Possible new rotary design?

#1

Possible new rotary design?

Hello all, I don't know if this has been posted or not but found this video from MIT and quite interesting. I bet if the engine design is good enough Mazda would probably buy it. These guys are creative.

http://www.technologyreview.com/vide...engine-design/

http://www.technologyreview.com/vide...engine-design/

#2

Rotary Enthusiast

Love it. I'm looking forward to seeing more prototypes in action.

#4

I like it. A lot of machining work has gone into it. Replaceable counter weights, etc. I'd love to see it run.

I dont think it will be as high rpm stable as the wankel. It doesnt look suited to high rpm.

I dont think it will be as high rpm stable as the wankel. It doesnt look suited to high rpm.

#7

Full Member

iTrader: (2)

Join Date: Feb 2013

Location: Pacific Northwest

Posts: 158

Likes: 0

Received 0 Likes

on

0 Posts

I can see sealing being a challenge as well. Valves and piston rings with back up and oil control rings do such a decent job with so little wear and excellent tolerance to detonation... Very cool idea. Their prototype doesn't scream lightweight to me, but I'm sure that they will elaborate more on the pounds per fuel mass burned per minute or some other measure.

When they were moving the model around I kept looking at the massive rotor and thinking, that is a huge flywheel. Nice idea using it as one so they can run cycles without combustion. I bet it is very smooth and quiet as they say.

When they were moving the model around I kept looking at the massive rotor and thinking, that is a huge flywheel. Nice idea using it as one so they can run cycles without combustion. I bet it is very smooth and quiet as they say.

Trending Topics

#11

The rotor is geared so that its surface remains very tight to the outside sealing surface (air tight, to maintain the combustion chamber pressure). I think that due to the extremely tight tolerances necessary, if there were any sort of build up on that surface of the rotor it would bind against the housing and stop turning

#13

Their website is up. There's not much on there except an animation and a very brief description of the thermodynamic process.

What I don't understand is, how the fuel injection fits in. Is it port or direct injection? If it's port, you've got all the wall-wetting issues that current wankels (Renesis) do. If it's direct injection, where is the injector pointed, what pressure does it run at, and how do they avoid fuel impingement and diffusion flame with that shape of combustion chamber?

What I don't understand is, how the fuel injection fits in. Is it port or direct injection? If it's port, you've got all the wall-wetting issues that current wankels (Renesis) do. If it's direct injection, where is the injector pointed, what pressure does it run at, and how do they avoid fuel impingement and diffusion flame with that shape of combustion chamber?

#14

The gates in this mock-up made me think of a thought I've always had watching present rotary engine cycle:

It would be cool if you could develop some sort of cam/timing driven gate or rotating lobe that would move in and out to seal between the exhaust and intake ports depending on the position of the rotor during the cycle, so that peripheral ports had no overlap.

It would be cool if you could develop some sort of cam/timing driven gate or rotating lobe that would move in and out to seal between the exhaust and intake ports depending on the position of the rotor during the cycle, so that peripheral ports had no overlap.

#16

This is from their new website. The engine has changed a lot since the video the OP put up here, so much of our discussion has been pretty irrelevant.

Gordon

How It Works | LiquidPiston

Gordon

How It Works | LiquidPiston

#22

Full Member

iTrader: (8)

Join Date: Oct 2006

Location: Atlanta, GA

Posts: 116

Likes: 0

Received 0 Likes

on

0 Posts

Not trying to steal your thread but here's another idea for a rotary engine I saw on kickstarter:

Rotary Dynamic & Positive Displacement Devices by Jesse J. Vazquez — Kickstarter

Rotary Dynamic & Positive Displacement Devices by Jesse J. Vazquez — Kickstarter

#23

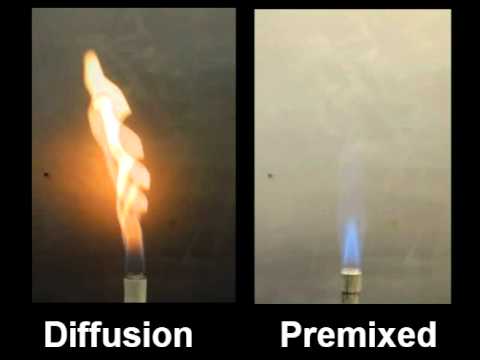

Diffusion flame is the one on the left. Remember turning that dial on the burner and seeing that it's all smoky? It's not a very clean burn. Then you turn it the other way and get the blue flame, the premixed flame. The same thing happens in an internal combustion engine. Generally speaking, for our purposes premixed flame = good and diffusion flame = bad. The reason why this matters is because basically any diffusion flame = vehicle will never pass modern emissions, the standards that will come into effect for around 2017 model year when everything tightens up. Mazda has probably been working on this issue for a very long time. Specifically I am talking about HC emissions, but especially particulate emissions (the same nasty stuff that comes out of smoky diesels).

Let's go back to piston engines, because they are in production right now and rotary engines are (except a few random military uses) not. Diffusion flame occurs when fuel impinges on the valve or piston surface. It's caused by poor spray targeting, a drip at the end of injection, poor mixture formation, improper injection timing, or too much spray penetration (fuel pressure too high maybe).

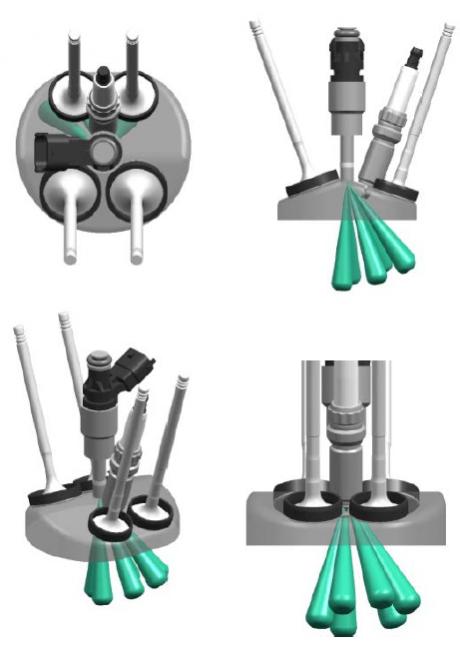

That's side mounted direct injection. This is on most production DI engines today. If the spray hits the piston or valve, you get diffusion flame, smoke, loss of fuel economy, etc. If it hits the bore wall, you get oil dilution and possible scuffing. There are all sorts of ways to arrange the sprays. The other more expensive alternative is central injection:

This is less prone to impingement if the spray is targeted correctly and the injection timing is right. It's what BMW uses for example.

On this LiquidPiston engine, if they spray right into that combustion chamber and fuel sticks to everything, it will never pass emissions. If they have a narrow spray cone and low fuel pressure (less spray penetration), the fuel tends to atomize poorly and it will have poor combustion efficiency. It's a very difficult problem. I'm not saying it's drastically different from what a new Mazda wankel engine would run into, but Mazda has literally been working on and off with DI rotaries for decades. And it's taken years and years to address it on piston engines. My guess is that LiquidPiston is using some kind of port injection, but then you have all the drawbacks of PFI like higher tendency to knock and less ability to light off a cat. I suppose if this engine is as efficient as they claim, port injection might be all they need.

My guess with this architecture is that it could be put in some oddball small engine or as a passenger car engine in a weird market with very limited regulation. I've been to a number of conferences/expos and there are usually startups peddling revolutionary new engines. Typically they are trying to sell some intellectual property to an OEM and cash out. They haven't thought through all the implications of making the thing work in the real world with real regulations and real market demands. Like how the hell would you do an OBD II misfire monitor or air fuel imbalance monitor on an engine like that. At least Mazda has been doing this stuff with rotaries for so long that somebody knows what they're doing.

#24

Racing Rotary Since 1983

iTrader: (6)

speaking of new rotary designs...

this statement was in a recent email i received from a very high up Mazda dev engineer who has had a rotary history as well as being a central figure in turbo design.

"i am very busy developing the next generation power train."

for all i know it could be just additional diesel stuff although i doubt it. if he has anything to do w the rotary it will be a positive. he is a super guy/engineer/racer.

the biggest factor as to the possibility of another rotary, IMO, is Mazda buying Ford's stock back. it has been stated privately that the Ford ownership stake greatly blunted Mazda's typical front-running designed product.... that the RX8 is the prime example of the Ford/Mazda muddle.

the FD is the prime example of what Mazda operating on its own can do.

recent(6-13) public statements are supportive:

"Mitsuo Hitomi, general manager of powertrain development at Mazda recently said that the company plans to complete development of such an engine that will also meet future fuel-economy and emissions standards.

“We think we’ve found a way to improve the rotary’s fuel economy to be truly equal to that of conventional piston engines and, if so, we believe we can reintroduce the rotary to the market,” Hitomi recently told Ward’s Auto.

Much of the new technological breakthrough came in changing the shape of the troichoid housing so that the seals remained flush to the housing. Better sealing means better fuel economy and overall performance. Since the early days of rotary engines, its seals and its “sealability” have always been an issue, dating back to the mid-1960s. “Even with our current 1.3L Renesis rotary, gaps can develop between the apex seal and troichoid housing in light-load operation when imbalances in centrifugal force and gas pressure occur,” Himoti said."

my apologies for taking the thread a tad off the original direction but i thought those interested in the rotary would be interested.

howard

this statement was in a recent email i received from a very high up Mazda dev engineer who has had a rotary history as well as being a central figure in turbo design.

"i am very busy developing the next generation power train."

for all i know it could be just additional diesel stuff although i doubt it. if he has anything to do w the rotary it will be a positive. he is a super guy/engineer/racer.

the biggest factor as to the possibility of another rotary, IMO, is Mazda buying Ford's stock back. it has been stated privately that the Ford ownership stake greatly blunted Mazda's typical front-running designed product.... that the RX8 is the prime example of the Ford/Mazda muddle.

the FD is the prime example of what Mazda operating on its own can do.

recent(6-13) public statements are supportive:

"Mitsuo Hitomi, general manager of powertrain development at Mazda recently said that the company plans to complete development of such an engine that will also meet future fuel-economy and emissions standards.

“We think we’ve found a way to improve the rotary’s fuel economy to be truly equal to that of conventional piston engines and, if so, we believe we can reintroduce the rotary to the market,” Hitomi recently told Ward’s Auto.

Much of the new technological breakthrough came in changing the shape of the troichoid housing so that the seals remained flush to the housing. Better sealing means better fuel economy and overall performance. Since the early days of rotary engines, its seals and its “sealability” have always been an issue, dating back to the mid-1960s. “Even with our current 1.3L Renesis rotary, gaps can develop between the apex seal and troichoid housing in light-load operation when imbalances in centrifugal force and gas pressure occur,” Himoti said."

my apologies for taking the thread a tad off the original direction but i thought those interested in the rotary would be interested.

howard

#25

Howard,

Your point about a new Mazda Wankel rotary isn't so far off topic. I think a lot of the problems that Mazda is facing are still going to be faced by any alternative rotary architecture. As I pointed out, meeting upcoming particulate emission (Euro 6C and California LEV III) standards on an engine without a reciprocating piston is going to encounter some of the same challenges. On a piston engine, if I have the right spray targeting and injection timing, it's possible to meet the standard by not hitting the piston. How the heck do you do that on a small rotating chamber? We can only speculate.

Your point about a new Mazda Wankel rotary isn't so far off topic. I think a lot of the problems that Mazda is facing are still going to be faced by any alternative rotary architecture. As I pointed out, meeting upcoming particulate emission (Euro 6C and California LEV III) standards on an engine without a reciprocating piston is going to encounter some of the same challenges. On a piston engine, if I have the right spray targeting and injection timing, it's possible to meet the standard by not hitting the piston. How the heck do you do that on a small rotating chamber? We can only speculate.