fabricating a intake manifold..

#1

Auto-Ex Noob

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: new hampshire

Posts: 209

Likes: 0

Received 0 Likes

on

0 Posts

fabricating a intake manifold..

im in the process of build a complete custom intake manifold, the one that i have designed has a 1300 cc surge tank, is this too large, i was planning on using the stock throttle body so that kinda locked some of the dim. i had to work with. is there really a big advantage to using like a mustang throttle body, also i was planning 1.5 dia. runner are these too large?? As far as the mat. i plan on using 18 ga. s.s. and s.s. runners. i would fab the whole thing out of alum. but i have only been tig welding for about 2 years and i am not confident enough in my alum welding skills. the runners will be mandrel bend due to the fact that i also run a unison breeze cnc mandrel bending machine. it also helps that i work as a machinist/mechanic for a living.

the picture attached is the mandrel bender.

thanks

--joe

the picture attached is the mandrel bender.

thanks

--joe

#2

If you are using a single plenum, there is no advantage to using a single plate tb such as a Mustang unit. The problem with the stock tb that many people don't understand isn't in it's total flow capability but rather a problem with the intake manifold itself. The primary ports are fed entirely from 1 small throttle plate. The secondary ports are fed by twice as much throttle area as there are 2 plates. This isn't an issue for naturally aspirated engines that are stock or streetported though as flow won't be an issue with them. For a bridgeport I'd absolutely use a single plenum and/or a single plate tb. You will notice the drivability of the car change with a single plenum though.

1.5" runners are fine for the secondary runners. I'd use 1.375" for the primaries. Stainless steel will be fine. I'm sure someone will complain that it weighs too much but the couple of pounds you gain in manifold weight over aluminum will be more than offset by the heat rejecting properties of the stainless compared to aluminum. Aluminum heat soaks very fast by comparison and the few pounds difference won't make you any slower.

1.5" runners are fine for the secondary runners. I'd use 1.375" for the primaries. Stainless steel will be fine. I'm sure someone will complain that it weighs too much but the couple of pounds you gain in manifold weight over aluminum will be more than offset by the heat rejecting properties of the stainless compared to aluminum. Aluminum heat soaks very fast by comparison and the few pounds difference won't make you any slower.

#4

By surge tank I assume you mean plenum. That really depends as there is no correct size. Fab up the manifold in a way that allows you to unbolt it from the runners just like stock. this way you can try a few different sizes to see what works best for you. Unfortunately this is going to be trial and error. As a place to start, use roughly the same size as stock and play from there. Larger will typically give better top end and vice versa but larger and larger isn't better and better.

#6

Take a look at this,

http://www.grapeaperacing.com/GrapeA...tech/index.cfm

Look under induction systems, it's a pdf file

Intake design is not as crucial with turbo intake manifolds as with N/A

As long as you get your runner length the same then you'll have no problem

http://www.grapeaperacing.com/GrapeA...tech/index.cfm

Look under induction systems, it's a pdf file

Intake design is not as crucial with turbo intake manifolds as with N/A

As long as you get your runner length the same then you'll have no problem

#7

Auto-Ex Noob

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: new hampshire

Posts: 209

Likes: 0

Received 0 Likes

on

0 Posts

ok so after reading those extremely informative pdf files, correct me if i am wrong but i should build a single plane plemum and port tuning is not as important due the fact of forced induction, will keep a high pressure area behind the port untill it opens, it will be a 2 peice design so the plemum will be able to unbolt and as for as the size of the plemum im gonna try to make it about 60% of the total displacment for the engine. but i deff recommend that site above excellent information thanks.

please feel free to correct me if i am wrong and suggestions are deff welcome.

thaks --joe

please feel free to correct me if i am wrong and suggestions are deff welcome.

thaks --joe

Trending Topics

#10

To make big hp the bigger the compressor wheel the better, or though it has to be within reason. The manifold will flow whatever the compressor wheel flows. Try to minimise losses with free flowing bends and joints as this will also aid in throttle response. All that is required is equal length runners that join to a basic pipe/plenum. Make sure the runner ends - where they join to the plenum are rounded and smooth flowing.

Basically, that's the theory behind my intake manifold design. I did extensive research on turbo intake manifold design, information was hard to get, but I read a few books from my university library and they proved valuable.

Nothing beats practical experience though and I have none with intake manifolds, just theoretical

I hope to do another manifold design some day, with velocity stacks etc, for a comparison

I'm curious to read rotarygod's theory on longer runner length

Basically, that's the theory behind my intake manifold design. I did extensive research on turbo intake manifold design, information was hard to get, but I read a few books from my university library and they proved valuable.

Nothing beats practical experience though and I have none with intake manifolds, just theoretical

I hope to do another manifold design some day, with velocity stacks etc, for a comparison

I'm curious to read rotarygod's theory on longer runner length

#14

The unfortunate thing is that there isn't alot of good info out there when it comes to turbos and intake manifolds. There actually isn't much to know though. When it comes to forced induction and intakes, once the turbo (or supercharger) is in positive pressure, intake is irrelevant. It's all about flow at that point and tuning isn't an issue. You let the turbo do all the work. At this point an intake manifold is nothing more than the channel that directs the air to where it needs to go. For this reason many state that intake length isn't important.

However, we aren't always in boost. Take cruising around on the freeway for example. In most driving situations you aren't under boost. Under normal driving, you only hit boost during acceleration. If you have fun with your foot planted to the floor all the time and are always in boost, you aren't within the realm of normal driving patterns of most people! You need to think about turbo intake tuning just as you would n/a intake tuning but with a twist. With a naturally aspirated engine, you balance intake length and diameter based on where the engine needs to make it's max power. If you need max power to occur at 6500 rpm, you design intake runners around this length. Remember on an n/a, you are relying on the intake manifold to help cram more air into the engine than no manifold could. It's length and diameter affect where this benefit will be. Shorter runners tune higher and longer lower. Generally speaking of course. I'm not going to get into orders of harmonics and how they can change things a bit.

What is a turbo car when not under boost? It's naturally aspirated! Boost kicks in pretty quickly when on the throttle but below the boost threshold or when cruising, the engine is relying on the intake manifold to help it get air. With short runners, it's not as efficient at doing it. At least not at the speeds and loads that it won't be under boost. What this means is that we need to design our intake manifold with runners long enough to giving a tuning benefit at these rpms. We also need to be sure that from a pure flow standpoint that this intake manifold setup can meet the requirements of the turbo. You don't have to have short runners to have the flow capacity that is needed.

As load is increased, the boost threshold is reached faster. That means that the engine needs the most help at low loads and rpms. At low loads, any engine needs all the help it can get anyways. Let's say for example's sake, and I'm completely making these number up as I go, we have runners that are 17" long and the engine n/a makes peak power at 6500 rpm. Now with a turbo let's say that the highest rpm that we can reach not under boost is while cruising lightly at 3500 rpm on the freeway. We should try to tune our manifold length based on this number instead. That means the runners need to get longer. There will come a certain point where the runners get too long to fit in the engien bay nicely but that's where harmonic order comes into play. As I said earlier, I'm not going to get into that here though.

Now with longer runners, our engine is more efficient when out of boost. Why does anyone care you say? First of all it makes you more fuel efficient. Some people don't care but there is one very nice performance benefit from it as well. An engine that makes more power, has more exhaust. If you make more power down low, you have more exhaust energy going out the exhaust ports which means you also have more energy to spin a turbo up sooner! Now who doesn't want that?

Too many people rely on overly small exhaust wheels and a/r's to get quick spool up. However this hurts top end performance. Using longer intake runners to get more low end power and quicker spool means that you can use larger exhaust wheels and a/r's and retain the same spool rate that you had before. It also means that you can retain the better flow necessary for better top end power too. Longer intake runner on turbos can therefore aid in getting better off boost fuel economy and power, faster turbo spool, and with resized turbos, better top end power too.

You need to design an intake around the engine and forced induction system that you have. This means that an intake manifold that is optimized for a turbo will not be the same as that which is optimized for a centrifugal supercharger or a positive displacement supercharger. They each have their own requirements. Sadly there isn't much info out there telling you this and I'm not even sure how many people have thought about it properly.

Hopefully that makes it a little bit more clear.

However, we aren't always in boost. Take cruising around on the freeway for example. In most driving situations you aren't under boost. Under normal driving, you only hit boost during acceleration. If you have fun with your foot planted to the floor all the time and are always in boost, you aren't within the realm of normal driving patterns of most people! You need to think about turbo intake tuning just as you would n/a intake tuning but with a twist. With a naturally aspirated engine, you balance intake length and diameter based on where the engine needs to make it's max power. If you need max power to occur at 6500 rpm, you design intake runners around this length. Remember on an n/a, you are relying on the intake manifold to help cram more air into the engine than no manifold could. It's length and diameter affect where this benefit will be. Shorter runners tune higher and longer lower. Generally speaking of course. I'm not going to get into orders of harmonics and how they can change things a bit.

What is a turbo car when not under boost? It's naturally aspirated! Boost kicks in pretty quickly when on the throttle but below the boost threshold or when cruising, the engine is relying on the intake manifold to help it get air. With short runners, it's not as efficient at doing it. At least not at the speeds and loads that it won't be under boost. What this means is that we need to design our intake manifold with runners long enough to giving a tuning benefit at these rpms. We also need to be sure that from a pure flow standpoint that this intake manifold setup can meet the requirements of the turbo. You don't have to have short runners to have the flow capacity that is needed.

As load is increased, the boost threshold is reached faster. That means that the engine needs the most help at low loads and rpms. At low loads, any engine needs all the help it can get anyways. Let's say for example's sake, and I'm completely making these number up as I go, we have runners that are 17" long and the engine n/a makes peak power at 6500 rpm. Now with a turbo let's say that the highest rpm that we can reach not under boost is while cruising lightly at 3500 rpm on the freeway. We should try to tune our manifold length based on this number instead. That means the runners need to get longer. There will come a certain point where the runners get too long to fit in the engien bay nicely but that's where harmonic order comes into play. As I said earlier, I'm not going to get into that here though.

Now with longer runners, our engine is more efficient when out of boost. Why does anyone care you say? First of all it makes you more fuel efficient. Some people don't care but there is one very nice performance benefit from it as well. An engine that makes more power, has more exhaust. If you make more power down low, you have more exhaust energy going out the exhaust ports which means you also have more energy to spin a turbo up sooner! Now who doesn't want that?

Too many people rely on overly small exhaust wheels and a/r's to get quick spool up. However this hurts top end performance. Using longer intake runners to get more low end power and quicker spool means that you can use larger exhaust wheels and a/r's and retain the same spool rate that you had before. It also means that you can retain the better flow necessary for better top end power too. Longer intake runner on turbos can therefore aid in getting better off boost fuel economy and power, faster turbo spool, and with resized turbos, better top end power too.

You need to design an intake around the engine and forced induction system that you have. This means that an intake manifold that is optimized for a turbo will not be the same as that which is optimized for a centrifugal supercharger or a positive displacement supercharger. They each have their own requirements. Sadly there isn't much info out there telling you this and I'm not even sure how many people have thought about it properly.

Hopefully that makes it a little bit more clear.

#15

The unfortunate thing is that there isn't alot of good info out there when it comes to turbos and intake manifolds. There actually isn't much to know though. When it comes to forced induction and intakes, once the turbo (or supercharger) is in positive pressure, intake is irrelevant. It's all about flow at that point and tuning isn't an issue. You let the turbo do all the work. At this point an intake manifold is nothing more than the channel that directs the air to where it needs to go. For this reason many state that intake length isn't important.

However, we aren't always in boost. Take cruising around on the freeway for example. In most driving situations you aren't under boost. Under normal driving, you only hit boost during acceleration. If you have fun with your foot planted to the floor all the time and are always in boost, you aren't within the realm of normal driving patterns of most people! You need to think about turbo intake tuning just as you would n/a intake tuning but with a twist. With a naturally aspirated engine, you balance intake length and diameter based on where the engine needs to make it's max power. If you need max power to occur at 6500 rpm, you design intake runners around this length. Remember on an n/a, you are relying on the intake manifold to help cram more air into the engine than no manifold could. It's length and diameter affect where this benefit will be. Shorter runners tune higher and longer lower. Generally speaking of course. I'm not going to get into orders of harmonics and how they can change things a bit.

What is a turbo car when not under boost? It's naturally aspirated! Boost kicks in pretty quickly when on the throttle but below the boost threshold or when cruising, the engine is relying on the intake manifold to help it get air. With short runners, it's not as efficient at doing it. At least not at the speeds and loads that it won't be under boost. What this means is that we need to design our intake manifold with runners long enough to giving a tuning benefit at these rpms. We also need to be sure that from a pure flow standpoint that this intake manifold setup can meet the requirements of the turbo. You don't have to have short runners to have the flow capacity that is needed.

As load is increased, the boost threshold is reached faster. That means that the engine needs the most help at low loads and rpms. At low loads, any engine needs all the help it can get anyways. Let's say for example's sake, and I'm completely making these number up as I go, we have runners that are 17" long and the engine n/a makes peak power at 6500 rpm. Now with a turbo let's say that the highest rpm that we can reach not under boost is while cruising lightly at 3500 rpm on the freeway. We should try to tune our manifold length based on this number instead. That means the runners need to get longer. There will come a certain point where the runners get too long to fit in the engien bay nicely but that's where harmonic order comes into play. As I said earlier, I'm not going to get into that here though.

Now with longer runners, our engine is more efficient when out of boost. Why does anyone care you say? First of all it makes you more fuel efficient. Some people don't care but there is one very nice performance benefit from it as well. An engine that makes more power, has more exhaust. If you make more power down low, you have more exhaust energy going out the exhaust ports which means you also have more energy to spin a turbo up sooner! Now who doesn't want that?

Too many people rely on overly small exhaust wheels and a/r's to get quick spool up. However this hurts top end performance. Using longer intake runners to get more low end power and quicker spool means that you can use larger exhaust wheels and a/r's and retain the same spool rate that you had before. It also means that you can retain the better flow necessary for better top end power too. Longer intake runner on turbos can therefore aid in getting better off boost fuel economy and power, faster turbo spool, and with resized turbos, better top end power too.

You need to design an intake around the engine and forced induction system that you have. This means that an intake manifold that is optimized for a turbo will not be the same as that which is optimized for a centrifugal supercharger or a positive displacement supercharger. They each have their own requirements. Sadly there isn't much info out there telling you this and I'm not even sure how many people have thought about it properly.

Hopefully that makes it a little bit more clear.

However, we aren't always in boost. Take cruising around on the freeway for example. In most driving situations you aren't under boost. Under normal driving, you only hit boost during acceleration. If you have fun with your foot planted to the floor all the time and are always in boost, you aren't within the realm of normal driving patterns of most people! You need to think about turbo intake tuning just as you would n/a intake tuning but with a twist. With a naturally aspirated engine, you balance intake length and diameter based on where the engine needs to make it's max power. If you need max power to occur at 6500 rpm, you design intake runners around this length. Remember on an n/a, you are relying on the intake manifold to help cram more air into the engine than no manifold could. It's length and diameter affect where this benefit will be. Shorter runners tune higher and longer lower. Generally speaking of course. I'm not going to get into orders of harmonics and how they can change things a bit.

What is a turbo car when not under boost? It's naturally aspirated! Boost kicks in pretty quickly when on the throttle but below the boost threshold or when cruising, the engine is relying on the intake manifold to help it get air. With short runners, it's not as efficient at doing it. At least not at the speeds and loads that it won't be under boost. What this means is that we need to design our intake manifold with runners long enough to giving a tuning benefit at these rpms. We also need to be sure that from a pure flow standpoint that this intake manifold setup can meet the requirements of the turbo. You don't have to have short runners to have the flow capacity that is needed.

As load is increased, the boost threshold is reached faster. That means that the engine needs the most help at low loads and rpms. At low loads, any engine needs all the help it can get anyways. Let's say for example's sake, and I'm completely making these number up as I go, we have runners that are 17" long and the engine n/a makes peak power at 6500 rpm. Now with a turbo let's say that the highest rpm that we can reach not under boost is while cruising lightly at 3500 rpm on the freeway. We should try to tune our manifold length based on this number instead. That means the runners need to get longer. There will come a certain point where the runners get too long to fit in the engien bay nicely but that's where harmonic order comes into play. As I said earlier, I'm not going to get into that here though.

Now with longer runners, our engine is more efficient when out of boost. Why does anyone care you say? First of all it makes you more fuel efficient. Some people don't care but there is one very nice performance benefit from it as well. An engine that makes more power, has more exhaust. If you make more power down low, you have more exhaust energy going out the exhaust ports which means you also have more energy to spin a turbo up sooner! Now who doesn't want that?

Too many people rely on overly small exhaust wheels and a/r's to get quick spool up. However this hurts top end performance. Using longer intake runners to get more low end power and quicker spool means that you can use larger exhaust wheels and a/r's and retain the same spool rate that you had before. It also means that you can retain the better flow necessary for better top end power too. Longer intake runner on turbos can therefore aid in getting better off boost fuel economy and power, faster turbo spool, and with resized turbos, better top end power too.

You need to design an intake around the engine and forced induction system that you have. This means that an intake manifold that is optimized for a turbo will not be the same as that which is optimized for a centrifugal supercharger or a positive displacement supercharger. They each have their own requirements. Sadly there isn't much info out there telling you this and I'm not even sure how many people have thought about it properly.

Hopefully that makes it a little bit more clear.

Great post

#16

Rotary Enthusiast

Wasnt the general concensus on this , longer runner length=more low end torque and shorter runner=more high end power?

BTW very informative piece here

Also is there a real benefit in using velocity stacks on a turbo charged application ?

i can imagine normally aspirated , but will it make a difference under boost?

BTW very informative piece here

Also is there a real benefit in using velocity stacks on a turbo charged application ?

i can imagine normally aspirated , but will it make a difference under boost?

#17

Rotary Freak

Join Date: Dec 2001

Location: chandler, AZ

Posts: 2,402

Likes: 0

Received 0 Likes

on

0 Posts

Velocity stacks will increase flow which will help on either application. However, some have noted that raised stacks are a no-no in a turbo charged app, they should be radiused from the wall of the plenum.

#18

Rotary Enthusiast

i was brainstorming on that the other day ...it seems a bit logical right , also makes a lot of sense also

should be a bit difficult to make though right ?

very curious

good info here

should be a bit difficult to make though right ?

very curious

good info here

#19

Auto-Ex Noob

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: new hampshire

Posts: 209

Likes: 0

Received 0 Likes

on

0 Posts

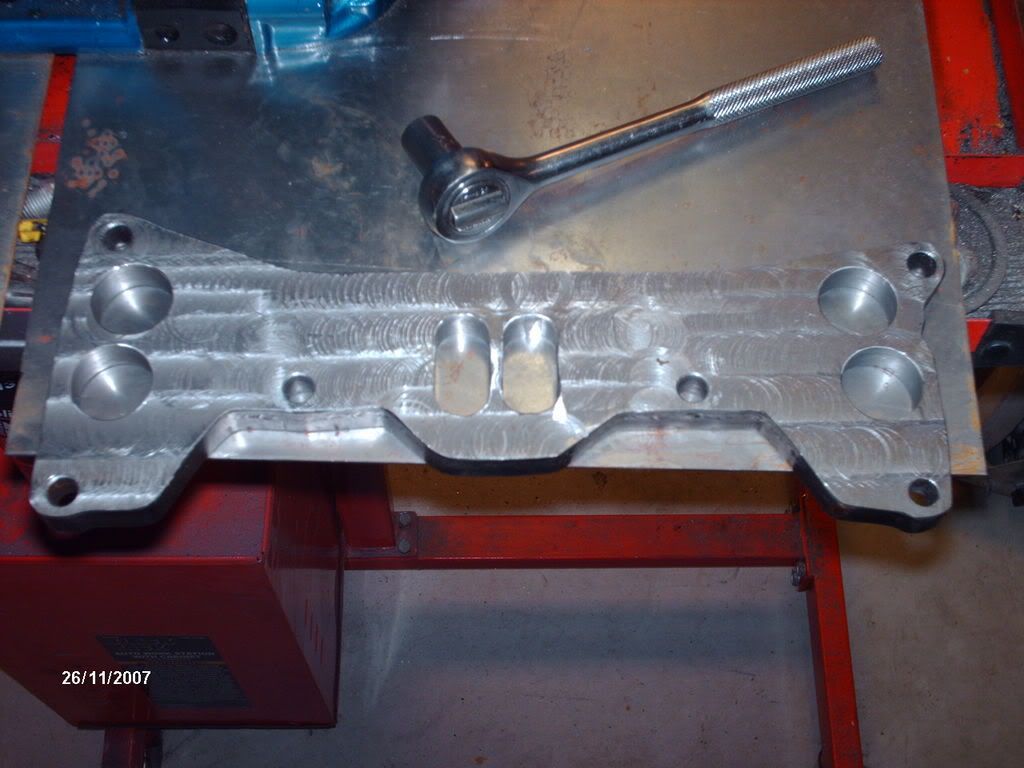

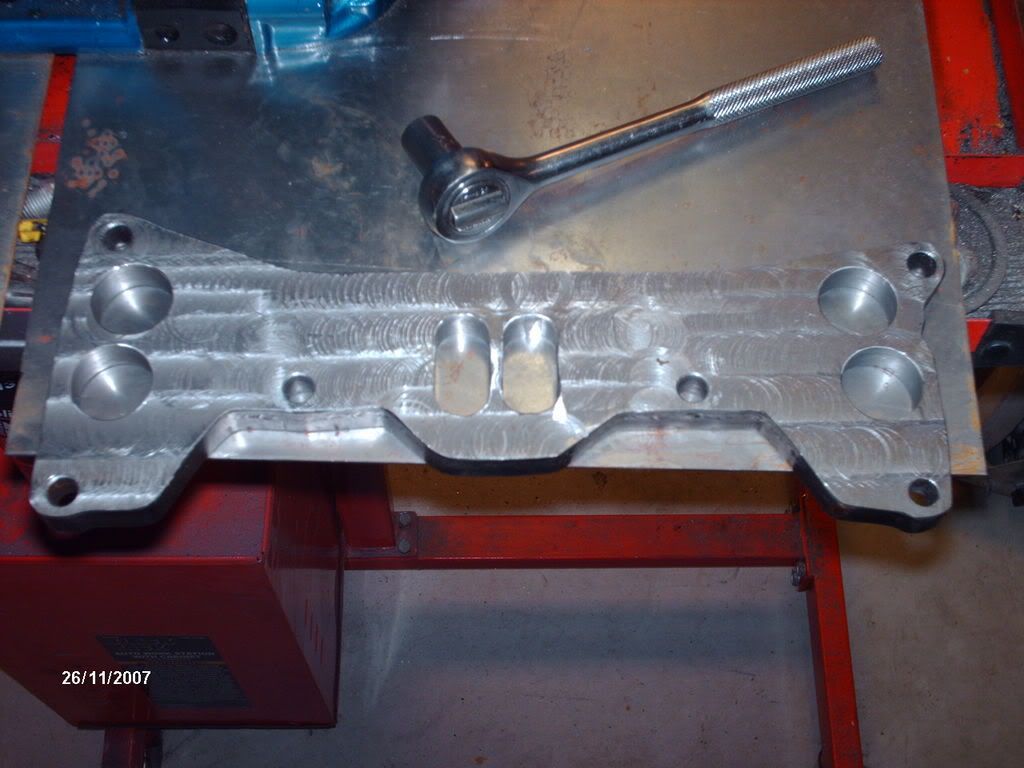

well i got the sheetmetal into today, i have decide to make a 2 peice design so the plenum can be unbolted, single plane and due to budgets im gonna use the stock TB for right now just ported all to hell, i chose to tune the intake runners on the 3rd RV wave for 2700 rpms as for the measurements i dont have them infront of me right now but i will be posting pics starting next week as the build starts.

i do have a pic of the mani-to block flange that i finished already

thanks for all the info

--joe

i do have a pic of the mani-to block flange that i finished already

thanks for all the info

--joe

Last edited by fast87t2; 07-11-08 at 12:33 PM.

#20

Rotary Freak

Join Date: Dec 2001

Location: chandler, AZ

Posts: 2,402

Likes: 0

Received 0 Likes

on

0 Posts

#21

Rotary Enthusiast

thats pretty neat , i can see that the material is shaped inward , how did you manage to make the piece run inward ,

it looks as if you had a flat piece , which was pushed inward , but the runners seem to be pretty long without a weld right afer the velocity stack

regardless , very nice, welds look pretty good too

it looks as if you had a flat piece , which was pushed inward , but the runners seem to be pretty long without a weld right afer the velocity stack

regardless , very nice, welds look pretty good too

#24

Rotary Freak

Join Date: Dec 2001

Location: chandler, AZ

Posts: 2,402

Likes: 0

Received 0 Likes

on

0 Posts

haha, its very technical... I took the right sized socket that had a slight radius on the o.d. and pressed the runner tubes over it to flare them in a hydraulic press. Lots of grinding and sanding and viola!