Something completely different - a very long term tube chassis project

#126

spoon!

Thread Starter

Chugging away at stuff.

Spoke profile on the outside isn't quite right, but inner barrel and spoke profile is dimensionally accurate, which means I can use it for brake alignment which was the point.

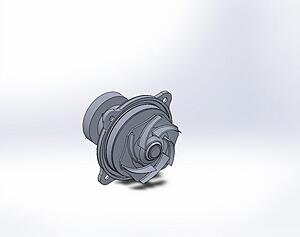

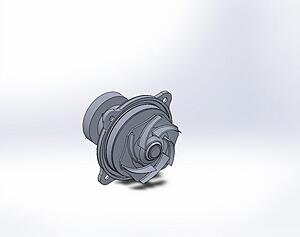

Stewart Pro Series pump cartridge reverse engineered; going to be working on water pump housing to take it because I do not trust EWPs, and... well generally it seems silly to rely on production pump housings that came from god knows what junkyard.

Spoke profile on the outside isn't quite right, but inner barrel and spoke profile is dimensionally accurate, which means I can use it for brake alignment which was the point.

Stewart Pro Series pump cartridge reverse engineered; going to be working on water pump housing to take it because I do not trust EWPs, and... well generally it seems silly to rely on production pump housings that came from god knows what junkyard.

#127

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,844

Received 2,606 Likes

on

1,849 Posts

you might look at the water pumps Mazda is using on the Skyactive stuff, https://www.ebay.com/itm/372901193881

#129

spoon!

Thread Starter

The following 2 users liked this post by Kenku:

j9fd3s (02-07-22),

mustanghammer (02-06-22)

#132

spoon!

Thread Starter

Honestly? I was ordering a few wheel bearings to reverse engineer and I expanded the scope by one since on Saturday, while reading the Timken wheel bearing catalog (as one does on a weekend) it looked like it'd fit, and I wanted to find out if my method of figuring that out worked. But it's always nice to find a new double wishbone upright I can use for things, and now having the RX-8 upright be able to be either 4x100 or 5x4.5" is interesting.

#133

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,844

Received 2,606 Likes

on

1,849 Posts

Honestly? I was ordering a few wheel bearings to reverse engineer and I expanded the scope by one since on Saturday, while reading the Timken wheel bearing catalog (as one does on a weekend) it looked like it'd fit, and I wanted to find out if my method of figuring that out worked. But it's always nice to find a new double wishbone upright I can use for things, and now having the RX-8 upright be able to be either 4x100 or 5x4.5" is interesting.

#135

spoon!

Thread Starter

It's the darnedest thing; progress is slow when all my money is going to daycare and RL is stressful and stuff. Oh well, got an answer I needed today.

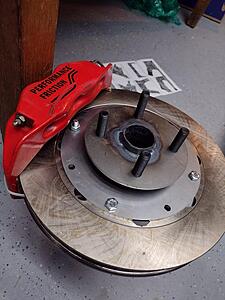

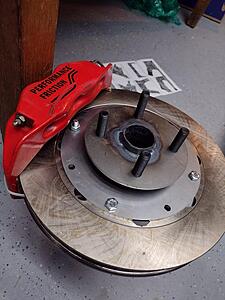

Fitment checker tool! Brake rotor and caliper are bolted to that flange which is welded to a tube. Wheel mount flange is welded to a second tube that telescopes in that tube. There's a clamp to hold the two together.

In position... that's an 11.75x1.25" rotor with a ZR34 caliper (Superlite size) in a 15x7 wheel.

Closeup of clearance.

So the point is move it to the minimum clearance, unbolt the wheel, measure wheel mount face to rotor face, which gives me minimum dimension for brake rotor hat. Which gives me rotor position that works for sure, which means I can finally finalize front suspension geometry.

Fitment checker tool! Brake rotor and caliper are bolted to that flange which is welded to a tube. Wheel mount flange is welded to a second tube that telescopes in that tube. There's a clamp to hold the two together.

In position... that's an 11.75x1.25" rotor with a ZR34 caliper (Superlite size) in a 15x7 wheel.

Closeup of clearance.

So the point is move it to the minimum clearance, unbolt the wheel, measure wheel mount face to rotor face, which gives me minimum dimension for brake rotor hat. Which gives me rotor position that works for sure, which means I can finally finalize front suspension geometry.

The following 2 users liked this post by Kenku:

gracer7-rx7 (05-29-22),

j9fd3s (05-28-22)

#136

spoon!

Thread Starter

Back to work a bit... suffice to say that there's been a lot of non-car related stuff occupying time and money.

So OK, let's rejigger the bellhousing design

So that's a bellhousing to bolt an aftermarket sequential (looking at Elite IL200 wide gear version) with a Ford Type 9 bolt pattern up to a 13B that's using a Tilton small diameter small block Chevy flywheel and reverse mount starter... and that sounds weird but all the individual decisions there make sense, trust me.

So OK, let's rejigger the bellhousing design

So that's a bellhousing to bolt an aftermarket sequential (looking at Elite IL200 wide gear version) with a Ford Type 9 bolt pattern up to a 13B that's using a Tilton small diameter small block Chevy flywheel and reverse mount starter... and that sounds weird but all the individual decisions there make sense, trust me.

The following users liked this post:

j9fd3s (08-27-22)

#137

spoon!

Thread Starter

Well a lot of stuff kept me off track but back to it.

3d printed fitment test jig designed to hold caliper (PFC ZR34; Wilwood Superlite class) and BMW Mini rear hub (here to be used as front hub) and 3d printed brake hat designed to an offset I was pretty sure should work. But does it...?

Oooh, looks promising...

Just fits! Everything (barely) clears; probably going to space the wheel out by maybe 2mm and then there'll "lots" of space. This is, for the record, an 11.75x1.25" brake rotor, a Superlite size caliper, and an off the shelf cast 15x7 wheel.

Back side. Upright won't actually look like that but it was a quick and dirty design with enough meat for me to tap into it for the caliper mount.

So I'm going to do another test or two (thicken the wheel mount face of the brake hat by 2mm, see if there's any chance in hell of fitting 12.19"x1.25" rotors) but fundamentally... that's that, now I know where the rotor and caliper have to go. Which means I can finalize the front suspension design, which means I can finalize the front bit of the chassis!

3d printed fitment test jig designed to hold caliper (PFC ZR34; Wilwood Superlite class) and BMW Mini rear hub (here to be used as front hub) and 3d printed brake hat designed to an offset I was pretty sure should work. But does it...?

Oooh, looks promising...

Just fits! Everything (barely) clears; probably going to space the wheel out by maybe 2mm and then there'll "lots" of space. This is, for the record, an 11.75x1.25" brake rotor, a Superlite size caliper, and an off the shelf cast 15x7 wheel.

Back side. Upright won't actually look like that but it was a quick and dirty design with enough meat for me to tap into it for the caliper mount.

So I'm going to do another test or two (thicken the wheel mount face of the brake hat by 2mm, see if there's any chance in hell of fitting 12.19"x1.25" rotors) but fundamentally... that's that, now I know where the rotor and caliper have to go. Which means I can finalize the front suspension design, which means I can finalize the front bit of the chassis!

The following 2 users liked this post by Kenku:

gracer7-rx7 (12-15-22),

mustanghammer (12-14-22)

#138

Old [Sch|F]ool

neeeet

I did a 5 lug swap to a Mini Cooper this year.

The easy way to do this was to use a Subaru rear suspension.

Also a Subaru front suspension, and drivetrain.

It's a lot of work....

I did a 5 lug swap to a Mini Cooper this year.

The easy way to do this was to use a Subaru rear suspension.

Also a Subaru front suspension, and drivetrain.

It's a lot of work....

The following 2 users liked this post by peejay:

diabolical1 (08-11-23),

j9fd3s (12-15-22)

#139

spoon!

Thread Starter

Funny, I've been thinking of doing a stupid Toyota build on a similar theme (transverse not longitudinal because I've developed Opinions about Subaru's powertrains) but I probably really shouldn't launch another biggish car project in the midst of this thing.

Mini cooper bearings are nice for what I'm doing because 4x100 and they made a pile of them... what'll be fun is what I have in mind for how to use them on the rear axle, which is shaping up to be possibly the oddest "RX-7" axle ever.

Mini cooper bearings are nice for what I'm doing because 4x100 and they made a pile of them... what'll be fun is what I have in mind for how to use them on the rear axle, which is shaping up to be possibly the oddest "RX-7" axle ever.

#141

spoon!

Thread Starter

I've been kind of thinking of doing a billet knuckle to take the Mini rear bearing for strut use too for grins; sooner or later I'm going to slap together a street FB and I'm coming up with all of this manufacturing toolchain and spare parts sitting around...

I'm still really really excited to get the fabricated Mazda 7" housing together though; I've let it sit because it's not holding up anything the way the front suspension is, but there's some funny little design wrinkles I don't know if have been done for an FB before.

I'm still really really excited to get the fabricated Mazda 7" housing together though; I've let it sit because it's not holding up anything the way the front suspension is, but there's some funny little design wrinkles I don't know if have been done for an FB before.

The following users liked this post:

gracer7-rx7 (12-15-22)

#143

Regarding the rear axle housing, Charlie Clark's EP RX7 has a fabricated rear axle housing that uses the center of the OE housing. I believe the axle tubes were sourced from Speedway Engineering with Mini-GN snouts. The hubs are Mini-GN and the axles came from Moser. He did this to get full floating axles. They fabricated OE style mounts to stay compliant. Once they got it done, a local shop straightened for them. www.KCRaceware,com

I believe Jesse Prather's EP RX7 (the car he had before he went to the Dark BMW Side) had the same thing.

I believe Jesse Prather's EP RX7 (the car he had before he went to the Dark BMW Side) had the same thing.

#144

spoon!

Thread Starter

Regarding the rear axle housing, Charlie Clark's EP RX7 has a fabricated rear axle housing that uses the center of the OE housing. I believe the axle tubes were sourced from Speedway Engineering with Mini-GN snouts. The hubs are Mini-GN and the axles came from Moser. He did this to get full floating axles. They fabricated OE style mounts to stay compliant. Once they got it done, a local shop straightened for them. www.KCRaceware,com

I believe Jesse Prather's EP RX7 (the car he had before he went to the Dark BMW Side) had the same thing.

I believe Jesse Prather's EP RX7 (the car he had before he went to the Dark BMW Side) had the same thing.

#145

Old [Sch|F]ool

A friend bought Lynn Hannover's old stuff and I got to see the full floater setup he had. It looked for all the world like someone just stuck a 4x4's spindle snout on the thing, like from an old Jeep or maybe even an Explorer or Bronco II.

Gave me ideas, none of them good. The nice thing about the Explorer/Bronco II setup is that it is small enough to fit a 5x4.5" bolt pattern wheel without a huge center hole. The bad thing is the bearings are very close together and it was almost impossible to get the bearings set up to where they didn't have a ton of free play.

Gave me ideas, none of them good. The nice thing about the Explorer/Bronco II setup is that it is small enough to fit a 5x4.5" bolt pattern wheel without a huge center hole. The bad thing is the bearings are very close together and it was almost impossible to get the bearings set up to where they didn't have a ton of free play.

#146

Huh, that seems borderline for EP but hey. I'm going a little further... I have laser cut plates for the center housing to get bent up like a Strange fabricated 9". Trick will be outer CVs to accept camber with better longevity; well that and the Speedway stuff, I don't think you can get it down to 4x100 with the bearings Speedway chose.

#147

spoon!

Thread Starter

A friend bought Lynn Hannover's old stuff and I got to see the full floater setup he had. It looked for all the world like someone just stuck a 4x4's spindle snout on the thing, like from an old Jeep or maybe even an Explorer or Bronco II.

Gave me ideas, none of them good. The nice thing about the Explorer/Bronco II setup is that it is small enough to fit a 5x4.5" bolt pattern wheel without a huge center hole. The bad thing is the bearings are very close together and it was almost impossible to get the bearings set up to where they didn't have a ton of free play.

Gave me ideas, none of them good. The nice thing about the Explorer/Bronco II setup is that it is small enough to fit a 5x4.5" bolt pattern wheel without a huge center hole. The bad thing is the bearings are very close together and it was almost impossible to get the bearings set up to where they didn't have a ton of free play.

I think the bolt on Mini bearings should work interestingly though. Worse comes to worst I can make something different later.

#148

spoon!

Thread Starter

Ah, so, been a while.

So... two sticking points, and I think they're showstoppers.

Number 1 is costs... no matter how much elbow grease I put into fabricating everything, there's enh, maybe 20 grand worth of Stuff that I have to figure out how to afford to make a car that isn't held back by parts, all of that with maintenance costs and so on. I can be clever, but I can't clever my way out of that, and in the near term with a kid and such, it's not happening.

Number 2... car counts. Just looking at June Sprints results for this year and there was a grand total of zero GT3 cars entered. There were various efforts by people to get people to bring GT3 cars out in the last few years but things are here and that doesn't bode well...

So I'm shelving all of this stuff. But the nice thing is that in the mean time, SCCA kind of fixed a lot of my gripes with the idea of building a 1st gen for E Production - where there's car counts, and a competitive field, and they're in a run group with other stuff that makes lap times in a same way. And wouldn't you know it, most of the fancy bits I bought for the GT3 car already would work perfectly well in an EP car (not the trick magnesium diff carrier though, sigh) and at least some of the scanning and stuff I was doing transfers over. Oh, and I have 3 13Bs worth of EP ported irons and housings sitting on my shelf so that's nice plus a shell already stripped of most of its sound deadening and seam sealer. And a lot of the fun parts are still valid... playing with shock valving, and custom cast bits, and new suspension ideas...

I'll get another thread started after work or so, where I can post pictures of what I'm working on for it.

So... two sticking points, and I think they're showstoppers.

Number 1 is costs... no matter how much elbow grease I put into fabricating everything, there's enh, maybe 20 grand worth of Stuff that I have to figure out how to afford to make a car that isn't held back by parts, all of that with maintenance costs and so on. I can be clever, but I can't clever my way out of that, and in the near term with a kid and such, it's not happening.

Number 2... car counts. Just looking at June Sprints results for this year and there was a grand total of zero GT3 cars entered. There were various efforts by people to get people to bring GT3 cars out in the last few years but things are here and that doesn't bode well...

So I'm shelving all of this stuff. But the nice thing is that in the mean time, SCCA kind of fixed a lot of my gripes with the idea of building a 1st gen for E Production - where there's car counts, and a competitive field, and they're in a run group with other stuff that makes lap times in a same way. And wouldn't you know it, most of the fancy bits I bought for the GT3 car already would work perfectly well in an EP car (not the trick magnesium diff carrier though, sigh) and at least some of the scanning and stuff I was doing transfers over. Oh, and I have 3 13Bs worth of EP ported irons and housings sitting on my shelf so that's nice plus a shell already stripped of most of its sound deadening and seam sealer. And a lot of the fun parts are still valid... playing with shock valving, and custom cast bits, and new suspension ideas...

I'll get another thread started after work or so, where I can post pictures of what I'm working on for it.

The following users liked this post:

gracer7-rx7 (08-07-23)

#150

spoon!

Thread Starter

On the other hand Prod keeps having new stuff come to the forefront and get added and stuff without seriously moving the lap time goalposts or really, truly obsoleting anything. There were some stuff that held back the 1st gen but I have ideas how to work around it.