port flow

#1

Junior Member

Thread Starter

Join Date: Mar 2013

Location: Modesto, ca

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

port flow

Anybody know what the stock or ported ports of a 13b/rew flow?

I searched but didnt find anything. I thought it would have been discussed already, so maybe I'm sesrching wrong?

I searched but didnt find anything. I thought it would have been discussed already, so maybe I'm sesrching wrong?

#4

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

Ports aren't rated in cfm. Rotary engine ports are equivalent to the intake and exhaust valve geometry, lift, and duration on a piston engine, which are also not rated in cfm.

#5

Junior Member

Thread Starter

Join Date: Mar 2013

Location: Modesto, ca

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

All the information I have seen about cylinder heads are rated in cfm@x amount of lift. There's no equivalent way to measure the ports of the rotary engine to see how much air they flow?

#7

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

If you explain why you want to know this information then we can maybe point you in the right direction.

Trending Topics

#8

Junior Member

Thread Starter

Join Date: Mar 2013

Location: Modesto, ca

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I was more just curious. In piston motors its give an idea of what kind of power the engine can make. I have a feeling that the rotary engines ports flow a lot of cfm when compared to a piston engine.

I was reading somewhere a while ago that rotary engines require a lot of fuel because they have 1/3 the amount of time to get all the air and fuel into the engine when compared to a conversation 4 stroke engine.

Any truth to that? Maybe why they flow a lot of cfm? It's more just for info, trying to learn

I was reading somewhere a while ago that rotary engines require a lot of fuel because they have 1/3 the amount of time to get all the air and fuel into the engine when compared to a conversation 4 stroke engine.

Any truth to that? Maybe why they flow a lot of cfm? It's more just for info, trying to learn

#10

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

Yes, that is a major factor in the rotary engine's superior breathing efficiency.

Go to this website and read the Rotary Engine books by Kenichi Yamamoto. The two editions have slightly different information, which is why I recommend both.

Foxed.ca - Mazda RX-7 Manuals

Just so that you have a reference point to avoid confusion when reading about rotary engines, the Mazda RX-7 rotary engines are the NSU-Wankel type.

#11

Old [Sch|F]ool

That is a common misconception. The reason that it doesn't always work out that way is because that while the head may flow a lot of cfm on the flow bench, the combustion chambers may not be able to burn the larger mixture volume efficiently, resulting in less power output. The cfm numbers are really more for matching purposes.

A shorthand way of measuring this concept is port volume, but that only works if you are talking about a given cylinder head. So knowing the port volume for a 23 degree small block Chevy is somewhat meaningless if you want to compare to a Ford or a big-block or even 18 or 15 degree heads.

And then it gets extra fun when you start to wrap your head around different displacements wanting different things. A 500hp 434 is going to want a different cylinder head than a 500hp 302 even though they are both small block Chevys that are in theory moving the same amount of air. One is going to want a lot more velocity in the runner, or more accurately one is going to need less help making velocity in the runner...

The rotary shorthand is port diameter for peripheral ports, and the style of housings used on side ports. Turbo II have much larger runners than the 4-port stuff (I don't think you can port a 4-port as large without hitting water all around!) for example.

#12

Old [Sch|F]ool

The reality is that a 13B moves air like a 2.6l piston engine. And the wonderful combustion chamber shape and high internal surface area mean that they make power like a 2.0l engine and make heat like nothing else.

#14

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,800

Received 2,574 Likes

on

1,830 Posts

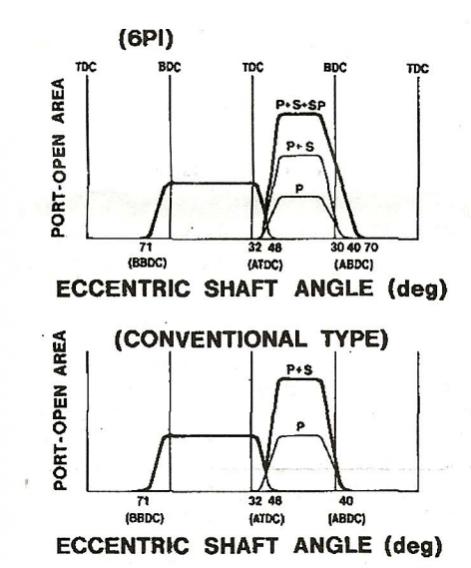

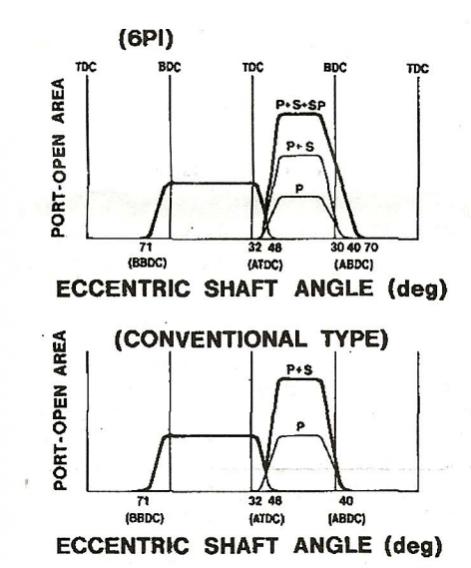

the big one is that there are three working chambers per rotor, but the rotor is geared so it spins once for 3 revolutions of the output shaft. so this means it takes three revolutions of the output shaft to have a power stroke on all three chambers, or to put it another way, it takes 1080 degrees to go through all 4 strokes, so each stroke is 270 degrees, unlike a piston engine, which has 180 degree strokes. if you think about it in relation to cam/port timing, the piston is ~260degrees out of 180, and the rotary is ~260degrees out of 270....

the other difference is that the rotary has a different physical location for each stroke, unlike a piston engine which does all four in the same place.

so from this we can conclude that the piston engine is quite lazy, it does like half the work of the rotary in the same time period.

#15

Junior Member

Thread Starter

Join Date: Mar 2013

Location: Modesto, ca

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I definitely see the piston engine as lazy when compared to the rotary engine.

The rotor is always on a power stroke while the piston spends half its time waiting.

The rotor is always on a power stroke while the piston spends half its time waiting.

#17

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,800

Received 2,574 Likes

on

1,830 Posts

so a big cam in a piston engine is like 300 degrees of open time, yes? a stroke in the piston engine is 180 degrees, so the 300 - 180 = 120 degrees where the valve is open outside of the stroke.

the rotary however has a 270 degree stroke, so a 300 degree port is only open for 30 degrees outside of its given stroke.

in theory this means that a given port/cam timing is less aggressive in the rotary vs the piston.

what it actually means is that a 300 degree cam in a piston engine and a 300 degree port in a rotary are two different things.

isn't theory fun? zomg, two different things are different!

the rotary however has a 270 degree stroke, so a 300 degree port is only open for 30 degrees outside of its given stroke.

in theory this means that a given port/cam timing is less aggressive in the rotary vs the piston.

what it actually means is that a 300 degree cam in a piston engine and a 300 degree port in a rotary are two different things.

isn't theory fun? zomg, two different things are different!

#19

you can open early for some exhaust over lap(which has it's benefits), and if you have forced induction, or an intake that has over 100 efficiency you can close them after the piston turns around and starts compressing, but only by a few degrees, not 120...

also cams spin at two to one, so a 282 degree cam is only open 141 degrees. (right?)

#20

Old [Sch|F]ool

No. Cam timing is in relation to crank degrees. The valve starts opening before TDC (limited by factors like "click clearance" against teh closing exhaust valve, and valve-piston clearance) and closes well after BDC.

A cam with duration like 230 degrees at .050 (a common mild-performance cam spec) means that there is 230 degrees of crank rotation where the valve is at least .050 off the seat. .050 is commonly chosen to measure duration because the first few thousandths of lift are on the takeup ramp part of the camlobe and this is greatly affected by lash. Plus, the port isn't really flowing anything yet.

The exhaust valve similarly will start to open well before BDC. The blowdown period uses combustion pressure to get 90% of the exhaust gases out, the rest of the exhaust gases are pulled out by the vacuum generated by the high speed slug of gases in the header. This vacuum is also useful to start the bowl area of the intake port moving. An eye opening statistic is that, for a certain NASCAR engine, the intake port was moving 80mph while the piston was still at TDC during the overlap period.

The moving air in the intake port will have its own inertia as well, and the optimal time to close the valve is when the pressure of the airflow moving into the cylinder is when it is exactly counteracted by the rising pressure from the piston coming back up after BDC. This maximizes the amount of air that the intake port will push into the cylinder. Because this is highly RPM dependent, this is why intake closing is the most critical point as far as determining where the powerband is.

Now. Yes, all of this timing theory does apply to rotaries, with the added feature/bug that port size and shape also affect timing. You can't have a huge high flowing port with mild timing.

This should also serve to illustrate why ports that take minimal effort to get moving, and can generate hurricane-like velocities, are very good ports. The air isn't pulled in by the piston/rotor so much as it starts getting pulled in like a Slinky and the real "magic" happens after TDC when the slinky is still moving and pushing air into the chamber. How much extra air gets in is dictated by how fast that air is moving and how much energy it requires to have that much velocity...

A cam with duration like 230 degrees at .050 (a common mild-performance cam spec) means that there is 230 degrees of crank rotation where the valve is at least .050 off the seat. .050 is commonly chosen to measure duration because the first few thousandths of lift are on the takeup ramp part of the camlobe and this is greatly affected by lash. Plus, the port isn't really flowing anything yet.

The exhaust valve similarly will start to open well before BDC. The blowdown period uses combustion pressure to get 90% of the exhaust gases out, the rest of the exhaust gases are pulled out by the vacuum generated by the high speed slug of gases in the header. This vacuum is also useful to start the bowl area of the intake port moving. An eye opening statistic is that, for a certain NASCAR engine, the intake port was moving 80mph while the piston was still at TDC during the overlap period.

The moving air in the intake port will have its own inertia as well, and the optimal time to close the valve is when the pressure of the airflow moving into the cylinder is when it is exactly counteracted by the rising pressure from the piston coming back up after BDC. This maximizes the amount of air that the intake port will push into the cylinder. Because this is highly RPM dependent, this is why intake closing is the most critical point as far as determining where the powerband is.

Now. Yes, all of this timing theory does apply to rotaries, with the added feature/bug that port size and shape also affect timing. You can't have a huge high flowing port with mild timing.

This should also serve to illustrate why ports that take minimal effort to get moving, and can generate hurricane-like velocities, are very good ports. The air isn't pulled in by the piston/rotor so much as it starts getting pulled in like a Slinky and the real "magic" happens after TDC when the slinky is still moving and pushing air into the chamber. How much extra air gets in is dictated by how fast that air is moving and how much energy it requires to have that much velocity...

#21

Red Pill Dealer

iTrader: (10)

Good post. I know people really into piston engine building and they say total lift is old school and not as important (yet important) as was once thought.

Here's how it was explained to me: The valve is only at full lift once. And briefly. But, it's near the seat twice in it's action. They spend a lot of time on the flow bench getting air to flow at the low lift points by shrinking the land (~.030 or even less) and using multi angle seat cuts way more than the old school three angle. Even hand working those into a radius.

I think this does apply to the ports on a rotary by the fact a radius helps flow and not just saving seals.

Here's how it was explained to me: The valve is only at full lift once. And briefly. But, it's near the seat twice in it's action. They spend a lot of time on the flow bench getting air to flow at the low lift points by shrinking the land (~.030 or even less) and using multi angle seat cuts way more than the old school three angle. Even hand working those into a radius.

I think this does apply to the ports on a rotary by the fact a radius helps flow and not just saving seals.

#22

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,800

Received 2,574 Likes

on

1,830 Posts

#23

Red Pill Dealer

iTrader: (10)

As I said before, lift is important but getting flow right off the seat is also important. My previous post takes in the assumption that the modifications already include max lift and dwell.

It really is amazing what can be done in the seat area of the valve in a piston engine and it's ability to flow at low lift. Good flow from the get go equals a fuller cylinder.

It really is amazing what can be done in the seat area of the valve in a piston engine and it's ability to flow at low lift. Good flow from the get go equals a fuller cylinder.

#24

So for a rotary, you've got a 4 port or a 6 port assuming you are talking side intake ports. The 6 port has a longer duration.

like exactly what kind of piston engines are we talking about here. 10-15 year old high revving n/a port injected engines with simple variable valve timing? Oldschool n/a fixed cam pushrod V8's? Or turbo direct injected engines with some really advanced valve timing tricks (cam phasers and a variable lift system).

All these flow bench charts you see online for piston engines don't show tumble or swirl flow strength. When you start grinding away at a head and port you can kill charge motion. Historically that's been an emissions thing for the most part, but now with turbo direct injected engines it's more important. The flow at lower lifts is important for better mixing with the direct injection, and for providing turbulent kinetic energy to reduce knocking tendency.

There's a scatterband among piston engines that expresses the tradeoff between the flow capability and the charge motion strength. The steeper the valve angle, the more flow possible (compare a modern Hemi to a 60s one - 60s one had way steeper valve angle) or the more tumble possible. However there are drawbacks to steep valve angles and the cylinder head has to fit in the car.

like exactly what kind of piston engines are we talking about here. 10-15 year old high revving n/a port injected engines with simple variable valve timing? Oldschool n/a fixed cam pushrod V8's? Or turbo direct injected engines with some really advanced valve timing tricks (cam phasers and a variable lift system).

All these flow bench charts you see online for piston engines don't show tumble or swirl flow strength. When you start grinding away at a head and port you can kill charge motion. Historically that's been an emissions thing for the most part, but now with turbo direct injected engines it's more important. The flow at lower lifts is important for better mixing with the direct injection, and for providing turbulent kinetic energy to reduce knocking tendency.

There's a scatterband among piston engines that expresses the tradeoff between the flow capability and the charge motion strength. The steeper the valve angle, the more flow possible (compare a modern Hemi to a 60s one - 60s one had way steeper valve angle) or the more tumble possible. However there are drawbacks to steep valve angles and the cylinder head has to fit in the car.