Microtech Pump Settings

#1

Rotary Enthusiast

Thread Starter

Pump Settings

I was wondering if there is any downside to changing the PUMP1 settings so it works basically straight off idle? Off hand I cannot remember what all the triggers are for this but I assume it just means changing the vac point trigger setting so work in vac rather than positive pressure. Basically I want pump to do some of the work as you go off idle and it hits a lean spot. I know that cell will be richer than I would otherwise like generally due to Microtech limits but wanted to try and minimise that with the Pump Setting if possible.

#2

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

By default the pump settings are triggered by manifold pressure.

I'd suggest changing at least PUMP1 to use TPS instead. You'll get far better transition for light throttle applications.

I'd suggest changing at least PUMP1 to use TPS instead. You'll get far better transition for light throttle applications.

#3

Rotary Enthusiast

Thread Starter

Okay Aaron I will check this option out. So by default will pump1 then kick in as soon as you touch the pedal or do you need to set a tps % as a trigger. If the latter what would you suggest? Also if the TPS wonders with temp will it try and kick pump1 on at idle. For now I think I have accounted for a bit of wonder but I gather the TPS can have a bit of a mind of it's own!?

#4

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

Once you set it to TPS I believe the Pump1% will become active. Start with 10% and make sure that is triggering the pump at mild to moderate throttle applications. Decrease/increase if necessary. You don't want to cause a rich spot when the throttle is just lightly tapped.

The TPS should not wander at all, really. If it is, then something mechanically or electrically is wrong.

Not sure what you mean by using pumps at idle but they are only designed to add extra fuel when the throttle is stabbed. It's the poorly implemented electronic equivalent of a carburetor accelerator pump.

The TPS should not wander at all, really. If it is, then something mechanically or electrically is wrong.

Not sure what you mean by using pumps at idle but they are only designed to add extra fuel when the throttle is stabbed. It's the poorly implemented electronic equivalent of a carburetor accelerator pump.

#5

Rotary Enthusiast

Thread Starter

Thanks Aaron I will give this a go. So 10% refers to the amount of fuel or the TPS position? What I meant about the pump working at idle was if the TPS wonders off 0 will the ECU trigger the pump o. By mistake. I have found the TPS wonders slightly with temperature.. I just set the 0 point back a bit to counter that. I have read a few comments saying similar and I thought one reason of going I to matrix mode was to cold this? By the way. Best thing I ever did! I have hot idle I. The 13's now and 0.86ms in the idle cell vs 1.10 before! I am finding sometimes the car dies downshifting to a stop not Sure if it is this one cell now a bit lean or if I can adjust up around it to sort that. Still playing.

#6

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

I believe there are two settings. One defines at what TPS percent change the pump activates, the other defines how much fuel to add. Don't have my manual handy.

The TPS shouldn't wander. Sounds like it might be binding up or the throttle body isn't returning to idle fully.

Yes, stalling after decal usually means that there is a lean spot below when the engine idles or the decal fuel cut is too aggressive.

The TPS shouldn't wander. Sounds like it might be binding up or the throttle body isn't returning to idle fully.

Yes, stalling after decal usually means that there is a lean spot below when the engine idles or the decal fuel cut is too aggressive.

#7

Rotary Enthusiast

Thread Starter

I will try this also.. So was the 10% referred to above the TPS change amount to set the trigger or the fuel amount? I assume the former and fuel addition may well need to be similar? I will have a look at the settings when I next get a chance.Thanks again.

Trending Topics

#8

Rotary Enthusiast

Thread Starter

Aaron, I gather I can use timing to try and pull the car out of stalling off throttle. How much would you advise adding max and where. I assume I would add it into the 500rpm box in the T_rpm table? I think there is 5degs there now and I believe I have around 7 degs showing in the timing display during hot idle so I guess I have a few degs in the T_map table too. I haven't really touched this though.

Thanks

Lee

Thanks

Lee

#9

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

Leave your existing pump amount the same, set the pump trigger to 10%.

Yes, you can certainly add a few degrees to the 500 RPM bin. Add 3 degrees and see if that helps. You can do the same with the fuel bin just under idle as well. Will help catch a wandering idle.

Yes, you can certainly add a few degrees to the 500 RPM bin. Add 3 degrees and see if that helps. You can do the same with the fuel bin just under idle as well. Will help catch a wandering idle.

#10

Rotary Enthusiast

Thread Starter

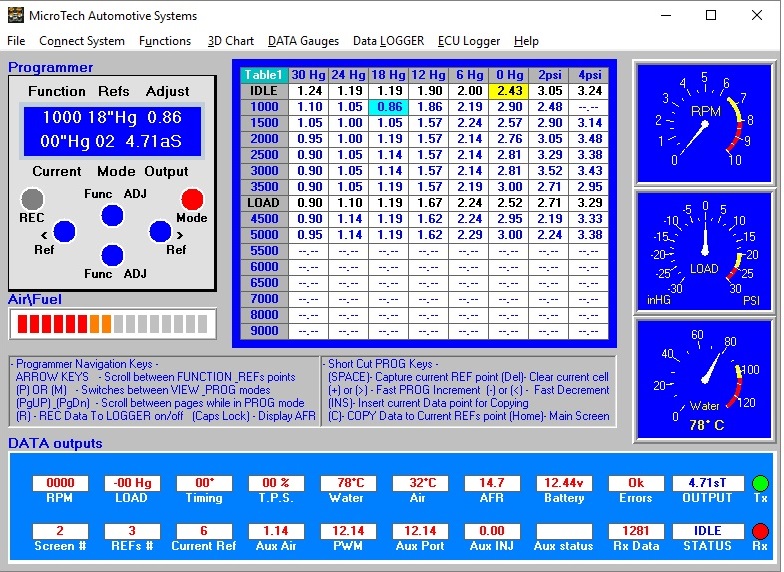

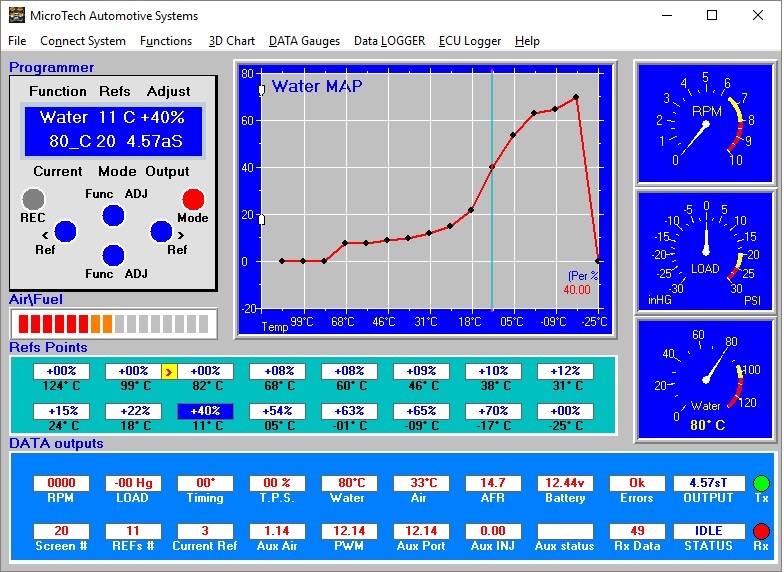

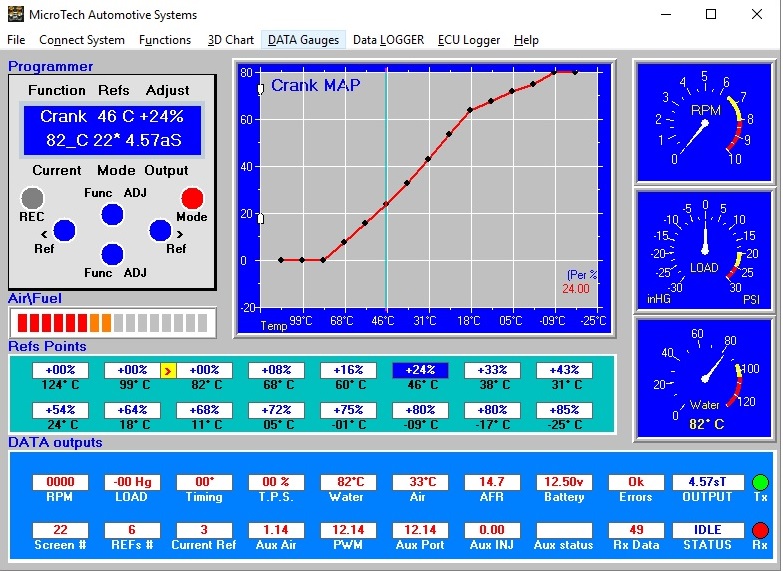

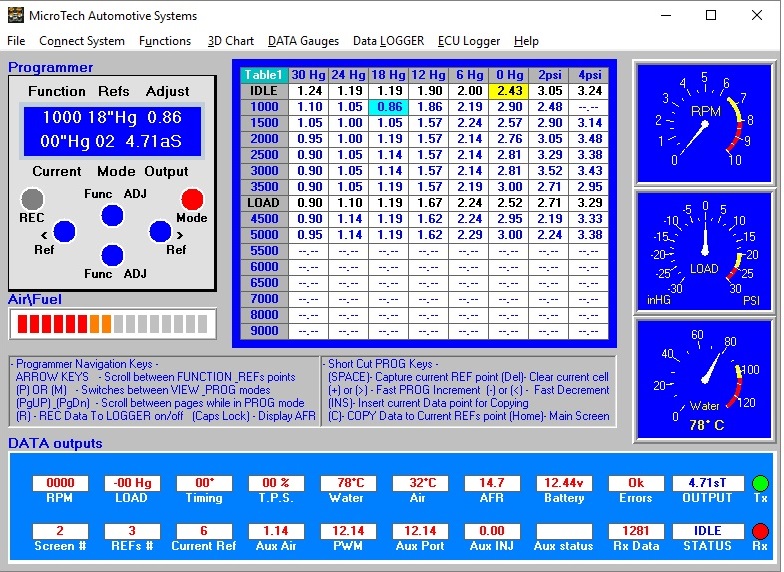

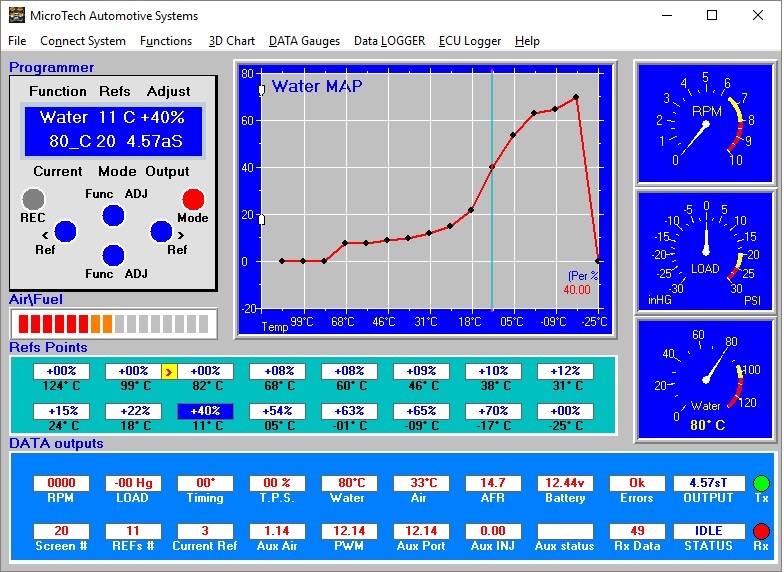

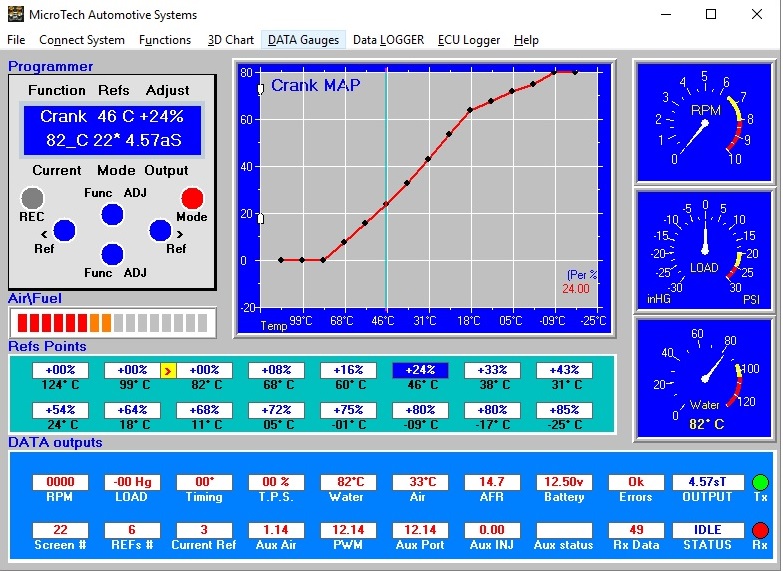

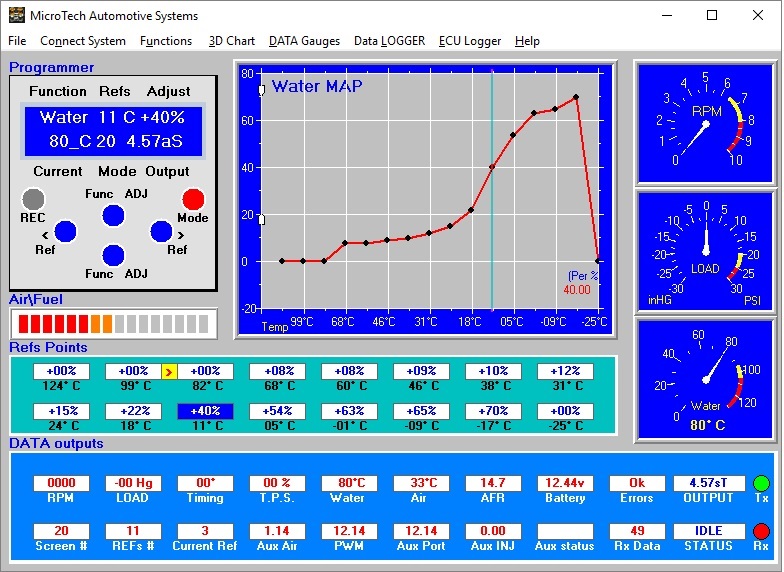

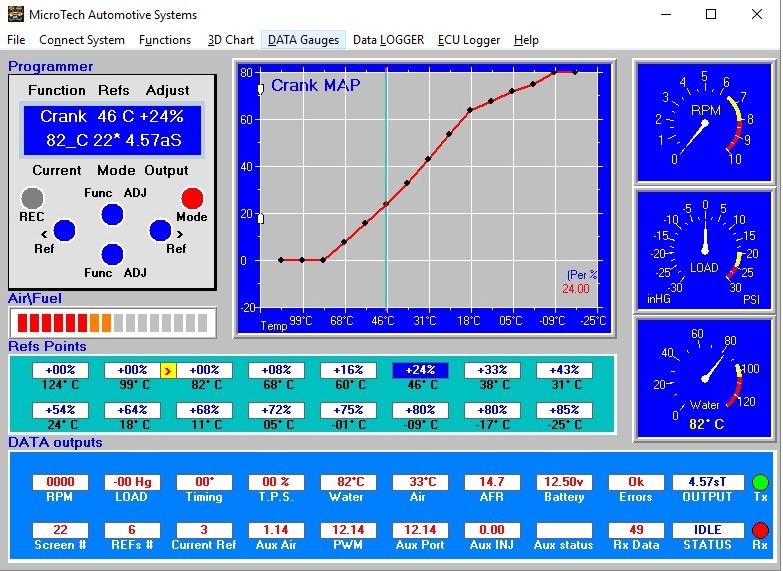

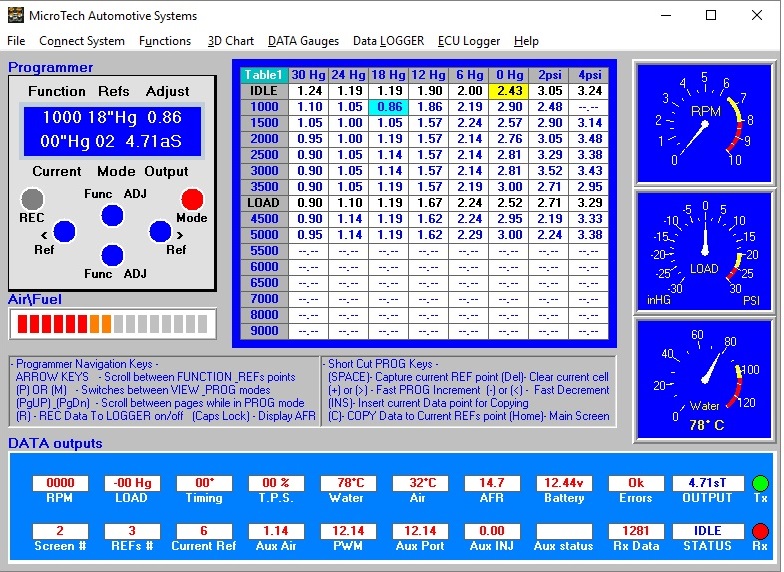

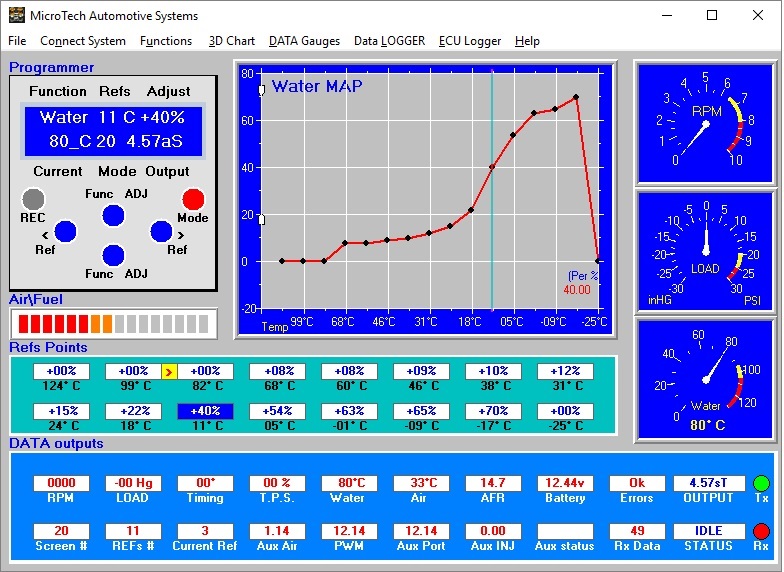

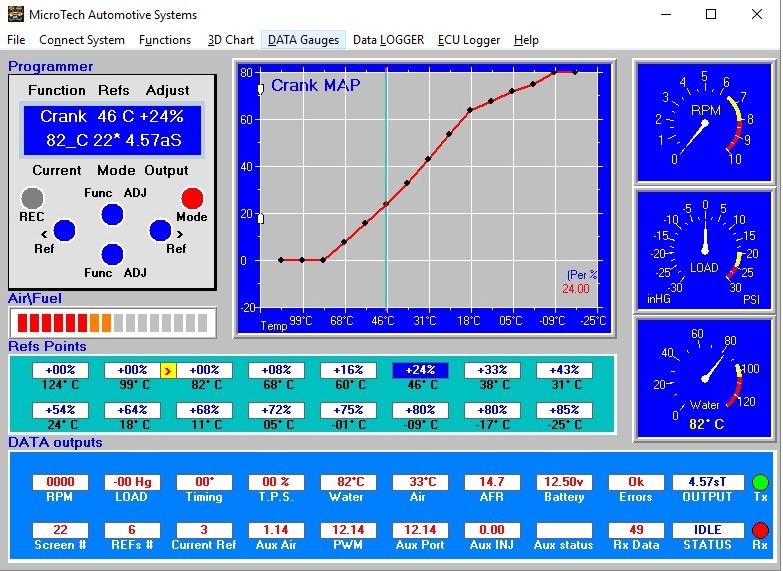

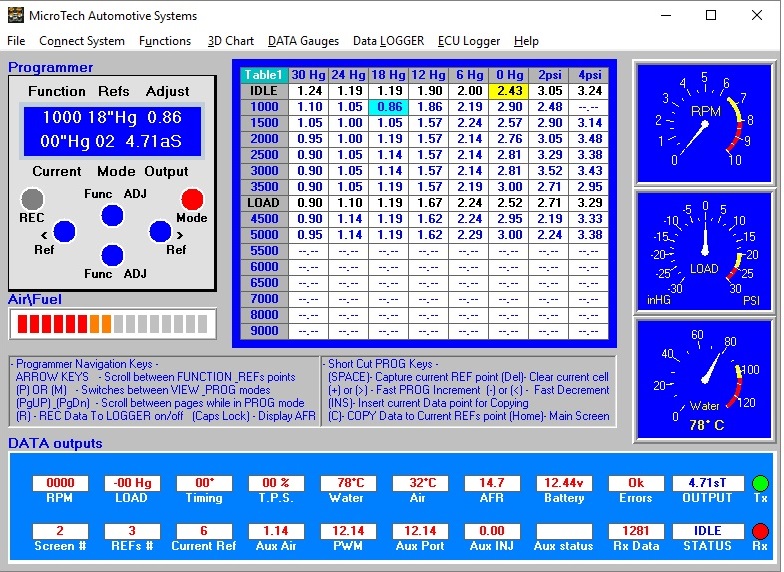

So I had a little drive out today..I looked at the Pump1 settings and I cannot see where to change this to TPS. I will have to dig out the manual as the settings did not read how I expected. To be fair though after my changes the last time I drove it I seem to have nailed the flat spots I had. Sometimes you get a tiny little fluff if you are quick on the throttle but that's all. If it stays like that after a proper drive and I don't find I need to pull fuel out of the cells I have added it to for other reasons I might just stick with it as is. On the other hand the decel issue is still there and I a still working through my rough running at 65degs I mentioned a while ago. The latter does appear to be fuel and going lean as after tweaking the water map and the 500rpm line it is much better and I have found the issue has moved to a higher temperature now. around 75degs. I guess I will have to flatten off my water map so I can keep it a bit richer at this point until the issue is resolved. What I find a bit like the decel stalling is when I rev it the rpm doesn't level back off straight away. it drops into the 500rpm cell and lingers a bit.. stumbles slightly then pulls itself back up. When it is warmed right up it revs and pulls back into the idle cell pretty well. a bit slower than I would ideally like but not bad. Is okay most of the way through warm-up to until we hit around the 68 degs area. I thought pictures speak a thousand words. So here are a couple of screens from my map. My matrix table. Water map and crank map. remembering I have 875cc primaries are these roughly where you would expect. Especially around the idle cell which is the 0.86 one and the 500rpm line.

I wondered if the decel was too harsh with my stalling as it was set to 20"Hg so I dropped it back to 22"Hg. Still stalled on the downshift. I will try 23"Hg next time. Car only pulls 24"hg so should hopefully work okay still. When it stalls I cannot tell if the decel is taking too long to switch off leading to the stall or if it is just lean. It certainly does only seem to stall when the decel has kicked in. I guess I could check that by turning Decel off and going for a drive? If it is not that, I cannot tell which cell for sure it hits that causes the stall as it is rapidly covering quite a few cells? Would logging help pin point it? I wanted to try and add some timing in the 500rpm cell in the T_rpm table to see if it helps. However when I add it it seems to effect the idle timing even though idle is 1160rpm and the 1000rpm T-rpm value is set to 0? what gives?

Last of all to add to this as it is kind of related. When you start the car does it use the 0"Hg cell in the 500rpm line for a base value? i,e if I add fuel to this will it globally help when cranking. Generally I would say the car cranks a lot to start and you end up having to give a light bit of pedal and it goes. Not too bad when it's hot but much more when cold or warm. That is why I posted the cranking table as well. I a a little wary of messing too much with this and flooding it if I get it wrong!

Thanks Aaron you are really helping me out. Gradually getting the little niggles ironed out!

Not sure why the images are not showing. Done the same as normal? Just have to click the link. Sorry!

I wondered if the decel was too harsh with my stalling as it was set to 20"Hg so I dropped it back to 22"Hg. Still stalled on the downshift. I will try 23"Hg next time. Car only pulls 24"hg so should hopefully work okay still. When it stalls I cannot tell if the decel is taking too long to switch off leading to the stall or if it is just lean. It certainly does only seem to stall when the decel has kicked in. I guess I could check that by turning Decel off and going for a drive? If it is not that, I cannot tell which cell for sure it hits that causes the stall as it is rapidly covering quite a few cells? Would logging help pin point it? I wanted to try and add some timing in the 500rpm cell in the T_rpm table to see if it helps. However when I add it it seems to effect the idle timing even though idle is 1160rpm and the 1000rpm T-rpm value is set to 0? what gives?

Last of all to add to this as it is kind of related. When you start the car does it use the 0"Hg cell in the 500rpm line for a base value? i,e if I add fuel to this will it globally help when cranking. Generally I would say the car cranks a lot to start and you end up having to give a light bit of pedal and it goes. Not too bad when it's hot but much more when cold or warm. That is why I posted the cranking table as well. I a a little wary of messing too much with this and flooding it if I get it wrong!

Thanks Aaron you are really helping me out. Gradually getting the little niggles ironed out!

Not sure why the images are not showing. Done the same as normal? Just have to click the link. Sorry!

Last edited by Leeroy_25; 07-08-17 at 05:58 PM.

#11

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

Problem is that unlike other ECUs, the Microtech doesn't have a fuel adder when coming out of decal. After decal, all the fuel is sucked from the walls of the port runners so a little more fuel is needed for the first second or so to re-wet the walls. You need to compensate for this in your map.

The high vacuum area that decal transitions into might need to be a bit richer.

Remember that the table is interpolated (badly) so that if you increase the 500 RPM timing, it will have a slight effect on the 1000 RPM timing.

You can bump the MAP timing a few degrees at high vacuum to compensate as well. For reference, here's a base timing chart I use with Megasquirt;

http://www.aaroncake.net/rx-7/megasq...on_table_1.gif

Note how much timing is in the high vacuum decal areas of the map.

I think the car uses the 500 RPM cell as a base cranking value. There is also a crank table that adds fuel during cranking based on temperature. That's where you will make the majority of cranking adjustment once the fuel table is dialed in fairly close.

The high vacuum area that decal transitions into might need to be a bit richer.

Remember that the table is interpolated (badly) so that if you increase the 500 RPM timing, it will have a slight effect on the 1000 RPM timing.

You can bump the MAP timing a few degrees at high vacuum to compensate as well. For reference, here's a base timing chart I use with Megasquirt;

http://www.aaroncake.net/rx-7/megasq...on_table_1.gif

Note how much timing is in the high vacuum decal areas of the map.

I think the car uses the 500 RPM cell as a base cranking value. There is also a crank table that adds fuel during cranking based on temperature. That's where you will make the majority of cranking adjustment once the fuel table is dialed in fairly close.

#12

Rotary Enthusiast

Thread Starter

Hi Aaron, Thanks for input again.. So I am not sure what units are on the left of the megasquirt graph? I assume it is upside down compared to microtech so vac is at the bottom row? so there are some pretty big numbers in there for timing. Not sure what that equates to in "Hg though? and where idle is by comparison??

So I think I have progressed some more by trial and error as usual and by chance in some respects. after last running I tried some stop starting when hot to see if I could get that better assuming 0HG cell was where the base value for crank came from. adding fuel seemed to make it worse if anything. So I gave up in the end. Mainly because out of no where the car developed a hunting issue. Not like richness hunting more like idle valve hunting. which I don't have plugged in! So the only thing I could think was air leak (hoped).So I check around all my hoses and found a few clips a little loose and my brake servo one particularly loose. Maybe I didn't tighten it after the engine went back in!? So I ran it up again today and straight away I could tell it wanted fuel out of the water table and once hot back out of the main map! Which I guess is in line with an air leak. So idle was back to normal. So I thought I would try and mess with my idle recovery just static. I found that in fact adding fuel was making worse.. so I pulled the 500rpm line down and in fact almost in line with my idle cell now and idle now barely drops into that cell when you free rev it. I have not been for a long drive yet to see what I get when really hot but I did get it up to temp and it seemed a lot better. Also on the little drive I did I tried to make it stall by dipping the clutch and holding neutral on the down shift. No stall.. and decel was set back at 22Hg too.. So fingers crossed. It seems I had an air leak issue combined with actually going to rich on those cells. Time will tell when I get out again properly.

So I started to wonder if the start up being sluggish was too much fuel.. I pulled 0Hg and the cell 6Hg right down and start-up for sure was better when hot. I tried tweaking a bit more either way on each and could seem to make a notable difference. Now it cranks for 2 or 3 secs then starts to try and fire and you need to give it a little dab on the throttle and it goes. So I think it is maybe the 6Hg or next cell along I need to adjust to pick it up but not sure. I know it can fire up without throttle as it did it in carb mode hot, cold or whatever. that is one good thing it did in carb mode! Last week I felt like it was going backwards again with the hunting but after today I think I made another step forward. If I can get startup and staging better I am laughing. Cruise is nice. idle is nice. For a Basic ECU it is getting there.

You mention about the bad interpolation. Does it actually use the line on the graph for values or jump between the values in the matrix. what the AFR and general behaviour it would make you think the latter.

I have my 500rpm timing at 7degrees now and seems okay short of more time on the road to monitor behaviour. I don't know what changing the 500rpm line should impact the idle time though when idle is 1150 rpm. if the graph was interpolated properly. idle would be based on a vlaue between the 1000rpm line and 1500rpm line. Nothing to do with the 500rpm line? It is like when it hits idle it defaults to the 500rpm value. i,e whatever value I put here is what my timing says in the box at the bottom?

I don't support you have a crank map and matrix map from you microtech days with a similar setup to me? there are a couple of cells I want to check out the trend of and also have an idea where my cranking might want to be?

Thank you

Lee

So I think I have progressed some more by trial and error as usual and by chance in some respects. after last running I tried some stop starting when hot to see if I could get that better assuming 0HG cell was where the base value for crank came from. adding fuel seemed to make it worse if anything. So I gave up in the end. Mainly because out of no where the car developed a hunting issue. Not like richness hunting more like idle valve hunting. which I don't have plugged in! So the only thing I could think was air leak (hoped).So I check around all my hoses and found a few clips a little loose and my brake servo one particularly loose. Maybe I didn't tighten it after the engine went back in!? So I ran it up again today and straight away I could tell it wanted fuel out of the water table and once hot back out of the main map! Which I guess is in line with an air leak. So idle was back to normal. So I thought I would try and mess with my idle recovery just static. I found that in fact adding fuel was making worse.. so I pulled the 500rpm line down and in fact almost in line with my idle cell now and idle now barely drops into that cell when you free rev it. I have not been for a long drive yet to see what I get when really hot but I did get it up to temp and it seemed a lot better. Also on the little drive I did I tried to make it stall by dipping the clutch and holding neutral on the down shift. No stall.. and decel was set back at 22Hg too.. So fingers crossed. It seems I had an air leak issue combined with actually going to rich on those cells. Time will tell when I get out again properly.

So I started to wonder if the start up being sluggish was too much fuel.. I pulled 0Hg and the cell 6Hg right down and start-up for sure was better when hot. I tried tweaking a bit more either way on each and could seem to make a notable difference. Now it cranks for 2 or 3 secs then starts to try and fire and you need to give it a little dab on the throttle and it goes. So I think it is maybe the 6Hg or next cell along I need to adjust to pick it up but not sure. I know it can fire up without throttle as it did it in carb mode hot, cold or whatever. that is one good thing it did in carb mode! Last week I felt like it was going backwards again with the hunting but after today I think I made another step forward. If I can get startup and staging better I am laughing. Cruise is nice. idle is nice. For a Basic ECU it is getting there.

You mention about the bad interpolation. Does it actually use the line on the graph for values or jump between the values in the matrix. what the AFR and general behaviour it would make you think the latter.

I have my 500rpm timing at 7degrees now and seems okay short of more time on the road to monitor behaviour. I don't know what changing the 500rpm line should impact the idle time though when idle is 1150 rpm. if the graph was interpolated properly. idle would be based on a vlaue between the 1000rpm line and 1500rpm line. Nothing to do with the 500rpm line? It is like when it hits idle it defaults to the 500rpm value. i,e whatever value I put here is what my timing says in the box at the bottom?

I don't support you have a crank map and matrix map from you microtech days with a similar setup to me? there are a couple of cells I want to check out the trend of and also have an idea where my cranking might want to be?

Thank you

Lee

#13

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

On the left is engine load. Basically manifold pressure in KpA. Bottom is RPM.

Idle is right around 1000 RPM and 40 or so KpA. This map has a lot of timing at idle which isn't typical.

Hunting is generally lean, not rich. Air leaks don't effect a speed density system like the Microtech the way they do with a metered system but certainly an air leak will move the idle into an area of the map which perhaps isn't tuned for a stable idle.

Unless the current load point of the engine is dead on a cell (ie. exactly 2" at 1000 RPM) then a linear interpolation is run between the cells the current load point is closet to and that value is used to open the injectors or set the timing. Without actually seeing the code running in the ECU we can only guess. Whatever the code, it is pretty crude. It is nowhere nearly as smooth as other ECUs. And combined with the fact that the stage method increases the primary pulsewidth, it ends up with fairly poor resolution.

7 degrees is a good idle value.

The screenshot of my crank map wouldn't help you very much. The car is bridgeported so it is a crazy amount of fuel to get it started.

Idle is right around 1000 RPM and 40 or so KpA. This map has a lot of timing at idle which isn't typical.

Hunting is generally lean, not rich. Air leaks don't effect a speed density system like the Microtech the way they do with a metered system but certainly an air leak will move the idle into an area of the map which perhaps isn't tuned for a stable idle.

Unless the current load point of the engine is dead on a cell (ie. exactly 2" at 1000 RPM) then a linear interpolation is run between the cells the current load point is closet to and that value is used to open the injectors or set the timing. Without actually seeing the code running in the ECU we can only guess. Whatever the code, it is pretty crude. It is nowhere nearly as smooth as other ECUs. And combined with the fact that the stage method increases the primary pulsewidth, it ends up with fairly poor resolution.

7 degrees is a good idle value.

The screenshot of my crank map wouldn't help you very much. The car is bridgeported so it is a crazy amount of fuel to get it started.

#14

Rotary Enthusiast

Thread Starter

Appreciate your map might be no good. Is there anything on my screen shots for the matrix and maybe the crank map that sings alarm bells for you .. Mainly in the idle area around 18Hg and 1000rpm and the 500rpm cranking cells?

I read Lean is normally the result of hunting but certainly not on mine. It hunts rich and if it is lean it just dies! Hopefully it was airleaks and not an ECU funny 5 mins or something else that might come back and haunt me again!

Looking at your map now I know where to look the idle and high vac timing values are huge! So at least I know I can add this in if required.

Thanks for info.

I read Lean is normally the result of hunting but certainly not on mine. It hunts rich and if it is lean it just dies! Hopefully it was airleaks and not an ECU funny 5 mins or something else that might come back and haunt me again!

Looking at your map now I know where to look the idle and high vac timing values are huge! So at least I know I can add this in if required.

Thanks for info.

#15

Full Member

Join Date: Mar 2013

Location: Western Australia

Posts: 145

Likes: 0

Received 0 Likes

on

0 Posts

I found the decel doesnt really work and results in the engine cutting out and then cutting back in too harshly so ive turned mine off and manually tuned the decel cells.

Your water and crank maps should be similar to the basemap sticky at the top of this section.

Next time it wont start on its own adjust just the mixtrim to say +10 or 20%. Play around with mixtrim until you get it to start on its own with no pedal. If that doesnt work try -10 or 20%. Dont forget to return mixtrim to its starting position which will probably be 0 when you have finished.

Your pics arent working for me so i cant see your map.

Your water and crank maps should be similar to the basemap sticky at the top of this section.

Next time it wont start on its own adjust just the mixtrim to say +10 or 20%. Play around with mixtrim until you get it to start on its own with no pedal. If that doesnt work try -10 or 20%. Dont forget to return mixtrim to its starting position which will probably be 0 when you have finished.

Your pics arent working for me so i cant see your map.

Last edited by rx3sum; 07-17-17 at 04:11 AM.

#16

Rotary Enthusiast

Thread Starter

Hey RX3Sum.. So I found the decel quite aggressive too but after the last drive it seems to work okay now since I found a couple of potential air leaks. I am yet to go out on a long drive and get it really hot which is when it was worse. It also appears I had gone too rich in the 500rpm cells. So we will see.

regarding the pictures I think Photobucket have stopped letting us use them for hosting only. Anyone got an alternative option?

Do these links work instead?

The water and Matrix are slightly different now since I have fixed my airleaks. Basically the 500rpm line is pretty much 2 or 3 clicks lower most of the way along. The 0Hg at 500rpm is set at 2.33 and 0Hg above idle is now at 0.90

Adjusting the mixtrim is a good idea.. If it is richer easy enough. if it is leaner I would have to compensate the idle cell first as it would most like stall due to that being lean much more than 5-10% adjusted. if that method works would you then take or add fuel somewhere in the matrix or adjust the cranking table by that amount all the way along? The amount of cranking seems pretty consistent whether hot or cold. I have not tried anything mid way yet. wanted to get it sorted hot first so I have a baseline right!

Cheers

Lee

regarding the pictures I think Photobucket have stopped letting us use them for hosting only. Anyone got an alternative option?

Do these links work instead?

The water and Matrix are slightly different now since I have fixed my airleaks. Basically the 500rpm line is pretty much 2 or 3 clicks lower most of the way along. The 0Hg at 500rpm is set at 2.33 and 0Hg above idle is now at 0.90

Adjusting the mixtrim is a good idea.. If it is richer easy enough. if it is leaner I would have to compensate the idle cell first as it would most like stall due to that being lean much more than 5-10% adjusted. if that method works would you then take or add fuel somewhere in the matrix or adjust the cranking table by that amount all the way along? The amount of cranking seems pretty consistent whether hot or cold. I have not tried anything mid way yet. wanted to get it sorted hot first so I have a baseline right!

Cheers

Lee

#17

Rotary Enthusiast

Thread Starter

#18

Full Member

Join Date: Mar 2013

Location: Western Australia

Posts: 145

Likes: 0

Received 0 Likes

on

0 Posts

Just adjust the mixtrim and nothing else. I cant see your maps but it could be too lean or too rich after corrections to start on its own.

Adjusting mixtrim will tell you which way you need to be heading.

Adjusting mixtrim will tell you which way you need to be heading.

#19

Rotary Enthusiast

Thread Starter

This hosting thing is a bummer.. Good tip I will try it..

Can you let me know if this link works. I saved an album on my facebook page.

Hopefully you can see that. It would be great to see someone elses map to see what the general matrix trend is failing all else.

Can you let me know if this link works. I saved an album on my facebook page.

Facebook Post

Hopefully you can see that. It would be great to see someone elses map to see what the general matrix trend is failing all else.

#20

Full Member

Join Date: Mar 2013

Location: Western Australia

Posts: 145

Likes: 0

Received 0 Likes

on

0 Posts

That matrix table is pretty messy

In my tune all cells from LOAD (4000)- 9000 are the same so fill those in.

There are lots of bumps in your matrix so flatten them out by adding fuel to the low spots.

You have a massive step from 1000 18Hg to 1000 12 Hg and above.

Is it happy idling when warmed up without fan on, and what rpm and vacumn does it idle at and what AFR ?

Remember stay out of boost until you are 100% sure of the tune.

In my tune all cells from LOAD (4000)- 9000 are the same so fill those in.

There are lots of bumps in your matrix so flatten them out by adding fuel to the low spots.

You have a massive step from 1000 18Hg to 1000 12 Hg and above.

Is it happy idling when warmed up without fan on, and what rpm and vacumn does it idle at and what AFR ?

Remember stay out of boost until you are 100% sure of the tune.

#21

Rotary Enthusiast

Thread Starter

Thanks for feedback... Remember it is a work in progress! I can only see a couple of obvious rich bumps which I will check next time I drive it. The jump from 18HG to 12HG you pointed out is where you jump to as you touch the throttle. If I lean that off it stutters. . Do I want to bring that down a bit and try and use pump1 to resolve that instead? which is kind of where I am not sure at the moment. the 500-1500rpm cells between 18HG and 0HG. whether they are on the right lines or fuel can come down in line with the cells below and add in pump correction for getting on the throttle.

Idle is the 0.86 cell 1000rpm/18HG. It is happy as Larry there AFR fluctuates a bit between 12.5-13.2 ish.. That kind of area when warm. I am off boost at the mo anyway as running in and just about to go up to 5000rpm when my tuner is next free. hence the lower part of the table is blank! The jumps in the matrix at 3500rpm/0Hg are where it start staging and last time we started playing with this. Currently it goes way rich when staging so it needs playing with and trying a few things suggested by Aaron.

Idle is the 0.86 cell 1000rpm/18HG. It is happy as Larry there AFR fluctuates a bit between 12.5-13.2 ish.. That kind of area when warm. I am off boost at the mo anyway as running in and just about to go up to 5000rpm when my tuner is next free. hence the lower part of the table is blank! The jumps in the matrix at 3500rpm/0Hg are where it start staging and last time we started playing with this. Currently it goes way rich when staging so it needs playing with and trying a few things suggested by Aaron.

#22

Full Member

Join Date: Mar 2013

Location: Western Australia

Posts: 145

Likes: 0

Received 0 Likes

on

0 Posts

I had a look at your build thread and thats a pretty amazing ride

I do it a bit differently than Aaron and use pump1 off a vacumn setting and use pretty much what is in the basemap.I have an old S4 tps that wanders around where as your TPS should be better so may be able to run the pump1 accurately.

Whichever way you go you should be using pump 1 and not the load map. The large step around idle may cause your AFR to wander.

I do it a bit differently than Aaron and use pump1 off a vacumn setting and use pretty much what is in the basemap.I have an old S4 tps that wanders around where as your TPS should be better so may be able to run the pump1 accurately.

Whichever way you go you should be using pump 1 and not the load map. The large step around idle may cause your AFR to wander.

#23

Rotary Enthusiast

Thread Starter

Thanks for the kind words.. It has nearly broken me at times but getting there!

So with the matrix around my idle cell would you expect to see just 1 or 2 clicks up? Or are most of them okay.. Just the big jump on the left where it skips to as you hit throttle? I have taken some of them down since fixing my airleak but I don't think I really touch that one. I will have a tinker over the weekend and post a revised matrix if I get time. If I try to take as much up with pump as I can that is good to know. I know pump1 AMT is set around 10% at the mo. and I think 2psi. Maybe if I just bring down the trigger point to just below 12Hg? that will help? I was going to try the TPS mode bu I cannot see where to switch it over and cannot find anything in the manual about it? I guess once I can get it to free rev across those cell nicely I can then go for a drive and fine tune or make any slight additions for the load as you pull away. I thought it looked like a big jump in the map but it seemed to want it before. My primary injectors are 875cc so not sure a base map will work although I would see the cell trend from that.

Thanks

Lee

So with the matrix around my idle cell would you expect to see just 1 or 2 clicks up? Or are most of them okay.. Just the big jump on the left where it skips to as you hit throttle? I have taken some of them down since fixing my airleak but I don't think I really touch that one. I will have a tinker over the weekend and post a revised matrix if I get time. If I try to take as much up with pump as I can that is good to know. I know pump1 AMT is set around 10% at the mo. and I think 2psi. Maybe if I just bring down the trigger point to just below 12Hg? that will help? I was going to try the TPS mode bu I cannot see where to switch it over and cannot find anything in the manual about it? I guess once I can get it to free rev across those cell nicely I can then go for a drive and fine tune or make any slight additions for the load as you pull away. I thought it looked like a big jump in the map but it seemed to want it before. My primary injectors are 875cc so not sure a base map will work although I would see the cell trend from that.

Thanks

Lee

#24

Full Member

Join Date: Mar 2013

Location: Western Australia

Posts: 145

Likes: 0

Received 0 Likes

on

0 Posts

Changing to TPS for pump 1 is setting pump1 stop to off.

I couldnt find much info on the net about how microtech does its calculations and interpolates etc and the people who know dont want to share the info.

So your left guessing and experimenting.

So the following is from my experimenting.(and could be wrong)

I believe you shouldnt have a large step of over 100% between cells.

Scan across your matrix lines and look at the trend as it slopes up it should be a fairly steady slope. (yours currently has a large dip)

Then scan down each line and repeat the process.

Its best to add fuel to the low spots to avoid running lean. If its then rich you bring it down and add slight adjustments to the cells around it.

Take your manual and a copy of the basemap into the car and set up all your pump,water and crank settings after noting down your current ones in case you want to return to their current settings.

Take note of the current settings in the matrix below and then try these changes.

As a rough guide id expect your matrix to be

30 Hg All .8

25 Hg All 1.20

20 Hg All 1.1 except 1000 and 1500 which are 1.15

15 Hg All 1.35

That should give you a pretty steady idle and AFR.

Let me know how it goes

I couldnt find much info on the net about how microtech does its calculations and interpolates etc and the people who know dont want to share the info.

So your left guessing and experimenting.

So the following is from my experimenting.(and could be wrong)

I believe you shouldnt have a large step of over 100% between cells.

Scan across your matrix lines and look at the trend as it slopes up it should be a fairly steady slope. (yours currently has a large dip)

Then scan down each line and repeat the process.

Its best to add fuel to the low spots to avoid running lean. If its then rich you bring it down and add slight adjustments to the cells around it.

Take your manual and a copy of the basemap into the car and set up all your pump,water and crank settings after noting down your current ones in case you want to return to their current settings.

Take note of the current settings in the matrix below and then try these changes.

As a rough guide id expect your matrix to be

30 Hg All .8

25 Hg All 1.20

20 Hg All 1.1 except 1000 and 1500 which are 1.15

15 Hg All 1.35

That should give you a pretty steady idle and AFR.

Let me know how it goes

#25

Rotary Enthusiast

Thread Starter

Thank you for the input.. I have been working on pulling the 30Hg cells down but I wasn't sure how far to go. I will pull it down. Mostly it goes to around 16AFR on decel until decel kicks in. As For the 24HG cells I can even those out as you suggest. For the 18Hg where idle is.. There is no way I fa. Add that much fuel in. Idle would be way rich. Off idle cells at higher rpm are pretty much there. Nice AFR at cruise around 13 off the top if my head. If I can go leaner and the car will let me I think I will be better trying pull that line down to say 0.9 all over. Same for the 12Hg cells I have got a nice AFR on cruise of 13ish. Sure thing a couple of dips or blips to take out which I may have done last time. But I don't think I can move the values too much. If I can Get the pump to sort out the huge rich spot I should be able to bring the values down to consistent number as least. What turns pump 1 on/off when TPS? Or is it just on when tps moves and switches to pump2 over 2000rpm?

going by your map what would you expect the rest of my 500rpm line to look like up to 0Hg?

going by your map what would you expect the rest of my 500rpm line to look like up to 0Hg?