Possible new rotary design?

#26

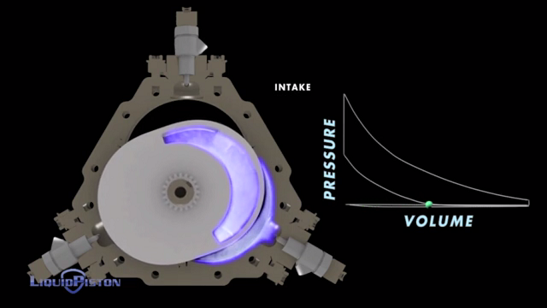

So in the animation notice how they don't show a fuel injection event at all. I think that's because they haven't figured figured that part out yet.

Do you spray it here? If so, how do you target the sprays, how many injections do you have, what's the total mass % for each injection, and what's the fuel pressure and timing?

Do you spray it there? If so, how do you target the sprays, how many injections do you have, what's the total mass % for each injection, and what's the fuel pressure and timing?

See what happens is, the more complicated the fuel injection and emissions issue is, the more it ends up being like a diesel. Modern Diesels have expensive injectors at very high pressure (more friction and pumping work) with 3 or more injection events per cycle. Then they have particulate filters, NOx traps and/or urea injection, oxidation catalysts, etc. They have very high cylinder pressures (over 160-170bar at full load, compared to ~100 bar on the most advanced gasoline direct injection engines) and thus need really strong components to hold up.

The more crap you have to put on the engine to make it meet the targets, the less advantage it has over existing designs. The OEM says "screw it, we'll take x existing design that's already has tooling for production, add some cost to it to meet new targets, and not risk it on some unproven technology." The same issues apply to a Mazda rotary, but Mazda has 50 years of corporate history with it. The rotary is an institution and has been since Mazda was still called Toyo Kogyo.

#27

Where do you find the people to work on something like this? Let's go back to more conventional technology for a second. Do you know how many people know how to make a turbo direct injection piston engine, especially with some advanced valve timing strategies, actually work? There's only a very small group of people who know how to mess with this technology. If I had to guess, the number of people on planet earth who can tune the super complicated model-based controls and design the engine hardware as a system might be a little over a 100. Maybe 200.

How can that be, you ask? Well think about it. What do you do when your business wants to get involved with something to respond to a market demand, but doesn't have the expertise? You make alliances, or you hire an outside company (if you don't hire staff from competitors). This happens all the time in engine development, and you never hear about it. There are half a dozen consulting companies that do much of the advanced engine development through supplying on-site contactors or through outsourcing large portions of the work at the consulting companies' facilities. The same German dudes who designed an engine for one OEM did it for the others, whether the OEM is American, Asian, or European. And you hardly ever hear about it.

So if it's that hard to find people who can work on advanced conventional engines, who are you going to hire to work on this thing? With LiquidPiston, there's probably 4 guys in the company who really understands the engine. So if I'm the OEM, who's going to do the ho-hum stuff like make the OBD system work? It's really risky from a manpower perspective. The average person in powertrain is a specialist who really only knows one or two things--piston ring design, catalyst design, NVH. You need people with a really broad knowledge of a ton of systems. Those are hard to find and they are in high demand.

In Mazda's case, they have a 50 year tradition with rotary engines. The only other company that has any experience with wankel engines, besides some old-timers at Audi from the NSU days, is AVL in Austria. They're the ones who did the rotary for an Audi concept range-extending hybrid. That's still a lot better than LiquidPiston, EcoMotors, Scuderi Split Cycle, and all these other revolutionary "game changing" engines.

100 years ago, there were dozens of car companies primarily in Michigan, Ohio, Illinois. Anybody could get into making cars and engines. To some extent the same could be said about making personal computers in the early 80s. Now internal combustion engines, and mass market computers for consumers, are very mature technologies that are very difficult to break into.

#28

In our 13b's, don't injectors inject into the LIM? i.e. before reaching the ports of the housing?

would it not be similar in this engine, where the "intake" being shown flowing into their rotor is already mixed with fuel and air---i.e. injection is somewhere further up the line?

the video, not sure if it has been posted

would it not be similar in this engine, where the "intake" being shown flowing into their rotor is already mixed with fuel and air---i.e. injection is somewhere further up the line?

the video, not sure if it has been posted

#29

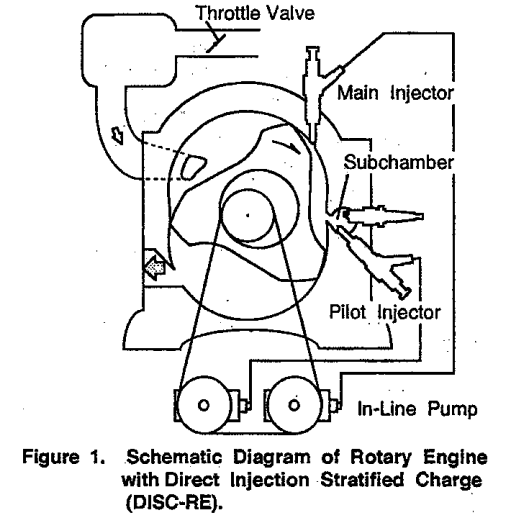

The port injection has a serious HC emission problem due to wall wetting. That's why there's an elaborate air-assisted injector atomization system on the Rx-7's, and an even more advanced version on the Rx-8. The Rx-8 needed to use an HC trap catalyst, dual-layer exhaust manifold, and a smog pump. Those technologies are normally found on the cleanest piston engines that pollute like a Prius (California SULEV standard). So Mazda had to throw a lot at the rotary to make it barely pass.

When you use port injection, you don't have the fuel cooling the mixture like in direct injection. Port injection has higher knock tendency because all that cooling gets wasted on the metal surfaces it touches. And with PFI you can't feasibly use stratified combustion to allow for fast catalyst light off like all current DI engines.

would it not be similar in this engine, where the "intake" being shown flowing into their rotor is already mixed with fuel and air---i.e. injection is somewhere further up the line?

You might do a limited roll out of the engine with PFI, but it has to be direct injected at some point.

#31

Actual Tiny Prototype

This is really bringing this thread back from the dead, but I saw that they posted a video of an actual running prototype a few months ago here: (https://vimeo.com/99002635. Does this help shed any light on what they are doing for fuel injection and the potential viability of this design? They just landed a million dollar DARPA contract (which I realize that they hand out like candy, and that most of the tech they sponsor goes no where).

They claim that the thermal efficiency is good enough that they don't need liquid cooling, which I think would be fantastic.

They claim that the thermal efficiency is good enough that they don't need liquid cooling, which I think would be fantastic.

#32

There was another video showing the combustion of the motor here: https://vimeo.com/111796558?from=outro-local

But from that video you shared it could be the spark plug is on one "iron" and the injector is on the opposite "iron".

But from that video you shared it could be the spark plug is on one "iron" and the injector is on the opposite "iron".

Thread

Thread Starter

Forum

Replies

Last Post

datfast1

Old School and Other Rotary

18

06-20-19 10:53 PM

Under PSI

3rd Generation Specific (1993-2002)

19

09-23-15 11:47 PM

rx8volks

Canadian Forum

0

09-01-15 11:02 PM