just had that in my head from the perspective of an intended competition alcohol engine build

I’m already using 1.5 oz. Redline premix with 1/2 oz. top end alcohol oil for E50, can’t recall the non-fracturing apex seal brand, but not i-R. It doesn’t fog though.

.

guess I just had that in my head from the perspective of an intended competition alcohol engine build

I’m already using 1.5 oz. Redline premix with 1/2 oz. top end alcohol oil for E50, can’t recall the non-fracturing apex seal brand, but not i-R. It doesn’t fog though.

.

Last edited by TeamRX8; 05-28-22 at 10:10 AM.

#136

First time poster

Hello guys, Long time reader and first time poster. I have recently restored and built an FD in Dubai and since there are no rotary shops here I'm doing a lot of the mechanical work myself. if you want to see the build on Instagram its Dubai_rotary no fancy videos sorry just the build journey

I have just had my first experience with loosing compression on one rotor. I will reserve my judgment of the cause until I get the engine apart next week but I'm now just leaning that heat and EGT's can cause soft seals to warp. I'm currently running E&J seals in the build that should be seeing 98 and E85 fuels. After talking to Edgar at E&J he mentioned they his seals do not like seeing EGT's above 730 degrees and that its likely I have warped a seal from my engine seeing 820- 850 EGT. He also mentioned that he recommends an AFR no leaner then 12.6 which I can only assume is at cruseing? These EGT's are also mentioned on a youtube video her had posted.

Can I ask what AFR's you guy would run in a street car that operating at cursing speed for most of it life and that would be able to keep the EGT's this low?

My next choice of seal will be to run an I-Rotary seal but I'm worried that they will also warp in street car applications unless I cruise at a rich AFR in the 12's?

Any advice would be appreciated.

I have just had my first experience with loosing compression on one rotor. I will reserve my judgment of the cause until I get the engine apart next week but I'm now just leaning that heat and EGT's can cause soft seals to warp. I'm currently running E&J seals in the build that should be seeing 98 and E85 fuels. After talking to Edgar at E&J he mentioned they his seals do not like seeing EGT's above 730 degrees and that its likely I have warped a seal from my engine seeing 820- 850 EGT. He also mentioned that he recommends an AFR no leaner then 12.6 which I can only assume is at cruseing? These EGT's are also mentioned on a youtube video her had posted.

Can I ask what AFR's you guy would run in a street car that operating at cursing speed for most of it life and that would be able to keep the EGT's this low?

My next choice of seal will be to run an I-Rotary seal but I'm worried that they will also warp in street car applications unless I cruise at a rich AFR in the 12's?

Any advice would be appreciated.

Last edited by joelO; 11-23-22 at 04:14 AM.

#137

F'n Newbie...

iTrader: (6)

Random question: are you running an OMP?

If not, are you running fuel cut on decel?

I've seen many instances of reputable seals failing/warping prematurely due to fuel cut on decel causing excess friction and heat.

If not, are you running fuel cut on decel?

I've seen many instances of reputable seals failing/warping prematurely due to fuel cut on decel causing excess friction and heat.

The following users liked this post:

Howard Coleman (11-23-22)

#138

Racing Rotary Since 1983

iTrader: (6)

RE post 136

there are a number of apex seals that will work well for you. the newer somewhat softer seals will warp rather than break. most of the seals that are good will warp similarly. E & J certainly belongs on the recommended list.

i feel comfortable in thinking that it was not your seal choice that caused your problem. what are your compression numbers?

re your account of Edgar's recommended max EGT number 730 c/1346 F.... that doesn't seem correct as most see significantly higher numbers and don't have warped seals. your 820-850 C (1508 -1562 F) is a normal number.

please tell us more about your setup... ECU, turbo, intercooler, spark plugs, coils and sensors.

what is your lead and trail timing at peak torque?

there are a number of apex seals that will work well for you. the newer somewhat softer seals will warp rather than break. most of the seals that are good will warp similarly. E & J certainly belongs on the recommended list.

i feel comfortable in thinking that it was not your seal choice that caused your problem. what are your compression numbers?

re your account of Edgar's recommended max EGT number 730 c/1346 F.... that doesn't seem correct as most see significantly higher numbers and don't have warped seals. your 820-850 C (1508 -1562 F) is a normal number.

please tell us more about your setup... ECU, turbo, intercooler, spark plugs, coils and sensors.

what is your lead and trail timing at peak torque?

#139

Thanks for the responses guys,

As I said I wont blame the seals until open the engine but Edgar from E&J did tell me via email this week that anything over 730 Degrees C is a danger zone and that my 820-850 has likely caused the seal to warp. This is also stated in a youtube video he made explaining what causes his seals to warp where at around 4 minutes in he mentioned EGT over 1350-1400 F can cause the seals to warp.

Again It surprised me because so many people use them without any issues and it may turn out that its not my issues either, I just found that info interesting.

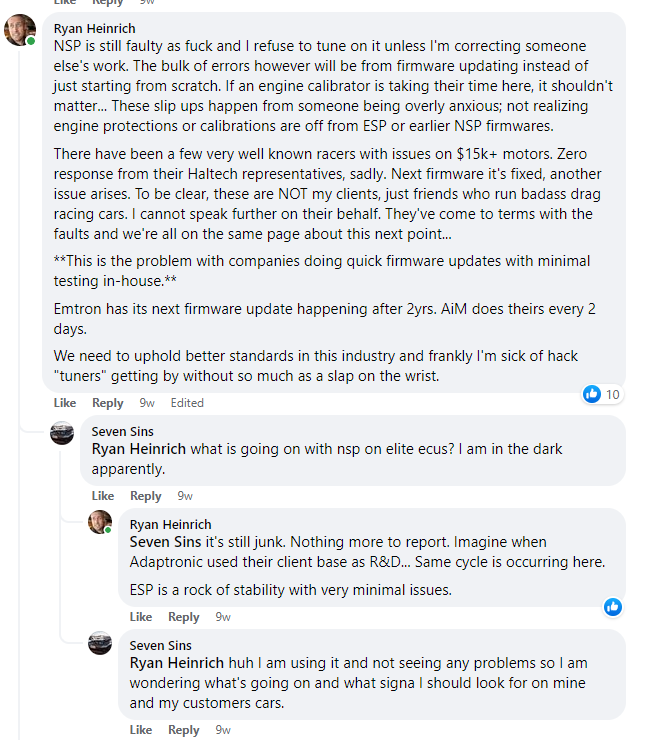

So I'm running 8:1 compression rotors machined in AUS by xtream rotary. its a 13b REW in an FD, I have a Borg warner EFR9180, ID1300cc primaries and ID2600 Secondaries. A radium fuel rail, radium surge tank with 2 x walbro 526 pump and large 10g power wires.

I'm running E&J seals on new housings.

I'm running a Haltech Elite 1500 with NSP software, haltch IGN-1A coils on a haltech terminated loom. Haltech Can Wideband and EGT sensor, NGK BR9EG plugs (Tuning at14 PSI) will run a different plug for E85 when I get there.

I'm also running a plazaman front mount intercooler.

My current comp numbers in the one rotor that is down are in the mid to high 70's cold and mid 50's hot.

The other rotor is in the high 90's cold and high 80's hot.

As I said I wont blame the seals until open the engine but Edgar from E&J did tell me via email this week that anything over 730 Degrees C is a danger zone and that my 820-850 has likely caused the seal to warp. This is also stated in a youtube video he made explaining what causes his seals to warp where at around 4 minutes in he mentioned EGT over 1350-1400 F can cause the seals to warp.

Again It surprised me because so many people use them without any issues and it may turn out that its not my issues either, I just found that info interesting.

So I'm running 8:1 compression rotors machined in AUS by xtream rotary. its a 13b REW in an FD, I have a Borg warner EFR9180, ID1300cc primaries and ID2600 Secondaries. A radium fuel rail, radium surge tank with 2 x walbro 526 pump and large 10g power wires.

I'm running E&J seals on new housings.

I'm running a Haltech Elite 1500 with NSP software, haltch IGN-1A coils on a haltech terminated loom. Haltech Can Wideband and EGT sensor, NGK BR9EG plugs (Tuning at14 PSI) will run a different plug for E85 when I get there.

I'm also running a plazaman front mount intercooler.

My current comp numbers in the one rotor that is down are in the mid to high 70's cold and mid 50's hot.

The other rotor is in the high 90's cold and high 80's hot.

#140

Racing Rotary Since 1983

iTrader: (6)

thanks for the info.

anything from Xtreme Rotary is top shelf.

your plugs are waaay too hot. 9s should never be anywhere near your engine. it appears you may be thinking that just because you are running 14 psi you are fine. 14 psi with a 9180 is a lot of power, more importantly, it is a lot of combustion chamber pressure and heat. you are frying the ground strap which will turn into a glow plug creating pre-ignition and knock. typical combustion chamber temp is below 2000 F. knock is around 3500 F.

in addition, hot plugs such as what you have in your motor, create more heat around the spark plug boss creating spark plug mountain. this protrusion raises the apex seal off the housing, losing compression and also creating chatter marks on your new housings.

you have major firepower in your coils and will have no problem firing 10 or 11 heat range plugs.

go to the "Tuning / Ignition" for proper spark plug part numbers and a more info

TUNING/ IGNITION

i still can't understand the EGT info you are getting. simply stated, your egts, in the 1500s, are fine and not the problem. i think your 9 plugs caused the problem. post a pic of them if you are able.

anything from Xtreme Rotary is top shelf.

your plugs are waaay too hot. 9s should never be anywhere near your engine. it appears you may be thinking that just because you are running 14 psi you are fine. 14 psi with a 9180 is a lot of power, more importantly, it is a lot of combustion chamber pressure and heat. you are frying the ground strap which will turn into a glow plug creating pre-ignition and knock. typical combustion chamber temp is below 2000 F. knock is around 3500 F.

in addition, hot plugs such as what you have in your motor, create more heat around the spark plug boss creating spark plug mountain. this protrusion raises the apex seal off the housing, losing compression and also creating chatter marks on your new housings.

you have major firepower in your coils and will have no problem firing 10 or 11 heat range plugs.

go to the "Tuning / Ignition" for proper spark plug part numbers and a more info

TUNING/ IGNITION

i still can't understand the EGT info you are getting. simply stated, your egts, in the 1500s, are fine and not the problem. i think your 9 plugs caused the problem. post a pic of them if you are able.

#141

My thought on the plug were as you said, I expected the power level to be ok for at least tuning and run in. My tuner has recommended a plug that is iridium with an 11 heat range which I have ordered.

I will have the engine out next week and will take some photos of the area around the plugs, the car has only done 5-6 full power dyno runs and 4-5 pulls on the road so hopefully they will be ok.

I have read through the tuning/timing link that you shared and it has a lot of good info in there. I will also be checking over my ignition system to make sure there are no problems in this area as well.

I cant upload the plug photo for some reason but its mostly a matt black color due to a misfire towards the end of my drive which I believe may have been a fowled plug probably from to much fuel in decal. The very tip of the electrode is a light grey/white color.

I'm hoping it is bent seals and nothing more serious. If this is the case I plan on try I rotary seals. I will take some photos of what evet my issue is and share it later next week.

The comments about EGT also surprised me a well but you can see Edgar mention in this video that EGT higher the 1400 F will be dangerous to the seals. watch from 3 minutes, https://www.enjautoworks.com/product...ce-apex-seals/ scroll down to see video

In his email to me he says the EGT should be 1350F ( the only thing I can think here is that he is expects them to be used with E85 and Methanol)

I will have the engine out next week and will take some photos of the area around the plugs, the car has only done 5-6 full power dyno runs and 4-5 pulls on the road so hopefully they will be ok.

I have read through the tuning/timing link that you shared and it has a lot of good info in there. I will also be checking over my ignition system to make sure there are no problems in this area as well.

I cant upload the plug photo for some reason but its mostly a matt black color due to a misfire towards the end of my drive which I believe may have been a fowled plug probably from to much fuel in decal. The very tip of the electrode is a light grey/white color.

I'm hoping it is bent seals and nothing more serious. If this is the case I plan on try I rotary seals. I will take some photos of what evet my issue is and share it later next week.

The comments about EGT also surprised me a well but you can see Edgar mention in this video that EGT higher the 1400 F will be dangerous to the seals. watch from 3 minutes, https://www.enjautoworks.com/product...ce-apex-seals/ scroll down to see video

In his email to me he says the EGT should be 1350F ( the only thing I can think here is that he is expects them to be used with E85 and Methanol)

#142

from the enclosed I-Seals instructions...

"High Perforrmance Engines Using Methanol (Pure alcohol) Fuel

2 -2.5 oz/gal

High Perf Engines using E85 Fuel or Gasoline Fuel

1.5-2 oz/gal

Engines w Functioning Oil Metering Pump using Gasoline or E85 Fuels

1-1.25 oz/gal "

"High Perforrmance Engines Using Methanol (Pure alcohol) Fuel

2 -2.5 oz/gal

High Perf Engines using E85 Fuel or Gasoline Fuel

1.5-2 oz/gal

Engines w Functioning Oil Metering Pump using Gasoline or E85 Fuels

1-1.25 oz/gal "

I've seen the same notes - and have used Iannetti products for years in both ceramics and lately steels so much respect to the man and the products - but this smacks of CYA rather than actual observed best practices from him in my estimation:

I don't believe that that increases in power or CCP warrant MORE premix as first we're talking about a friction modifier on the surface that doesn't particularly see more load with higher combustion pressures and second increased lubrication is already accomplished solely due to the fact that increased fuel is added. RPMs? Sure, I can see an argument though I've never needed to adjust this on engines I routinely run to 9-10k.

I don't believe that E85 and gasoline configurations should be lumped in together in their recommended oiling either.

Lastly I think that the recommended oil additive on a car with a functional OMP is probably in the range of 2x of whats needed - I'm not saying that one SHOULDN'T premix with a functionl OMP mind, just that the numbers seem an out of proportion SWAG.

I've run and torn down countless long term race engines and my go to for oiling rarely changes. Also remember that these are completely my personal opinion from observed teardowns etc so take it all with a grain of salt. I cannot fix your warranty claim if you deviate from what Iannetti or any builder other than myself suggests. I'd also love to hear what any other experienced builders have to say on the matter.

#145

Sure, buy why? These particular arguments (both housing lubrication and apex seal choice) seem to be parroted and opined without any sort of information to back it up past, 'xxx company said to do it'. Even if data in this case is difficult to parse/quantify for most applications I'd hope at the very least we could get enough heuristics from experienced people to have a reasonable conversation about it.

#146

because imo it adds an alcohol specific lubricity component beyond what a premix will provide to ethanol fuel. Premix only always seems a bit sticky/tacky to me, but I donít have any science to back that up. In fact Iím generally one to chide people for playing mad scientist concocting up magic potions. We had some real doozies over on RX8Club back in the day.

It could even be because Iím only running the standard Redline 2-stroke racing oil which is rated up to E50 since thatís what Iíve been doing. RL recommends their alcohol-specific premix above E50, but thereís a white paper stating itís the same 2-stroke racing lube less the gasoline specific detergents. Which they do sell an alcohol specific 4-stroke top lube additive as well. So it *seems* not to serve the same function as a pre-mix.

https://www.redlineoil.com/Content/f..._PROD_INFO.pdf

https://www.redlineoil.com/Content/f...Tech_6.20_.pdf

I could just be a clueless chicken-little though by running 1.5 oz. premix and 0.5 oz top lube per gallon of fuel (2 oz total per gal) in E50.

it was discussed some in the past here as well, likely a drag race specific comment:

https://motoiq.com/Top-Lube-for-E85/

.

It could even be because Iím only running the standard Redline 2-stroke racing oil which is rated up to E50 since thatís what Iíve been doing. RL recommends their alcohol-specific premix above E50, but thereís a white paper stating itís the same 2-stroke racing lube less the gasoline specific detergents. Which they do sell an alcohol specific 4-stroke top lube additive as well. So it *seems* not to serve the same function as a pre-mix.

https://www.redlineoil.com/Content/f..._PROD_INFO.pdf

https://www.redlineoil.com/Content/f...Tech_6.20_.pdf

I could just be a clueless chicken-little though by running 1.5 oz. premix and 0.5 oz top lube per gallon of fuel (2 oz total per gal) in E50.

it was discussed some in the past here as well, likely a drag race specific comment:

Some crew chiefs were adding two stroke oil and mixing as much as one ounce per gallon and even 3 ounces per gallon on rotaries. Some were complaining of lube separation when using two stroke oil. All said that adding some lube ended their injector and pump issues with ethanol for good.

.

Last edited by TeamRX8; 11-25-22 at 05:32 PM.

Thread

Thread Starter

Forum

Replies

Last Post