What else do I need to build a dual oilcooler setup

#102

development

Originally Posted by airborne

Did you get your mounts from HDR?

#103

King of the Duct Tape

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

Those are the acronyms I like to see. What is the white thing you're using as a spacer/damper?

Are you doing any ducting? I was considering making slits in the fender liner and pulling them out towards the wheel to kind of pull air through. I've seen that on a number of cars with coolers in similar positions. May not be close enough or may need some backend ducting.

Are you doing any ducting? I was considering making slits in the fender liner and pulling them out towards the wheel to kind of pull air through. I've seen that on a number of cars with coolers in similar positions. May not be close enough or may need some backend ducting.

#104

development

I just went out and finished the driver's side mounts...exactly the same as the passenger side, so it only took about an hour.

here is the mounting (single side) break down for reference...sorry I don't have the reciept or packages in front of me to list $ or lengths. I did get a 3' piece of flat aluminum to bang the brackets out of...all done for under $25.

2x L bracket

2x 12mm bolts that bolt into the stock cooler location and the tow hook location (can be fitted on top of the hook)

1x 10mm short bolt (flat washer, lock washer, and nut)

1x 10mm longer bolt with nylon spacer (flat washer, lock washer, and nut)

the top S bracket got cut off in the photo (only bracket you have to drill a single hole for on the car)

1x 10mm longer bolt with nylon spacer (flat washer, lock washer, and nut)

2x 10mm short bolt (flat washer, lock washer, and nut)

here you can see the angle back

not bad symetry for an idiot and DIY (except the picture is crooked...we'll blame the beer)

new dual coolers

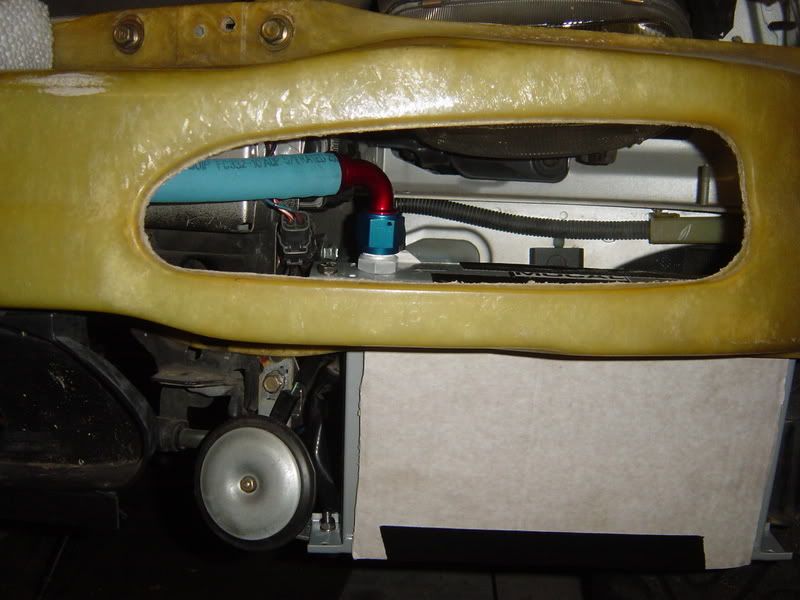

I don't think I'll be ducting...this is pretty damn close to being a "the duct"

this pic I took to show they don't hang lower than the bumper...

here is the mounting (single side) break down for reference...sorry I don't have the reciept or packages in front of me to list $ or lengths. I did get a 3' piece of flat aluminum to bang the brackets out of...all done for under $25.

2x L bracket

2x 12mm bolts that bolt into the stock cooler location and the tow hook location (can be fitted on top of the hook)

1x 10mm short bolt (flat washer, lock washer, and nut)

1x 10mm longer bolt with nylon spacer (flat washer, lock washer, and nut)

the top S bracket got cut off in the photo (only bracket you have to drill a single hole for on the car)

1x 10mm longer bolt with nylon spacer (flat washer, lock washer, and nut)

2x 10mm short bolt (flat washer, lock washer, and nut)

here you can see the angle back

not bad symetry for an idiot and DIY (except the picture is crooked...we'll blame the beer)

new dual coolers

I don't think I'll be ducting...this is pretty damn close to being a "the duct"

this pic I took to show they don't hang lower than the bumper...

#105

Speed Mach Go Go Go

iTrader: (2)

Join Date: Oct 2001

Location: My 350Z Roadster kicks my RX7's butt

Posts: 4,772

Likes: 0

Received 2 Likes

on

2 Posts

Very nice  I should have went to Home Depot for inspiration but I used whatever leftover parts I had in the garage. I currently only have only one cooler(other one broke off on frwy) but had planned on a dual setup. I won't decide on the 2nd one untill I hit the track and see temps. I reused my duct, just had to cut the corner off that indented. I can't see the tie downs, so I can't tell the size. Are they 25row? Are you going to run them paralel or in series and are you going to run the lines in the bay or strait accross under the bumper? Oh, my fittings are 120 on the outside and 150 on the inside. The 120 gives the outside line less of a bend, so no kinkage. I'm not shure if 180's would clear the cooler but they may give the hose too much of a bend.

I should have went to Home Depot for inspiration but I used whatever leftover parts I had in the garage. I currently only have only one cooler(other one broke off on frwy) but had planned on a dual setup. I won't decide on the 2nd one untill I hit the track and see temps. I reused my duct, just had to cut the corner off that indented. I can't see the tie downs, so I can't tell the size. Are they 25row? Are you going to run them paralel or in series and are you going to run the lines in the bay or strait accross under the bumper? Oh, my fittings are 120 on the outside and 150 on the inside. The 120 gives the outside line less of a bend, so no kinkage. I'm not shure if 180's would clear the cooler but they may give the hose too much of a bend.

Here's some thermostat mounting ideas for ya. I used titanium hard lines but you can make some out of aluminum.

I should have went to Home Depot for inspiration but I used whatever leftover parts I had in the garage. I currently only have only one cooler(other one broke off on frwy) but had planned on a dual setup. I won't decide on the 2nd one untill I hit the track and see temps. I reused my duct, just had to cut the corner off that indented. I can't see the tie downs, so I can't tell the size. Are they 25row? Are you going to run them paralel or in series and are you going to run the lines in the bay or strait accross under the bumper? Oh, my fittings are 120 on the outside and 150 on the inside. The 120 gives the outside line less of a bend, so no kinkage. I'm not shure if 180's would clear the cooler but they may give the hose too much of a bend.

I should have went to Home Depot for inspiration but I used whatever leftover parts I had in the garage. I currently only have only one cooler(other one broke off on frwy) but had planned on a dual setup. I won't decide on the 2nd one untill I hit the track and see temps. I reused my duct, just had to cut the corner off that indented. I can't see the tie downs, so I can't tell the size. Are they 25row? Are you going to run them paralel or in series and are you going to run the lines in the bay or strait accross under the bumper? Oh, my fittings are 120 on the outside and 150 on the inside. The 120 gives the outside line less of a bend, so no kinkage. I'm not shure if 180's would clear the cooler but they may give the hose too much of a bend.Here's some thermostat mounting ideas for ya. I used titanium hard lines but you can make some out of aluminum.

#106

Speed Mach Go Go Go

iTrader: (2)

Join Date: Oct 2001

Location: My 350Z Roadster kicks my RX7's butt

Posts: 4,772

Likes: 0

Received 2 Likes

on

2 Posts

Originally Posted by rynberg

You are very wrong. At redline, the oil pressure should be in the 100-120 psi range. Spiking above this may and does occur, especially when jumping on the throttle when the engine oil is cooler.

#107

development

I like how you located your T-stat...is it pretty stable, because it doesn't look like it is mounted to anything???

I used 25row, and they will be plumbed in series with the lines thru the bay.

I did some test fitting, and it appears with the AQP hose (more flex) I will be able to use the 90's.

I used 25row, and they will be plumbed in series with the lines thru the bay.

I did some test fitting, and it appears with the AQP hose (more flex) I will be able to use the 90's.

#109

Speed Mach Go Go Go

iTrader: (2)

Join Date: Oct 2001

Location: My 350Z Roadster kicks my RX7's butt

Posts: 4,772

Likes: 0

Received 2 Likes

on

2 Posts

Yeah, I was worried about the t-state not being secured but the hoses pull it down. Before that I had curved titanium hard line that tucked it in to the bar but I had to switch to the double swivel. I will change it again as soon as I can afford it. Oh, also if you look at the other pic I have the hoses secured before the cooler so that's why it doesn't bounce.

Are those fittings made for socketless hose? I like your setup though. Especially how you placed it right behind the bumper. I would have saved alot of cash fabbing my own brackets to.

Are those fittings made for socketless hose? I like your setup though. Especially how you placed it right behind the bumper. I would have saved alot of cash fabbing my own brackets to.

#110

development

Originally Posted by airborne

thats the socketless stuff right? what do you think of it so far?

the hose in the foreground definitely is demonstrating some flex.

the hose in the foreground definitely is demonstrating some flex.

So, far I like it...I haven't pushed the hose entirely on the barb as of yet...because once on, I think you'd have to cut it off. And yes, a lot more flex than a braided lines I've used in the past. I don't think I'll have any issues with this hose holding oil pressure.

Originally Posted by GoRacer

Are those fittings made for socketless hose? I like your setup though. Especially how you placed it right behind the bumper. I would have saved alot of cash fabbing my own brackets to.

#112

Speed Mach Go Go Go

iTrader: (2)

Join Date: Oct 2001

Location: My 350Z Roadster kicks my RX7's butt

Posts: 4,772

Likes: 0

Received 2 Likes

on

2 Posts

Front cover to t-start are Earls fittings. I have titanium from t-stat to hose to oil filter and on the bottom of the t-stat after earls 90 to/from cooler.I prefer hard lines for tight bends rather then ss braided.

I previously had a hard line attached from earls 90 in front cover to t-stat and it was curved so the t-stat actually tucked on to the sway bar (like a bar on your shoulder) and was held down. It was not tied down so it could move slightly. Although I do have eurothane mounts and you can't see the engine move like you can with oem rubber mounts.

None of those are my final version though. I want the t-stat secure but also some flex so it doesn't crack the front cover. I have ideas for the change, just no money left to do it. I prefer the hard lines for the curves because flexible hoses can kink. Well except for the socketless blue stuff, but I wouldn't exactly call that flexible.

I previously had a hard line attached from earls 90 in front cover to t-stat and it was curved so the t-stat actually tucked on to the sway bar (like a bar on your shoulder) and was held down. It was not tied down so it could move slightly. Although I do have eurothane mounts and you can't see the engine move like you can with oem rubber mounts.

None of those are my final version though. I want the t-stat secure but also some flex so it doesn't crack the front cover. I have ideas for the change, just no money left to do it. I prefer the hard lines for the curves because flexible hoses can kink. Well except for the socketless blue stuff, but I wouldn't exactly call that flexible.

#115

King of the Duct Tape

Join Date: Feb 2001

Location: PA

Posts: 1,177

Likes: 0

Received 0 Likes

on

0 Posts

Hey dubulup, what is the approximate outside diameter of that hose? Right around an inch? I'd like to run pipe like you ran the OC line, OD is like 1.125. Should be nice and safe under there.

Looks like I have to cut out a piece of the rebar to fit my rads, guess they're a bit wider. Thats a pretty common thing to do right? Just gonna make a notch right where that inside fitting is on the OCs.

Looks like I have to cut out a piece of the rebar to fit my rads, guess they're a bit wider. Thats a pretty common thing to do right? Just gonna make a notch right where that inside fitting is on the OCs.

#116

development

The -10 hose I'm using is 7/8" OD. I think you could get a 1 1/4" OD pipe in that space. Notching the rebar shouldn't make a difference...(25 row coolers are an amazing fit)

If anyone is trying to duplicate what I've done...you could swap 2x 90* hose ends for 45* hose ends to have more clearance under the rebar; I don't think I'll have any issue with the hose rubbing the "black bracket" in the 1st picture, but I think you can get further off of it with a 45* hose end.

also (mentioned earlier in the thread) RE Speed has this nice pice...to get a temp reading and AN fitting to the oil filter pedestal.

If anyone is trying to duplicate what I've done...you could swap 2x 90* hose ends for 45* hose ends to have more clearance under the rebar; I don't think I'll have any issue with the hose rubbing the "black bracket" in the 1st picture, but I think you can get further off of it with a 45* hose end.

also (mentioned earlier in the thread) RE Speed has this nice pice...to get a temp reading and AN fitting to the oil filter pedestal.

#117

development

here are all the lengths I came up with (total 11.25')

from left to right...

t-stat outlet line...connecting line

outside P/S cooler...outside D/S cooler (you can see the front cover and filter lines in the background)

Connecting line...t-stat inlet

please excuse my dirty bay...I just dropped the motor in for mock-up.

The lines will clear the A/C compressor (not shown). I will need clamps for the two (non engine side) t-stat lines and some hose protection in a couple places. I will also need to enlarge the openings on the sides of the undertray for the outside fittings on the coolers to the t-stat...no biggie, it will still protect the lines from being snagged.

Overall, the socketless hose is a snap to assemble and very difficult to disassemble (compared to braided lines), ask me how I know...when I say snap, I'm referring to the tape-ing, cutting, lubing, tightening, adjusting, little cuts braided lines have given me in the past...I can cut the AQP hose with a razor and assemble with minimal lube and my hands; does require lots of force.

total project costs

$720 for coolers, t-stat, lines (~8' left over), and fittings

$35 for misc hardware and brackets

$80 for the pedestal

$40 for a temp gauge and sender (VDO Vision)

roughly $875...and a few nights working it out. Just took so long due to the holidays and business travel.

I hope this helps people out in the future...

from left to right...

t-stat outlet line...connecting line

outside P/S cooler...outside D/S cooler (you can see the front cover and filter lines in the background)

Connecting line...t-stat inlet

please excuse my dirty bay...I just dropped the motor in for mock-up.

The lines will clear the A/C compressor (not shown). I will need clamps for the two (non engine side) t-stat lines and some hose protection in a couple places. I will also need to enlarge the openings on the sides of the undertray for the outside fittings on the coolers to the t-stat...no biggie, it will still protect the lines from being snagged.

Overall, the socketless hose is a snap to assemble and very difficult to disassemble (compared to braided lines), ask me how I know...when I say snap, I'm referring to the tape-ing, cutting, lubing, tightening, adjusting, little cuts braided lines have given me in the past...I can cut the AQP hose with a razor and assemble with minimal lube and my hands; does require lots of force.

total project costs

$720 for coolers, t-stat, lines (~8' left over), and fittings

$35 for misc hardware and brackets

$80 for the pedestal

$40 for a temp gauge and sender (VDO Vision)

roughly $875...and a few nights working it out. Just took so long due to the holidays and business travel.

I hope this helps people out in the future...

Last edited by dubulup; 01-02-07 at 10:56 PM.

#119

development

Thanks...the gauge, I found the best price at http://www.egauges.com/vdo_mult.asp?...Vision&Units=E

I just wanted something simple.

No tricks for the pedestal install...simple as bolting the stock piece on. It does have two gauge ports on it...just wish I knew of a pressure sender that worked with the stock gauge.

I just wanted something simple.

No tricks for the pedestal install...simple as bolting the stock piece on. It does have two gauge ports on it...just wish I knew of a pressure sender that worked with the stock gauge.

#121

The socketless hoses/fittings seems like a great idea! But can they take the abuse? I just read that the AQP hoses have a very low temp range. This is from Aeroquips homepage: -40 to +300F (-40 to +150C). Air max +250F (+121C). Water max +180F (+82C).

Is that really enought?

I found the info here: http://www.aeroquip.com/media/perfor...1-E-p13-14.pdf

Edit: Forgot to say something...

150C seems lika pretty high temp but how hot does the oil get? If you mount the temp sensor at the oil filler neck the readings will not be accurate. Why do you want to know the temp AFTER the oil coolers?

Is that really enought?

I found the info here: http://www.aeroquip.com/media/perfor...1-E-p13-14.pdf

Edit: Forgot to say something...

150C seems lika pretty high temp but how hot does the oil get? If you mount the temp sensor at the oil filler neck the readings will not be accurate. Why do you want to know the temp AFTER the oil coolers?

Last edited by Zebb; 01-03-07 at 03:29 PM.

#122

development

Steel braided lines are rated -55 to 300F

oil should be close to water temps...not above 230F, and I'm expecting much less.

I want to know the temp after the oil coolers so I know how hot/cold the oil is going into my motor...why would I want to know pre-cooler temp? Sure both would be great, but I think one temp will do fine.

I want to know the temp after the oil coolers so I know how hot/cold the oil is going into my motor...why would I want to know pre-cooler temp? Sure both would be great, but I think one temp will do fine.

#123

What i mean is can the hoses handle a hot day at the track? Does anyone know how hot the oil is before the coolers? Maybe its over 300F? Sounds high, but you never know... 120C after the coolers is not uncommon with the stock coolers a very hot day.

I really want to use this kind of fittings and hoses on my setup, im only wondering if the temp margin is big enought.

I hope that made sense...

I really want to use this kind of fittings and hoses on my setup, im only wondering if the temp margin is big enought.

I hope that made sense...

Last edited by Zebb; 01-03-07 at 04:21 PM.

#124

development

248F is HOT...

I don't think this system will allow for oil to get over 300F.

rynberg has thousands of tracked miles in CA heat...using SS braided lines and this size cooler. I don't know if you saw the title on my last post but it states that braided lines (common to almost every oil cooler kit) are only rated up to 300F as well.

http://www.aeroquip.com/pages/prodinfo.html

I think this socketless hose will work just fine for the track in hot days...Louisiana is hot and humid, and I plan to track my car here as well.

I don't think this system will allow for oil to get over 300F.

rynberg has thousands of tracked miles in CA heat...using SS braided lines and this size cooler. I don't know if you saw the title on my last post but it states that braided lines (common to almost every oil cooler kit) are only rated up to 300F as well.

http://www.aeroquip.com/pages/prodinfo.html

I think this socketless hose will work just fine for the track in hot days...Louisiana is hot and humid, and I plan to track my car here as well.