Clearancing Apex Seals

#1

Clearancing Apex Seals

I'm trying to clearance the apex seals but I'm not sure if I'm doing it right. I'm rebuilding an engine for the first time with RA Super Seals and when I put the seals in to test clearance I couldn't fit a 0.0025 feeler all the way down (especially in the middle). I tried all 6 slots and all 6 seals. I then cleaned the grooves again just in case and lightly filed it, still pretty much the same. On one slot that i filed a little more I can now fit a 0.003 feeler but its very very tight in the middle (i have to force it to get there) but I can slide it across the top half.

I've been using the short apex spring to raise the seal a bit but have tried with the large and no spring and same result. So my question is when your clearancing the apex seals, does the feeler need to go all the way down to consider that as its clearance? Any help/advice would be appreciated. Just need to clearance the apex seals and side seals and then ready to assemble

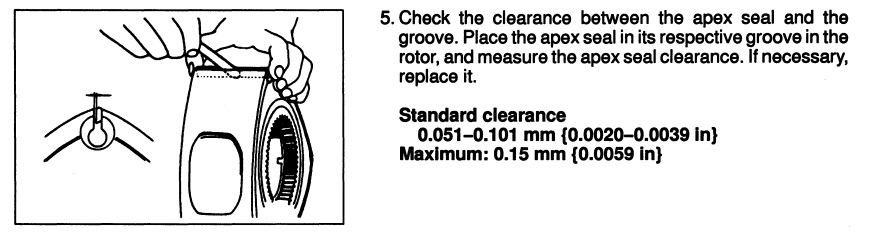

thewird

I've been using the short apex spring to raise the seal a bit but have tried with the large and no spring and same result. So my question is when your clearancing the apex seals, does the feeler need to go all the way down to consider that as its clearance? Any help/advice would be appreciated. Just need to clearance the apex seals and side seals and then ready to assemble

thewird

#2

Technically, the groove should be clearanced the whole way down and across. But the truth is, the seal doesn't see the entire depth during its travel. So you do what you feel safe with. I personally clearance the whole slot all the way down. It just takes a little time and patience...

-J

-J

#4

Technically, the groove should be clearanced the whole way down and across. But the truth is, the seal doesn't see the entire depth during its travel. So you do what you feel safe with. I personally clearance the whole slot all the way down. It just takes a little time and patience...

-J

-J

Agreed. It takes time and patience. A good file is your best friend.

#6

Banned. I got OWNED!!!

iTrader: (1)

Join Date: Jun 2006

Location: Denver

Posts: 697

Likes: 0

Received 0 Likes

on

0 Posts

I have used a file for quite some time, and have found a Swiss pattern file is easier to control how much material is removed and leaves a finer finish that the mill bastard files sold in most hardware stores. The ones made by Stahlwille seem to be the easiest to find, but check gunsmith or jewelers supply. Also, Goopy performance sells a rotor repair kit for 2mm and 3mm apex seal grooves with the file and other tools, its on their website.

#7

Old [Sch|F]ool

I use an old apex seal to scrape/clean the groove out, and then sand the seal to fit the groove. I figure, I don't want to modify the rotor to fit the seal, the seal is the wear item, it should be altered to fit the rotor. The rotor is doomed to having its apex slots open up as it ages, clearancing it is just shortening its lifespan.

(Then again, my engines tend to wear out rather than suffer catastrophic failure - I don't expect to destroy the rotor when engine failure occurs)

Plus, running a apex seal's side on a piece of fine emery paper on a flat block is a lot easier on the fingers than filing a rotor.

(Then again, my engines tend to wear out rather than suffer catastrophic failure - I don't expect to destroy the rotor when engine failure occurs)

Plus, running a apex seal's side on a piece of fine emery paper on a flat block is a lot easier on the fingers than filing a rotor.

Trending Topics

#8

Alright got it all clearanced. Made sure 0.0025 fit all the way down and 0.003 at the top half. Does that sound right? This is for a car expected to make 400-450 rwhp, should I give it more clearance? Thanks for your help guys.

On a side note, finishing clearancing the side seals as well

thewird

On a side note, finishing clearancing the side seals as well

thewird