My daily driven AI build/dyno thread

#26

BDC Motorsports

sorry its been taking a while to get it to the dyno. its been raining almost everyday here making it hard for me to clean up the tune a bit. But i finally got it out two days ago and finished cleaning the tune for an afr range of 10.7-10.9. BUT as i was driving home all of the sudden i smelled oil, thought it was nothing but i pulled over to check something in the computer when all of the sudden the low oil buzzer came on.

Turns out i cracked the FRONT plate right were the oil feed bolt goes. =\. so i have two conclusions 1. cracked because it was not pinned. 2. Detonation occured.

Turns out i cracked the FRONT plate right were the oil feed bolt goes. =\. so i have two conclusions 1. cracked because it was not pinned. 2. Detonation occured.

I am and have been becoming an unfortunate expert on this subject over the past few years. Whatever occurred in the chamber can be classified in the general category of "knock". Although it could be, it might not have been actual detonation per say (extremely short-lived pressure spikes, very rapidly burning flame front, being a 2nd combustion event that occurs post timed spark-event usually due to the combination of high heat and way too much unburnt fuel left over) but could have been a number of things. I've been off and on chasing this down on my setup, too. Per the success of a handful of others, I think I've nailed mine down to being a lack of ignition power behind the plugs at higher loads when the chambers are soppin' wet, thick, and "crowded" with alcohol.

Whatever the type of knock it is, it's severe and it attempts to shove the rotor housing away laterally/perpendicularly from the irons. What winds up happening is the rotor housing attempts to move in some direction over and above the normal combustion forces that do constantly push at it on the plug-side of the engine. Constant pressure on the housing won't break the irons. They're only broken when the rotor housing, in one instance, bangs out and away from the irons. Consider that the plug-side of the engine is attempting to harness combustion energy in the form of heat and pressure and convert it to mechanical/kinetic energy by way of shoving against the leading edge of the rotor to continue rotating that eccentric shaft. Think of like the difference between hanging your body weight on the end of a ratchet or breaker bar to break a bolt and that of having that same breaker bar on there being smacked by a hammer/small sledge.

Here's the rundown: when the rotor housing moves, or grows, or twists, or whatever else, it's going to drag that upper dowel pin with it. The rotor housing is 80mm wide. The dowel pin is ~116mm long. A good 75% of that pin is taken ownership by the rotor housing with only about ~35mm or so of it sticking out the ends. When the rotor housing is encountering odd, intermittent, high pressure spikes in the chamber (any kind of serious engine knock - pre-ignition, auto-ignition types, detonation, idiotic tuning, heavy misfires from spark blowout due to lack of spark energy), it will move in a direction commensurate with where the pressure spikes in the chamber occur (before or after TDC) and will drag that dowel pin with it. When the dowel pin gets yanked along, those forces transfer over to the four spots on the upper dowel run: the front iron dowel land, the front side of the center iron, the rear side of the center iron, and the rear iron dowel land.

Read on.

The next time you take an engine apart or put one together, keep a close eye on the depth the upper dowel pins throw into their lands. If you look closely, you'll notice the dowel pin doesn't sit evenly (with an even amount of pin) sticking out both ends of the housing. It's longer on one side. The center housing is 50mm thick. The dowel pins stick out 25mm out the rear of the front rotor housing and 25mm out of the front of the rear rotor housing (25+25=50mm of pin throw). However, the pins only sit about 11mm into both the front and rear irons.

Ever wonder why the center housing never breaks?

It's lack of leverage. The pin is attempting to grab against iron in hopes of that iron holding itself in place, but there's not enough there for the pin/housing/chamber pressure to keep it. Since the pin only lands in that 11mm, it's not grabbing up against all of the housing; just the small amount it is pulling against. Look closely at the cracks and you'll notice that the crack normally extends down to and just barely past where the dowel pin lands. The pin isn't anywhere near deep enough to really grab ahold of and lean against enough iron plus there's nowhere near enough iron on the cast housing anyways. Mazda's workaround for this, keeping in mind they were stuck with power steering and A/C (the reason I believe the dowels are made the way they are) was to change the cast to make that short portion of iron on the FD and Renesis housings about twice as thick as the older ones. But, the same problem still exists -- only 11mm of throw into that dowel land and not enough iron for the pin to leverage against in the first place.

Practical comparison - a door with a deadbolt. The longer the deadbolt, the more wood stud in the wall it can "pull" against as the door is being slammed to open. The deeper the throw of the deadbolt, and the more wood stud there is accepting that throw, the greater the shear forces the door must overcome for the deadbolt to split and splinter the wood. Make sense?

So, when you think about it, those four points on the motor are holding every bit of combustion the engine ever goes through. Tension bolts (and those silly tension bolt sized studs) do nothing for this. It's only those points on the three irons holding *everything* thrown at it, good and bad combustion.

Some solutions are the additional dowels and dowelling type fixes with extra pins, adding weld to the existing land, and making/welding dowel pins together that are slightly longer with matching machine work to extend those pins deeper into their respective lands. I did the latter two on my engine.

There's little to no difference between front and rear irons with respect to this problem. They are both weak spots on the motors (even the FD's and the Renesis engines although they can withstand more impact forces). They both break. I've broken a front and a rear myself.

Be flattered. You were well past the normal, practical limits of those housings and making terrific power. Your car is broke because you "overpowered the engine".

im leaning more on the 1st conclusion as of now mostly because of the afrs that i was running along with the timing. as well a S4 rotors. BUT i was thinking what if the alcohol was not being distributed evenly among the rotors. i suppose ill have to wait and see till i take the motor apart for any signs of detonation. If you guys have any input on this feel free.

But I suspect that's not your problem.

possibly going 3rd gen plates and pinned now. seems like now i regretted not adding the extra dowels

XD

XD

B

#27

BDC Motorsports

There is an element of luck with the FC plates. I've never cracked an s4 or an s5 plate (front or rear) and I have detonated both. I've never had a dowelled or studded engine on my personal car.

Personally I think you should have run less timing given the type of turbo you have and what you are throwing at it. Lean = dangerous but rich AFR != safe if there is too much.

Personally I think you should have run less timing given the type of turbo you have and what you are throwing at it. Lean = dangerous but rich AFR != safe if there is too much.

#28

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

thnx BDC for the great info. very helpful =D, and yea i was going to borrow my fathers dual egt gauge just to make sure i wasnt getting more alcohol in a rotor.

I also would like to WARN people about a spike in boost that i got in my log. i was for sure at 20psi, my boost gauge read 20psi solid BUT in my data log i got a spike of 30psi. it literally went from 19psi to 30psi in one unit of the log, then back to the 19psi. Seems like the map sensor is not as accurate. Thus the portion of my fuel map that's on 30psi is pig rich since it is uncharted territory. That also means for that blip of a second my car went from 15-16deg of timing to 5deg, as well as the very rich point. Its so fast its unnoticeable driving wot, or on the wide-band. This can cause a misfire for sure causing a plate to weaken or crack. Think of it happening in a 50rpm gap or so. So for the handheld users check your logs, your boost gauge might be showing something but the computer read something else. Now the scary part is how to correct it, i would guess that i have to go to the 30psi section and input the correct fuel and timing for 20psi and not 30psi.

As for ignition setup im running MSD dis2 on the leading coils, spark plug gap was .020, trailing i am running second gen coils 10deg split. As most detonation occurs at the trailing edge would it be so wise to run such a strong spark? I remember that Carlos Lopez would shut off the trailing plugs when the car was well into boost, but idk if he still does that, this is from way back.

I also would like to WARN people about a spike in boost that i got in my log. i was for sure at 20psi, my boost gauge read 20psi solid BUT in my data log i got a spike of 30psi. it literally went from 19psi to 30psi in one unit of the log, then back to the 19psi. Seems like the map sensor is not as accurate. Thus the portion of my fuel map that's on 30psi is pig rich since it is uncharted territory. That also means for that blip of a second my car went from 15-16deg of timing to 5deg, as well as the very rich point. Its so fast its unnoticeable driving wot, or on the wide-band. This can cause a misfire for sure causing a plate to weaken or crack. Think of it happening in a 50rpm gap or so. So for the handheld users check your logs, your boost gauge might be showing something but the computer read something else. Now the scary part is how to correct it, i would guess that i have to go to the 30psi section and input the correct fuel and timing for 20psi and not 30psi.

As for ignition setup im running MSD dis2 on the leading coils, spark plug gap was .020, trailing i am running second gen coils 10deg split. As most detonation occurs at the trailing edge would it be so wise to run such a strong spark? I remember that Carlos Lopez would shut off the trailing plugs when the car was well into boost, but idk if he still does that, this is from way back.

#29

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

As for ignition setup im running MSD dis2 on the leading coils, spark plug gap was .020, trailing i am running second gen coils 10deg split. As most detonation occurs at the trailing edge would it be so wise to run such a strong spark? I remember that Carlos Lopez would shut off the trailing plugs when the car was well into boost, but idk if he still does that, this is from way back.

Donīt run pure alcohol. Its not knock suppressant - 50:50 water-methanol is proved - for over 60 years....

#30

talking head

actually all those using alky AI mixes should read up on MW 50 and MW 30

( and also EW 50 and EW 30 )

MW 50 is the 50 ( methanol ) /0.5 ( lube oil ) /49.5 ( water ) mix and it is actually less efficient at detonation control than the MW 30

the MW 50 was devised purely as a strategy to stop the AI freezing at altitude

how many of you are racing at 35 000 ft?

( and also EW 50 and EW 30 )

MW 50 is the 50 ( methanol ) /0.5 ( lube oil ) /49.5 ( water ) mix and it is actually less efficient at detonation control than the MW 30

the MW 50 was devised purely as a strategy to stop the AI freezing at altitude

how many of you are racing at 35 000 ft?

#31

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

But i would imagine that a spike of 10psi would at least show on the gauge though anyone have more input?, i know the 20psi is not as consistent purely because my log would fluctuate from 18psi-20psi, im running a divided exhaust T4, greddy wastegate 47mm. 860cc with 1600cc secondaries. Aeromotive FPR, 8an lines. Weldon Fuel pump 1000a. oh housing are ported as well.

#32

BDC Motorsports

thnx BDC for the great info. very helpful =D, and yea i was going to borrow my fathers dual egt gauge just to make sure i wasnt getting more alcohol in a rotor.

I also would like to WARN people about a spike in boost that i got in my log. i was for sure at 20psi, my boost gauge read 20psi solid BUT in my data log i got a spike of 30psi. it literally went from 19psi to 30psi in one unit of the log, then back to the 19psi. Seems like the map sensor is not as accurate. Thus the portion of my fuel map that's on 30psi is pig rich since it is uncharted territory. That also means for that blip of a second my car went from 15-16deg of timing to 5deg, as well as the very rich point. Its so fast its unnoticeable driving wot, or on the wide-band. This can cause a misfire for sure causing a plate to weaken or crack. Think of it happening in a 50rpm gap or so. So for the handheld users check your logs, your boost gauge might be showing something but the computer read something else. Now the scary part is how to correct it, i would guess that i have to go to the 30psi section and input the correct fuel and timing for 20psi and not 30psi.

As for ignition setup im running MSD dis2 on the leading coils, spark plug gap was .020, trailing i am running second gen coils 10deg split. As most detonation occurs at the trailing edge would it be so wise to run such a strong spark? I remember that Carlos Lopez would shut off the trailing plugs when the car was well into boost, but idk if he still does that, this is from way back.

I also would like to WARN people about a spike in boost that i got in my log. i was for sure at 20psi, my boost gauge read 20psi solid BUT in my data log i got a spike of 30psi. it literally went from 19psi to 30psi in one unit of the log, then back to the 19psi. Seems like the map sensor is not as accurate. Thus the portion of my fuel map that's on 30psi is pig rich since it is uncharted territory. That also means for that blip of a second my car went from 15-16deg of timing to 5deg, as well as the very rich point. Its so fast its unnoticeable driving wot, or on the wide-band. This can cause a misfire for sure causing a plate to weaken or crack. Think of it happening in a 50rpm gap or so. So for the handheld users check your logs, your boost gauge might be showing something but the computer read something else. Now the scary part is how to correct it, i would guess that i have to go to the 30psi section and input the correct fuel and timing for 20psi and not 30psi.

As for ignition setup im running MSD dis2 on the leading coils, spark plug gap was .020, trailing i am running second gen coils 10deg split. As most detonation occurs at the trailing edge would it be so wise to run such a strong spark? I remember that Carlos Lopez would shut off the trailing plugs when the car was well into boost, but idk if he still does that, this is from way back.

B

#33

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

If you think about it my setup is very simalar to Howards in his write up of 80% fuel and 30% alcohol. Both of us are running m10 nozzles, 20psi, and about the same amount of lbs/m of air, though i am running less compression (8:5:1) His knock detector was not reading any sort of knock at all. Not even when his AFRs were in the 9s. Now the difference mostly lies on the ignition system as well. Now i wish i had a knock detector similar to Howards for a comparrison. But i am starting to believe that my little spike of 30psi could have indeed been the cause. Retarding the timing and adding alot of fuel? sounds like a ticking time bomb to me. =\ (the 30psi spike was happening around 6500rpm and my car blasts off at 5k)

#34

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

If you think about it my setup is very simalar to Howards in his write up of 80% fuel and 30% alcohol. Both of us are running m10 nozzles, 20psi, and about the same amount of lbs/m of air, though i am running less compression (8:5:1) His knock detector was not reading any sort of knock at all. Not even when his AFRs were in the 9s. Now the difference mostly lies on the ignition system as well. Now i wish i had a knock detector similar to Howards for a comparrison. But i am starting to believe that my little spike of 30psi could have indeed been the cause. Retarding the timing and adding alot of fuel? sounds like a ticking time bomb to me. =\ (the 30psi spike was happening around 6500rpm and my car blasts off at 5k)

...

...This happened quite often on alcohol setups lately, whats wrong?

You should start gently, tune engine without any auxiliary, shoot for 0.75 Lambda, trim fuel maps just slightly with injection, and use 50:50 water-methanol. Log everything and make sure that ignition is up to task.

Easiest way tuning wise would be straight water - you can run any Lambda you want, right amount of water will keep everything in check - you just have to ignite it.

You should ask yourself, what you really want to accomplish. Aquamist website can help you big time. Or EFI university forum. There are guys with vast experience running engines with injection of any fluid....

#35

If you are getting knock due to some electrical/sensor issue, well obviously that needs to be taken care of.

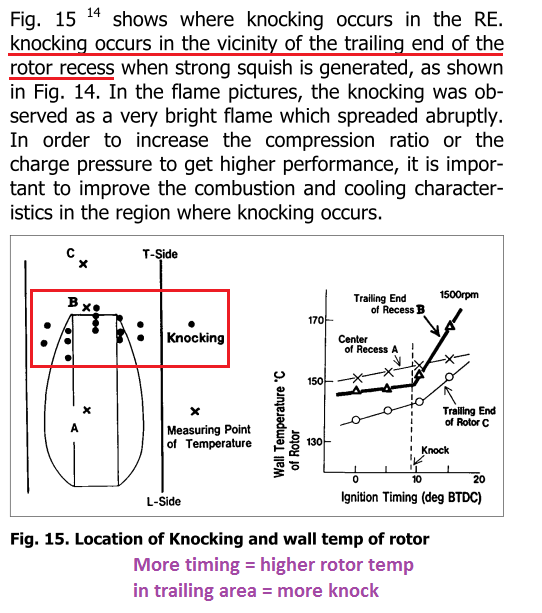

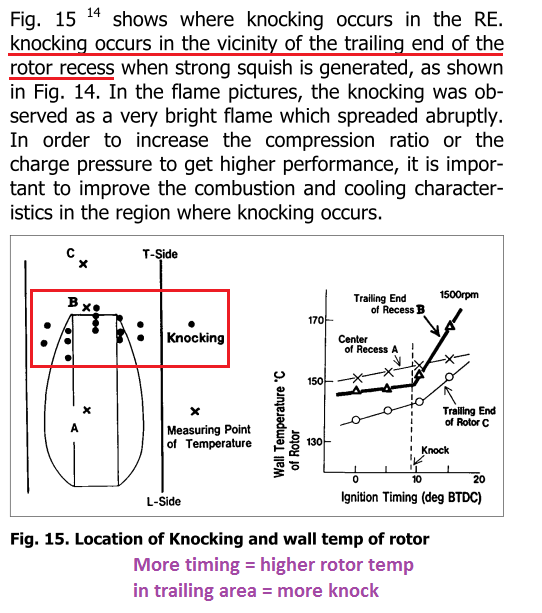

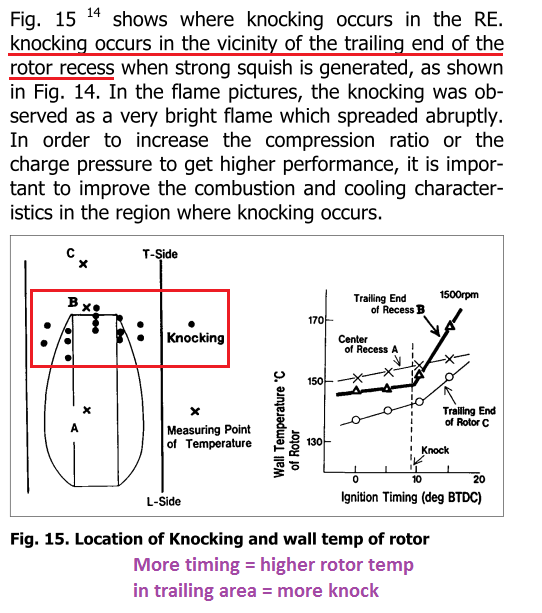

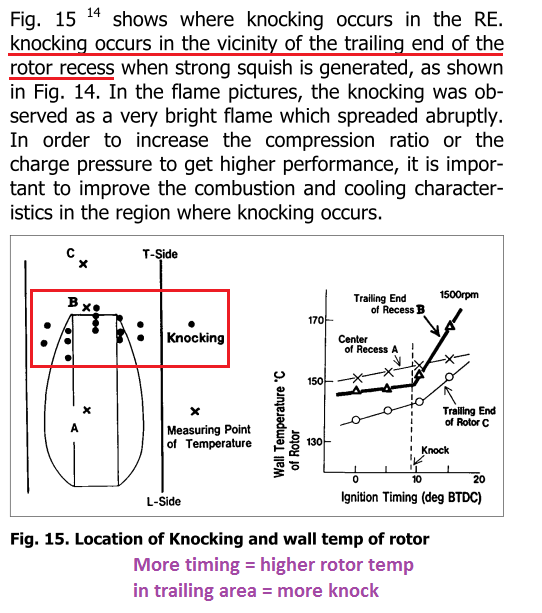

I see this issue as a matter more of controlling knock (detonation, pre-ignition, whatever) rather than strengthening the engine. Of course at some level of stress any component can break, but obviously knock greatly increases stress. I believe in the vast majority of applications, if you keep knock under control you won't have an issue with cracked plates--although the s4 plates still seem to be the most prone. Based on personal experience and based on a study Mazda did, I think we need to keep in mind the direct relationship between

1) rotor wall temperature

2) ignition timing

3) knock, specifically in the trailing portion of the combustion chamber

When rotor temperature goes up to a certain point, knock tends to occur near the trailing part of the rotor combustion bathtub (see boxed area above). We control temperature by keeping intake temps, coolant temps, and oil temps down. We also use AI and/or fuel enrichment, although AI is more effective than heavy fuel enrichment.

I argue that ignition timing can directly counteract the cooling effects of AI. There needs to be more of a balance between focusing on the AI aspect (lambda, methanol vs water blend %, nozzle size, etc) and this fundamental aspect of tuning. Besides changing the physical characteristics (redesigning) of the engine, what is the primary method the OEM's use to control detonation on port injected engines? They adjust ignition timing in response to a carefully tuned and filtered knock sensor signal. We are working with nonexistant or very crude knock control systems here, so we have to leave a wider safety margin with the timing.

If you look at the maps I run on the rotaries I tune (with or without AI), you will notice that they tend to run less timing than most tuners run, especially on the trailing plugs. I tend to model them on the OEM high octane ignition maps for heavily boosted piston engines, like the Evo X. This approach does cost some power, but the way I see it there isn't a better option for street cars because we don't have OEM-grade knock control systems.

I think I might make a dedicated thread about this point.

I see this issue as a matter more of controlling knock (detonation, pre-ignition, whatever) rather than strengthening the engine. Of course at some level of stress any component can break, but obviously knock greatly increases stress. I believe in the vast majority of applications, if you keep knock under control you won't have an issue with cracked plates--although the s4 plates still seem to be the most prone. Based on personal experience and based on a study Mazda did, I think we need to keep in mind the direct relationship between

1) rotor wall temperature

2) ignition timing

3) knock, specifically in the trailing portion of the combustion chamber

When rotor temperature goes up to a certain point, knock tends to occur near the trailing part of the rotor combustion bathtub (see boxed area above). We control temperature by keeping intake temps, coolant temps, and oil temps down. We also use AI and/or fuel enrichment, although AI is more effective than heavy fuel enrichment.

I argue that ignition timing can directly counteract the cooling effects of AI. There needs to be more of a balance between focusing on the AI aspect (lambda, methanol vs water blend %, nozzle size, etc) and this fundamental aspect of tuning. Besides changing the physical characteristics (redesigning) of the engine, what is the primary method the OEM's use to control detonation on port injected engines? They adjust ignition timing in response to a carefully tuned and filtered knock sensor signal. We are working with nonexistant or very crude knock control systems here, so we have to leave a wider safety margin with the timing.

If you look at the maps I run on the rotaries I tune (with or without AI), you will notice that they tend to run less timing than most tuners run, especially on the trailing plugs. I tend to model them on the OEM high octane ignition maps for heavily boosted piston engines, like the Evo X. This approach does cost some power, but the way I see it there isn't a better option for street cars because we don't have OEM-grade knock control systems.

I think I might make a dedicated thread about this point.

#36

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

When rotor temperature goes up to a certain point, knock tends to occur near the trailing part of the rotor combustion bathtub (see boxed area above). We control temperature by keeping intake temps, coolant temps, and oil temps down. We also use AI and/or fuel enrichment, although AI is more effective than heavy fuel enrichment.

At high RPMs rotor operates with substantially higher temps, of course, there is fraction of time when knock can occur...

Its just to much advance for given speed and load. Good engine combination doesnīt need much of it, but it brings us back to ignition - firing closer to TDC is harder than at more advanced position. If engine gains quite power from advancing, VE% is low, or dynamic compression is low, ir ignition is weak, or everything of above

#37

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

Still, nothing can be judged from this. Actual flow rate of gasoline and flow rate of methanol are unknown, fuel pressure, what was actual lambda or AFR.... intake temperatures ...

...

This happened quite often on alcohol setups lately, whats wrong?

You should start gently, tune engine without any auxiliary, shoot for 0.75 Lambda, trim fuel maps just slightly with injection, and use 50:50 water-methanol. Log everything and make sure that ignition is up to task.

Easiest way tuning wise would be straight water - you can run any Lambda you want, right amount of water will keep everything in check - you just have to ignite it.

You should ask yourself, what you really want to accomplish. Aquamist website can help you big time. Or EFI university forum. There are guys with vast experience running engines with injection of any fluid....

...

...This happened quite often on alcohol setups lately, whats wrong?

You should start gently, tune engine without any auxiliary, shoot for 0.75 Lambda, trim fuel maps just slightly with injection, and use 50:50 water-methanol. Log everything and make sure that ignition is up to task.

Easiest way tuning wise would be straight water - you can run any Lambda you want, right amount of water will keep everything in check - you just have to ignite it.

You should ask yourself, what you really want to accomplish. Aquamist website can help you big time. Or EFI university forum. There are guys with vast experience running engines with injection of any fluid....

#38

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

update. got my plates and ill i got to say is wow on the secondary ports lol, my s5 plates on a pretty big street port is still not as big as the stock fd secondary ports (talking about the intake manifold side. sent the plates out for street porting.

now idk if to add one more dowel in every corner. or add two on the oil filter and oil feed side. so far im thinking about adding one dowel in ever corner.

now idk if to add one more dowel in every corner. or add two on the oil filter and oil feed side. so far im thinking about adding one dowel in ever corner.

#39

BDC Motorsports

Senor Arghx,

I've stared at this diagram I don't know how many times now. It's gotten me thinking though recently. This is just right off the top of my head:

- Assuming slower burn rate of theoretically homogenous mixture of alcohol and gasoline, this demands much more lead advance; I know of nobody who's actually done experimentation on adjusting lead advance with heavy alcohol/gasoline mixtures to see differences both in EGT's, power, and knock - mechanical pressure switch to the ignitor lead, normally closed switch, to kill the ignitor from charging up the trail coils - Remember that stupid "anti-detonation device" many years back that was just an elimination of the trailing spark plug by inserting a machined aluminum (threaded) plug?

- Elimination of trailing spark at x boost, say 10psi and above, assuming the trailing spark plug may be inadvertently lighting a fuel-rich "chunk" of end gasses collecting at the trailing edge of the rotor, after the lead has fired, from a far too rich mixture in the first place (where the common practice of using fuel in an attempt to cool the chamber walls and rotor face may be a double-edged sword here as it might be enabling real detonation to occur)

- Pull AFR's back into the 12's to go leaner when using heavy mixtures of alcohol instead of into the 10's, or perhaps this is a benefit of the use of water over alcohol in that it isn't flammable in the first place and therefore won't enable a 2nd burn to possibly start?

- Too little spark to light this wet, soupy, busy mixture in the chamber (use of much more alcohol vs. gasoline to produce same heat energy?), leaving much unburnt fuel from **** poor burns and misfiring to pool up at trailing edge of rotor

Seems the common practice of tuner guys on these things, even long before us contemporary guys were messing with these cars, has been to turn up or jet more fuel into the chamber over and above what's actually necessary for proper combustion (arguably mid 13's:1 or somewhere around there) and proper power. The downside of the engine is its production of heat especially at higher RPM's. High consumption of air, lots of combustion. Perhaps the practice of going much richer (and the trend over the past many years on our turbo'd EFI cars has been towards even richer) has a drawback - fuel-laden end gasses, unburnt, collecting at the trailing edge of the rotor, which makes sense when you think about how the chamber is designed and how the rotor swings around, being lit to produce a second flamefront and then strong pressure wave that may be attempting to counter the rotation of the rotor. Know of anyone who doesn't run a trailing plug under big boost? How beneficial is it really way way up high? One car comes to mind I did about 8 years ago with a high boost (23psi) 9:1 motor on 117oct leaded C16 that gained 24hp (from 475 to 499) at the high end and a marginal amount of midrange torque by skinnying up the split from 11 to 6*. It's a 5% increase.

Or is this all really an issue of running too "hot" of a fuel in too hot of a chamber environment ala the same paradigm as spark plugs... I sure love cars sometimes.

Does anybody have any data on post turbo compressor discharge temperatures using pre and post water injection in varying amounts on a standard T4 turbo?

Whatcha think?

B

I've stared at this diagram I don't know how many times now. It's gotten me thinking though recently. This is just right off the top of my head:

- Assuming slower burn rate of theoretically homogenous mixture of alcohol and gasoline, this demands much more lead advance; I know of nobody who's actually done experimentation on adjusting lead advance with heavy alcohol/gasoline mixtures to see differences both in EGT's, power, and knock - mechanical pressure switch to the ignitor lead, normally closed switch, to kill the ignitor from charging up the trail coils - Remember that stupid "anti-detonation device" many years back that was just an elimination of the trailing spark plug by inserting a machined aluminum (threaded) plug?

- Elimination of trailing spark at x boost, say 10psi and above, assuming the trailing spark plug may be inadvertently lighting a fuel-rich "chunk" of end gasses collecting at the trailing edge of the rotor, after the lead has fired, from a far too rich mixture in the first place (where the common practice of using fuel in an attempt to cool the chamber walls and rotor face may be a double-edged sword here as it might be enabling real detonation to occur)

- Pull AFR's back into the 12's to go leaner when using heavy mixtures of alcohol instead of into the 10's, or perhaps this is a benefit of the use of water over alcohol in that it isn't flammable in the first place and therefore won't enable a 2nd burn to possibly start?

- Too little spark to light this wet, soupy, busy mixture in the chamber (use of much more alcohol vs. gasoline to produce same heat energy?), leaving much unburnt fuel from **** poor burns and misfiring to pool up at trailing edge of rotor

Seems the common practice of tuner guys on these things, even long before us contemporary guys were messing with these cars, has been to turn up or jet more fuel into the chamber over and above what's actually necessary for proper combustion (arguably mid 13's:1 or somewhere around there) and proper power. The downside of the engine is its production of heat especially at higher RPM's. High consumption of air, lots of combustion. Perhaps the practice of going much richer (and the trend over the past many years on our turbo'd EFI cars has been towards even richer) has a drawback - fuel-laden end gasses, unburnt, collecting at the trailing edge of the rotor, which makes sense when you think about how the chamber is designed and how the rotor swings around, being lit to produce a second flamefront and then strong pressure wave that may be attempting to counter the rotation of the rotor. Know of anyone who doesn't run a trailing plug under big boost? How beneficial is it really way way up high? One car comes to mind I did about 8 years ago with a high boost (23psi) 9:1 motor on 117oct leaded C16 that gained 24hp (from 475 to 499) at the high end and a marginal amount of midrange torque by skinnying up the split from 11 to 6*. It's a 5% increase.

Or is this all really an issue of running too "hot" of a fuel in too hot of a chamber environment ala the same paradigm as spark plugs... I sure love cars sometimes.

Does anybody have any data on post turbo compressor discharge temperatures using pre and post water injection in varying amounts on a standard T4 turbo?

Whatcha think?

B

If you are getting knock due to some electrical/sensor issue, well obviously that needs to be taken care of.

I see this issue as a matter more of controlling knock (detonation, pre-ignition, whatever) rather than strengthening the engine. Of course at some level of stress any component can break, but obviously knock greatly increases stress. I believe in the vast majority of applications, if you keep knock under control you won't have an issue with cracked plates--although the s4 plates still seem to be the most prone. Based on personal experience and based on a study Mazda did, I think we need to keep in mind the direct relationship between

1) rotor wall temperature

2) ignition timing

3) knock, specifically in the trailing portion of the combustion chamber

When rotor temperature goes up to a certain point, knock tends to occur near the trailing part of the rotor combustion bathtub (see boxed area above). We control temperature by keeping intake temps, coolant temps, and oil temps down. We also use AI and/or fuel enrichment, although AI is more effective than heavy fuel enrichment.

I argue that ignition timing can directly counteract the cooling effects of AI. There needs to be more of a balance between focusing on the AI aspect (lambda, methanol vs water blend %, nozzle size, etc) and this fundamental aspect of tuning. Besides changing the physical characteristics (redesigning) of the engine, what is the primary method the OEM's use to control detonation on port injected engines? They adjust ignition timing in response to a carefully tuned and filtered knock sensor signal. We are working with nonexistant or very crude knock control systems here, so we have to leave a wider safety margin with the timing.

If you look at the maps I run on the rotaries I tune (with or without AI), you will notice that they tend to run less timing than most tuners run, especially on the trailing plugs. I tend to model them on the OEM high octane ignition maps for heavily boosted piston engines, like the Evo X. This approach does cost some power, but the way I see it there isn't a better option for street cars because we don't have OEM-grade knock control systems.

I think I might make a dedicated thread about this point.

I see this issue as a matter more of controlling knock (detonation, pre-ignition, whatever) rather than strengthening the engine. Of course at some level of stress any component can break, but obviously knock greatly increases stress. I believe in the vast majority of applications, if you keep knock under control you won't have an issue with cracked plates--although the s4 plates still seem to be the most prone. Based on personal experience and based on a study Mazda did, I think we need to keep in mind the direct relationship between

1) rotor wall temperature

2) ignition timing

3) knock, specifically in the trailing portion of the combustion chamber

When rotor temperature goes up to a certain point, knock tends to occur near the trailing part of the rotor combustion bathtub (see boxed area above). We control temperature by keeping intake temps, coolant temps, and oil temps down. We also use AI and/or fuel enrichment, although AI is more effective than heavy fuel enrichment.

I argue that ignition timing can directly counteract the cooling effects of AI. There needs to be more of a balance between focusing on the AI aspect (lambda, methanol vs water blend %, nozzle size, etc) and this fundamental aspect of tuning. Besides changing the physical characteristics (redesigning) of the engine, what is the primary method the OEM's use to control detonation on port injected engines? They adjust ignition timing in response to a carefully tuned and filtered knock sensor signal. We are working with nonexistant or very crude knock control systems here, so we have to leave a wider safety margin with the timing.

If you look at the maps I run on the rotaries I tune (with or without AI), you will notice that they tend to run less timing than most tuners run, especially on the trailing plugs. I tend to model them on the OEM high octane ignition maps for heavily boosted piston engines, like the Evo X. This approach does cost some power, but the way I see it there isn't a better option for street cars because we don't have OEM-grade knock control systems.

I think I might make a dedicated thread about this point.

Last edited by BDC; 07-25-11 at 11:35 AM. Reason: Woops, forgot something.

#40

BDC Motorsports

update. got my plates and ill i got to say is wow on the secondary ports lol, my s5 plates on a pretty big street port is still not as big as the stock fd secondary ports (talking about the intake manifold side. sent the plates out for street porting.

now idk if to add one more dowel in every corner. or add two on the oil filter and oil feed side. so far im thinking about adding one dowel in ever corner.

now idk if to add one more dowel in every corner. or add two on the oil filter and oil feed side. so far im thinking about adding one dowel in ever corner.

B

#43

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

how many millimeters did you cut into the front plate? im assuming 4-6mm and around 8mm on the back plate. Using 12a dowells on the front plate and 13b on the rear plate. its around a 10mm in height difference between dowells.

Last edited by swkiller; 08-17-11 at 12:13 AM. Reason: more detail

#44

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

update: just took apart my motor today. everything came out great, but i did get chatter marks on my rear housing on the upper trailing edge, front rotor had no chatter marks. I never took the car past 8k, and it never leaned out on me during a boost run. So this fuels my belief that the car probably had nasty misfires. i guess my MSD Dis-2 H.O box was doing its thing.

#46

Racing Rotary Since 1983

iTrader: (6)

"I think I might make a dedicated thread about this point."

a thread around the knock being in the trailing area of the bathtub and various solutions would be a high value thread.

howard

a thread around the knock being in the trailing area of the bathtub and various solutions would be a high value thread.

howard

#47

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

update: motor is done need to get the engine hoist from a friends house and make another fuel rail for the fd lower intake manifold. funds are low and got a new job so while i break in new motor ill save up some backup money so i wont be afraid of breaking something again >.<

#48

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

update: ran into a small problem with making a secondary fuel rail on my fd lower manifold. since on the FD the injectors are more separated a fuel rail with a fitting wont fit because it will hit the waterpump housing. i have to find out what water pump housing people use to make a 120deg 8an fitting fit. =\

#49

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

i found an interesting post from Bumpstart about a year ago, reffering to running single spark plug for methanol users.

i am not the only one !

its also a trick used by some users of methanol ,, and also was basis of a mod and product seen some years ago in the US

( where the shop sold you trailing plug blanks as part of a "no det" mod )

its also what rotary power international where doing whilst they did extensive studies into LPG and NG fueled rotaries

the " late extra leading spark " of wastespark is beneficial in slow burning fuels

[ this is what is happening if you consider the crank degrees between ignition and the exhaust stroke in only one chamber ]

whilst the two converging flamefronts of the OEM trailing setup isnt necessarily so

- especially in view to the risks involved with keeping it with a fuel where the burn rate , stratification or combustion characteristics may not reflect those of petrol and the accepted timing splits

-- as noted above,, the split timing is there to maximise the burn of stratified fast burning fuel with a narrow explosive/combustion mixture range at either end of long, moving combustion chamber created by the spinning rotor

something LPG and NG are not,,neither stratified,, nor fast burning

and for that matter, ,, LPG, NG and methanol will combust slower,, with wider combustion mixture ranges than that of petrol

i see advantages of the single sparkplug ,, wastespark system in LPG, NG and methanol applications

-- and also maybe in hi risk ultra high RPM and boost petrol ones

( where chamber speed begins to overcome the natural flame speed )

but none in normal petrol uses

i am not the only one !

its also a trick used by some users of methanol ,, and also was basis of a mod and product seen some years ago in the US

( where the shop sold you trailing plug blanks as part of a "no det" mod )

its also what rotary power international where doing whilst they did extensive studies into LPG and NG fueled rotaries

the " late extra leading spark " of wastespark is beneficial in slow burning fuels

[ this is what is happening if you consider the crank degrees between ignition and the exhaust stroke in only one chamber ]

whilst the two converging flamefronts of the OEM trailing setup isnt necessarily so

- especially in view to the risks involved with keeping it with a fuel where the burn rate , stratification or combustion characteristics may not reflect those of petrol and the accepted timing splits

-- as noted above,, the split timing is there to maximise the burn of stratified fast burning fuel with a narrow explosive/combustion mixture range at either end of long, moving combustion chamber created by the spinning rotor

something LPG and NG are not,,neither stratified,, nor fast burning

and for that matter, ,, LPG, NG and methanol will combust slower,, with wider combustion mixture ranges than that of petrol

i see advantages of the single sparkplug ,, wastespark system in LPG, NG and methanol applications

-- and also maybe in hi risk ultra high RPM and boost petrol ones

( where chamber speed begins to overcome the natural flame speed )

but none in normal petrol uses

#50

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

Timing split is much more thing of opinions than facts

Zero split gives most power at full load - given that timing itself is optimized and not knock limited. All Mazda race cars run zero split...

Zero split gives most power at full load - given that timing itself is optimized and not knock limited. All Mazda race cars run zero split...Honestly, I donīt want to burst your bubble, but if you will have same tuning approach on new engine as previously, its fate will be same. Even with everything functioning properly, you canīt be sure about methanol distribution, just one rotor face wonīt get enough and engine goes south... Also alcohol fuels possess some nice property, inaudible detonation, you wonīt know what and when happened till its late. And this is not rotary specific, it happens on alcohol injected setups often. Just give it thought....