Grade my portjob

#1

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Memphis

Posts: 449

Likes: 0

Received 0 Likes

on

0 Posts

Grade my portjob

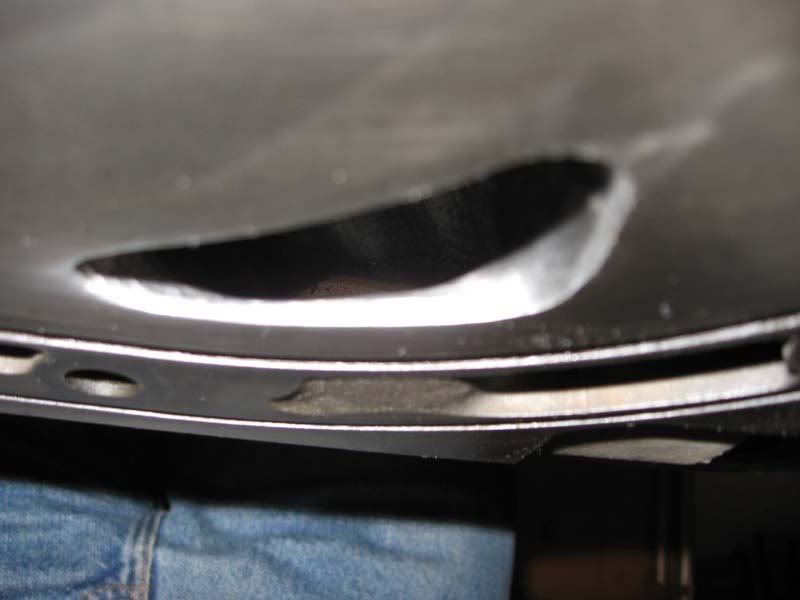

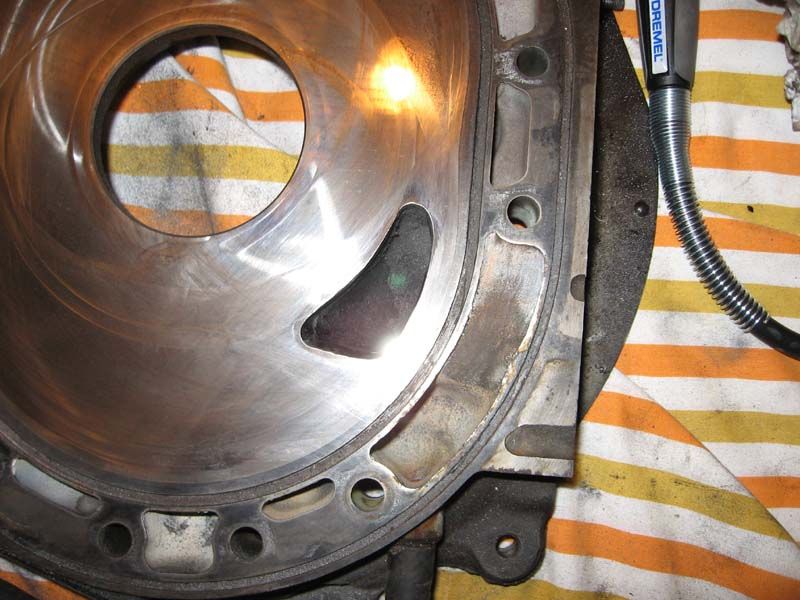

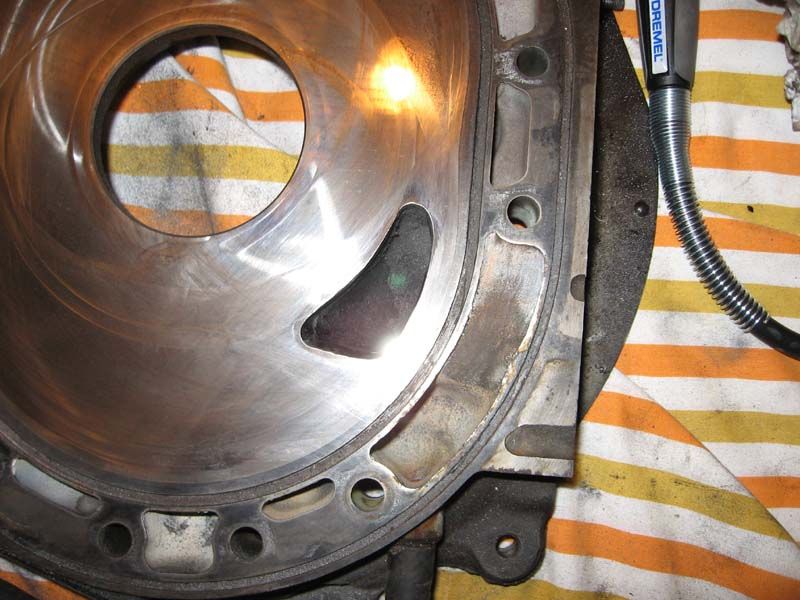

Ok, so this is my first attempt at porting my housings. I'll be doing the intermediate and exhaust ports tomorrow. Just thought I would see what you guys think about my technique.

All comments are appreciated. If there is something I did wrong or something I can do better, please let me know.

Thanks,

Jeremy

All comments are appreciated. If there is something I did wrong or something I can do better, please let me know.

Thanks,

Jeremy

#4

Did you try starting out with some kind of template, porting videos? I see that you widened the ports in the irons but the original casting is in the actual port. If your going to port do a complete job. Port the ENITRE thing to make a difference.

Also did you touch the side the oil control rings slide along?

Also did you touch the side the oil control rings slide along?

#7

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Memphis

Posts: 449

Likes: 0

Received 0 Likes

on

0 Posts

Trending Topics

#8

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Memphis

Posts: 449

Likes: 0

Received 0 Likes

on

0 Posts

Did you try starting out with some kind of template, porting videos? I see that you widened the ports in the irons but the original casting is in the actual port. If your going to port do a complete job. Port the ENITRE thing to make a difference.

Also did you touch the side the oil control rings slide along?

Also did you touch the side the oil control rings slide along?

As far as the inside where the oil control ring slides, I did barely touch that side to get to the outline of the template but it's more on the order of polishing than removing any serious material.

#9

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Memphis

Posts: 449

Likes: 0

Received 0 Likes

on

0 Posts

Did you try starting out with some kind of template, porting videos? I see that you widened the ports in the irons but the original casting is in the actual port. If your going to port do a complete job. Port the ENITRE thing to make a difference.

Also did you touch the side the oil control rings slide along?

Also did you touch the side the oil control rings slide along?

#10

There is no real purpose in just opening up the port on the actual face of the iron. Your still going to have the same air delivery if you didnt touch the actual inside part of the port and the openings on the outside of the irons. Clean up the inside of the port and open up them up on the outside to.

So I should get down inside the port? I didn't really do anything besides the outline.

As far as the inside where the oil control ring slides, I did barely touch that side to get to the outline of the template but it's more on the order of polishing than removing any serious material.

As far as the inside where the oil control ring slides, I did barely touch that side to get to the outline of the template but it's more on the order of polishing than removing any serious material.

#12

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Memphis

Posts: 449

Likes: 0

Received 0 Likes

on

0 Posts

Do you guys have any pictures of what you're suggesting? I don't want to get into the water jacket or anything like that. What are my limits for porting the outside of the intake port (where the lim connects)?

#13

There is no real purpose in just opening up the port on the actual face of the iron. Your still going to have the same air delivery if you didnt touch the actual inside part of the port and the openings on the outside of the irons. Clean up the inside of the port and open up them up on the outside to.

-J

#15

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Memphis

Posts: 449

Likes: 0

Received 0 Likes

on

0 Posts

What is the most glaring mistake that you guys see? How could I do better?

#17

You really need to get the Mazdatrix Porting video. It's $40. I bought it at Sevenstock last year even though I've been porting rotaries for over a decade. It's great info. It isn't a completely step by step on many little subtle nuances but it's good enough and shows you the tools needed for the job. If your video budget is higher, the DIY-13B video would be very nice to show you the complete in's and out's of engine rebuilding. At the very least also pick up a rebuild video from Atkins Rotary.

http://www.mazdatrix.com/videos.htm

http://www.mazdatrix.com/videos.htm

#18

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Memphis

Posts: 449

Likes: 0

Received 0 Likes

on

0 Posts

Do you think that the oil control ring is going to have a problem with the port that I did?

You really need to get the Mazdatrix Porting video. It's $40. I bought it at Sevenstock last year even though I've been porting rotaries for over a decade. It's great info. It isn't a completely step by step on many little subtle nuances but it's good enough and shows you the tools needed for the job. If your video budget is higher, the DIY-13B video would be very nice to show you the complete in's and out's of engine rebuilding. At the very least also pick up a rebuild video from Atkins Rotary.

http://www.mazdatrix.com/videos.htm

http://www.mazdatrix.com/videos.htm

#19

On FD irons, the oil control ring edge of the port is so close to the line from stock, there's usually not much to gain going in any more on a minor/medium street port. On an FC iron, there's a little more meat to get into before you're at the line however.

#20

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Memphis

Posts: 449

Likes: 0

Received 0 Likes

on

0 Posts

Honestly the one (front) iron looks to be into the control ring path slightly, so this engine may smoke a bit and eat a little oil.

On FD irons, the oil control ring edge of the port is so close to the line from stock, there's usually not much to gain going in any more on a minor/medium street port. On an FC iron, there's a little more meat to get into before you're at the line however.

On FD irons, the oil control ring edge of the port is so close to the line from stock, there's usually not much to gain going in any more on a minor/medium street port. On an FC iron, there's a little more meat to get into before you're at the line however.

I'm not exactly sure how those things seal. I thought that they sealed the oil from the e-shaft from getting into the intake. Wouldn't the width of the ring have to breach the intake port to lose any oil or am I missing something?

Also, why is there an inner and outer control ring?

Last edited by 3rd Gen Jeremy; 03-13-08 at 04:28 PM.

#21

-J

#22

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Memphis

Posts: 449

Likes: 0

Received 0 Likes

on

0 Posts

Saying things like this is NOT understanding... Think about it this way, if you left the runner and bowl un ported and could make the port opening SMALLER would it still have "the same air delivery"? Because if what you're saying was true....than what I just said would have to be as well and IT IS NOT.

-J

-J

I think what he's referring to is the duration that the port is open will be longer and therefore will allow more air into the combustion chamber.

#25

I wish I was driving!

Honestly the one (front) iron looks to be into the control ring path slightly, so this engine may smoke a bit and eat a little oil.

On FD irons, the oil control ring edge of the port is so close to the line from stock, there's usually not much to gain going in any more on a minor/medium street port. On an FC iron, there's a little more meat to get into before you're at the line however.

On FD irons, the oil control ring edge of the port is so close to the line from stock, there's usually not much to gain going in any more on a minor/medium street port. On an FC iron, there's a little more meat to get into before you're at the line however.

However, there are sections of the oil ring path that will never open. To make any real use of porting in that direction, you really need to mock up a rotor, iron, housing assembly to a flowbench and experiment with scrap irons.